Transcription

Scroll CompressorTechnologyOptimizing EfficiencyGreg SwierczEngineering Manager – Emerson ClimateTechnologies Canada

AgendaCommercial Update– Market OutlookR-410A UpdateDesign Comparison – Recip. vs. ScrollR410A model line– Fixed Capacity Scrolls– Tandems– Ultratech– Digital ScrollEfficiency Standards

R-410A Update

R-22 Phase-Out TimelineR-22Phase-OutR-22 Banned From New U.S. System Installations In 2010In 2015, R-22 Production Drops To 10% Of 1996 LevelsProduction Of R-22 For Service Needs Ends 2020 In U.S.100%1996CAP100%Montreal Protocol/US Phase-OutTodayEU Phase-Out65%5035%25%10%0New Equipment Life: 15 Year Avg.19992004No NewEquipment EU2010No NewEquipment US20152020R-22 Phase-Out

Commercial Conversion To R-410AR-410A“Green Buildings” Encourage Alternate Refrigerant Specifications– LEED Program Gaining Momentum– LEED Ordinances By State And CityGovernments/Institutions Adopting LEED– Environmental Stewardship– Product Life CycleMajor Retailers Specifying R-410A Systems– Wal-Mart Specified R-410A In Jan. 2004– Others Include Kroger, IKEA, Hobby Lobby, Bed Bath & Beyond– Total Cost Of Ownership Over Life Cycle

Commercial A/C Refrigerant Trends –North America Systems To 100 Tons(% Of 0A 8%200815%22%25%35%201050%56%95%100%

Scroll Overview

Semi-Hermetic Compressors Semi-HermeticDesign & ConstructionLow PressureGasSuctionReedHigh PressureGasDischargeReed

How Semi-Hermetic Compressors WorkSemi-Hermetic1. Start of cycle.2. Low pressure refrigerant gas enters cylinderon piston down-stroke.3. Pressure equalizes and suction reed closes.

How Semi-Hermetic Compressors WorkSemi-Hermetic4. Piston up-stroke increases pressureand temperature of refrigerant in cylinderand causes discharge reed to open.6. High pressure gas must re-expand tolow pressure before suction reed canopen. This “volumetric expansion loss”limits the compressor’s efficiency.5. Pressure equalizes and discharge reedcloses. Small volume of high pressure gasremains in valve plate port and clearancebetween piston and valve plate.

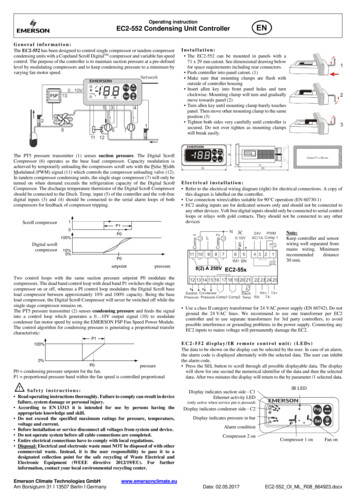

Scroll Compressors – Design &ConstructionIPR ValveCheck ValveFixed ScrollFloating SealOrbiting ScrollPress & StakeMain Bearing HousingDU Drive AndMain BearingsMolded PlugLower Bearing

How The Copeland Scroll WorksFixed ScrollOrbiting ScrollKG gate 8 review 2-03:saj 12

How a Compliant Scroll WorksSuctionPocketIntermediatePocketSc r1o l l s w i l l c o m p r e s s g a s o2n l y w h e n o p e r a t e din t he c orrec t direc t ion of rot at ionHigh PressureDischargePocket34KG gate 8 review 2-03:saj 13

All Sides Pump At lCenterDischargeCo n t i n u o u s Co m p r e s s i o nKG gate 8 review 2-03:saj 14

““CompliantCompliant Scroll” – What Is It?Scroll” “Compliance” Is The Ability Of Scrolls To SeparateUnder Abnormal Conditions Scrolls Separate For Better Liquid Handling &Debris Tolerance Two Types Of Compliance Radial & Axial Directions Patented Technology Found In No Other Scroll Compliance Allows Scrolls To “ Wear In” - No TipSeals To Wear Out Full Compliance Improves Efficiency, Durability,Sound, And ReliabilityKG gate 8 review 2-03:saj 15

Copeland Compliant ScrollsAxial ComplianceRadial ComplianceAxial compliance isthe key to DigitalModulationKG gate 8 review 2-03:saj 16

Floating SealAir ConditioningRefrigerationLOADED 11:1 26:1UNLOADED 11:1 26:1

Scroll TechnologyFloating Seal

R410A ScrollCompressor AvailabilitySingle Stage Compressors

Copeland ScrollAir Conditioning Product OfferingFamily:Quantum1,2,3 Quest1,2,35GSummit2,3Specter3LCS3Frame:637053 & 63Cap. (HP): 2-44-6.51.5-57-12 157.5-1520-30Mfg.MissouriLocation: LouisianaOhioThailandChinaN. IrelandMissouriLouisianaOhioThailandN. IrelandChinaMissouriLouisianaThailandN. IrelandChinaOhioThailandBelgiumN. CarolinaBelgiumOhioBelgium1. Available With UltraTech, Two Stage Modulation2. Available With Digital, Continuous Modulation3. Available In Tandem Options“Specter” nowonly produced inEurope for service

Copeland Has Introduced NewGeneration Scroll Product for R410ADeveloped New Scroll Technology That Increases CapacityWithin A Given Diameter–New Scroll Designs – Optimized–Smaller Diameter Motors–Higher EfficiencyLight Commercial Applications Will Also Use New Scrolls–Rooftop, Splits–Other Derivative Applications–13 SEER Residential Standard a driving force

ZPK5 ScrollImproved R410A PerformanceRange:1.5 – 5.0 TonsRefrigerant:R-410AApplication:ZPK5 13 SEERSingle Phase And Three PhaseFull Envelope50/60 HzEfficiency:10.0-10.6 EER (3 Phase)1-5% Higher EfficiencySound:66 dBA(2-4 dBA Quieter Than ZPK3)Production:In Production

R-410A Summit & LCS PY705ZPY855Drawings OnlyFinal Released Tandem/TrioSEPTEMBER 2007 Final ReleaseNOVEMBER 2007 Final ReleaseJANUARY 2008 Final ReleasePhase-Out In March 2008No Tandem Development Will HappenNo USA Production Release Planned AtThis Time - Only Drawings

LCS Update

ZP295KCE – 26HP DesignZP295 Is R410A Derivative Of ZR310– Alternative To ZP285– In Production Since 2005Increased Cooling Capacity 16K Btu/hr ( 5.8%)Reduction In Efficiency– -0.1 EER Rated Difference In OPI (-0.9%)– ZP285 Gains Driven By Large SuctionBenefits Of ZP295– Sidney Production Begins October 2007– ZP285 Phase-Out Effective March 31, 2008

25-26HP Technical Comparison (R-410A)25-26HP(R-410A)(60Hz, 45 /130 )20 HPModelZP235KCERefrigerantR-410ACooling Capacity- Kbtu/hr235Efficiency- EER (COP)11.1 (3.25)Dimensions- mm427 x 376 x 737Weightlbs. (kg)324 (147)Suction- Brazed1-5/8" ID- Rotalock/Flange2-1/4" x 12UNDischarge- Brazed1-3/8" ID- Rotalock/Flange1-3/4" x 12 UN25 HP26 HP32 38511.4 (3.34)11.3 (3.31)11.1 (3.25)447 x 427 x 734447 x 390 x 734447 x 427 x 734417 (189)353 (160)390 (177)2-1/8" ID2-1/4" x 12UN1-5/8" ID2-1/4" x 12UN1-5/8" ID2-1/4" x 12UN1-3/8" ID1-3/4" x 12 UN1-3/8" ID1-3/4" x 12 UN1-3/8" ID1-3/4" x 12 UN

R410A Fixed Capacity ScrollSummaryWidest selection available in theindustryNominal Tonnage from 1.3 – 32 “tons”40 “ton” soon to be releasedContinual development ongoing toincrease compressor efficiency

Modulation- Manifolding- UltraTech Scroll- Digital Scroll

Modulation Methods OverviewManifolding Compressors– Stepped Capacity– Uneven & Even ConfigurationsCopeland Scroll UltraTech– Two-Step Scroll CapacityUltraTechUnloadingCopeland Scroll Digital– Infinitely Variable Scroll CapacityDigital Unloading

Tandems And TriosTandem Even And Uneven ForOptimal ModulationHigh Reliability– Symmetric Suction Design– Gas And Oil EqualizationLines To Ensure Equal OilDistribution At AnyOperating ConditionsNo Lead CompressorCompact Size And Ease OfAssembly

Tandem Performance & Reliability TestingTest/ItemPurpose / MethodDurationDesign Of Tubing ManifoldsBest Practices & CFD2-3 weeksCalorimeter Testing2-3 weeksOil Balancing ConfirmationStrain Gauging2-3 weeksAvoid Tubing Fatigue & ResonanceLife TestingConditionsConfirm Reliability Under Accelerated Field–Start/Stop Tests–Continuous Run21 days–HCR & Floodback60 daysLong Term Oil Starvation84 daysFinal Rating, Release, & CPID1-2 weeksSupply Chain4-6 weeksTotalProduction Readiness6 months

R410A Tandem Compressor AvailabilityEven and uneven tandems availableEven Tandems– ZPT100 – ZPT770 (8-64 TONS)100/50% capacity steps per unit(100/75/50/25% if 2 tandems are usedon separate circuits.)Uneven TandemsZPU274 – ZPU680 (23 -56 TONS)– 56/44% capacity split approx(depends on compressor match)*.PPT/DEPT 2/7/2008 08:43 32

Single Compressor Modulation PlatformsUltraTechResidential A/CSEER-Based nsportAsia Multi-EvapsCommercial A/C

UltraTech Scroll And Digital ScrollServe Different MarketsUltraTechDigitalDucted SystemsNon-Ducted SystemsOneMultipleRatingsSEER BasedEER/IPLV BasedCapacity Range67% Or 100%10% To 100%Full Load Efficiency95%100%67% Load Efficiency94%87%SEER RatingBestGoodIPLV RatingGoodBestTargetNumber of Evaps

Capacity Modulation Product PlanUltraTech Scroll (Two Step) Is The Right Technology ForU.S. Residential A/C Applications– Part Load Efficiency Is Excellent– 33% Unloading Adequate – Preferred For ResidentialDigital Scroll (Continuous) Is The Right Technology ForApplications Requiring Large Or Varied Steps OfUnloading– Commercial A/C Systems Requiring Steps 15 Tons– Specialty Applications Requiring Tight TemperatureControl– Commercial Systems With Wide Varying Loads– Multi-Evaporator / Single Condenser Systems

Copeland Scroll UltraTech100% Capacity67% CapacityBypassPorts ClosedModulationRing/BypassSealsBypassPorts Open High Efficiency 17.5 EER @ 45/100 (R-410A) Premium Comfort 67% Part Load Capacity Quiet Operation (Sound And Vibration) Easy To Apply/Control No Power Lead Switching No Shutdown To Change Capacity Control Via Solenoid Copeland Scroll g

UltraTech Design OverviewTwo Step Gas BypassBypassPorts Closed100% CapacityBypassPorts Open67% Capacity

UltraTech Design OverviewFixed Scroll Sub-AssemblyModulation RingAndBy Pass SealsBypass PortsSolenoidCoilAssemblyLocating & HoldDown Pins

Copeland Scroll UltraTech““AnAn Even Better Copeland Scroll”Scroll”Florida 2-Stepvs. Single SpeedFieldDataImprovesTempAndHumidityControl 53%OEMs Can Reach Higher EfficienciesReadings from 3/29/02 - 4/9/028580706560Fixed Speed5550RH16SEERT7514UltraTech451240Time (hr)Bristol TSUltraTechDrop-InSound Comparison“It’s SoSimple!”Bristol TSUltraTech“UltraTech Is Fabulous! It’s Extremely Quiet.I’m Very, Very Pleased” – California ContractorBristol TSUltraTech

Copeland Scroll Digital TechnologyContinuous Modulation From10-100% Capacity– Modulate Without InvertersNearly 200K Pcs Sold WorldwideSince 2001Digital Scroll Applications Include:– Rooftop A/C– Precision Cooling– Air Driers– Asia Multi-Evap– Specialty A/C EquipmentR-22 Models Available From 4-10 HP5-10 HP R-410A Models Launched In‘07

88-10HP-10HP Digital DesignComparison To Current DesignCurrent Design (4-7HP)New Design (8-10HP) Piston Lifts Fixed Scroll Up To Unload Tubing Routes Gas To Manifold In Shell External Tubing External Cartridge Valve Controls Gas FlowPiston ModulationIntermediateCavity Modulation

Digital Modulation – How It Works1.0 mm ScrollSeparationLoaded (1)Unloaded (0)Full CapacityZero Capacity20% OutputFull Capacity50% OutputFull c

Copeland Scroll Digital Controller Simple Controller That Enables OEM’s To Use Digital Scrolls Relieves OEM From Developing Special Controllers Faster Time To Market Copeland Controller FunctionsControls- Compressor Contactor- Capacity Modulation Solenoid- Vapor Injection SolenoidProtection- Excessive Discharge Temperature- Low Flow Conditions- Operation Under Fault ConditionsDiagnostics- 8 Codes Indicating Faults Module Is Installed In System Cabinet

Copeland Scroll Digital TechnologyHow It Works (40% Capacity Example)Example:40% CapacitySystem Controller orNeededThermostatRun 8 seconds LOADEDRun 12 Seconds UNLOADEDCompressor Controller10 HP Digital ScrollCopeland Scroll Digital Controller Checks For CoolingDemandController Then Sends Capacity Requirements ToCompressor– Run Loaded For 8 Seconds– Run Unloaded For 12 SecondsOver 20 Second Cycle, Average Compressor Output Is40% of full capacityAt End Of 20 Second Cycle, Controller Checks ForDemand & Adjusts Loaded/Unloaded Time Accordingly*.PPT/DEPT 2/7/2008 08:43 44

Input Signal From OEM Controller Digital Controller Receives 1.4-5.0 V Input Signal From System Controller 1.4-5.0 VDC Corresponds To 10-100% Compressor Capacity*.PPT/DEPT 2/7/2008 08:43 45

Copeland Digital Scroll ControllerOptional Pressure Signal FilteringFiltered Suction PressureAlarmOEMSystem ControllerCompressorCapacity RequestCapacity SignalSuction PressureCompressorCapacitySolenoidCONTACTORStart / StopDigital Controller Can Provide Suction Pressure Feedback– 5 VDC Suction Pressure Transducer Required– Algorithm “Filters” Suction Pressure Swings*.PPT/DEPT 2/7/2008 08:43 46

Who Benefits From Copeland ScrollDigital Technology?Applications That See Large Daily Temperature SwingsSchoolsRestaurantsNatatoriumsApplications With Tight Temperature/Humidity ControlRequirementsHospitalsMuseumsTelecom

Copeland Scroll DigitalApplication BenefitsMatch Varying Load–Hot Gas Bypass ReplacementPrecise Temp Control ( 0.5 F)Simple Modulation SchemeCompared To Inverter Drive–Less Complex Controls–No EMI Issues–No Oil Return IssuesModulation FeaturesBenefitsLower Operating CostImproved ComfortImproved Humidity ControlHigher ReliabilityLower Maintenance CostLower Installed Cost

TMCopeland Scroll DigitalTMPower Savings100%Hot Gas By-Pass90%Energy Savings80%70%60%50%Copeland Scroll Digital ReducesPower Consumption LinearlyAs It Modulates CapacityCopelandScroll tage Of Full Capacity80%90%100%

Modulation Overview – Micro ViewProper Matching Of Compressor Suction Pressure to Set PointCould Lead To Reduced Energy – Only Empirical InformationTo DateChart 2: Compressor Cycling Suction Pressure Load Matching18Suction Pressure17Without Good Load Matching161514Higher Energy Cost Due ToPressure Fluctuations13121110Tim eChart 3: Variable Speed Suction Pressure Load MatchingWith Good Load MatchingSu ctio n Pressu re1816Expected Energy Savings142-3% for LT1210TimeBlue – Set-point; Red - Actual3-7% for MT

Digital Scroll Offers Superior Part-LoadPart-LoadEfficiency Versus Hot Gas By-PassBy-Pass% FullCapacityHot Gas DigitalBy-Pass ScrollIPLVEEREER 2%100%11.511.31%IntegratedPart LoadValue6.78.8100%Part-Load Efficiency (IPLV)Hot Gas By-Pass30% Part-Load Efficiency ImprovementWith Copeland Scroll Digital!Digital Scroll

Digital Modulation Over Larger Capacities18 HP System Example18Digital12FixedCapacity#2DigitalDigital Can Be Used InParallel With Fixed CapacityScrolls To Get Even WiderRange Of CapacitiesPower Savings Still FollowThe Same Line6DigitalFixedCapacity#11. Ramp Digital 1. Turn On 1From .6 To 6 HP 6 HP Scroll2. Ramp DigitalFrom 6.6 To 12FixedCapacity#11. Turn On 2nd6 HP Scroll2. Ramp DigitalFrom 12.6 To 18 HPLeverages The Cost AndCapability Of One Digital OverLarger Systems

Digital Scroll Benefits Multi-CircuitMulti-CircuitApplicationsCapacity Range (4 Circuit System)0%25%50%ZPD83Digital75%System P)Capacity(HP)OFFOFF777OFFOFFOFF77ZP83Fixed4 Circuit 30HP SystemCoolingDemand (HP)Load 0Load 7.58.25 Load 1515.75 Load 22.522.5 Load 30Capacity(HP)OFF0.75 – 7.50.75 – 7.50.75 – 7.50.75 – 7.5CapacitySystem(HP)Output (HP)OFFOFFOFFOFF700.75 – 7.58.25 -- 1515.75 – 22.522.5 -- 30Leverage Cost & Capability Of 1 Digital Scroll Across Entire System

Copeland Scroll Digital – Product OfferingR-22 / R-407C – CurrentDigital Quantum – 36K (TF5), 42K (TFD) – ThailandDigital Quest – 49K, 61K, 72K, 81K (TFD)Digital Quest Tandems – 11M, 12M, 13M, 14M, 16M (TFD)Digital Summit – 94K, 125KR-410A – CurrentDigital Quest – 61K (TFD), 72K (TFD), 83K (TFD) – ThailandR-410A – In DevelopmentDigital Quantum – 42K5, 51K5 – ThailandDigital Quest – 61K (TF5), 72K (TF5), 83K (TF5) – ThailandDigital Summit – ZPD120

Copeland Scroll Digital – Product OfferingHP1 2R-22/R407CQuantum/QuestQuest TandemsSummitR-410AQuantum/QuestSummitSummit TandemsStretch QuestLCS345678910127 Models5 Models2 Models152025 30

Efficiency Standards

Regulatory Changes Converging In 20102010 Phase-Out Of R-22 In OEM ProductionMassive OEM System Redesign RequiredCommercial R-410A Adoption Rates Lagging Residential– Limited By OEM System Availability, Longer Design Cycles AndEnd User AwarenessEnergy Efficiency Standards2010 Federal Standards Increase Minimum Efficiency 10%Higher State/Regional Efficiency Standards May EmergeHigher Efficiency Tiers Will Provide DifferentiationCommercial Air Conditioning Industry Is FacingIts Greatest Changes In 20 Years

Commercial A/C Efficiency StandardsEnergy Policy Act Of 2005 Establishes FederalStandard– Averaging 10% Above Current ASHRAE 90.1Minimums– Effective January 2010; Coincides With R-22Phase-OutConsortium for Energy Efficiency Proposing TiersAbove EPACTSystemSizeASHRAE90.1Tier 1ProposedTier 2ProposedTier 36 – 10T10.0 EER11.0-11.2 EER 10-12%11.5 EER 15%11.9 IPLV12.0 EER 20%12.4 IPLV10 – 20T9.7 EER10.6-11.0 EER 9-13%11.5 EER 19%11.9 IPLV12.0 EER 24%12.4 IPLV20 – 60T9.2 EER9.5-10.0 EER10.5 EER10.8 EER

IEER Emerging As Part-LoadPart-LoadEfficiency ng100%80 F1%95 F2%75%80 F42%82 F62%50%80 F45%68 F24%25%80 F12%65 F12%

Discussion & Questions

Copeland Scroll Digital Technology How It Works (40% Capacity Example) Copeland Scroll Digital Controller Checks For Cooling Demand Controller Then Sends Capacity Requirements To Compressor -Run Loaded For 8 Seconds -Run Unloaded For 12 Seconds Over 20 Second Cycle, Average Compressor Output Is 40% of full capacity