Transcription

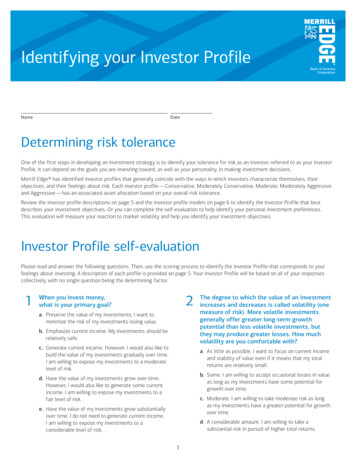

www.tanktech.co.krProduct ProfileTotal Solution Providerfor Shipboard Safety EquipmentSteel Structure Fabricatorfor Oil Major Project

GLOBAL TECHNOLOGYConstantly Challenging Company, Recognized Companyas a Quality, Person-centered Company, TANKTECH.TANKTECH are concentrating the whole power to reinforcePlant and Ship Building Business continuously.

www.tanktech.co.krCONTENTSManagement Motto2Company Outline3Company History4Major Products6Marine EquipmentSecurity28LNGC Equipment29Fabrication32Research & Development34Project Management34Quality Control Activities35World Wide Networks36FASTGOODCOMPETITIVETANK represents a storage vessel or tankerwhich can convey or store liquid cargo.TECH represents an abbreviation of Technology.Therefore,TANKTECH logo is the best factor with symbolof representing the image of company.TANKTECH1

We are always thinking safety and environment for youManagement MottoBeing the world best companyOn the basis of our company philosophy of “Technology created”.We are always seeking the customer's satisfaction” with qualifiedproducts & service.Tanktech is taking its step forward to become the world's leadinghidden champion.Tanktech has an powerful 28 years legacy of partnership withour valuable customers in successfully applying technology-basedsolutions and resolving client's critical problems.R&D centerEquipment Assembly ShopDormitoryR&D centerWorkshop #2, RT Bunker(L: 22m, B: 4m)Ware houseAssembly(Movable)Office building2TANKTECHAssembly shopWorkshop #3Painting shopsQuayWorkshop (Outdoor) #1PE Assembly shopShot blasting shopWorkshop (Indoor) #1, RT Bunker(L: 35m, B: 5m)

www.tanktech.co.krMajor ProductsMarine EquipmentLNGC EquipmentHull PipingMachinery Outfitting High Velocity Pressure/Vacuum Valve Water Mist Fire Fighting System Portable Tank Measuring SystemHull Outfitting Tank Cleaning Machine Eductor Emergency Towing Arrangement Water Spray System Quick Release Mooring System Anti Heeling System Towing & Mooring Fittings Auto Cleaning Filter Mobile Water Monitor & Lance Liquefied Gas Cargo Containment System Aluminum Wedges LNG Fuel Gas SystemSecurity Anti-Piracy Solution GunFabrication Large Steel Structure & Skid for LNG & Offshore Reference List for Large Steel Structure Fixed Long Jet MonitorMHB Headquarters & FactoryCompany Outline1991. 3. 1USD 1,400,000USD 40,000,000Total 90Busan City, ionsPlant AreaBusan Headquarters &Factory in GupyeongSales and Service NetworksBranch Office31,300 m²30 countries in the worldSeoul, Ulsan in Koreaand SingaporeAreaBuildingShot blasting shopPaint shop #1Paint shop #2Quay(Length/Depth)Crawler craneOverhead craneSemi-gantry craneTransporter31,300 m²5,518 m²525 m²525 m²525 m²120 m / 7 m180 ton100 ton, 40 ton15 ton, 30 ton200 tonTANKTECH3

We are always thinking safety and environment for youCompany History1991Despite the challenging industry environment, TANKTECH strives to bea Global Leader and has invested in the new capabilities to meet ourcustomer needs and retains a high skilled and motivated workforce.1994EstablishedKOREA STEEL POWER Co., Ltd.Built Factory & MovedHead Office to Gimhae-City,Gyeongnam Province.1996- Established R&D Institute- Certified forFactory Mutual Research1998Certified forQuality Management hanged Company Nameto TANKTECH Co., Ltd.

www.tanktech.co.kr2004Built Factory & Moved HeadOffice to NokSan NationalIndustrial Complex2008Built 2 Factories in Gunsan2011Moved Head Officeto Gupyeong in Busan2016Awarded"World Class 300 Company2020Global LeaderChanged Company C.I.1991 20031991 Established Korea Steel Power Co., Ltd. at Hanam City, Gyeong-Ki ProvinceAppointed as the Domestic-Product Development Enterprise for Tank Safety Valve1994 Moved Head Office & built new factory at Gimhae City, Gyeong-nam Province1996 Established a Research Institute of TechnologyObtained FMRC factory acknowledgement1998 Obtained ISO9001 Certificate (ABS)Selected to Enterprise for Venture by Small & Medium Business Administration1999 Awarded the first Gyeong-nam Best Trader by Gyeong-nam Province2000 Changed company name to TANKTECH CO., LTD.2001 Obtained USCG Certification for NEW-ISO-HV SERIES from USCGthat meets the latest requirement of RULE & REGULATION2002 Won Official Commendation from Minister of Ministry of Commerce,Industry and Energy (MOCIE)2003 Developed Water Mist Fire fighting System (X-MIST)2004 Present2004 Moved Head Office & built new factory to NokSan National Industrial Complex in BusanDeveloped programmable Single Nozzle Tank Cleaning Machine2006 Developed Deluge Valve and Deluge Nozzle2007 Developed Anti Heeling System for Dry cargo vessel2008 Awarded the Best Exporter 2008 by Busan City GovernmentConstructed steel structure production line in Gunsan.2009 Water Mist System(X-mist) awarded "Korea World-class Product Award 2009"2010 Awarded the Honor Enterprise by Prime Minister2011 Moved Head Office & built offshore system production line to Gupyeong in BusanObtained ASTM Cert. Code "S" & "U"2014 Obtained OHSAS 18001 Certificate by ABS2015 Awarded the prize of excellent capital goods enterprise by Prime Minister2016 Awarded "World Class 300 Company"2017 Developed Liquefied Gas Cargo Containment SystemDeveloped Long Jet Monitor2019 Developed Aluminum WedgesDeveloped BOG RecondensorTANKTECH5

Marine Equipment Hull Piping[ International patented ]High Velocity P/V Relief Valve (U-ISO-H/V/G Series)Non-Hammering High Velocity Pressure/Vacuum Relief Valve(With Gas Free Cover)PrincipleU-ISO-H/V/G series high velocity pressure/vacuum valve is designed to prevent the flamepassage into cargo tanks and to relieve excessive over pressure or under vacuum of cargo tanksduring cargo loading, discharging, ballasting and thermal variation.U-ISO-H/V/G series of high velocity pressure/vacuum valve, which provide Non-hammering, Nonaccumulation condensate vapor and Non-corrosion for marine cargo tanks, are very simple andadvanced models. U-ISO-H/V/G series is designed to prevent the flame passage into cargo tankin compliance with IMO MSC/Circ. 677/1009, ISO 15364 and vapor control system of USCG (46CFR.39-20.11 & 162.017)Basic Rule Requirements- IMO MSC/Circ.1009- IMO MSC/Circ.677- IMO MSC/Circ.450 Rev.1- IMO MSC/Circ.731- Solas Rule Reg. API 2000 - Flow test procedure- IMO MSC/Circ.585- International Standard 15364- ISO 16852Benefits for High Velocity P/V Relief Valve : Model U-ISO-H/V/G SeriesDisassembly procedure Replaceable disc & seat Adjustable setting Visible disc operating positionOption Combined gas free cover TANKTECH PATENT Easy full stroke check lifting No need greasing Low forced hinged check lifting Easy check lifting Visible from on-deck& walk-wayOptimum Design & Arrangements6TANKTECHOptional Arrangement 1Optional Arrangement 2Optional Arrangement 3MSC.1/Circ.1324 approvedHigh Velocity P/V Valve(MESG 0.65mm for chemical cargo)Electric heating TypeHigh Velocity P/V ValveSteam Tracing type or Thermal oilheating type High Velocity P/V Valve

www.tanktech.co.kr[ International patented ]High Velocity P/V Relief Valve (KSRP Series)No Leakage Rupture pin Type High Velocity Pressure/Vacuum ValveNEW APPROACHAn inveterate problem of leakage and corrosion on PV valves has completely beenresolved by Tanktech No leakage Rupture pin type PV valve (KSRP Series)One of the most difficult issues for oil tankers is how to reduce VOCs.The easiest and best solution is to increase the design pressure of the cargo tank high enough sothat VOCs can be liquefied. By simply changing the rupture pin, the design pressure of the cargotank can be easily adjusted without any design change.The huge amount of VOC leakage is occurred from the metal-contact-type valves. To prevent theleakage, the soft seal is adopted in the this valve. Although soft seal is applied the performancefor flashback is guaranteed on the basis of its special structure.Basic Rule Requirements- IMO MSC/Circ. 677/1009, ISO 15364, ISO 16852 - IMO MSC/Circ.450 Rev.1- IMO MSC/Circ.585 - IMO MSC/Circ.731 - IMO MSC.1/Circ.1324- API 2000 - Flow test procedure Vapor control system of USCG ( 46 CFR.39-20.11 & 162.017 )Benefits Prevention of Leakage Lesser VOC emission from Leakage Free setting pressure variation without design change Modification to higher setting pressure with low cost Low VOC generation with higher setting pressure Easy design for easy maintenance Decreased Lapping work for tightness Flame proof and Non oscillationAdvantage for Previous ModelNo.NoLeakage1Conventional DesignNew DesignMetal to MetalMetal to SealLessAccumulationLessCorrosionWeight Type23Rupture Pin& Weight TypeLeakage build up the accumulation of VOC,and the accumulation cause the pitting.Oil accumulation on seat & dosc should becontrolled due to leakage, and heavymaintenance work should be carried out.No leakage improve the corrosionresistance because it can preventthe built-up accumulation.TANKTECH7

Marine Equipment Hull PipingTank Cleaning Machine (UPM Series)Programmable Single Nozzle Tank Cleaning MachineIntroductionCLEANMAX UPM-4050 and UPM-6580 are completely a programmable single nozzle TankCleaning Machine to be equipped on the mounted tank top or deck. It will allow adapting in crudeoil and product/chemical tankers as well as industrial applications.TANKTECH can provide the COW(Crude Oil Washing) manual and the shadow diagram to bethoroughly complied with the latest IMO Assembly Resolution A.897(21).Optimized single nozzle unit of CLEANMAX will give much more advantages compared with twinnozzle unit deliberating on the savings in pumping, stripping and piping and more longer effectivejet length.OperationCLEANMAX UPM series is the fluid-driven machines and their spiral motion for the single nozzlefully managed by the integrated turbine driven control unit.It can set up to control a vertical pitch of nozzle as like 1 and 3 so that it is able to adjust thecleaning time and cleaning frequency, injection density during washing operation. It is possible tovary the cleaning time by setting the speed adjustment knob under the same flow rate.Most of all, it is possible to set up any required washing range within -25 to 155 during singleor multi-stage ITCHADJUSTERJIS 16K 80A FFINLET FLANGEINLET BODYJIS 5K 200ADECK FLANGE- Easy operation setting & all visible indication- Compact design- All setting can be adjusted during washing without stopping of cleaning agent supply.- Infinite repeating cycle without stop of washing operation after setting of operation range- No further requirement after setting of any required range- Easy maintenance & inspection- Operation of the machine is monitored by attaching the sensor, and the signal is transferred to AMS.STAND PIPE L (As Requested)General Data155 Connection:- Inlet :- Deck : Weight- Machine with 2.0m length of stand pipe :- Per additional meter of stand pipe :JIS 16K 40A/50A/65A/80A/100A Other standard availableJIS 5K 200AProgrammable Operation- Horizontal revolution :- Vertical movement :-25 8TANKTECH87 kg12 kg360 -25 155 - Pitch for vertical movement :1 and 3 - Speed adjustment :Low, High- Single or multi stage operation at any desired angle range

www.tanktech.co.krTank Cleaning Machine (NPM Series)Non-programmable Twin Nozzle Tank Cleaning MachineIntroductionNPM-40 and NPM-50 can be used on all kind of chemical tanker as well as crude oil tanker. Inorder to select the specification of Tank Cleaning Machine, pump capacity, machine quantityoperated simultaneously, related standard, the kind of cargo, etc, are required with generalinformation of cargo tank such as dimension and shape. TANKTECH can provide crude oilwashing manual and shadow diagram.OperationThe body of NPM Series is rotated around the vertical axis by cleaning fluid. At the same time,the cleaning fluid spins the nozzles around the horizontal axis. As a result, the grid pattern tracesare generated on the walls of tank. The tank cleaning operation by NPM Series consists of cyclepatterns as followed figures. The whole part of cargo tank is covered by these 4 cycles.SpecificationsMaterials: Stainless Steel 316L, Teflon, Peek etc.: 5 12 kg/cm²Operating Pressure RangeMaximum Operating Temperature : 90 (194 F)Lubrication & Cooling: Both lubrication and cooling by cleaning fluid: On request(Flange or Coupling)Connection: About 7kgWeightPortable TypeModel : NPM-40PPortable Machine Ass’ySubmerged Type Model : NPM-40SFlange Type Machine Ass’yFixed TypeModel : NPM-40FStand Pipe and Machine Ass’yTANKTECH9

Marine Equipment Hull PipingAutomatic Storage Tank Cleaning M/CClean Max Tank CleaningThe machine is using fresh crude oil (or Gasoil) as cleaning agent and a pump supplies the fresh crudeoil to the jet nozzle via hoses.The technology is used for cleaning of ; Crude oil tanks Petro-products tanksApplication ProcedureBenefitsSTEP 1Measuring of sludge profileSTEP 2Installation Plan for Tank Cleaning MachineSTEP 3JettingSTEP 4Extraction of sludge-oil mixtureSTEP 5Measuring of sludge profile Automatic tank cleaning No waiting time for gas-freeing High recycle rate of extracted sludge-oil mixture Easy maintenance & operationwith all visible operating status Compact designApplicationLEGENDRIGID PIPEFLEXIBLE HOSE(RUBBER)PHANTOMBUTTERFLY VALVEPRESSURE GAUGETO GAS FREEINGMANIFOLDGUIDE PIPEFLOATING ROOF GUIDE PIPESTORAGETANKPONTOONRECIRCULATIONHOR. 360 PUMP & MOTORNOZZLE MOVING ANGLEAS PER REQUESTFRESH CRUDE OILFROM OTHER TANKFROM SUMPGAS RETURN TOTANKSUCTION PUMPRECEIVINGTANKRESIDUAL SEMI-LIQUIDSLUDGE10TANKTECHFRESH CRUDE OILINTERMEDIARYTANK

www.tanktech.co.krOperationModule packageCLEANMAX UPM series is the fluid-driven machines and their spiralmotion for the single nozzle fully managed by the integrated turbinedriven control unit.It can set up to control a vertical pitch of nozzle as like 1 and 3 so thatit is able to adjust the cleaning time and cleaning frequency, injectiondensity during washing operation. It is possible to vary the cleaningtime by setting the speed adjustment knob under the same flow rate.Most of all, it is possible to set up any required washing range within-25 to 155 during single or multi-stage operations.“A” partGeneral Data Connection“B” part- Inlet- Deck WeightJIS 16K 40A/50A/65A/80A/100AOther standard availableJIS 5K 200A- Machine with 2.0m length of stand pipe- Per additional meter of stand pipe87 kg12 kgProject ReferencePROJECTCUSTOMEROIL FIELD / OPERATORQTYMoho Bilondo field, Congo10 setsBahregan field, Persian Gulf, Iran101 setsAbu Cluster field, Malaysia55 setsBunga Orkid field, Malaysia46 setsBach Ho field, Vietnam57 setsCendor Phaze II field, Malaysia48 setsNorth Refineries, Iraq44 setsAl Ghaith, Qatar1 full systemAkita Oil Storage, Japan10 setsFloating Production UnitOffshoreMFloating Production Storageand Offloading UnitOnshoreHBFloating Storageand Offloading UnitExternal Floating Roof TankMMHHBBTANKTECH11

Marine Equipment Hull PipingPortable Tank Measuring SystemType approved by MED(BV), USCG, ABS, RRS, CCS, CANADA, Korean &Japanese Administration, ATEX-IECExT2000-TFC-02GAS-TIGHT TYPEPORTABLE OIL / WATERINTERFACE DETECTORT2000-TFS-01RESTRICTED TYPEPORTABLE OIL / WATERINTERFACE DETECTORPortable Oil/Water Interface Detectorfor ullage, oil / water interface & temperature gauging 2 mmVisible and Audible15 m / 30 m / 40 mMetric1 mm34 mm8 mm-20 C to 50 C-20 C to 90 C0.1 C 0.1 C ( 0 C to 60 C ) C (Celsius) or F4- 7 SegmentPF 2-1/4″ TAP7.4 kg / 15m6.4 kg / 30mAPP. 585 X 346 X 150 mmAPP. 607 X 297 X 140 mm9 Volt ( Model : MN1604)Ex ia IIB T4Accuracy of ullage, interface detectionIndication of level divided by ullage and interfaceTape lengthTape graduationTape resolutionDiameter of probeMinimum detectable levelAmbient temperature rangeTemperature sensor measurement rangeTemperature measurement resolutionAccuracy over calibration rangeTemperature reading modeLCD displayTop Coupling (Connection)WeightTFC-02TFS-01Overall dimensions (H X W X T)TFC-02TFS-01BatteryIntrinsically safe typeAdvantagesModel : T2000-TFC-02 Gas-Tight TypeAudible & distinguishable soundGas-tight &waterproof casingfor intrinsic safetyof gas, oil & waterLCD displayEasy operationRotating handle & push stopperfor measuring and rewindingShowing ullage, temperature& oil/water interfaceDISPLAYAnti-fog glass windowfor easy tape scale readingTape wiperfor cleaning and long lifetimeGas-tight storage tube ofsensor probe※ Phosphorous green backlightOnly one switch action(On / Off) for all measurement simulation Tape protection device avoid from thecut by careless valve closing. Sensor probe will be inserted to theprotection pipe during tape rewindingand this protection device will becompletely protected by the tape. Tape and protection device are easyto separated.12TANKTECHGrounding clampfor static dischargeQuick opening andclosing deck valveQuick coupling& convertible adaptorDemonstration tubeto other makerNon-corrosive tape scalecoated by Tefzel ETFETeflon sensor probe headProtection of corrosion and tank explosionfrom the spark.Sensor probe is ultrasonic,RTD temperature & conductivity sensor.Sensor probeGasOilWaterfor submerging & non-floating

www.tanktech.co.krCargo Liquid Sampling Devicefor liquid samplingTape lengthTape graduationTape resolutionTape accuracyTop coupling (Connection)WeighOverall dimensions (H X W X Capacity of Sampling bottle15 m / 30 m / 40 mMetric1 mm 3.2 mm / 30mPF 2-1/4″ TAP12.4 kg / 15m9.1kg / 30mAPP. 1112 X 346 X 180 mmAPP. 950 X 346 X 180 mm0.5 LiterTank Bottom Liquid and Sediments Checking Devicefor tank bottom dryness checking, etc.T2000-TLS-01Tape lengthTape graduationTape resolutionTape accuracyTop coupling (Connection)WeightOverall dimensions (H X W X T)30 m / 40 m / 50 mMetric1 mm 3.2 mm / 30 mPF 2-1/4” TAP5.0 kg / 30 m / 50 mAPP. 850 X 310 X 75 mmInert Gas Sampling Hose & Adaptorfor oxygen and flammable gas concentration measuringT2000-TOS-01Hose sizeHose lengthTop coupling (Connection)WeightO.D 8 x I.D 6 mm20 m / 35 m / 45 mPF 2-1/4” TAP3.5 kg / 35 mPressure Gauge for inert gas pressureT2000-TPG-01Pressure rangeAccuracyTop coupling (Connection)Weight-1000 to 3000 mmH2O1.5% of full scalePF 2-1/4” TAP1.2 kgShut On / Off Valve ( Vapor Control Valve )for tank gauging stationTVC-01TVC-02Top Conn. : PF 2-1/4” TAPFlange Conn. : 25A JIS 5K F.For 50A JIS 5K F.FFunction :Vapor Lock Installation of PMSBottom Dryness Checking, Etc.Top Conn. : PF 2-1/4” TAPFlange Conn.: 50A JIS 5K F.For 80A JIS 5K F.FFunction :Vapor Lock Installation of PMSMain Tank Gauging Station(Ullage Gauging & Sampling)TVC-04Top Conn. : PF 2-1/4” TAPFlange Conn. : 100A JIS 5K F.FFunction :Vapor Lock Installation of PMSMain Tank Gauging Station(Ullage Gauging & Sampling)TANKTECH13

Marine Equipment Hull PipingEductor (TSE Series)GeneralEductor, having no moving parts, lubricating and leaking parts, is widely used for marine system.TANKTECH TSE series are made for more efficiency and more easily to handle for the all user.Basic ideaMotive fluid which has low velocity, it is spout out through the special nozzle, converting staticpressure into high velocity. For this reason, inside mixing chamber has the low pressure areabehind the nozzle. At this time the suction fluid is flown into the chamber.GL Type ApprovedStep 1Step 2Step e motive fluid is going to through a driving utThe motive fluidthrough the specialnozzle, it converts static pressure into high velocity.DischargelineDischargeline has a low pressure areaInside mixing chamberDischarge(vacuum) behind the linenozzle. The suction fluid is flowninto the chamber.

www.tanktech.co.krLow Pressure Eductor(TSE-LP series)Side Type(LP, HP High Pressure Eductor(TSE-HP series)MDRIVINGHSUCTIONSize1 1/2-2-2 1/22-2 A400ALow Pressure Eductor(TSE-LPI series)In-Line Type(LPI, HPI 80A250A300A350ALHigh Pressure Eductor(TSE-HPI series)MSUCTIONHDRIVINGSize1 1/2-2-2 1/22-2 ATANKTECH15

Marine Equipment Hull PipingAnti Heeling SystemGeneralAnti heeling system is designed to automatically balance the vessel in upright position bypumping ballast water of ballast tank during loading and unloading. The main components ofsystem are main control panel including inclinometer, pump starter panel, reversible propellerpump and pneumatic actuator valve.Anti Heeling Pump Outside Motor TypeRequirements1. The inclination angle, fault signal and system status shall be centrally controlled andmonitored.2. The control console shall be provided with a manual emergency OFF switch for ships which areoperated only under supervision.3. Systems which are also operated without supervision shall be provided with a manualemergency OFF switch and an automatic stop device which shuts down the systemindependently of the control when the maximum permitted angle of inclination is reached.Type of Anti Heeling SystemAnti Heeling Pump Outside Motor Type16TANKTECH

www.tanktech.co.krSystem SequenceCCRPORTTANKMAIN CONTROL S-PAOV-PAOV-SLS-SAIR SUPPLYMain Components1. Pump & Motor- The type of pump is vertical reversible propeller pump.It is driven by electric motor and installed inline type.- These pump & motor transmit water from port ballast tankto stbd ballast tank or in the opposite direction.- Pump condition is indicated on main control panel.2. Butterfly valve with pneumatic actuator- The butterfly valve is operated by pneumatic actuator andnormally installed between pump and ballast tank.- Valve condition is indicated on main control panel.3. Main control panel- This system can be automatically and manually controlled by the panel.- Because the relevant information of system is indicated and control buttonsare installed on front panel, the crew easily controls the systemand checks each component simultaneously.4. Pump starter panel- The pump starter panel should be designed to consider motor power.- This system can be manually controlled by pump starter panel.5. Level switch(Option)- In order to prevent damage of pump,the level switch could be installed at lowlevel of each water ballast tank upon request.TANKTECH17

Marine Equipment Hull PipingWater Spray SystemApplied Rule & Regulation IGC (International code for the construction and equipment of ships carrying liquefied gases inbulk) ch. 11.3 & 17.20.17 Resolution A.123(V) ; Recommendation on fixed fire extinguishing systems for special category spaces 1998 SOLAS II-2 Reg. 37 ; Protection of special category spaces ch. 1.3 1998 SOLAS II-2 Reg. 53 ; Fire protection arrangements in cargo spaces ch.2 Ro/Ro cargo spaces 1998 SOLAS II-2 Reg. 54 ; Special requirements for ships carrying dangerous goodsApplicationOn ships carrying flammable or toxic products or both, a water spray system for cooling, fireprevention and crew protection should be installed to cover3。3。1.5。 Escape route systemPersons onboard can safelyand swiftly escape to the lifeboatand life craft embarkation Hatch cover of container ship carrying danger cargoesKind of Water Spray Nozzle CJ Nozzle Hollow Cone Spray Full Cone Spray Flat Fan SprayThe prescriptive requirementsof fixed fire-extinguishingsystems for R0-R0 spacesand special category spaceCone shaped spray jetwith circular ring-shapedimpingement areaCone shaped spray jetwith circular shapedimpingement areaSame as flat jet, spraypattern of a flat jet nozzlewith slightly elliptical orstraight lineimpingement areaDNV Type Approved18TANKTECH

www.tanktech.co.krAuto Cleaning FilterIntroductionLow capacityTKT ACF is an automatic cleaning filter system which can beused in various industries.It is composed of various models of wide range of capacity(250 4000m³/h) and element mesh(10 200 ).It has the optimized design for small installation andmaintenance space. For the filter system, the most importantfunction is the continuous operation without any clogging andproblem. TKT ACF guarantees the extremely long operationtime with no trouble and the best performance to customers.Touch screenAdvantageHigh capacity High removal efficiency. Guarantee flow rate up to 4000m³/h. Space-saving : Miniaturization of the Filter system. Minimum pressure drop. Short backflushing time. Excellent backflushing ability without backflushing pump. Easy and convenient maintenance.Touch screenSpecificationElementFilter housingSizingTYPECONTENTElement TpyeMesh TypeMaterialDegree(μm)Design pressure(bar)Design temperature( C)Power supplyMaterialBackflushingOptionCandle, BasketWedge wire screen, Sintered meshSUS 316L10 2001 1060Electric and pneumaticCarbon steel CoatingDifferential pressure/pumpBackflushing Pump, Touch 012501500175020002500300035004000Pipe erationFiltrationThe fluid enters through INLET and flows from inside to outsideof the filter. During the filtration process, large particles thanelement mesh size are filtered on the surface of filter element.BackflushingDifferential pressure increases due to contaminants building upon the element surface. When differential pressure reaches theset ΔP by contamination, backflushing is automatically started.The filtered fluid is discharged through backflushing line.TANKTECH19

Marine Equipment Hull PipingMobile Water Monitor & Lancefor the fire protection of on deck container stacksGeneral The X-Monitor & X-Lance is water discharge device ofportable type for the fire protection of on deck container stacksin accordance with 2016 SOLAS regulation II-2/10.7.3. Ships constructed on or after 1 January 2016 designed to carryfive or more tiers of containers on or above the weather deckshall carry at least two or four mobile water monitor. Ships constructed on or after 1 January 2016 designed to carrycontainers on or above the weather deck shall carry at least onewater mist lance.Benefits High-efficiency performance at the low flow rate and low pressure Three legs of hook type in order to install easily on the board Easy mobility and quick operation by one crew memberApplied Rule & Regulation 2016 SOLAS Ch. II-2, Reg. 10.7.3 IMO MSC.1/Circ. 1472Mobile Water MonitorItemModelBody MaterialWeightNozzle typeNormal flow rateNormal pressureNormal jet lengthNormal jet heightNormal spray angleRotation rangeElevation rangeConnection sizeApproved byMED, DNV GL, ABS, NKX-MonitorWM65-SWM65-ASUS316LAluminum alloy22kg12.5kgDual-purpose (Jet/Spray)61 m³/h4bar42m24m at pressure 4bar65 0 360 -30 100 65AWater Mist LanceNozzleApproved byDNV GL, ABS, NK20TANKTECHFilterItemModelBody MaterialWeightNormal flow rateNormal pressureNormal Spray angleConnection sizePiercing methodX-LanceWML25-SSUS316L3.2kg20l/min4bar120 25AElectric Drill

www.tanktech.co.krFixed Long Jet MonitorNew Solution of Container ship Fire AccidentBackgroundFire accident of the container ship's cargo area is 31% of the entire ship fire, 59million dollarsaverage property loss due to fire.Due to the increase in the size of the container vessel, the number of stacking containersincreased and faced limits on fire suppression only existing fire hose. Fires involving thecontainers on deck, especially with the volume of cargo now being carried, can present asubstantial risk to the safety of the crew and the vessel.To solve this problem, TKT has developed a special device(as name Long Jet Water Monitor) thatcan shoot extinguishing water at a relatively low pressure and low flow rate.General ArrangementLong Jet Water MonitorFunnel TopFixed Monitor 4 setsCompass DeckFixed Monitor 4 setsBooster Pump(One working, one stand-byBooster Pump(One working, one stand-byBallast Pump or Em’cy Fire Pump, Fire & G/S PumpFixed Long Jet MonitorMain purpose of the system To protect crew members To improve cooling effect To increase customer satisfactionItemModelBody MaterialNozzle MaterialNozzle typeOperation MethodWeightFlow ratePressure at water inletMax. jet lengthRotation rangeElevation rangeConnection sizeMonitor colorX-MonitorFWM-150SCarbon SteelStainless Steel 316Jet TypeManual Reduction Gear Driving TypeAbt. 130kg2503/h15.0 bar110m0 360 -50 90 JIS 20K 150A (DIN and ANSI are also availableREDTANKTECH21

Marine Equipment Machinery Outfitting[ International patented ]Water Mist Fire Fighting SystemX-MIST SYSTEM extinguishes or controls fires by cooling, oxygen displacement by water vapor and radiant heatattenuation. The ex

Shot blasting shop 525 m² Paint shop #1 525 m² Paint shop #2 525 m² Quay(Length/Depth) 120 m / 7 m Crawler crane 180 ton Overhead crane 100 ton, 40 ton Semi-gantry crane 15 ton, 30 ton Transporter 200 ton Headquarters & Factory M H B TANKTECH www.tanktech.co.kr 3