Transcription

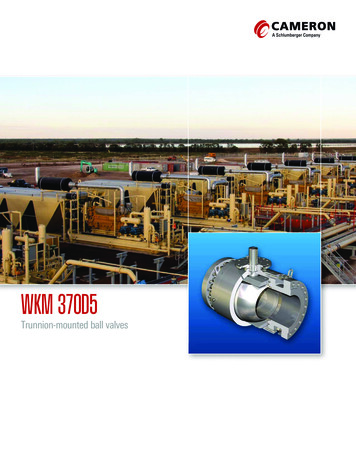

WKM 370D5Trunnion-mounted ball valves

2

ContentsWKM 370D5* trunnion-mounted ball valvesIntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4ASME Classes 150, 300, and 60018, 20, and 24 in [450, 500, and 600 mm]Expanded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Materials list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7How to order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Weight and CV data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Torque chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Services for valves and actuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Oklahoma City, Oklahoma, USAWKM 370D5 trunnion-mounted ball valvesCameron is a leading provider of valve,valve automation, and measurementsystems to the oil and gas industry.We offer products primarily used tocontrol, direct, and measure the flow ofoil and gas as it is moved to refineries,petrochemical plants, and industrialcenters for processing.4We provide valve products that are sold through distributor networksworldwide. Our products are used in oil, gas, and industrial applicationsand include widely recognized brands such as DEMCO* valves; NAVCO*floating ball valves; NEWCO* gate, globe, and check valves; DOUGLASCHERO* forged-steel gate, globe, and check valves; NUTRON* ball valves;THORNHILL CRAVER* choke valves; TOM WHEATLEY* check valves;WHEATLEY* check valves; and WKM* valves.WKM valves are recognized throughout the world for durable, reliable, andflexible operation in challenging situations. Our portfolio of valves includesgate valves, trunnion-mounted and floating ball valves, and butterfly valves,all built to standards for demanding applications.

ASME Classes 150, 300, and 60018, 20, and 24 in [450, 500, and 600 mm]Expanded ViewTailpieceCapscrewAdapter plateStem bearingStem seal O-ringsThrust washerStemStem keyTop coverCapscrewsSteminjectionfittingCheckvalveDrive pinStem bearingSeat springsBearing retainerClosure seal O-ringSeat grease O-ringBallSeat backup ringSeat seal O-ringSeat assembly (seat ringand seat face seal inmaterial list)Top cover O-ringBodyDrain valveThrust washersBearing retainer pinStudSeat injection fittingFeatures and specifications Three-piece forged constructionDouble block-and-bleed designStem and seat injectionAdapter plate for direct-mount gearASME Pressure ClassesSize, in [mm]18 [450]20 [500]24 [600]Nut150300600 Conformance to API Specification 6D NACE MR0175/ISO 15156 MSS-SP-6 (standard finishes for pipe flanges) MSS-SP-25 (standard marking system for valves) API Standard 607 and Specification 6FA (fire test)In addition, WKM valves with DynaSeal* pressure seals can be supplied tocomply with these standards: API Standard 598 (valve inspection and testing) MSS-SP-61 (pressure testing of steel valves) ASME B16.104 (valve seat leakage).5

Materials ListBody Group Trim NumberPartBodyTailpieceSupport legs (not shown)Drain valveCheck valvePlugsTop coverAdapter plateStem keyLifting lugAnchor pinStudsNutsCapscrewsSpacerInternal Group Trim NumberPartBearing retainerBearingsCarbon Steel (NACE) 24A105A105Carbon steelStainless steelStainless steelCarbon steelA105A105Carbon steelCarbon steelCarbon steelA193 Gr. B7MA194 Gr. 2HMA193 Gr. B7MStainless steelSeat springsSeat stop washerBallStemGland bushingDrive pinBearing retainer pinGround deviceCarbon Steel (NACE) 24A516 Gr. 70Stainless steel and filledpolytetrafluoroethylene (PTFE)4130 and 1-mil-thick electroless nickelplating (ENP)X-750A105A105 and 1-mil-thick ENP4130 and 1-mil-thick ENP4130 and 1-mil-thick ENPType 6301040Stainless steelX-750A105CF8MType 6304130 and 1-mil-thick ENPType 6301040Stainless steelSeal Group Trim CodePartTemperature limitsFace sealThrust washerStem O-ringsStem backup ringsSeat O-ringsSeat backup ringsBody and tailpiece O-ringDRF 20 to 250 degF [ 29 to 121 degC]Devlon V-API materialStainless steel and filled PTFEHNBRNylon 6HNBRNylon 6HNBRDWF 20 to 300 degF [ 29 to 149 degC]Devlon V-API materialStainless steel and filled PTFEFKM GLTNylon 6FKM GLTNylon 6FKM GLTSeatNACE indicates compliance with NACE MR0175/ISO 15156.6Stainless Steel (NACE) 23A516 Gr. 70Stainless steel and filled PTFE316 stainless steel

DimensionsN M—Bolt circle Q—Hole size (numberof holes) straddleRcenterlineStem —LKey size—PVKJTUBB—Bore (If required) H2 HWAX Bare stem valve.VValve with gear.Full Port DimensionsASME Class 150 Full Port Dimensions, in [mm]Size,ABHH2in [mm] RFRJ183434.49 17.2517.07 18.13[450][864] [876][438.2] [433.5] [460.5]203636.50 19.2518.15 25.91[500][914] [927][488.9] [461][658]244242.52 23.2521.46 31.81[600][1,067] [1,080] [590.55] [545][808]ASME Class 300 Full Port Dimensions, in [mm]Size,ABHH2in [mm] RFRJ183636.6117.2516.67 20.41[450][914] [930][438.2] [423.5] [518.5]203939.7619.2518.70 20.47[500][991] [1,010] [488.9] [475][520]244545.8723.2521.93 25.43[600][1,143] [1,165] [590.55] [557][646]ASME Class 600 Full Port Dimensions, in [mm]Size,ABHH2in [mm] RFRJ184343.1117.2516.69 21.46[450][1,092] [1,095] [438.2] [424][545]204747.2419.2518.70 20.47[500][1,194] [1,200] [488.9] [475][520]245555.3923.2521.85 24.51[600][1,397] [1,407] [590.55] 8]0.866[22]0.866 (8)[22]0.866 (8)[22]1.063 60[320]16.14[410]0.708[18]0.708[18]0.866[22]0.866 (8)[22]0.866 (8)[22]1.063 4[410]18.90[480]0.866[22]0.866[22]1.260[32]1.063 (8)[27]1.063 (8)[27]1.181 7[598.7]27.91[708.9]30[762]36[914.4]36[914.4]7

Weight and Cv DataWeight (Valve Only, Bare Stem), lbm [kg]Size, in [mm]Valve Pressure Class15018 [450]3,476 [1,577]20 [500]4,850 [2,200]24 [600]7,200 [3,266]3003,584 [1,626]5,090 [2,309]7,560 [3,429]6004,553 [2,065]6,340 [2,876]9,430 [4,277]Weight (Worm Gear Actuator Only), lbm [kg]Size, in [mm]Valve Pressure Class15018 [450]150 [68]20 [500]150 [68]24 [600]148 [67]300150 [68]150 [68]148 [67]600148 [67]148 [67]402 ow Characteristics (CV )Size, in [mm]18 [450]20 [500]24 [600]Valve Pressure Class15056,22171,060106,055Torque ChartASME Classes 150 through 600 Max. Operating PressureBall Valve Torque ChartSize in, [mm]Gauge Pressure,psi18 (450)20 (500)24 (600)0 to 285286 to 740741 to 1,4800 to 285286 to 740741 to 1,4800 to 285286 to 740741 to 1,480Torque Expressions,in.lbfBreak Torque,in.lbfRun Torque,in.lbfReseat Torque,in.lbf19,440 (55.08 P)19,440 (40.44 P)19,440 (46.32 P)20,880 (70.56 P)20,880 (61.68 P)20,640 (56.40 P)40,044 (97.92 P)40,044 (81.60 P)37,680 (74.64 4,36180,342118,518Max. Allowable Stem Torque (MAST), in 676323,784184,524184,524349,560349,560The above values are new valve torque values, where P is the maximum operating pressure of the valve.These torque values do not contain service factors.Soaking effects, particle matter, or both in the valve may cause an increase in the torque.For intermediate pressure, use the torque expressions for the stated pressure range. For example, an intermediate gauge pressure of 1,000 psi uses thetorque equations that correspond to the 751- to 1,500-psi gauge pressure range.The reseat torque is taken as 0.8 times the break torque.For power operation, multiply all of the above values by a factor of 1.25 or customer-specified factor, whichever is larger.Actuator selection should be made on customer experience and appropriate service factors.9

How to OrderExample20 D5 600 RF RF 24 D R F 24 WGASize,in [mm]18 [450]20 [500]24 [600]Valve ModelD5 370D5PressureClass150300600EndConnectionsRF RFBody Group24 CarbonNACE—buriedSeat GroupD DevlonV-APImaterialSeal GroupR HNBRW FKM GLTThe chart above identifies in general terms each of the standard WKM valve trims. Valves ordered with worm gears (WGA) are shipped with gears installed, but handwheelsare not installed (shipped separately). Valves ordered less gear (LG) are shipped with gear mounting plate installed (for actuationby others).The trim charts provide more specific application details, including availability of fire-tested materials.Contact Cameron for information concerning availability of trims other than those listed or for anyadditional information concerning the choice or guidance for application of the trims listed.NACE MR0175/ISO 15156 Compliance—Materials of construction shall be in compliance withthe prequalified material requirements specified by NACE MR0175/ISO 15156. According to NACEMR0175/ISO 15156, it is the manufacturer’s responsibility for meeting metallurgical requirements andthe customer’s and user’s responsibility to ensure that a material will be satisfactory in the intendedenvironment. When given the application requirements (environment) by the customer or user, Cameroncan make technical recommendations in accordance with NACE MR0175/ISO 15156, but that in no waycertifies or warrants the product or materials for the application.820D5600RF RF24DRF24WGA:18-in [450-mm], Model D5, pressure class600, RF RF end connections, carbon NACEbody, Devlon V-API material seat, HNBR seal,fire-tested, carbon steel NACE internal, wormgear actuationFire TestedF Fire testedInternal Group23 Stainlesssteel NACE24 Carbonsteel NACEActuationWGA Worm gearLGLess gear††With mounting plate

Distributed by Distribuido por :INFO@ANYTHINGFLOWS.COMWWW.ANYTHINGFLOWS.COMFlow Control , our passion Life Flows on TMSCAN ME

THORNHILL CRAVER* choke valves; TOM WHEATLEY* check valves; WHEATLEY* check valves; and WKM* valves. WKM valves are recognized throughout the world for durable, reliable, and flexible operation in challenging situations. Our portfolio of valves includes gate valves, trunnion-mounted and floating ball valves, and butterfly valves,