Transcription

Product Data SheetPS–00374December 2002Micro Motion ELITE Mass Flow and Density MetersAvailable with MVD Technology!

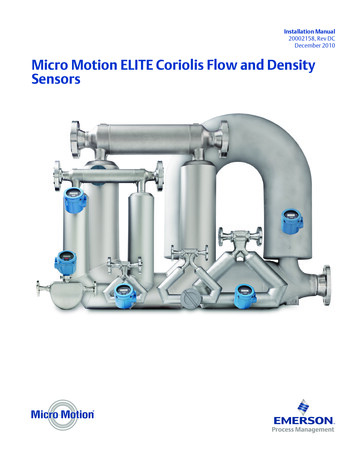

Micro Motion ELITE metersExperience the most accurate Coriolismeters available today.Micro Motion ELITE meters are the leadingflowmeters for precision flow measurement. Andwith good reason. ELITE meters offer the mostaccurate measurement available for virtually anyprocess fluid, while exhibiting exceptionally lowpressure drop.Seven sizes of ELITE meters offer direct massflow, volume flow, density, and temperaturemeasurement of liquids, gases, and slurries —without the need for additional equipment,manual calculations, or estimations.Micro Motion ELITE meters are designed forunsurpassed performance in even the mostharsh operating environments. They have nomoving parts, and no special mounting or flowconditioning requirements. Every ELITE meterfeatures standard secondary containment, andis available with stainless steel or nickel alloywetted parts and a wide variety of processconnections to meet your every need. And theyrequire no maintenance — saving you moneyover the course of their lifetime by helping youmake the most of your time, people, andmaterials.ELITE meters carry hazardous area approvalsfor the U.S.A. and in Canada, Europe, Australia,Japan and other areas in the Asia-Pacificregion.2Micro Motion ELITE Meters

Special applicationsSystem integrationSeveral ELITE meters have been designed forspecial applications. The CMF010 is oursmallest meter, designed for remarkably highperformance in low-flow applications. It featuresa single, continuous flow tube, and is alsoavailable in a high-pressure model, forapplications up to 6000 psi (413 bar).Micro Motion offers a variety of microprocessorbased transmitters, any of which can beconnected to our ELITE sensors. Depending onthe transmitter model, features includemilliampere and frequency/pulse outputs,transmitter and process control functions in asingle device, and Petroleum Measurementoutputs for crude oil and other hydrocarbonfluids.Much larger in size is our CMF400. This 4-inchmeter offers the most accurate measurementavailable in a high-capacity meter.The 3-inch CMF300A is a high-temperaturemeter. It provides the same accuracy andmeasurement capabilities as our other ELITEmeters, at temperatures up to 650 F (343 C).Our CMF025, CMF050, and CMF100 metersare available with optional flangeless, waferstyle process connections.MVD TechnologyMicro Motion ELITE meters are available withMVD Technology — an innovative, multivariable,digital signal processing capability. A coreprocessor, integrally mounted on the ELITEsensor, works with 4-wire transmitters toimprove ease of use, reduce downtime, andlower your flow metering costs. Meters withMVD Technology provide cleaner, noise-freedigital signals. Digital signal processing meansfaster response times, enhanced diagnosticcapabilities, higher accuracy, and betterrepeatability.Other options include transmitters that can beinstalled in instrument racks or panels, orhoused in NEMA or explosion-proof enclosures.Sensors and explosion-proof transmitters canbe installed in the same hazardous area.Micro Motion ELITE meters can be installed aspart of a Bell 202 multidrop network, an RS-485digital communications network, or a ProfibusPA or FOUNDATION Fieldbus system.Transmitters feature HART , Modbus ,FOUNDATION Fieldbus, Profibus-PA, and othercommunication protocols. And all ourtransmitters support Emerson ProcessManagement’s PlantWeb field-basedarchitecture, which uses the power of intelligent,interoperable field devices to improve plantperformance.Micro Motion is known worldwide for increasingplant efficiency, production, and profitability.More than 400,000 Micro Motion meters areinstalled and working in processes just likeyours. Contact us and discover the bestprecision flowmeters available today — MicroMotion ELITE meters.Micro Motion ELITE Meters3

Liquid performance specificationsLiquid flowMassNominal flow lb/min0 to 30 to 400 to 1250 to 5000 to 16000 to 50000 to 15,000kg/h0 to 820 to 10900 to 34000 to 13,6000 to 43,5500 to 136,0800 to 409,000gal/min0 to 0.40 to 50 to 150 to 600 to 1920 to 6000 to 1800l/h0 to 820 to 10900 to 34000 to 13,6000 to 43,5500 to 136,0800 to rs with MVD Technology 0.10% of rate(3)All other transmittersstability- 100 % of rate------------------------------- 0.10% zeroflow rate Transmitters with MVD Technology 0.05% of rate(3)All other transmittersstability- 100 % of rate------------------------------- 0.05% ½ zeroflow rate Maximum flow rateMass flowaccuracy(2)Mass flowrepeatability(2)VolumeZero stabilityCMF010High-pressure 0.0040.0270.1630.6802.186.8040.91(1)Micro Motion has adopted the terminology "nominal flow range." The upper limit of this range is the flow rate at which water atreference conditions causes approximately 15 psid (1 bar) of pressure drop for ELITE sensors.(2)Accuracy includes the combined effects of repeatability, linearity, and hysteresis. All specifications for liquids are based onreference conditions of water at 68 to 77 F (20 to 25 C) and 15 to 30 psig (1 to 2 bar), unless otherwise noted.(3)4stability- , accuracy equals zerostability- 100 % of rate ---------------When flow rate is less than zero flow rate 0.001stability- 100 % of rate.-------------------------------repeatability equals ½ zeroflow rate Micro Motion ELITE Meters

Liquid performance specifications continuedTypical mass accuracy, turndown, and pressure drop with transmitter with MVD Technology(1)2.5CMF010N, CMF010M, 100.10liquid (psi) 0 00.10.214.5liquid (bar) 0 00.010.011.0Pressure drop1.0Accuracy, %liquid 1.2510:11.5Accuracy ( 030405060708090100Nominal flow rate, %2.5CMF010P, CMF050, CMF100, 0:120:110:11:10.500.100.100.10Accuracy ( %)Pressure dropliquid (psi) 0 00.10.213.5liquid (bar) 0 00.010.010.93Accuracy, %1.0liquid 0708090100Nominal flow rate, 0.200.100.10liquid (psi) 0 0 00.214.1liquid (bar) 0 0 0.010.011.01.0Accuracy, %liquid 5Pressure drop10:11.5Accuracy ( 405060708090100Nominal flow rate, %(1)To determine accuracy, turndown, and pressure drop using your process variables, use Micro Motion’s product selectorat www.micromotion.com.Micro Motion ELITE Meters5

Gas performance specificationsFlow specificationsWhen selecting sensors for gas applications, measurement accuracy is a function of fluid mass flow rate independent ofoperating temperature, pressure, or composition. However, pressure drop through the sensor is dependent uponoperating temperature, pressure, and fluid composition. Therefore, when selecting a sensor for any particular gasapplication, it is highly recommended that each sensor be sized using Micro Motion’s product selector, available atwww.micromotion.com.Typical flow ratesVolume at referenceconditions(1)MassFlow rates that produce approximately 10 psid (0.68 bar) pressure drop on air at 68 F (20 C) and 100 psi (6.8 5309410,26826,252Flow rates that produce approximately 50 psid (3.4 bar) pressure drop on natural gas (MW 16.675) at 68 F (20 C)and 500 psi (34.0 0CMF300CMF400lb/min1164218456018564698Transmitters with MVDTechnology 0.35% of rate(3)All other transmittersRepeatability(2)Transmitters with MVDTechnologyAll other transmittersZero stabilityCMF010High-pressure 22stability- 100 % of rate------------------------------- 0.50% of rate zeroflow rate 0.20% of rate(3)stability- 100 % of rate------------------------------- 0.25% of rate zeroflow rate d (scfm) reference conditions are 14.7 psia and 68 F. Normal (Nm3/h) reference conditions are 1.013 bar-a and 0 C.(2)Flow accuracy includes the combined effects of repeatability, linearity, and hysteresis.(3)6stability- , accuracy equals zerostability- 100 % of rate ---------------When flow rate is less than zero flow rate 0.0035stability- 100 % of rate.-------------------------------repeatability equals ½ zeroflow rate Micro Motion ELITE Meters

Gas performance specifications continuedTypical accuracy and pressure drop with CMF100 and transmitter with MVD TechnologyAir at 68 F (20 C), static pressures as indicated on graphpsibarinH2O1.50.90.8300500 psig1000 psig100.71.00.60.52000.450.5Pressure dropAccuracy ( % of rate)100 1201403000001604000Flow rateNatural gas (MW 16.675) at 68 F (20 C), static pressure as indicated on graphpsibarinH2O1.50.90.81.0500 psig101000 psig0.70.60.52000.450.5Pressure dropAccuracy ( % of rate)300100 1203000140001604000Flow rateStandard or Normal Volumetric CapabilityStandard and normal volumes are "quasi mass" flow units for any fixed composition fluid. Standard and normal volumes do not vary with operating pressure,temperature, or density. With knowledge of density at standard or normal conditions (available from reference sources), a Micro Motion meter can beconfigured to output in standard or normal volume units without the need for pressure, temperature, or density compensation. Please reference EXPERT2 ,available at www.micromotion.com, or your local sales representative for more information.Micro Motion ELITE Meters7

Performance specifications continuedwith Model 2700,3500, 3700, or RFT9739transmitterDensitywith IFT9701transmitterkg/m3 2.0 0.5g/cc 0.008 0.002kg/m3 8.0 2.0High-pressure CMF010PAll other modelsliquidliquidg/cc 0.002 0.0005Repeatability(1)High-pressure CMF010PAll other modelsliquidliquid 0.001 0.0002 1.0 0.2 0.004 0.001 4.0 1.0RangeAll models0 to 50 to 50000 to 50 to 5000AccuracyAll models 1 C 0.5% of reading in CRepeatabilityAll models 0.2 CAccuracy(1)TemperatureRange(2)CMF010, CMF025,CMF050, CMF100,CMF200, CMF300M,CMF300H, CMF400(3)(4)High-temperatureCMF300A(3) F–60 to 257 C–50 to 125process fluidwith junctionbox–400 to 400–240 to 204process fluidwith coreprocessor onextended mount–60 to 400–50 to 204process fluid32 to 6500 to 343process fluid–40 to 248–40 to 120with coreprocessorsensorjunction boxambient(1)Accuracy includes the combined effects of repeatability, linearity, and hysteresis. All specifications for liquids are based onreference conditions of water at 68 to 77 F (20 to 25 C) and 15 to 30 psig (1 to 2 bar), unless otherwise noted.(2)For ATEX-compliant sensors, the "T" rating and hazardous area classification depend on the maximum process fluid and ambienttemperature. See page 12.(3)For ATEX-compliant sensors, the maximum ambient temperature is 55 C (60 C for CMF400 sensors). Use of sensors with ajunction box above this temperature is acceptable, provided the ambient temperature does not exceed the "T" rating listed onpage 12 for temperature of the fluid.(4)For ATEX-compliant sensors, the minimum process fluid and ambient temperature is –20 C (–50 C for CMF400 sensors). If theprocess fluid remains at or above 0 C, ambient temperature below –20 C (CMF400 sensors, min. ambient temp. is –50 C) isacceptable for sensors with a junction box. For sensors with a core processor, an ambient temperature of –40 C is allowed.8Micro Motion ELITE Meters

Performance specifications continuedPressure ratingsFlow tube rating (1)Stainless steel sensorsNickel-alloy sensorsHigh-pressure CMF010PPED compliancebar100148413Sensors comply with council directive 97/23/EC of 29 May 1997 on Pressure EquipmentHousing rating 0730365325bar38787857502522Short-termhousing rating (1)(3)(1)psi145021606000Pressure ratings at 77 F (25 C), according to ASME B31.3. For higher operating temperatures, pressure needs to be derated asfollows:Flow tubesFlow tubesHousing316L sensorsnickel alloy sensors all sensorsAll sensors201 to 300 F (94 to 148 C)none2% deratingnone301 to 400 F (149 to 204 C) 7.2% derating9.2% derating7.2% deratingHigh-temperature CMF300A 401 to 500 F (205 to 260 C)501 to 600 F (261 to 316 C)601 to 650 F (317 to 343 C)13.8% derating19.2% derating20.1% deratingnot applicablenot applicablenot applicable11.4% derating16.2% derating18.0% derating(2)Optional rupture disks for high-pressure CMF010 will burst if pressure inside sensor housing reaches 400 psi (27 bar).(3)Housing pressure rating for 10 hours or less, according to ASME B31.3.Micro Motion ELITE Meters9

Functional specificationsEnvironmental effectsProcesstemperature effectProcess temperature effect is defined as the worst-case zero offset due to process fluidtemperature change away from the zeroing temperature for flow rate and calibration temperaturefor density.Process temperature essure effect% of nominal flow rate per C(1) 0.00025 0.00025 0.00025 0.00025 0.001 0.001 0.001density accuracy per C(2) 0.000015 g/cc 0.000015 g/cc 0.000015 g/cc 0.000015 g/cc 0.000015 g/cc 0.000015 g/cc 0.000015 g/ccPressure effect is defined as the change in sensor flow due to process pressure change away fromthe calibration pressure. Pressure effect can be corrected.Pressure effect on flow % of rate per Power consumptionAll meters with core processor3 watts(1)Nominal flow rate is the upper limit of the nominal flow range.(2)For –100 C and above.10Micro Motion ELITE Meters% of rate per barnonenonenone–0.003–0.012–0.009–0.015

Functional specifications continuedHazardous area classificationsUL is a U.S.A. approvals agency. CSA is a Canadian approvals agency that provides approvalsaccepted both in the U.S.A. and in Canada. ATEX is a European standards organizations, andSAA is an Australian approvals agency. (ATEX approval data is shown on page 12.)UL and CSAClass I, Div. 1, Groups C and DClass I, Div. 2, Groups A, B, C, and DClass II, Div.1, Groups E, F, and GSAACMF025CMF050CMF100CMF200CMF300CMF400Ex ib IIC T5Ex ib IIC T5Ex ib IIC T6Ex ib IIB T6Ex ib IIB T6SAA approval not availableMicro Motion ELITE Meters11

Functional specifications continuedATEX (1)CMF010, CMF025, CMF050, CMF100CE 0575II 2G EEx ib IIC T1.T5CMF200, CMF300CE 0575II 2G EEx ib IIB T1.T5max. ambient temp. ( C)Sensors with core processorDe-rate atslope –0.093 C ambient per C fluid554546103T5T4T38645T1-T2150200CMF400CE 0575II 2G EEx ib IIB T1.T5max. ambient temp. ( C)sensor fluid temp. ( C)De-rate atslope –0.093 C ambient per C fluid469250127sensor fluid temp. ( C)CMF010, CMF025, CMF050, CMF100CE 0575II 2G EEx ib IIC T1.T6CMF200, CMF300CE 0575II 2G EEx ib IIB T1.T6max. ambient temp. ( C)Sensors with junction box,except CMF300A554535T6T535T3T445T1-T215085200CMF400CE 0575II 2G EEx ib IIB T1.T6max. ambient temp. ( C)sensor fluid temp. ( C)7792127sensor fluid temp. ( C)CE 0575II 2G EEx ib IIB T1.T6max. ambient temp. ( C)CMF300A55T6T5 T45873T2T3108173sensor fluid temp. ( C)(1)ATEX "T" rating depends on the maximum temperature shown in the graphs above.12Micro Motion ELITE MetersT1268343

Physical specificationsMaterials of constructionWetted h-temperature CMF300ACMF400Housing304L stainless steelJunction boxEpoxy-coated aluminumCore processornot available withCMF300A316L stainless steel orepoxy-coated aluminumStainless steel316L or 304L316L or 304L316L or 304L316L or 304L316L or 304L316L or 304L316L316LNickel alloyInconel alloy 686Hastelloy C-22Hastelloy C-22Hastelloy C-22Hastelloy C-22Hastelloy C-22not availablenot availableWith junction boxlbkg147841262913632916575441200With core processorlbkg1781151573215663016876444201Weight neral corrosion guides do not account for cyclical stress, and therefore should not be relied upon when choosing a wettedmaterial for your Micro Motion sensor. Please refer to Micro Motion’s corrosion guide for proper material compatibility information.(2)The CMF010P has nickel alloy tubes and SST fittings.(3)Weight of sensor with ANSI 150 lb weld neck raised face flanges.Micro Motion ELITE Meters13

CMF010 dimensionsDimensions in inches(mm)CMF010 with stainless steel core processorFLOW2x 1 9/16(40)Temperature extender option3 5/16(84)Ø1 1/4(32)2x 1/2"–14 NPT femalepurge fitting(optional)8 1/16(205)1 13/16(47)1/2"–14 NPT femaleorM20 x 1.5 female2 13/16(71)8 1/4(209)2 7/8(73)9 15/16(252)4 9/16(116)CMF010 with aluminum core processor2x 1 9/16(40)FLOWTemperature extender option3 5/16(84)2x 1/2"–14 NPT femalepurge fitting(optional)Ø1 1/4(32)8 7/16(214)1 13/16(47)1/2"–14 NPT femaleorM20 x 1.5 female2 13/16(71)8 1/4(209)2 7/8(73)9 15/16(253)4 9/16(116)CMF010 with junction boxFLOW2x 1 9/16(40)Temperature extender option3 5/16(84)Ø1 1/4(32)2x 1/2"–14 NPT femalepurge fitting(optional)7 3/4(197)3/4"–14 NPT female1 13/16(47)2 13/16(71)2(50)3 5/16(84)14Micro Motion ELITE Meters7 5/16(186)8 11/16(220)

CMF010 dimensions continuedDimensions in inches(mm)2x 1 3/8(35)Dim. Aface to face 1/8 ( 3)7/8(23)4 3/8(111)Dim. Aface to face 1/8 ( 3)4 9/16(116)7 1/8(180)2x 5/16 (59)thruDim. Ø B2x rupture disks(optional)3 3/8(86)Back view withunion fittingsSide view withrupture diskFlange dimensions9(229)CMF010 process fittingsFittings for 316L stainless steel sensors(1)1/2-inch 150 lb ANSI weld neck raised face flange1/2-inch 300 lb ANSI weld neck raised face flange1/2-inch 600 lb ANSI weld neck raised face flange1/2-inch sanitary fitting15 mm DIN PN40 weld neck, DIN 2635, type C face15 mm DIN PN100 weld neck, DIN 2637, type E face15 mm JIS 10K weld neck15 mm JIS 20K weld neck1/4-inch NPT female union fitting1/4-inch tube compression fitting6 mm tube compression 5Dim. AFace-to-face7 7/8 (199)8 3/16 (209)8 11/16 (221)6 15/16 (177)7 7/16 (189)8 (203)7 3/16 (183)7 3/16 (183)6 7/16 (164)6 7/16 (164)6 7/16 (164)Dim. BOutsidediam.3 1/2 (89)3 3/4 (95)3 3/4 (95)1 (25)3 3/4 (95)4 1/8 (105)3 3/4 (95)3 3/4 (95)-------Fittings for 304L stainless steel sensors(1)1/2-inch 150 lb ANSI weld neck raised face flange1/2-inch 300 lb ANSI weld neck raised face flange15 mm DIN PN40 weld neck, DIN 2635 type C face4134144237 7/8 (199)8 3/16 (209)7 7/16 (189)3 1/2 (89)3 3/4 (95)3 3/4 (95)Fittings for nickel alloy sensors(1)1/2-inch 150 lb ANSI lap joint flange1/2-inch 300 lb ANSI lap joint flange15 mm DIN PN40 lap joint, DIN 265615 mm JIS 10K lap joint flange1/4-inch NPT female union fitting5205215235223237 7/8 (199)8 3/16 (209)9 7/16 (240)8 3/16 (208)6 7/16 (164)3 1/2 (89)3 3/4 (95)3 3/4 (95)3 3/4 (95)---Fittings for high-pressure sensors(1)1/4-inch NPT female union fitting1/4-inch tube compression fitting6 mm tube compression fitting3233243256 7/16 (164)6 7/16 (164)6 7/16 (164)-------(1)Fittings listed here are standard options. Other types of fittings are available. Contact your local Micro Motion representative.Micro Motion ELITE Meters15

CMF025 dimensionsDimensions in inches(mm)CMF025 with stainless steel core processorFLOW2x 2 1/4(58)3 5/16(84)Temperature extender option2x 1/2"–14 NPT femalepurge fitting(optional)9 11/16(246)Ø1 1/4(32)1 5/8(41)2 13/16(72)2 15/16(75)1/2"–14 NPT femaleorM20 x 1.5 female8 5/16(212)10(255)4 5/8(118)CMF025 with aluminum core processor2x 2 1/4(58)FLOWTemperature extender option3 5/16(84)2x 1/2"–14 NPT femalepurge fitting(optional)10 1/16(255)Ø1 1/4(32)1 5/8(41)1/2"–14 NPT femaleorM20 x 1.5 female2 13/16(72)2 15/16(75)8 5/16(212)10 1/16(256)4 11/16(119)CMF025 with junction boxFLOW2x 2 1/4(58)3 5/16(84)Temperature extender option2x 1/2"–14 NPT femalepurge fitting(optional)9 11/16(246)Ø1 1/4(32)2 13/16(72)1 5/8(41)3/4"–14 NPT female2 1/16(53)7 7/16(87)16Micro Motion ELITE Meters7 7/16(190)8 3/4(223)

CMF025 dimensions continuedDimensions in inches(mm)Dim. A 1/8( 3)15/16(24)2 1 13/16(46)Dim. Aface to face 1/8 ( 3)Dim. Aface to face 1/8 ( 3)Dim. Ø BDim. B1/2"–14 NPT female8 1/4(209)Back view withunion fittingsFlange dimensions10(255)Back view withwafer style fittingsCMF025 process fittingsFittings for 316L stainless steel sensors(1)Wafer style, 1/2" ANSI (150 lb, 300 lb, 600 lb bolt kit)Wafer style, 15 mm DIN 2635, type C facing (PN40 bolt kit)Wafer style, 15 mm DIN 2635, type N grooved facing (PN40 bolt kit)Wafer style, 15 mm DIN 2637, type E facing (PN100 bolt kit)Wafer style, 15 mm DIN 2637, type N grooved facing (PN100 bolt kit)Wafer style, 15 mm, standard JIS facing (10K, 20K bolt kit)1/2" ANSI 150 lb weld neck raised face flange1/2" ANSI 300 lb weld neck raised face flange1/2" ANSI 600 lb weld neck raised face flange1/2" NPT female union fitting1/2" sanitary fitting15 mm DIN PN40 weld neck, DIN 2635, type C facing15 mm DIN PN40 weld neck, DIN 2635, type N grooved facing15 mm DIN PN100 weld neck, DIN 2637, type E facing15 mm DIN PN100 weld neck, DIN 2637, type N grooved facing15 mm JIS 10K weld neck15 mm JIS 20K weld 0301302303304305Dim. AFace-to-face2 3/8 (60)2 3/8 (60)2 3/8 (60)2 3/8 (60)2 3/8 (60)2 3/8 (60)6 3/4 (172)7 1/8 (181)7 5/8 (194)4 11/16 (119)4 11/16 (119)6 5/16 (160)6 5/16 (160)6 15/16 (176)6 15/16 (176)6 1/8 (156)6 1/8 (156)Dim. BOutsidediam.1 13/16 (46)1 13/16 (46)1 13/16 (46)1 13/16 (46)1 13/16 (46)1 13/16 (46)3 1/2 (89)3 3/4 (95)3 3/4 (95)---1 (25)3 3/4 (95)3 3/4 (95)4 1/8 (105)4 1/8 (105)3 3/4 (95)3 3/4 (95)Fittings for 304L stainless steel sensors(1)1/2" ANSI 150 lb weld neck raised face flange1/2" ANSI 300 lb weld neck raised face flange15 mm DIN PN40 weld neck, DIN 2635 type C face4134144236 3/4 (172)7 1/8 (181)6 5/16 (160)3 1/2 (89)3 3/4 (95)3 3/4 (95)Fittings for nickel alloy sensors(1)1/2" ANSI 150 lb lap joint flange1/2" ANSI 300 lb lap joint flange15 mm DIN PN40 lap joint flange, DIN 262615 mm JIS 10K lap joint flange5205215235226 3/4 (172)7 1/8 (181)7 5/16 (186)7 1/8 (181)3 1/2 (89)3 3/4 (95)3 3/4 (95)3 3/4 (95)(1)Fittings listed here are standard options. Other types of fittings are available. Contact your local Micro Motion representative.Micro Motion ELITE Meters17

CMF050 dimensionsDimensions in inches(mm)CMF050 with stainless steel core processorFLOW2 2 1/2(63)Temperature extender option4 3/8(111)2x 1/2"–14 NPT femalepurge fitting (optional)12 5/16(313)Ø1 1/4(32)2(51)5(126)3 1/16(77)1/2"–14 NPT femaleorM20 1.5 female8 7/16(214)10 1/8(257)4 3/4(120)CMF050 with aluminum core processorFLOW2 2 1/2(63)Temperature extender option4 3/8(111)12 11/16(322)2 1/2"–14 NPT femalepurge fitting (optional)Ø1 1/4(32)2(51)5(126)1/2"–14 NPT femaleorM20 1.5 female3 1/16(77)8 7/16(214)10 1/8(257)4 3/4(121)CMF050 with junction boxFLOW2 2 1/2(63)Temperature extender option4 3/8(111)12(305)2 1/2"–14 NPT femalepurge fitting (optional)3/4"–14 NPT female5(126)Ø1 1/4(32)2(51)3 1/2(89)2 3/16(55)18Micro Motion ELITE Meters7 9/16(192)8 7/8(225)

CMF050 dimensions continuedDimensions in inches(mm)Dim. A 1/8 ( 3)15/16(24)2 1 15/16(49)Dim. Aface to face 1/8 ( 3)Dim. Aface to face 1/8 ( 3)Dim. BDim. Ø B3/4 NPTfemale11 1/16(281)Back view withunion fittings14 5/16(364)Flange dimensionsBack view withwafer style fittingsCMF050 process fittingsFittings for 316L stainless steel sensors(1)Wafer style, 1/2" ANSI (150 lb, 300 lb, 600 lb bolt kit)Wafer style, 15 mm DIN 2635, type C facing (PN40 bolt kit)Wafer style, 15 mm DIN 2635, type N grooved facing (PN40 bolt kit)Wafer style, 15 mm DIN 2637, type E facing (PN100 bolt kit)Wafer style, 15 mm DIN 2637, type N grooved facing (PN100 bolt kit)Wafer style, 15 mm (10K, 20K bolt kit)1/2" ANSI 150 lb weld neck raised face flange1/2" ANSI 300 lb weld neck raised face flange1/2" ANSI 600 lb weld neck raised face flange3/4" NPT female union fitting3/4" sanitary fitting15 mm DIN PN40 weld neck, DIN 2635, type C facing15 mm DIN PN40 weld neck, DIN 2635, type N grooved facing15 mm DIN PN100 weld neck, DIN 2637, type E facing15 mm DIN PN100 weld neck, DIN 2637, type N grooved facing15 mm JIS 10K weld neck15 mm JIS 20K weld 0301302303304305Dim. AFace-to-face3 1/2 (89)3 1/2 (89)3 1/2 (89)3 1/2 (89)3 1/2 (89)3 1/2 (89)7 15/16 (202)8 5/16 (211)8 13/16 (224)6 1/2 (165)6 1/2 (165)7 1/2 (191)7 1/2 (191)8 1/16 (205)8 1/16 (205)7 1/4 (184)7 1/4 (184)Dim. BOutsidediam.1 13/16 (46)1 13/16 (46)1 13/16 (46)1 13/16 (46)1 13/16 (46)1 13/16 (46)3 1/2 (89)3 3/4 (95)3 3/4 (95)---1 (25)3 3/4 (95)3 3/4 (95)4 1/8 (105)4 1/8 (105)3 3/4 (95)3 3/4 (95)Fittings for 304L stainless steel sensors(1)1/2" ANSI 150 lb weld neck raised face flange1/2" ANSI 300 lb weld neck raised face flange15 mm DIN PN40 weld neck, DIN 2635 type C face4134144237 15/16 (202)8 5/16 (211)7 1/2 (191)3 1/2 (89)3 3/4 (95)3 3/4 (95)Fittings for nickel alloy sensors(1)1/2" ANSI 150 lb lap joint flange1/2" ANSI 300 lb lap joint flange15 mm DIN PN40 lap joint flange, DIN 262615 mm JIS 10K lap joint flange5205215235227 15/16 (202)8 5/16 (211)8 1/2 (216)8 1/4 (210)3 1/2 (89)3 3/4 (95)3 3/4 (95)3 3/4 (95)(1)Fittings listed here are standard options. Other types of fittings are available. Contact your local Micro Motion representative.Micro Motion ELITE Meters19

CMF100 dimensionsDimensions in inches(mm)CMF100 with stainless steel core processor2 3 5/16(83)FLOWTemperature extender option5 3/8(136)2x 1/2"–14 NPTfemale purgefitting (optional)16 7/16(418)Ø1 1/4(32)3 9/16(91)1/2"–14 NPT femaleorM20 1.5 female5 15/16(150)3 13/16(96)9 3/16(233)10 7/8(276)5 1/2(139)CMF100 with aluminum core processor2 3 5/16(83)FLOWTemperature extender option5 3/8(136)16 13/16(426)2x 1/2"–14 NPTfemale purgefitting (optional)Ø1 1/4(32)3 9/16(91)1/2"–14 NPT femaleorM20 1.5 female5 15/16(150)3 13/16(96)5 1/2(139)9 3/16(233)10 7/8(277)CMF100 with junction box2 3 5/16(83)Temperature extender optionFLOW5 3/8(136)2x 1/2"–14 NPTfemale purgefitting (optional)16 1/8(409)Ø1 1/4(32)3 9/16(91)3/4"–14 NPT female5 15/16(150)2 15/16(74)4 1/4(108)20Micro Motion ELITE Meters8 5/16(211)9 5/8(244)

CMF100 dimensions continuedDimensions in inches(mm)Dim. A 1/8 ( 3)1 5/16(33)Dim. Aface to face 1/8 ( 3)Dim. Ø BDim. B15 15/16(405)Flange dimensions21 1/2(546)Back view withwafer style fittingsCMF100 process fittingsFittings for 316L stainless steel sensors(1)Wafer style, 1" ANSI (150 lb bolt kit)Wafer style, 1" ANSI (300 lb, 600 lb bolt kit)Wafer style, 25 mm DIN 2635, type C facing (PN40 bolt kit)Wafer style, 25 mm DIN 2635, type N grooved facing (PN40 bolt kit)Wafer style, 25 mm DIN 2637, type E facing (PN100 bolt kit)Wafer style, 25 mm DIN 2637, type N grooved facing (PN100 bolt kit)Wafer style, 25 mm (10K, 20K, 30K bolt kit)1" ANSI 150 lb weld neck raised face flange1" ANSI 300 lb weld neck raised face flange1" ANSI 600 lb weld neck raised face flange1 1/2" ANSI 600 lb weld neck raised face flange1" sanitary fitting25 mm DIN PN40 weld neck, DIN 2635, type C facing25 mm DIN PN40 weld neck, DIN 2635, type N grooved facing25 mm DIN PN100 weld neck, DIN 2637, type E facing25 mm DIN PN100 weld neck, DIN 2637, type N grooved facing25 mm JIS 10K weld neck25 mm JIS 20K weld 9306307308309317318Dim. AFace-to-face4 (102)4 (102)4 (102)4 (102)4 (102)4 (102)4 (102)9 1/4 (235)9 3/4 (248)10 1/4 (260)10 7/8 (276)8 3/8 (213)8 5/16 (211)8 5/16 (211)9 11/16 (246)9 11/16 (246)8 5/16 (211)8 5/16 (211)Dim. BOutsidediam.2 1/2 (64)2 1/2 (64)2 1/2 (64)2 1/2 (64)2 1/2 (64)2 1/2 (64)2 1/2 (64)4 1/4 (108)4 7/8 (124)4 7/8 (124)6 1/8 (156)2 (50)4 1/2 (115)4 1/2 (115)5 1/2 (140)5 1/2 (140)4 15/16 (125)4 15/16 (125)Fittings for 304L stainless steel sensors(1)1" ANSI 150 lb weld neck raised face flange1" ANSI 300 lb weld neck raised face flange25 mm DIN PN40 weld neck, DIN 2635 type C face4154164249 1/4 (235)9 3/4 (248)8 9/16 (217)4 1/4 (108)4 7/8 (124)4 1/2 (115)Fittings for nickel alloy sensors(1)1" ANSI 150 lb lap joint flange1" ANSI 300 lb lap joint flange25 mm DIN PN40 lap joint flange, DIN 262625 mm JIS 10K lap joint flange5305315335329 1/4 (235)9 3/4 (248)9 9/16 (243)9 5/16 (237)4 1/4 (108)4 7/8 (124)4 1/2 (115)4 15/16 (125)(1)Fittings listed here are standard options. Other types of fittings are available. Contact your local Micro Motion representative.Micro Motion ELITE Meters21

CMF200 dimensionsDimensions in inches(mm)CMF200 with stainless steel core processor11 7/8(301)6 1/2(165)4 13/16(122)FLOW10 3/16(258)Ø1 1/4(32)9 1/8(241)11 7/8(301)1/2"–14 NPT femaleorM20 1.5 female2x 1/2"–14 NPTfemale purgefitting (optional)2 4 5/16(109)7(178)Temperature extender option5 9/16(142)14(356)CMF200 with aluminum core processor11 7/8(302)6 1/2(165)10 3/16(258)4 13/16(122)FLOW9 1/2(232)11 7/8(301)1/2"–14 NPT femaleorM20 1.5 femaleØ1 1/4(32)2x 1/2"–14 NPTfemale purgefitting (optional)2 4 5/16(109)7(178)14(356)22Micro Motion ELITE MetersTemperature extender option5 9/16(142)

CMF200 dimensions continuedDimensions in inches(mm)CMF200 with ju

Micro Motion ELITE Meters 5 Liquid performance specifications continued Typical mass accuracy, turndown, and pressure drop with transmitter with MVD Technology(1) (1) To determine accuracy, turndown, and pressure drop using your process variables, use Micro Motion's product selector at www.micromotion.com . 0 10 203040 50 607080 90100 Accuracy, %