Transcription

1.PAULSON Training Program on Injection Molding ProcessObjectivesPaulson offers the most comprehensive training and service package availableto the plastics industry. Paulson Training Programs provides a board range ofmolding training solution to help businesses grow and compete on a globalscale. It has always been our goal to provide convenient, high-quality, andaffordable solutions while utilizing the latest technology.Our extensive Injection Molding Training library provides solutions for everyarea of your company – from front office to shop floor. It’s a total solution for anycompany.

Paulson’s Training Program Contents Overview#Module Name1Practical Injection Molding - Basic2Practical Injection Molding - M/c & Process Optimizing3Practical Injection Molding - Expert Series4Skill Builder – for M/C Optimizing 5Skill Builder – for Problems & Solutions6Injection Molding Part – Problems & SolutionsTotal No. of Hours to Complete the Course – 25Hrs minimumRelevanceFor People ConcernedwithProduct of injectionmolded PartsFor People concernedwith Design of plasticparts & Molds

2.PAMSTAMP – Software Solution for Sheet Metal StampingPAM-DIEMAKERPAM-QUICK STAMPPAM-AUTOSTAMP

PAMSTAMP – Software Solution for Sheet Metal StampingObjectivesPAM-STAMP 2G is a complete software solution for sheet metal stamping tosimulate the entire industrial chain from die design feasibility to processvalidation and optimization.PAM-DIEMAKERRapid Die DesignWith its robust and fast parametric surface engine, PAM-DIEMAKER allowsfocusing on rapid draw die design and optimization. It also ensure optimal datatransfer with user’s standard CAD geometry.

PAM-QUIKSTAMPFast Feasibility AssessmentWith its new incremental formulation PAM-QUIKSTAMP enables a quickevaluation of the draw die design. It represents the optimal solution betweenaccuracy and computation time.PAM-AUTOSTAMPSimulation for production ValidationWith its newly re-engineered platform PAM-AUTOSTAMP allows the finalvalidation quality control, tolerances, trimming, improved spring back andflanging.PAM-STAMP 2G allows users to make decision on-line in a continuousimprovement process within a collaborative environment bringing together thedesign engineer, the material provider, the die designer and the try-out pressshop from an early stage of the design right through to production. Projectsresults are easily shared within the project team by making use of integratedreporting tools. This web-enabled technology allows images, annotation, text and3D, models to be shared, thus supporting a truly collaborative engineeringenvironment.

3. DFMA – Software for Design for Manufacturability & AssimilabilityObjectivesThe goal is to help companies stimulate the creativity, innovation, and teamworknecessary for the development of world-class product by imparting systematictraining in the DFMA software.Boothroyd Dew Hurst DFMA Software tools allow companies to develop productwith fewer parts at lower coast and with higher quality than was previouslypossible. Its disciplined approach to product development provides an early andaccurate understanding of product cost and the capability to manage cost duringthe product development process. Finally it puts manufacturing information in thehands of design teams.Industries all over the world have been using DFMA software tools since 1983.Our aim is to train our client for competitive advantage in their marketplace, andthey understand the importance of crating products that are simple in structure,low in cost, and high in quality.

5. GD&T – Software for Geometric Dimensioning & Toleranceingvide ASME-Y14.5-1998ObjectivesOne can evaluate his/her knowledge on Geometric Dimensioning & Tolerancingfrom fundamentals to advanced levels, The topics covered areSI.No Topics1Introduction2Modifiers & Symbols3Rules4Flatness5Straightness6Circularity

14Profile of a Line15Profile of a Surface16Circular Runout17Total Runout

FREQUENTLY ASKED QUESTIONS (FAQ’S)ABOUTCOMPUTER BASED TRAINING (CBT)AT NTTF-TAGMA LIBRARY

1. What are the Computer Based Training (CBT) Modules available at NTTFTAGMA library?1.1 Paulson’s Training on Injection Molding Process from USA1.2 Mold flow Analysis for injection Molded Plastic Part from USA1.3 Formability Analysis for Sheet metal components ‘Pamstamp’ from France1.4 Design For Manufacturing & Assembly (DFMA) Software from USA1.5 Geometric Dimension & Tolerancing software from NTTF2.Where is NTTF-TAGMA Library Located?NTTF-TAGMA LibraryAt NTTF Training Centre23/24, 2nd Phase, Peenya Industrial AreaBanglore-560058Ph: 080-41271054Mob: 91-9945776517

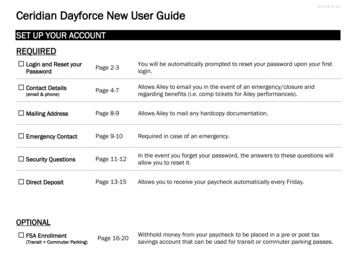

3. What is the programme fee and how to send it?The training charges for using the CBT Lab are as follows:Course Details:Course FeesCourseDurationPaulson's TrainingProgramme4 DaysRs. 8,000/-Rs. 10,000/-GeometricDimensioning &Tolerancing3 DaysRs. 6,000/-Rs. 7,500/-For MembersFor nonMembersPayment to be made by DD in favour of NTTF Bangalore.(Fee includes 2 Tea and 1 working Lunch)4. Who can attend?Anybody interested in improving his / her knowledge in areas mentioned in #1.

5. Where do I stay? What is the cost?Accommodation booking will be done by NTTF in hotel ‘Krishna ChandraResidence’ or Vishwas Lodge’ at TVS cross, 1 km from Training venue.Boarding and Lodging charges to be borne by the participants.Tariff:#12Hotel NameDeluxe RoomSingleDoubleKrishna ChandraResidencyNot Available Rs. 500 / dayVishwas LodgeRs. 350 / dayRs. 500 / dayA/cRs.700-800 /dayNot availableFor accommodation, booking should be informed 2 days minimum in advance.6. What is the training duration and timings?4days (Any consecutive working days in a week.(In special cases, we can accommodate On Sundays also)Timings: 09-00a.m. to 05-00p.m.

7. What are the other facilities available at NTTFTAGMA Library?News papers, Magazines, Internet Browsing,Reference books andfollowing Video and Knowledge based CD’s

8. Contact Person:LibrarianNTTF – TAGMA LibraryPh: 080-41271054Mob: 91-9945776517Email: library@tagmaindia.orgMark a copy of your mail to pgschool@nttf.co.in for additional information9. Remarks:9.1 Maximum number of participants for CBT program is limited to 10 at anygiven time.9.2 It is recommended that participants come in group of not less than five.9.3 Video CD’s & other knowledge base CD”S can be viewed only. Theycannot be copied as they are meant only for training by NTTF.

Total No. of Hours to Complete the Course - 25Hrs minimum 6 Injection Molding Part - Problems & Solutions For People concerned with Design of plastic parts & Molds 5 Skill Builder - for Problems & Solutions 4 Skill Builder - for M/C Optimizing 3 Practical Injection Molding - Expert Series 2 Practical Injection Molding - M/c & Process Optimizing.