Transcription

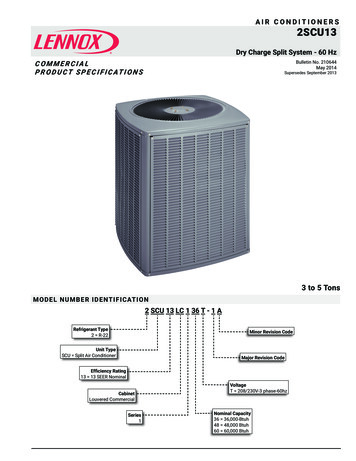

AIR CONDITIONERS2SCU13Dry Charge Split System - 60 HzCOMMERCIALP R O D U C T S P E C I F I C AT I O N SBulletin No. 210644May 2014Supersedes September 20133 to 5 TonsM ODEL NUMBER IDENTIF IC ATION2 SCU 13 LC 1 36 T - 1 ARefrigerant Type2 R-22Minor Revision CodeUnit TypeSCU Split Air ConditionerMajor Revision CodeEfficiency Rating13 13 SEER NominalCabinetLouvered CommercialSeries1VoltageT 208/230V-3 phase-60hzNominal Capacity36 36,000-Btuh48 48,000 Btuh60 60,000 Btuh

CON T ENTSApprovals and Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2Dimensions - Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2Installation Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7Model Number Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1Optional Accessories - Order Separately . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Optional Conventional Temperature Control Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4Sound Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A P P ROVALS AND WARRANT YAPPROVALS Rated according to U.S. Department of Energy (DOE) test procedures Units and components within bonded for grounding to meet safety standards for servicing required by UL Units are UL listedWARRANTY Compressor: Limited five years in non-residential installations All other covered components: Limited one year in non-residential installationsNOTE - Refer to Lennox Equipment Limited Warranty certificate included with unit for specific details.F EAT URESAPPLICATIONS 3 to 5 ton nominal sizes Nitrogen-charged for replacement of R-22 componentsonly Three-phase power supply Sound levels as low as 76 dB Designed for ambients up to 125 F Indoor coil orifice shipped with outdoor unit for optimumefficiency and capacity Installer must set outdoor unit, connect refrigerant linesand make electrical connections to complete jobREFRIGERATION SYSTEMOutdoor Coil Fan Direct drive fan Vertical air discharge Sleeve bearings Inherently protected Totally enclosed fan motor Louvered steel top fan guard Fan service access accomplished by removal of top panelCopper Tube/Enhanced Fin Coil Enhanced aluminum fins and copper tubing for highefficiency and capacity Raised coil prevents debris from collecting in bottom ofcoil Lanced fins for maximum fin surface exposure Fin collars grip tubing for maximum contact area2SCU13 Dry Charge Split System Air Conditioners / Page 2 Flared shoulder tubing connectionsSilver soldering constructionEntire coil is accessible for cleaningFactory tested under high pressureHi-Capacity Liquid Line Drier Furnished with unit for field installation Traps any moisture or dirt that could contaminate therefrigerant systemOptional AccessoriesExpansion Valve Kits Must be ordered separately and field installed on certainindoor units Chatleff-style fittingsFreezestat Installs on or near the vapor line of the indoor coil or onthe suction line Senses suction line temperature and cycles thecompressor off when suction line temperature fallsbelow it’s setpoint Opens at 29 F and closes at 58 FHigh Pressure Switch Protects the system from high pressure conditions Automatic resetLoss of Charge Kit Helps protect the compressor from damage due lowrefrigerant charge conditions SPST, normally closed switch, automatic reset switchmounted on suction line

F EAT URESCOMPRESSORScroll Compressor High efficiency with uniformsuction flow Constant discharge flow, highvolumetric efficiency and quietoperation Low gas pulses duringcompression reduces operationalsound levels Compressor motor is internallyprotected from excessive currentand temperature Muffler in discharge line reducesoperating sound levels Compressor is installed in the unit on resilient rubbermounts for vibration free operationScroll Compressor Operation Two involute spiral scrolls matched together generate aseries of crescent-shaped gas pockets between them During compression, one scroll remains stationary whilethe other scroll orbits around it Gas is drawn into the outer pocket, the pocket is sealedas the scroll rotates As the spiral movement continues, gas pockets arepushed to the center of the scrolls. Volume between thepockets is simultaneously reduced When the pocket reaches the center, gas is now at highpressure and is forced out of a port located in the centerof the fixed scrolls During compression, several pockets are compressedsimultaneously resulting in a smooth continuouscompression cycle Continuous flank contact, maintained by centrifugalforce, minimizes gas leakage and maximizes efficiency Compressor is tolerant to the effects of slugging andcontaminants. If this occurs, scrolls separate, allowingliquid or contaminants to be worked toward the centerand dischargedOptional AccessoriesCompressor Crankcase Heater Protects against refrigerant migration that can occurduring low ambient operationCompressor Sound Cover A reinforced vinyl compressor cover containing a 1-1/2inch thick batt of fiberglass insulation All open edges are sealed with a one-inch wide hook andloop fastening tapeCABINET Heavy gauge steel cabinet Five station wash process Baked polyester paint finish Full metal louvered panel coil guard protection Louvered panels can be quickly removed by looseningtwo screws per panel Controls located in corner post for installation andservice assessibility Rounded corners for safetyRefrigerant Line Connections, Electrical Inlets, ServiceValves Sweat connection suction and liquid lines are located oncorner of unit cabinet Fully serviceable brass service valves prevent corrosionand provide access to refrigerant system Suction valve can be fully shut off, while liquid valvemay be front seated to manage refrigerant charge whileservicing system Refrigerant line connections and field wiring inlets arelocated in one central area of cabinet for easy access.See dimension drawingPermaGuard Unit Base Durable zinc-coated base section resists rust andcorrosionCONTROLSOptional AccessoriesCompressor Low Ambient Cut-Off Non-adjustable switch (low ambient cut-out) preventscompressor operation when outdoor temperature isbelow 35 FCompressor Time-Off Control Kit prevents compressor short-cycling and allows timefor suction and discharge pressure to equalize Permits compressor start-up in an unloaded condition Automatic reset with 5 minute delay betweencompressor shut-off and start-upIndoor Blower Off Delay Relay Delays the indoor blower-off time during the coolingcycleLow Ambient Kit Air conditioners operate satisfactorily down to 45 Foutdoor air temperature without any additional controls Low Ambient Control Kit allows unit operation down to30 FNOTE - Freezestat should be installed on compressorsequipped with a low ambient kit.2SCU13 Dry Charge Split System Air Conditioners / Page 3

OP T IONAL CONVENTION AL TEMPERAT U R E CO NTRO L S YS TEMSComfortsense 7500 Commercial 7-DayProgrammable ThermostatComfortsense 3000 Commercial 5-2 DayProgrammable ThermostatMAINTCommercial Four-Stage Heating / Two-Stage CoolingUniversal Multi-StageIntuitive Touchscreen InterfaceAutomatic Changeover between Heating and CoolingFull Seven-Day ProgrammingFour Time Periods Per Day Temperature and Humidity ControlOne-Touch Away ModeHoliday SchedulingSmooth Setback Recovery (SSR)Performance iditrol Control for Split Systemsand Rooftop UnitsEconomizer Relay ControlBacklit DisplayWallplate FurnishedFDD, ASHRAE and IECC Compliant Two-Stage Heating / Two-Stage CoolingConventional SystemsIntuitive Interface5-2 Day ProgrammingProgram HoldRemote Indoor Temperature SensingSmooth Setback Recovery (SSR) Economizer Relay ControlMaintenance/Filter/Service RemindersBacklit DisplayWallplate Furnished Simple Up and Down Temperature ControlComfortsense Non-Programmable Thermostat One-Stage Heating / CoolingConventional SystemsIntuitive InterfaceManual ChangeoverBacklit DisplaySimple Up and Down Temperature ControlO P T IONAL CONV ENTION AL TEMPERAT U R E CO NTRO L S YS TEMSDescriptionModel No.Catalog 8Comfortsense 3000 Commercial 5-2 Day Programmable ThermostatC0STAT05FF1LThermostat wall mounting plate C0MISC17AE1Temperature SensorRemote non-adjustable wall mount 10k averaging C0SNZN73AE1Comfortsense Non-Programmable ense 7500 Commercial 7-Day Programmable ThermostatUniversal thermostat locking guard (clear)Temperature¹ Remote non-adjustable wall-mount 20kSensors¹ Remote non-adjustable wall-mount 10kRemote non-adjustable discharge air (duct mount)Outdoor temperature sensor 1R emote wall-mount sensors can be applied in any of the following combinations:One Sensor - (1) 47W36Two Sensors - (2) 47W37Three Sensors - (2) 47W36 and (1) 47W37Four Sensors - (4) 47W36Five Sensors - (3) 47W36 and (2) 47W372SCU13 Dry Charge Split System Air Conditioners / Page 4

SP ECIFICATIONSGeneralDataModel No.2SCU13LC148T2SCU13LC160T345Liquid line o.d. - in.3/83/83/8Suction line o.d. - in.7/87/87/85 lbs. 12 oz.7 lbs. 8 oz.10 lbs. 0 oz.Nominal TonnageConnections(sweat)12SCU13LC136TRefrigerant charge field supplied (R-22)OutdoorCoilTube diameter - in.OutdoorFan5/165/165/16Number of rows112Fins per inch262222Diameter - in.182222Number of 30V208/230VMotor hpRpmShipping Data - lbs. 1 packageELECTRICAL DATALine voltage data - 60 hz - 3ph2Maximum overcurrent protection (amps)3Compressor253035Minimum circuit ampacity14.517.720.8Rated load amps10.812.815.3Locked rotor amps7393104Full load amps1.11.71.7767878 CondenserFan MotorSOUND DATASound Rating Number (dBA)OPTIONAL ACCESSORIES - ORDER SEPARATELYCompressor Low Ambient Cut-Off45F08 Compressor Crankcase Heater93M04 93M05Compressor Sound Cover69J03 Compressor Time-Off Control47J27 Expansion Valve Kits26K34 26K35 91M01Freezestat 3/8 in. tubing93G35 5/8 in. tubing50A93 High Pressure Switch Kit94J46 Indoor Blower Off Delay Relay58M81 Loss of Charge Kit84M23 24H77 4Low Ambient Kit (30 F)NOTE - Extremes of operating range are plus 10% and minus 5% of line voltage.1Refrigerant charge sufficient for 15 ft. length of refrigerant lines.2HACR type circuit breaker or fuse.3Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.4Freezestat is recommended with Low Ambient Control.2SCU13 Dry Charge Split System Air Conditioners / Page 5

D IMENSIONS - UNITABCModel U13 Dry Charge Split System Air Conditioners / Page 6

INSTALL AT ION C LEA RANC ES36 in. (914 mm)36 in.(914 mm)36 in.(914 mm)NOTES:Service clearance of 30 in. (762 mm) must be maintained onone of the sides adjacent to the control box.Clearance to one of the other three sides must be 36 in.(914 mm).Clearance to one of the remaining two sides may be 12 in. (305mm) and the final side may be 6 in. (152 mm).A clearance of 24 in. must be maintained between two units. 48in. (1219 mm) clearance required on top of unit.CONTROL BOX36 in. (914 mm)2SCU13 Dry Charge Split System Air Conditioners / Page 7

R EVISIONSSectionsRefrigeration SystemDescription of ChangeFilter/Drier now shipped with unit for field installation.Visit us at www.lennox.comFor the latest technical information, www.lennoxcommercial.comContact us at 1-800-4-LENNOXNOTE - Due to Lennox’ ongoing commitment to quality, Specifications, Ratings and Dimensions subject to change without notice and without incurring liability.Improper installation, adjustment, alteration, service or maintenance can cause property damage or personal injury.Installation and service must be performed by a qualified installer and servicing agency. 2014 Lennox Industries, Inc.

SCU Split Air Conditioner Refrigerant Type 2 R-22 Series 1 Major Revision Code Minor Revision Code Cabinet Louvered Commercial Nominal Capacity 36 36,000-Btuh 48 48,000 Btuh 60 60,000 Btuh Voltage T 208/230V-3 phase-60hz COMMERCIAL PRODUCT SPECIFICATIONS MODEL NUMBER IDENTIFICATION 2SCU13 3-5 TON AIR CONDITIONERS