Transcription

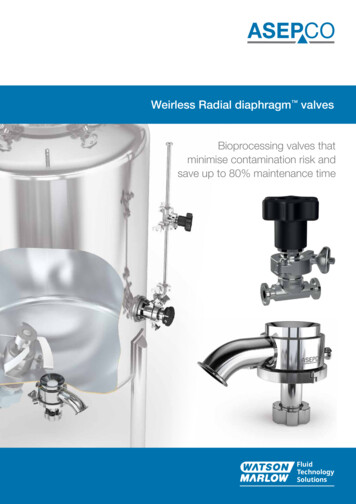

Weirless Radial diaphragm valvesBioprocessing valves thatminimise contamination risk andsave up to 80% maintenance timeFluidTechnologySolutions

ASEPCO: Dedicated to qualityEfficiency by designASEPCO was established over 20 years ago with a single mission:to make the world’s best valves for aseptic processing.Every aspect of an ASEPCO valve is designed to minimise contamination risk, reducemaintenance and lower lifetime cost.Since then, biotechnology andpharmaceutical professionals havecome to realise a well designed,precisely built valve saves time andmoney, and reduces risk. We’vegrown and today we manufacturethe aseptic processing industry’svalve of choice.When you entrust your processfluid to an ASEPCO valve, wetake that responsibility seriously.We ensure every aspect of ourprocess—from the raw material tofast, convenient delivery—meetsyour needs.Fully traceable materialsSaves you time and moneyValves are made from fullytraceable materials, regardlessof the type of alloy you chooseensuring they meet your localstandards and codes.Our valves are designed to saveyou time and money. Changing adiaphragm only takes seconds,making our valves simple toinspect, easy to clean, andeffortless to use.Long‑lasting surface finishEach valve is fully machined,electropolished and passivated asstandard; giving you a consistent,long‑lasting surface finish.ASEPCO valves are designed to minimise risk.Changing a diaphragm takes seconds, with no needfor special tools or training, and a simple Tri‑Clamp assembly makes inspection fast and easy. Everysurface material that touches your process fluid ismanufactured to comply with multiple global industrystandards, safeguarding you and your process.12ASEPCO in‑line valves are built aroundour radial diaphragm that forms twoseals in one. This Weirless Radialarchitecture virtually eliminates the riskof contamination by entrapment, andmakes cleaning fast and easy.Defined shoulder seal eliminates entrapmentfor easy cleaningIn‑line valve features a 180 degree install anglewith full drainability in multiple orientationsTank‑bottom valves with up to three portsfor CIP/SIP or flushing while closedSimple Tri‑Clamp assembly makesmaintenance 80% faster43Simple Tri‑Clamp assemblyUp to 80% faster maintenance34Strong and lightweightactuators12FlowWeirless Radial diaphragmtank valvesASEPCO tank valves are also builtaround our patented radial diaphragm.Valves can be welded truly flush tothe bottom of your tank with no needfor gaskets, bolts or seams. With ourflexible design and manufacturingapproach, we can customise valves tosuit your needs.4311Static radial shoulder seal2Supports full drainability and providessimple, uniform sealing every time2Every valve serialised and laser‑etchedIntegrated travel stopsRestriction‑free drainabilityFully drainable in multiple orientationsManual or pneumatic optionsWe inspect every valve—not just arepresentative sample. Each valvehas passed stringent quality testsat every stage of production.Designed to save you timeStatic radial shoulder sealSimple, uniform sealing every timeQuality you can rely onContamination‑free and consistently dependableAround the world, ASEPCO Weirless Radialdiaphragm valves deliver consistency inbiotechnology and pharmaceutical processeswhile reducing maintenance time by up to 80%.Their unique construction and radial diaphragmdesign makes them completely drainable andvirtually eliminates the risk of contamination.Weirless Radial diaphragmin‑line valvesSimple Tri‑Clamp assemblyMakes inspection fast and easy3Weirless Radial diaphragmVirtually eliminates the risk of contaminationby entrapmentNo readjustment or retightening4Weld flangeHeavy‑duty, extra thick flange that helpsprevent warping during installation23

Valves specific to your applicationWithin our two valve ranges (in‑line andtank) we offer up to five different valvestyles with a variety of configurationsand material choices. Our tank valverange covers the most common sizesfrom 0.5” through 4”, while our in‑linevalve range is made up of 0.5” to 2”sizes.Weirless Radial diaphragm tank valvesFully tested and traceableCompliant with ASME BPVC, ASME BPE, CRN and CE‑PEDSupplied with material test reportsEvery valve serialised and laser‑etched316L stainless steel dual certified to EN 1.4435 andASME SA479 (also available in other materials)Our tank valves are designedspecifically to meet the stringentrequirements of the bioprocessingindustry. We offer several optionsto help solve the most challengingapplications.It is easy to weld our valves trulyflush to the bottom of your tankwith our heavy‑duty, thick weldflange. There are no gaskets, boltsor seams.Can’t find what you need?Our experienced engineerswill develop a custom valveconfiguration to meet your specificprocessing needs.Weirless Radial diaphragm in-line valvesDesigned to accelerate and simplify change-over times, the weirless in-line valve serieshas been developed with time and cost savings in mind.In‑line valveComposed of a forged body,the in-line valve is designedto provide a less restrictive flowpath over traditional weir stylevalves. The weirless designalso eliminates the potentialof trapping material throughour innovative, industryleading shoulder seal design.Configured to suit with clamp‑end or weld‑endconnections, or a secondary valveComplete fluid isolationEasy to assemble and inspect: Eliminates sources ofcontamination and reduces cleaning timeClean, self‑draining designDefined shoulder seal ensures contamination-freeprocessingEvery surface material that touches yourprocess fluid is manufactured to comply withmultiple global industry standards, safeguardingyou and your process.4Process valveOur hydrodynamic designgives you clean, consistentsampling every time. Thebehind‑the‑seat‑flowpath allows for easyclean‑in‑place/steam‑in‑placebetween samples.A valve with a simpleclamp connection foreasy installation in yourpiping systems. Optionalclean‑in‑place port allowssteam‑in‑place or flushthrough, without dead legs.Point‑of‑use valveDivert valveCreated for low‑pointdraining or sampling inpiping systems, this valveeliminates dead legsand helps promotedrainage.Designed to allow divisionand blending of two orthree fluid paths in a singleassembly. This valveeliminates dead legs. Easy to install and never needs adjustingor re-tightening Available with EPDM, Silicone, Viton and PTFE One minute diaphragm change-overSterile access valveBlock‑and‑bleed valve Easy to install and never needs adjusting orre‑tighteningMinimise hold‑up volume,with two flow paths in oneefficient valve.We’ve eliminated theusual dead leg betweenseal points, in a reliableblock‑and‑bleed valve. Available with EPDM and siliconediaphragms.Sample valve One minute diaphragm change-over1”, 1.5”, 2”DIN 11866, DIN 32676 Series A: DN 10,DN 15 Drop‑in replacement for most commondiaphragm (weir‑style) valvesThe leading aseptictank-bottom valve.Machined frombar material,the tank valve isavailable in multipleconfigurations. Likeour in-line weirless design,the tank valve also eliminatesthe potential of trapping material through ourinnovative, industry-leading shoulder sealdesign. Every surface material that touchesyour process fluid is manufactured to complywith multiple global industry standards,safeguarding you and your process. Available in sizes, 0.5”, 1”, 1.5”, 2”, 3”, 4” Available in sizes ASME BPE: 0.5”, 0.75”, Fully drainable in multiple orientationsTank‑bottom valve Sterile access: Eliminatesfittings and saves time,space, and money. Block‑and‑bleed:Eliminates sources ofcontamination and reducescleaning time.Sterillite valveAn integrated steam valve has been addedto our best‑selling tank‑bottom valve. Thisallows steam‑in‑place or flush through,without dead legs.5

World class supportStrong and ligghtweight actuatorsThe ASEPCO AKS actuatorseries** for the in‑line and tankvalves is a durable, easy tomaintain actuator made of aplastic housing and stainless steeldiaphragm interface. The resultingactuator is a hygienic design whichis GMP‑compliant.The operation of AJS and AKSpneumatic actuators can beautomated using ASEPCOswitches, or any manufacturers’linear switch and controllerwithout the need for modification.Watson‑Marlow Fluid TechnologySolutions (WMFTS) is a globalgroup of quality‑focused brandseach leading in different aspects offluid path technologies. With sectorspecialists located in our localsales companies across the globe,we’re able to offer the highestlevels of service and technicalsupport worldwide.Our tank valves are also availablein the ASEPCO AJS actuatorseries, an all stainless steel actuatorproviding all the same performance,but in a heavy‑duty package.We are dedicated to deliveringour products on time to meet yourproduction timelines and accelerateyour speed to market andthey’re backed by the strongestguarantees in the industry.Both series offer manual andpneumatic options, are providedwith laser‑etched serial numbersfor traceability, and carry amarket‑leading three year warranty.AJS SeriesAKS SeriesLong‑lasting, quick‑change diaphragmsThe valve diaphragm can bechanged in seconds, withoutspecial training or tools. Customerstell us this reduces maintenancetime by as much as 80% comparedto other valve technologies. Ourpatented, radial shoulder sealdesign gives consistent, leak‑free,uniform sealing.Our diaphragms are USP ClassVI tested and approved. Theyundergo extensive steam andlifecycle testing using ASME BPEstandard process test conditionswith at least 100 cycles. A cycle isone hour of steam (132-137C), 40minutes of cooling.Extensively tested to ensurelong service lifeLeak‑free static shouldersealHigh performance withminimal maintenanceNeed guidance on yourapplication? Our sales engineerscan help you choose, configure, orcustom engineer the perfect valvesolution for your requirements.Market‑specific solutionsBiotechnology and pharmaceuticalprocesses are among themost critical in the world.Watson‑Marlow Fluid TechnologySolutions allows you totalconnectivity along your fluid path.Connecting vessel to vessel withWatson‑Marlow peristaltic pumps,Watson‑Marlow Tubing, BioPuresingle‑use components, FlowSmartgaskets and ASEPCO WeirlessRadial diaphragm valves all worktowards delivering repeatable andconsistent performance throughoutyour fluid handling processes.Diaphragm materials for every temperature, pressure and chemical challengeDiaphragms are offered in eightdifferent materials to cover everybiotechnology and pharmaceuticalapplication. Each material hasbeen extensively tested to ensurelongevity. Every diaphragm ismarked with its cure date andbatch number for completetraceability.Silicone††EPDM††Viton AViton GFSilicone PlusEPDM Plus††Viton A (steam‑resistant)PTFE** ASEPCO AKS actuator series only available on0.5‑1.5” sizes6††Diaphragms only available in Silicone, EPDM and EPDM Plus forin‑line valves. All materials available for tank‑bottom valves.7

FluidTechnologySolutionsBIOTECHNOLOGY AND PHARMACEUTICAL SOLUTIONSWatson-Marlow Fluid Technology SolutionsWatson-Marlow Fluid Technology Solutions supportsits customers locally through an extensive globalnetwork of direct sales operations and distributorsCopyright 2022 Watson‑Marlow Fluid Technology SolutionsH B0493 Is su e 3wmfts.com/globalDisclaimer: The information contained in this document is believed to be correct but ASEPCO Corporationaccepts no liability for any errors it contains and reserves the right to alter specifications without notice. Itis the users responsibility to ensure product suitability for use within their application. Watson‑Marlow is aregistered trademark. Radial diaphragm is a trademark of ASEPCO Corporation. Tri‑Clamp is a registeredtrademark of Alfa Laval Corporate AB.A Spirax‑Sarco Engineering plc company

Silicone†† EPDM†† Viton A Viton GF Silicone Plus EPDM Plus†† Viton A (steam‑resistant) PTFE Diaphragm materials for every temperature, pressure and chemical challenge †† Diaphragms only available in Silicone, EPDM and EPDM Plus for in‑line valves. All materials available for tank‑bottom valves. The operation of AJS and AKS