Transcription

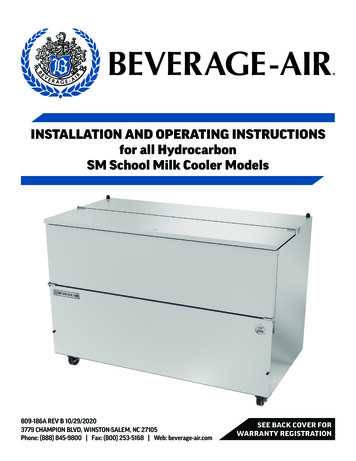

INSTALLATION AND OPERATING INSTRUCTIONSfor all HydrocarbonSM School Milk Cooler Models809-186A REV B 10/29/20203779 CHAMPION BLVD, WINSTON-SALEM, NC 27105Phone: (888) 845-9800 Fax: (800) 253-5168 Web: beverage-air.comSEE BACK COVER FORWARRANTY REGISTRATION

User Manual for SM School Milk CoolerBeverage-AirWELCOMECongratulations on your purchase of Beverage-Air foodservice equipment. Every employee welcomes you to thefamily of satisfied Beverage-Air customers.From the earliest stages of production design, to focusedsteps in fabrication and assembly, rigid standards ofquality are maintained by our staff of skilled employees.Beverage-Air strives to supply superior products throughstrict quality control guidelines exceeding industrystandards, this means that each unit, given the propermaintenance will provide years of trouble free experienceto its owner.Additionally, Beverage-Air food service equipment hasone of the best warranties in the food service industry,and backed by a professional staff of service techniciansacross the country.We thank you for your choice and confidence in BeverageAir Equipment.For part inquiries or orders please call our TechnicalService Department at (800) 684-1199. 8:00 AM to 5:00PM EST.Important Information PLEASE READ THESE INSTRUCTIONS CAREFULLYBEFORE INSTALLING OR USING, IF RECOMMENDEDPROCEDURES ARE NOT FOLLOWED, WARRANTYCLAIMS MAY BE DENIED. Your warranty registration information is located withthis manual. Please complete the card and submit it toBeverage-Air within TEN days of installation. Failureto properly register equipment may limit or void thewarranty. Beverage-Air reserves the right to changespecifications and product design withoutnotice. Such revisions do not entitle the buyer tocorresponding changes, improvements, additions, orreplacements for previously purchased equipment.ContentsSafety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Clearance and Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6Unpacking and Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Using The Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Sequence of Operations Refrigerator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Cleaning and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14Condenser Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15Methods For Cleaning Stainless Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17For The Service Tech - R290 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18For The Service Tech - Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20Limited Warranty (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212Beverage-AirRev. 10/20

User Manual for SM School Milk CoolerBeverage-AirSAFETYThis appliance has been designed with your safety in mind. It has many features to keep you from being harmed. However,safe operation and maintenance are your responsibilities.CAUTIONUse: When using this unit, please: Move it carefully. If on casters be sure the casters doNOT run over the power cord. Lock the casters when in use. Seek help. This machine is heavy! Be sure to movewith enough help to avoid tipping or dropping thecabinet. Prevent children from playing in or on the cabinet.Persons unable to use this product must beprevented access. Follow all instructions. There are many safety labelsand directions on the unit. Heed them. Watch your fingers. There may be pinch points nearthe door hinges.CAUTIONMaintenanceDo NOT:Do ALWAYS Clean a frozen evaporator with a sharp object Clean a dirty condenser with a sharp object.Use a Beverage-Air recommended technician certifiedto repair R290 equipment. Store gasoline, kerosene or any other flammablematerial near the cabinet. Use ONLY Beverage-Air factory service parts. Use ofnon OEM parts can be dangerous because of the designchanges needed to safely use R290.Important Information to AddRecord the model number, serial number and the date of installation here for future reference. The model and serialnumbers are on the unit's serial number dataplate, which is located on the left inside wall.Model NumberSerial NumberDate of InstallationPurchased FromCAUTIONRev. 10/20WARNINGObserve the Caution and Warning notices. They are indicators ofimportant safety information. Keep this manual for future reference.Beverage-Air3

User Manual for SM School Milk CoolerBeverage-AirIMPORTANT INFORMATIONThis unit is intended to be used in a commercial application. That includes schools and cafeterias.If installed in a residence some commercial service companies may not be able to service it on site.The manufacturer has designed and produced this machine with the finest in materials. The manufacturer assumes noliability for units that have been altered in any way. Alterations or part substitutions will void the warranty.LimitationsThe machine is designed for use indoors in a controlledenvironment. It must be kept dry, not overheated orsubjected to excessive cold. May only be connected toa dedicated electrical circuit. Extension cords are notpermitted.MinimumMaximumVoltage104127Room Air Temp60º F100º FAir FlowAgency ApprovalsThese marks appear on the dataplate or serial tag, locatedin the inside of the left wall. The dataplate also containsthe model and serial numbers as well as electricalrequirements.4Beverage-AirRev. 10/20

User Manual for SM School Milk CoolerBeverage-AirPRODUCT INFORMATIONCabinet Dimensionsw x d x h (Inches)Glassor SolidDoorFullLoadAmpsSM34HC34 x 30 5/8 x 41 1/8Solid2.2SM49HC49 x 30 5/8 x 41 1/8Solid2.2SM58HC58 x 30 5/8 x 41 1/8Solid2.2ModelPower CordPlug (NEMA)Refrigerant Type/ Charge g /Charge ozR-290 / 60 / 2.125-15PR-290 / 70 / 2.82Height includes casters All models will maintain product temperature between 35.5 and 40.5 degrees F. at the factory setting of 38.0F. All models are 115 volts, 60 Hz AC. ALWAYS REFERENCE YOUR EQUIPMENT DATA PLATE AMPS, REFRIGERANT AND REFRIGERANT CHARGE FOR THEMOST UP TO DATE AND ACCURATE VALUES. There are no access valves on the refrigeration system.Rev. 10/20Beverage-Air5

User Manual for SM School Milk CoolerBeverage-AirCLEARANCE AND PLACEMENT4CLEARANCEPlacementConsider the following when selecting a location for your Refrigerator:Clearance: Must not be covered - Top 0" - Left 0" - Right 0" - Rear 4" - BelowFloor Load: the floor on which the Refrigerator is located must be even and level, free from vibrations, and strong enoughto support the combined weights of the unit and maximum product load.Ventilation: Grille area at front must be free and clear of any object or wall.Power Outlet: Dedicated power outlet is located within the length of the unit's power cord.6Beverage-AirRev. 10/20

User Manual for SM School Milk CoolerBeverage-AirUNPACKING AND SET UPCarefully inspect the shipping carton for damage. This is the only time that shipping damage may be claimed. If damage issuspected, open the carton immediately and, if there is damage, retain the carton and contact the shipper to make a claim.Do NOT contact the manufacturer.UncratingTools Needed: ¾” box wrench, adjustable wrench, level,flat head screw driver, and box cutter.3. Then, move unit as close to final position as possiblebefore removing the skid.1.4. Move unit as close to final position as possible beforeremoving the skid.First, remove the cardboard top capping, all cleartape, and all staples including those at the bottom ofthe cardboard carton and skid.2. Next, start from the top of the carton. Using the boxcutter, carefully make one continuous cut to thebottom of the skid. Remove cardboard carton anddiscard.Note: The skid must be removed before the casters or legscan be attached.Do NOT tip unit on its front or sides. If tipped onto theback, unit must not be started for 3 hours.Leveling:Cabinet must be installed on a level surface. Failure toinstall on a level surface may result in the door not sealingor not remaining in position correctly, or during defrostmaintenance, condensed water not draining properly.Install or attach any accessories that will be usedRemove any plastic covering the stainless steel.CAUTIONRev. 10/20Do NOT loosen casters to levelthe cabinet. Casters MUST betightly secured to cabinet forfull strength.Beverage-Air7

User Manual for SM School Milk CoolerBeverage-AirELECTRICALThis is a cord-connected unit, and must be connected to its own dedicated power supply. Check the dataplate on themachine to confirm the voltage and per the dataplate use the correct fuses or HACR circuit breakers.Note: Do not connect to GFI / GFCI outlets. Connection to that type of outlet can result in product loss due to unsafecabinet temperature when GFI device trips from moisture.Power CordThis 115 volt model is equipped with a cord and 5-15P plug.If the power cord becomes damaged, it must be replacedwith the identical cord.Follow All National and Local CodesThis Unit Must Be Grounded. Do not use extension cordsand do not disable or by-pass ground prong on electricalplug.Initial Start UpPlug the power cord into the proper power supply.The cabinet will soon begin to blow warm air out of thebottom area, and the inside wall of the cabinet will beginto become cold.The cabinet temperature has been set at the factory andshould not need adjustment, however if it was changed,the standard setting is 38º F.CautionsCAUTION8Care must be taken whenevermoving or servicing the unit. Therefrigerant is contained in a sealedsystem, but if released it may beflammable.Beverage-AirRev. 10/20

User Manual for SM School Milk CoolerBeverage-AirUSING THE UNITOperation is simple, just keep it connected to the correctpower supply and the refrigerator will maintain theinternal temperature it has been set to. Keep the doorsand / or drawers closed as much as possible to avoidunnecessary run time.To manually defrost your milk cooler:1.Remove the product from your milk cooler and placeit in another refrigerated storage area.The controller displays the current internal temperature.2. Open the lids and doors of your milk cooler andunplug the power to the unit.Adjusting the set temperature lower will NOT cause thesystem to lower the temperature faster. When on, therefrigeration system is always operating at maximum.3. Wait approximately 30 min for the frost to melt anddrain to the floor drain. Times may vary with ambienttemperature in the room and ice build-up.The temperature was set at the factory at 38º F, butyou can adjust it to your own selected temperature. 30seconds after adjustment, the display automaticallyreverts to showing the current temperature.4.SM units must be manually defrosted periodically. “ColdWall” units like the SM maintain the air temperature ofthe cabinet at the set point by cooling the walls belowthe set point to approximately 20 F. Because the walls ofthe cooler are below the freezing temperature of water,ice may build up over time. It is important to occasionallymanually defrost the unit to minimize ice build-up.WARNING: DO NOT SCRAPE THE WALLS TO SPEED UPDEFROSTING. SCRAPING MAY RUIN SURFACE FINISHOR PUNCTURE WALL AND DAMAGE REFRIGERATIONTUBING BEHIND THE WALLAfter manual defrost, Close the lid and doors andpower the unit by plugging it into the outlet. Returnproduct to the cooler after the air in the cabinet hascooled to the desired temperature.The compressor and condenser fan motor will only be onwhen the controller senses an increase in internal cabinettemperature passed the set pointIncreaseDefrost38.0SelectoFDecreaseIn most cases the only thing displayed will be the cabinet temperature. When something other than normal operation hasoccurred, a message will be shown.Message DisplayedWhyWhat to doHidOrCabinet temperature too warmConfirm doors or drawers are closed.Door is openClose door, if message does notchange, call for service.LEACompressor run time too longCheck doors closed. If yes, call forservice.E01, E02, E03, E04Sensor unplugged or has failedCall for service.Rev. 10/20Beverage-Air9

User Manual for SM School Milk CoolerBeverage-AirSEQUENCE OF OPERATIONS REFRIGERATORThe refrigerator operates based on the air temperature measured by the probe located at the return air.ONConditionCONTROLLER ACTIONThe CompressorContact is energizedCompressor turnsoff when the airtemperature at probe isequal to or less than the(ERC 112 – Terminal #1)set point -2The Condenser Fanis wired directly tothe Compressor, notthrough the controllerThe Condenser Fanturns off when theCompressor is notrunningCabinet Temp Set point 2ONONONON or OFFCabinet Temperature Set point - 2OFFOFFONON or OFFDefrostOFFOFFONON or OFF10Beverage-AirThe CompressorContact is deenergized(ERC 112 – Terminal#1)The Condenser Fanis wired directly tothe Compressor, notthrough the controllerLightsCONDENSER FANThe Condenser Fanturns on whenthe Compressor r turnson when the airtemperature at theprobe is above thesum of the set point 2CONTROLLER ACTIONCondenser FanOPERATIONCompressorCOMPONENTOFFRev. 10/20

User Manual for SM School Milk CoolerBeverage-AirElectronic ControllerDEFROST (ESC)UPSELECT (OK)DOWNControl Panel DisplayNote: Defrost is manual, LED indicator is inoperative.Defrost LEDAlarm LEDOn fixed:Defrost activeOn fixed:ALARM PresentOff:Defrost is offFlashing:ALARM SilencedOff:No AlarmFan LEDCompressor LEDOn fixed:Fan activeOn fixed:Compressor activeOff:Fan OffFlashing:Delay, protection or activation blockedOff:No AlarmNOTE: When switched on, the instrument panel performs a lamp test for a few seconds.Keyboard FunctionsUPDOWNDEFROST (ESC)SET (ENTER)Quick press and releaseQuick press and releaseQuick press and releaseQuick press and release Increases Set Point Decreases Set Point Activates manual defrost Toggles lights on/offLong press and releaseLong press and releaseLong press and releaseLong press and release Increases display brightness Decreases display brightness Controller enter stand-by mode Toggles display F/ CNote: When the controller is in a Standby Mode, a blue dotwill be displayed as shown here. To switch out of StandbyMode, push and release the Defrost button.Rev. 10/20Beverage-Air.11

User Manual for SM School Milk CoolerBeverage-AirControl Panel ConnectionsChanging the Set pointElectronic Controller AlarmsThe alarm condition is always signaled by the alarm icon. To turn off the relative icon will continue flashing.NOTE: If alarm exclusion times are in progress (ALA folder of the parameter table), the alarm is not signaled.12Beverage-AirRev. 10/20

User Manual for SM School Milk CoolerAlarm TriggerCodeBeverage-AirAutomatic OutputsClearanceComments"Hi"Air temperature is higher than"ALA- Hat for "ALA- Htd"UserconfiguredBl ink "Hi" with the highest temperature; Ifconfigured: cut in alarm relay, beep the buzzerHigh temperaturealarm"Lo"Air temperature is lower than"LAt" for "Ltd''UserconfiguredBlink "Lo" with the lowest temperatu re. Ifconfigured: cut in alarm relay, beep the buzzerLow temperaturealarm"Con"Condenser temperature is toohigh or too lowUserconfiguredBlink "Con". If configured: cut in alarm relay, beep the Condenser alarmbuzzer"dor"Door open for more thanAlwaysBlink "dor". If configured: cut in alarm relay, beep the Door open alarmbuzzer"uHi"Line voltage is higher than "Cop- Always uHi"Blink "uHi". If configu red: cut in alarm relay, beep the High voltage alarmbuzzer"uLi"Line voltage is higher than "Cop- Always uLi"Blink "ulo". If configured: cut in alarm relay, beep the Low voltage alarmbuzzer."LEA"Compressor cont inuous running Alwaysfor more than "ALA- LEA"Blink "LEA". If configured: cut in alarm relay, beep the Leakage alarmbuzzer"E01""S1" errorAlwaysBlink "SOl ". lf configured: cut in alarm relay, beep the "S1" sensor failurebuzzer(short or open)"E02""S1" errorAlwaysBlink "SO2". lf configured: cut in alarm relay, beep the "S2" sensor failurebuzzer(short or open)"E03""S1" errorAlwaysBlink "S03 ". lf configured: cut in alarm relay, beepthe buzzer"S3" sensor failure(short or open)"E04""S1" errorAlwaysBlink "SO4 ". lf configured: cut in alarm relay, beepthe buzzer"S4" sensor failure(short or open)How to Acknowledge AlarmsRev. 10/20Beverage-Air13

User Manual for SM School Milk CoolerBeverage-AirCLEANING AND MAINTENANCECleaning Schedule:CabinetCondenser coilGasketsRoutine maintenanceDaily wipe downQuarterly cleaningDaily inspectionAnnuallyWeekly interiorDaily Exterior CleaningIt is much easier to clean on a regular basis than to have to remove stains once they have built up.1.Wash with a clean sponge and a mild detergent thatdoes not contain chlorine.4. Polish with a soft cloth, wiping with the grain.5. Wipe weekly with stainless steel cleaner.2. Rinse with clean water.3. Dry with a soft cloth.Weekly Interior Cleaning1.Remove all food, food related items. Store the food ata safe temperature.2. Disconnect power to the unit (unplug it or switch thebreaker off).3. Remove all loose food particles from the inside walls,floor, door liner and ceiling.warm (100oF to 110oF) detergent solution and a softscrub brush.5. Rinse with clean water and allow to air dry.6. Restore power.7.Return food to the unit when it has reached a safetemperature.4. Scrub all interior surfaces and door gaskets with aDefrostingST units must be manually defrosted periodically. “ColdWall” units like the SM and ST maintain the air temperatureof the cabinet at the set point by cooling the walls belowthe set point to approximately 20 F. Because the walls ofthe cooler are below the freezing temperature of water,ice may build up over time. It is important to occasionallymanually defrost the unit to minimize ice build-up.To manually defrost your milk cooler:1.Remove the product from your milk cooler and place itin another refrigerated storage area.2. Open the lids and doors of your milk cooler and unplugthe power to the unit.143. Wait approximately 30 min for the frost to melt anddrain to the floor drain. Times may vary with ambienttemperature in the room and ice build-up.WARNING: DO NOT SCRAPE THE WALLS TO SPEED UPDEFROSTING. SCRAPING MAY RUIN SURFACE FINISH ORPUNCTURE WALL AND DAMAGE REFRIGERATION TUBINGBEHIND THE WALL4. After manual defrost, Close the lid and doors and powerthe unit by plugging it into the outlet. Return product tothe cooler after the air in the cabinet has cooled to thedesired temperature.Beverage-AirRev. 10/20

User Manual for SM School Milk CoolerBeverage-AirCONDENSER CLEANINGKeeping the condenser coil clean is critical to efficientoperation.1.Unplug unit from power supply.CAUTIONRotating fan blade can causepersonal injury.Unplug unit from power supplybefore beginning to cleancondenser2. Remove the Phillips head screws on the left and rightof the rear panel3. Pull the panel away from the unit.4. Brush off the surface of the condenser fins. Do NOTbend the fins.5. Vacuum the surface of the condenser fins.6. To reinstall the rear panel line up the screw holes andreinstall the Philips head screws.Note: If the coil is greasy, the coil will need to be cleanedwith coil cleaner and that should be left to an experiencedtechnician.Note: Air filters are not recommended as they restrict theflow of cooling air.Rev. 10/20Beverage-Air15

User Manual for SM School Milk CoolerBeverage-AirMETHODS FOR CLEANING STAINLESS STEELCleaning NeededCleaning AgentMethod of ApplicationAffect on FinishSmears and fingerprintsAreal 20, Lac-O-Nu, Lumin WashO’Cedar Cream Polish, StainlessShine.Rub with cloth as directedon the package.Satisfactory for use on allfinishes.Provides barrier film tominimize prints.Allchem Concentrated Cleaner.Apply with damp sponge orcloth.Rub with damp cloth.Samae, Twinkle or Cameo CopperCleanerRub with damp cloth.Grade FFF Italian pumice, whiting,or talc.Rub with dry cloth.Liquid NuSteelPaste NuSteel or DuBois Temp.Copper’s Stainless Steel CleanerRevere Stainless CleanerHousehold cleansers, such asOld Dutch, Lighthouse, Sunbrite,Wyandotte, Bab-O, Gold Dust,Sapolio, Bon Ami, Ajax, or CometGrade F Italian Pumice, SteelBright, Lumin Cleaner, Zud,Restore, Sta-Clean, or Highlite.Penny-Brite or Copper-Brite.Use small amount of cleaner.Rub with dry cloth using asmall amount of cleaner.Apply with damp sponge orcloth.Rub with a damp cloth. Maycontain chlorine bleaches.Rinsethoroughly after use.Rub with a damp cloth.Rub with a dry cloth using asmall amount of cleaner.Heat tint ordiscolorationPenny-Brite or Copper-Brite.Past NuSteel, DuBois Temp,or Tarnite. Revere Stainless SteelCleaner. Allen Polish, Steel Bright,Tenacious Deposits,Rusty Discolorations,IndustrialAtmospheric Stains Wyandotte,Bab-O or Zud.Rub with a dry cloth.Rub with a dry cloth or stainless steel wool.Apply with damp sponge orcloth.Rub with a damp cloth.Burnt-On Foods andGrease Fatty Acids,Milkstone (whereswabbing or rubbingis not practical)Easy-Off, De-Grease-It, 4 to 6%hot solution of such agents astrisodium phosphate or sodiumtripolyphosphate or 5 to 15% causticsoda solutionApply generous coating. Allowto stand for 10-15 minutes.Rinse.Repeated application may benecessary.Tenacious Deposits,Rusty Discolorations,IndustrialAtmospheric StainsSwab and soak with cleanOakite No. 33, Dilac Texo 12, Texo NY, cloth.Flash-Klenz, Caddy Cleaner,Let stand 15 minutes or moreTurco Scale 4368 or Permag 57.according to directions onpackage, then rinse and dry.Hard Water Spotsand ScaleVinegar.5% oxalic acid, 5% sulfamic acid, 5 to10% phosphoric acid, or Dilac, OakiteNo. 33, Texo 12, Texo N.Y.Stubborn Spots andStains, Baked-OnSplatter, and OtherLight Discolorations16Swab or wipe with cloth. Rinsewith water and dry.Swab or soak with cloth. Letstand 10-15 minutes. Alwaysfollow with neutralizer rinse,and dry.Beverage-AirUse in direction of polish lineson No. 4 (polished) finish. Mayscratch No.2 (mill) and Nos. 7 and 8(polished) finishes.Excellent removal, satisfactoryfor use on all finishes.Satisfactory for use on allfinishesSatisfactory for all finishes.Satisfactory for all finishes.Effective on tenacious depositsor where scalehas built up.Rev. 10/20

User Manual for SM School Milk CoolerBeverage-AirHELPTrouble Diagnosis for the UserMalfunctionPossible CauseLikely SolutionNo cooling - unit is silentUnit not plugged in.Fuse or circuit breaker tripped.Power cord plug loose in outlet.Connect to proper voltage circuit Replacefuse or reset breaker.Check outlet for loose connection, replaceas neededUnit cools but seems to be on all the timeDirty condenserClean condenserDirty condenserEvaporator iced over Unit in hightemperature environmentClean condenser Defrost unitReduce temperature of roomTemperature controlAdjust or replace controlTemp control stuck in open positionReplace temp control.Space temperature too highSpace temperature too lowTrouble Diagnosis for the TechnicianNo cooling - compressor does not humNo cooling - compressor hums but does not Low voltage to unit.startCompressor starting system failureCheck voltage, correct as needed. Checkstart relay and start capacitor. See nextstep.No cooling - compressor starts but shutsoffCompressor start relay failure Compressorstart capacitor failureReplace relay. Replace capacitor.No cooling - compressor cycles on and offOverheating weak overloadClean condenser, check fan motor andblade. Check refrigerant charge. Replaceoverload.Unit cools but turns on and off frequentlyFill cabinet Replace controlNo product in cabinet. Temperature controlHave system checkeddefective Refrigeration issueMakes excessive noiseRev. 10/20Tubing rattle Loose partsBent or broken fan blade Noisy fan motorBeverage-AirCheck tubing for routing Check for loosecomponents Replace fan bladeReplace fan motor17

User Manual for SM School Milk CoolerBeverage-AirFOR THE SERVICE TECH - R290Refrigeration service should only be attempted by a trained trade professional certified to work on R290 systems.Here are some critical service items.Other Information:This list does not qualify anyone to service the unit. It is areminder and checklist for the service tech. Keep these inmind for R290 service:Evacuation: It is critical that a refrigeration system beleak free and internally dry. A thorough evacuation witha good vacuum pump with a micron gauge attached is theonly way to ensure that the system is dry and ready for acharge of refrigerant. Wire nuts are NOT to be used when changing anelectrical part. The switches in this product are sealed, only exactreplacements may be used. The process tubes are to be used for service access. Cut out (with tubing cutter) refrigeration componentsthat are to be replaced. Do NOT un-braze.Charging: The system is critically charged and the propertype and amount MUST be weighed in. Because R290 can be vented into the air duringservice, the venting MUST be in an area free fromflame or spark. It must also be in a well ventilatedarea, with a nearby open window or door. A sign noting service of a system containing propanemust be attached to the unit during refrigerationservice. A combustible gas leak detector must be used toinform anyone in the area when propane is present inthe air.18Overcharge symptoms: Unit will cool properly butthe suction line temperature will be unusually cold.Compressor run time will be longer than normal.Undercharge symptoms: Long run time, poor cooling anda hot compressor dome are the main symptoms of anundercharge.Beverage-AirRev. 10/20

User Manual for SM School Milk CoolerBeverage-AirFOR THE SERVICE TECH - WIRING DIAGRAMWHITEBLACK23CNTRLBLACKWHITE*SEE CONTROLLER DETAILWHITEBLACKCONDENSER FAN21OL*SEE CONTROLLER DETAILCURRENT RELAYRMSS1C COMPCOMPRESSOR DETAIL (115V 1PH)Rev. 10/20Beverage-Air19

User Manual for SM School Milk CoolerBeverage-AirLIMITED WARRANTYWARRANTY (Warranty valid in USA and Canada)BEVERAGE-AIRTHREE (3) YEAR PARTS AND LABOR WARRANTY:Also, this extended compressor-part only warranty doesNOT apply to any electrical controls, condenser, evaporator,fan motors, overload switch, starting relay, capacitors,temperature control, filter/drier, accumulator, refrigerationtubing, wiring harness, labor charges, or supplies which arecovered by the warranty above.Beverage-Air Corporation warrants to the originalpurchaser of Beverage-Air branded equipment, includingall parts thereof, that such equipment is free from defectsin material and workmanship, under normal use, propermaintenance, and service as indicated by Beverage-Airinstallation and operation instructions, for a period of three(3) years from the date of installation, or thirty-nine (39)Months from the date of shipment from the manufacturer,whichever is earlier.ADDITIONAL FOUR (4) YEAR COMPRESSOR PARTWARRANTY*: In addition to the warranty set forth above,Beverage-Air warrants the hermetically/semi-hermeticallysealed compressor (part only) for an additional FOUR (4)years beyond the first three (3) years warranty period;not to exceed eighty-seven (87) months from the date ofshipment from Beverage-Air, provided upon receipt of thecompressor, manufacturer examination shows the sealedcompressor to be defective. This extended warranty doesnot cover freight for the replacement compressor or freightfor the return of the failed compressor.* Units shipped after 03/01/2020. Previous warrantyapplies to units shipped prior.EXCEPTIONS:CT96 Models carry a one (1) year parts and labor warranty,limited to fifteen (15) months from date of shipmentfrom Beverage-Air. These are excluded from additionalcompressor warranty.SR/SF (Slate) models carry a two (2) year parts and laborwarranty, limited to twenty-seven (27) months from date ofshipment from the Beverage-Air.Blast Chillers carry a three (3) year parts and laborwarranty; additio

Beverage-Air strives to supply superior products through strict quality control guidelines exceeding industry standards, this means that each unit, given the proper . the model and serial numbers as well as electrical requirements. User Manual for SM School Milk Cooler Beverage-Air Rev 020 Beverage-Air 5 Model Cabinet Dimensions w x d x h .