Transcription

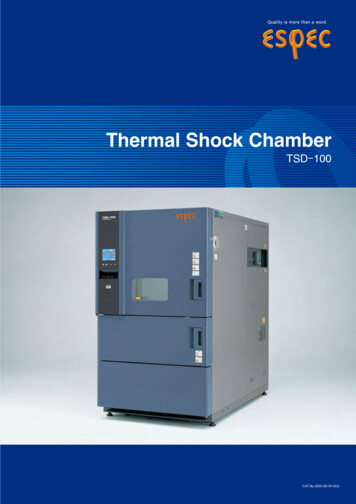

Thermal Shock ChamberTSD 100CAT.No.E05139-W1203

Large-capacity two-zone chambercapable of exposing specimens toa uniform thermal stress.Two-zone thermal shock chamber ideally suited forJapanese and international test standards such as MIL, IEC or JASO .With its 100L test area, and its outstanding thermal uniformity characteristics,the TSD Thermal Shock Chamber from ESPEC can test specimens under a uniform thermalstress, and is ideally suitable for a wide range of applications,from research and development to inspection or production.1

*The viewing window, paperless recorder and additional overheat protector are optional.2

PerformanceMeeting the high performance required by today's test standardsSpecimen temperature recovery (example)(based on MIL-STD-883 condition C)Test conditionsTemperature uniformity measurement methodHigh temp. exposure: 155 for 30 min. Thermocouples were embedded in 10 ICsLow temp. exposure: 68 for 30 min.placed on two levels in each of the cornersSpecimens: ICs, 10 kgand in the center of a specimen basket.(Specimens with embedded thermocoupleswere placed beneath other ICs.)Temperature ( )200Temperature recovery timeshortened with the two-zone systemDuring testing of 10 kg of plastic moldedICs, at temperature settings of 150 and 65 , the specimen temperaturerecovers in less than 15 minutes.within 15 min.Meets International standards150Desig ned to comply with majorenvironmental test standards like MIL,IEC, JASO, JEITA. (p.9, 10)100500 50 100200within 15 min.210220230240250260270280290300310 320Time (min.)Temperature uniformity performance (example)Test conditionsTemperature uniformity measurement methodHigh temp. exposure: 150 for 30 min.Thermocouples were attached to the surfaceLow temp. exposure: 65 for 30 min.of 10 ICs placed on two levels in each ofSpecimens: ICs ( 10)the corners and in the center of a specimenbasket.200 0.8 Temperature ( )15010050 100200 0.5 210220230240250260270280290300310Time (min.)Test time comparison (example)Test conditionsMeasurementsHigh temp. exposure: 150 , 15 min. after recovery Test time reductions of approximatelyLow temp. exposure: 65 , 15 min. after recovery15 minutes per cycle compared to otherSpecimens: ICs, 10kgESPEC models. For 3,000 cycles testingControl points: Upstream of sensor positions this cuts previous test times from4.5 months to approximately 1 month.TSD-10020050 min.Temperature ( )100500 50 10030200Upstream sensor position6090120150180210240270300330360Time (min.)ESPEC damper-system thermal shock chamber65 min.150100500 50 10030Upstream sensor position60Reduced test time by meansof test area transferTe mp e r at u r e ex p o s u r e i s q u ick lychanged by moving the test area up anddown between the high temperature andlow temperature chambers, thus reducingthe ti me t a ken to reach the presettemperature as well as total test duration.Specimen TemperatureTrigger (STT) function150Temperature ( )T he chamber feat u res outst andingtemperature uniformity characteristics,30% b et t e r t h a n pr ev iou s ESPECmodels during temperature recovery; italso includes features to ensure uniformair flow into the test area. Specimensare thus subject to a more unifor mthermal stress, with reduced variationsin test results between specimens.0 503Improved temperatureuniformity performance90120150180210240270300330360Time (min.)The TSD-100 chamber now includes aSTT function. It monitors the specimentemperature using two sensors attachedto the specimen and starts to count theexposure time, or proceeds to the nextstep once the specimen temperaturereaches the preset temperature. Thiseliminates the need for pretesting,reducing the overall test time andensures an accurate specimen temperature attainment. The specimen andtest area temperatures can be recordedby connecting a temperature recorder.

UtilityBoast of a 100L capacityFeaturing a 100L test area capacity, thechamber dramatically increases theprocessing capabilities and even allowsto test A4-size printed circuit boardslaid flat at once.Smooth specimen transferThe “Soft-move mode” is used to reducevibration shocks when specimens aremovi ng bet ween the high and lowtemperature chambers.Test area anti-drop mechanismto protect specimensA braking system fitted to the drivemechanism prevents specimens fromfalling into the test area when thechamber stops operation.Test areas top: high temperature chamberbottom: low temperature chamber()Safe specimen handling thanksto ambient temperature recoveryA n a mbient temperat u re recover yfeature is included to draw in exteriorair after testing is complete and returnto a mbient temperat u re, allow i ngspecimens to be removed safely.Easy wiring accessA cable port is provided on the rightside to allow easy wiring of specimen formeasu rement du r ing high and lowtemperature cycle tests. (Optional cableport can also be provided on the left side.)Viewing window (option)An optional viewing window can beadded to check specimens and wiringduring testing. The viewing windowincludes an interior lighting.Specimen temperature measurementspecimen temperature input standard equipment: 2 locationsoptional: 3 locations()Comprehensive safety systemA dual safety system automaticallystops the test area drive mechanism ifthe door is left open, and automaticallylocks the door when the test area is inmotion.Viewing window (option)4

Control operationColor LCD interactivetouch-screen systemOperation and settings simplified by theuse of a touch-screen LCD display(instructions displayed on-screen). At-aglance confirmation of test patterns, testarea temperatures, temperature cycles,upstream/ downstream control, andtrend graph displays.Door-mounted instrumentationInstrumentation including the touchscreen controller is incorporated intothe door. It reduces the overall footprintand frees up both sides of the chamberfor easy access.InstrumentationSettingInteractive key input by touch panelDisplayTFT color LCD (6.5 inches)Test area: exposure temp.Temperature Hot chamber: pre-heating temp.Cold chamber: pre-cooling temp.controlCold chamber: defrosting temp.functionPID controlPresetHigh temperature: 60 to 205 temperatureLow temperature: 77 to 0 rangeSetting resolution 1 InputThermocouple type T(Copper/Copper-Nickel)Setting andPreset time: 0 min. to 99 hours and 59 min.indication ranges Preset cycle: 1 to 9,999 cycles5TestpatternsRAM mode: 40 patterns (registration possible)ROM mode: 20 standard test patterns (registered)AccessoryfunctionTimer presetTest continuity selectionOverheat/ overcool protectionUpstream/ downstream sensorselectionSTTTemperature attainment controlQuick exposure controlPower failure/ recovery selectionAutomatic defrostTemperature recovery time settingProgram memoryAutomatic power shut-offProgrammed time displayTest suspensionTest completion mode selectionTrend graphAlarm history displaySensor calibrationRS-485 communication

Control operationINSTRUMENTATION PANEL Testdetail monitorTest details are displayed while thetest is in progress. TestsettingDisplays the conditions to definefor the test. ServiceguideIf an inspection item is selected,a descr iption of the requiredmaintenance steps appears. Thisis useful before proceeding withtests or to assist during periodicmaintenance. Productsensor settingsPossibility to enable or disablethe specimen temperature sensorused for the STT function. Alarm ErrorDisplayed when a problem occurs,along with a buzzer. DetailedSame procedure for additionaloptional specimen temperaturesensors.descriptionDetails on the failure occured,troubleshooting and alarm resetprocedure.descriptionDetails the regular inspectionitems.6

Eco-friendlyA whole range of environmentally-friendly featuresReduced power consumptionReducing power consumption is animportant issue for our customers. TheTSD-100 employs number of measures,such as the use of electronic expansionvalves to regulate the refrigerationcapacity control, and thus reduce overallpower consumption by 30% (comparedto previous ESPEC models).Material labeling for easy recyclingBuilt-in paperless recorder (option)*Rear side, on the rightPlastic molded components are labeledand easily detachable to make recyclingeasier duning future disposal of theequipment.Paperless recorder (option)2 t y pes of paperless recorders areavailable (built-in or portable) to recordtemperatures from various sources,such as test area temperatures.Recording is possible on Compact FlashCard or via USB port.Portable paperless recorder (option)7

DIMENSIONS100(3.93)60(2.36)1965 (77.36)100(3.93)Unit: mm (inch)1100 (43.31)900 (35.43)1965 (77.36)30 125(1.18) (4.92)100(3.93)1020 (40.16)820 (32.28)345 (13.58)345 (13.58)100(3.93)707.5 (27.85)75 100(2.95)(3.93)1885 (74.21)752.5 (29.63)100 50(3.93)(1.96)100(3.93)710 (27.95)250 (9.84) 410 (16.14)8

TEST STANDARD (TSD-100 COMPATIBILITY)Temperature settingTest standardIEC 60749 25(JESD22 A104 D)High temp. ( )Low temp. ( )1/ 5/ 10/ 15 min.Not specified10% of soak time3 hours2 hours1 hour30 min.10 min.3 hours if not specified inproduct specifications510% of soak time3 hours2 hours1 hour30 min.10 min.3 hours if not specified inproduct specifications5・10B 125( 15, 0) 55( 0, 10) Specimen 5 to 14 min.C 150( 15, 0) 65( 0, 10) Specimen 5 to 29 min.H 150( 15, 0) 55( 0, 10) Specimen 5 to 14 min.M 150( 15, 0) 40( 0, 10) Specimen 5 to 15 min.IEC 60068 2 14 Na( JIS C 60068 2 14 NaDIN EN 60068 2 14 NaBS EN 60068 2 14 Na)IEC 61747 5 Na(EIAJ ED 2531A Na) 100 2 95 2 90 2 85 2 80 2 75 2 70 2 65 2 60 2 50 3 45 3 40 3 35 3 30 3 25 3 20 3 15 3 10 3 5 3 0 3A9Number of cycles 85( 10, 0) 55( 0, 10) Specimen 5 to 14 min. 65 3 55 3 40 3 25 3 5 3MIL STD 883Method 1010.8Soak timeA 200 2 175 2 155 2 125 2 100 2 85 2 70 2MIL STD 202Method 107GRecovery time 85( 3, 0) 55( 0, 3)B 125( 3, 0) 65( 0, 3)F 150( 3, 0) 65( 0, 5)A 85( 10, 0) 55( 0, 10)B 125( 15, 0) 55( 0, 10)C 150( 15, 0) 65( 0, 10)D 200( 15, 0) 65( 0, 10)F 175( 10, 0) 65( 0, 10)Upstreamof specimenwithin 5 min.Specimenless than15 min.28g and below:28 to 136g:136g to 1.36kg:1.36 to 13.6kg:13.6 to 136kg:More than 136kg:15 min.30 min.1 hour2 hours4 hours8 hours10 min. or longerafter transition start52550100At least 10

TEST STANDARD (TSD-100 COMPATIBILITY)Temperature settingTest standardIPC TM 650 2.6.6High temp. ( )A 125( 3, 0) 65( 0, 5)B 85( 3, 0) 55( 0, 5)SAE J1879JASO D001Low temp. ( ) 150Type 1 85Type 2 75Type 3 120Type 4Type 1 55 40 85EIAJ ED 4702EIAJ ED 7407 125( 3) 65( 3)B 100( 3) 65( 3)C 100( 3) 55( 3)Mounted printed circuit board Mounted printed circuit boardmax. operating temp.min. operating temp.A 125 5 25 5B 125 5 40 5C 80 5 30 5D̶30 min.5Specimen less than15 min.10 min. or longerafter transition start1000Air 5 min.0.2kg and below:0.2 to 0.8kg:0.8 to 1.5kg:More than 1.5kg:Air 5 min.Within 5 min. after solder joint temp.reaches 2 of preset temp. Or,0.2kg and below: 0.5 hours0.2 to 0.8kg: 1 hour0.8 to 1.5kg: 1.5 hoursMore than 1.5kg: 2 hourspreset temp20015g and below:15 to 150g:150 to 1,500g:More than 1,500g:10Depends on parties involvedADNumber of cycles 40Max. storage temp. Min. storage temp.EIAJ ED 4701Soak timeDepends on parties involvedJASO D902Type 2Recovery timeAir 5 min. or 10%of soak time,whichever is longer1 hour ( 15 min.)2 hours ( 15 min.)3 hours ( 15 min.)4 hours ( 15 min.)at least 10 min.at least 30 min.at least 60 min.individually specified6Air 5 min. or 10%of soak time,whichever is longer30 min.5 cycles unlessotherwisespecified̶7 min.after specimentemperature attainment̶Max. operating temp. Min. operating temp.10

SPECIFICATIONSModelTSD-100System2-zone transition by vertical transfer of specimensTest areaHigh temp. exposure range 60 to 200 ( 140 to 392 )Low temp. exposure range 65 to 0 ( 85 to 32 )Performance *1Temp. fluctuationHotchamberPre-heat upper limitColdchamberPre-cool lower limitTemp.recovery(2-zone) 1.0 205 Temp. heat up time *2Ambient temp. to 200 within 90 min. 77 Temp. pull down time *2Ambient temp. to 77 within 90 min.2-zone・High temp. exposure:・Low temp. exposure:・Power supply voltage:・Sensor position:・Specimen:Recovery conditionsTemp. recovery timeAmbientrecoverySpecimen IC temp. within 15 min.・High temp. exposure:・Ambient temp.:・Power supply voltage:・Specimen:Recovery conditionsAmbient temp. recovery timeCold-rolled rust-proofed steel plateTest area material18-8 Cr-Ni Stainless steel plateConstructionHeaterNichrome strip wire heaterSystemMechanical cascade refrigeration system (water-cooled condenser)RefrigeratorScroll-type compressorExpansion mechanismElectronic expansion valveRefrigerantR404A, R23CoolerPlate fin cooler and cold accumulatorAir circulatorSirocco fanElevating unitPower slider (250W)Cable port ID φ 100mm ( 1) on right side (left side available as option),specimen power supply control terminal, time signal ( 2), integrating hour meter,specimen temperature input terminal ( 2)FittingsInside dimensionsW710 H345 D410 mm (W27.95 H13.58 D16.14 inch)Test area capacity100 LTest area load resistance *430 kgOutside dimensions *5W1100 H1885 D1965 mm (W43.31 H74.21 D77.36 inch)WeightApprox. 1100 kgAllowable ambient conditions 5 to 35 ( 41 to 95 )Utility requirements200V AC 3φ 50/60HzPower supply64 A208V AC 3φ 60Hz *662 A220V AC 3φ 60Hz58 A380V AC 3φ 50Hz34 A400/415V AC 3φ 50Hz *732 ACooling water supply pressure *8Cooling water supply rate *90.2 to 0.5 Mpa (2 to 5 kg/ cm2G)2050L/ h (at reference water temp. 25 ), 3400L/ h (at reference water temp. 32 )Piping connection sizeOperating cooling water temp. rangeNoise level *10Exhaust heat quantityExhaust rate*1 The performance values are based on IEC 60068-3-5:2001,JTM K07:2007, under the conditions of a 23 ambienttemperature, cooling water temperature 25 , rated voltage,and no specimen inside the test area.*2 When each chamber is operated independently*3 Setting: High temp. exposure 155 , low temp. exposure 68 *4 When using the test area floor or heavy-duty shelves (option)11 150 to max. 55 23 rated voltagePlastic molded ICs, 10 kgWithin 90 min.Exterior materialRefrigerationunit 150 *3 30 min. 65 *3 30 min.rated voltagedownstreamPlastic molded ICs, 10kgCarbon steel pipe, ID 32 mm 5 to 38 ( 41 to 100 )Max. 65 dB12600 kJ/h (3000 kcal/h)250 m3/h*5 Excluding protrusions*6 This model complies with the requirements of the National Electric Code (NFPA 70) forthe United States of America (NEC spec.)*7 This model complies with the requirements of the European Community Directives (CE spec.)*8 A pressure regulator valve is required if the pressure exceeds 0.5MPa (5kg/cm2G)*9 Rate depends on the cleanliness of the heat exchanger*10 Measurements are to be taken in an anechoic room at a height of 1.2m from the floor, anda distance of 1m from the front panel (ISO 1996-1: 2003.A-weighted sound pressure level)

SAFETY DEVICES ACCESSORIESLeakage breaker (200, 220, 380V AC)Circuit breaker (208, 400/415V AC)Electrical compartment door switchHot chamber overheat protection switchCold chamber overheat protection switchHot chamber overheat protectors(Built into temperature controller)Cold chamber overheat/ overcool protectors (Built into temperature controller) Test area overheat/ overcool protectors(Built into temperature controller)Test area overheat/ overcool protectorsCircuit breakerRefrigerator high/ low pressure switchCompressor built-in protectorTemperature switch for compressorWater suspension relayTemperature switch for air circulatorAir circulator thermal relayMotor inverterMotor reserve prevention relayHot chamber door switchCold chamber door switchDoor lock mechanismsCartridge fuseSpecimen power supply control terminalCooling tower interlock terminal Specimen basket(18-8 Cr-Ni stainless steel: 5 mesh metal basket)W700 H40 D410 mm/ load capacity 5kg2Shelf brackets2 setsCartridge fuse (1A, 7A, 10A, 15A)4Cable port rubber plug2Perforated cable port cap1Wire fisher (specimen wiring tool)1Specimen temperature measuring thermocouple, JIS T2Specimen temperature input connector23-pole socket (208V AC spec. only)3Nipple R1 1/4 in. (32 mm)1Strainer R1 1/4 in. (32 mm)1Strainer element R1 1/4 in. (32 mm)1Operation manual1Safety precautions Donot use explosive substances, flammable substances, or substances that containthose substances as a specimen under any circumstances.Danger: Risk of explosion and fire Donot put corrosive substances inside the test area. If corrosive substances aregenerated from the specimen, the life of the product's corrosion resistance willdecrease dramatically due, in particular, to corrosion of stainless steel, resin, andsilicone. Donot use living organisms or items that exceed the allowable heat load as aspecimen. Alwaysread the operation manual before using the Product.12

OPTIONSPaperless recorderRecords temperature of each section suchas the temperature inside the chamber.Select either built-in or portable type.〈Built-in type〉Number of inputs (Initial setting):PL1S: 1 (5 more channels can be turned ON)Data saving cycle: 1 secPL3S: 3 (3 more channels can be turned ON)Data saving cycle: 1 secPL3L: 3 (3 more channels can be turned ON)Data saving cycle: 5 secPL5S: 5 (1 more channels can be turned ON)Data saving cycle: 1 secPL5L: 5 (1 more channels can be turned ON)Data saving cycle: 5 secPL6S: 6 Data saving cycle: 1 secPL6L: 6 Data saving cycle: 5 secTemperature range: 100 to 220 External memory media:CF memory card (256MB)USB portLanguage support: ENG, JPNTemperature recorder (digital)Total cycle counter 100 to 220 /100 mm・RK-61: 1 pen・RK-63: 3 pens・RK-64: 6 dotsIndicates cycle counts.Display range: 1-99999999(with resetting function)Auxiliary cooling injector (LCO2)Recorder wiringPreparation of a power cable, temperature sensor, and a grounding wirefor a dd it ional i nst allat ion i n t hefuture.Recorder terminalUsed to output the temperature withintest area, hot chamber, cold chamber.Us e d t o r e d u c e t h e t e m p e r a t u r erecover y time of low temperat ureexposure by injecting liquefied carbondioxide at beginning of exposure.Auxiliary cooling injector (LN2)Us e d t o r e d u c e t h e t e m p e r a t u r erecover y time of low temperat uree x p o s u r e by i nje c t i n g l iq u ef ie dnitrogen at beginning of exposure.Viewing windowBuilt-in type〈Portable type〉Number of inputs (Initial setting):PPL1S: 1 (5 more channels can be turned ON)Data saving cycle: 1 secPPL3S: 3 (3 more channels can be turned ON)Data saving cycle: 1 secPPL3L: 3 (3 more channels can be turned ON)Data saving cycle: 5 secPPL5S: 5 (1 more channels can be turned ON)Data saving cycle: 1 secPPL5L: 5 (1 more channels can be turned ON)Data saving cycle: 5 secPPL6S: 6 Data saving cycle: 1 secPPL6L: 6 Data saving cycle: 5 secTemperature range: 100 to 220 External memory media:CF memory card (256MB)USB portLanguage support: ENG, JPN13Portable typeThermocoupleAttached to specimens to measurespecimen temperature.・Thermocouple type T without ball(Copper/ Copper-Nickel)*Same as accessory itemsSTT 3-point expansion3 thermocouples provided to measurethe specimens' temperature via theSTT function (2 inputs are equippedas standard.)Exposure signal outputA signal is output via a contact switchwhen test area temperature is withinthe user-selected range. This signalcan be used to cont rol per ipheralinstruments, like applying a voltage tospecimens only du r ing high temperature exposure, or monitoring testoperation from a remote point.Used for observation of the specimensinside the chamber.Dimensions: W190 H340 mmChamber lamp: Halogen lamp ( 1)

OPTIONSAdditional cable portAdditional overheat protectorInterfaceProvided in addition to the standardcable port. (right side)Location: Left side of the main unitInternal diameter: 100 mmAdditional preventive measures can betaken for excessive temperature rise inthe chamber, in addition to the standardequipped double overheat protector.・ RS-232C・ GPIB* Select one, instead of standard RS-485.Communication cablesCable port rubber plugExternal alarm terminalPrevents air leakage from the cableport.If the safety device of the chamber isactivated, the external alarm terminalwill notify :t to a remote point.・ RS-485・ RS-232C・ GPIB5m/ 10m/ 30m1.5m/ 3m/ 6m2m/ 4mPower cableHeavy-duty shelf・5 m・ 10 mUsed to hold heavy specimen exceeding the load capacity of the standardspecimen basket.Load capacity: 15 kg* Not applicable for optional 208, 380 and400/415V AC power supply specification.* Equally dist ributed load, not included shelfbrackets and specimen baskets.Specimen basket/ shelf bracketEquivalent to standard accessory.Material: Stainless steel (5 mesh)Emergency stop pushbuttonStops the chamber immediately.Anchoring fixturesUsed to bolt the chamber to the floor.CastersInstalled for mobility.6 casters: 6levelling-feet: 4Chamber dew trayPrevents water leaks from the chamberonto the floor.* The use of casters is recommended to facilitateoperation. Some photographs presented in this catalog contain Japanese display.14

http://www.espec.co.jp/englishHead Office3-5-6, Tenjinbashi, Kita-ku, Osaka 530-8550, JapanTel : 81-6-6358-4741Fax : 81-6-6358-5500ESPEC NORTH AMERICA, INC.Tel : 1-616-896-6100 Fax : 1-616-896-6150ESPEC EUROPE GmbHTel : 49-89-1893-9630 Fax : 49-89-1893-96379ESPEC (CHINA) LIMITEDTel : 852-2620-0830Fax : 852-2620-0788ESPEC ENVIRONMENTAL EQUIPMENT (SHANGHAI) CO., LTD.Head OfficeTel : 86-21-51036677 Fax : 86-21-63372237BEIJING BranchTel : 86-10-64627025 Fax : 86-10-64627036TIANJIN BranchTel : 86-22-26210366 Fax : 86-22-26282186GUANGZHOU BranchTel : 86-20-83317826 Fax : 86-20-83317825SHENZHEN BranchTel : 86-755-83674422 Fax : 86-755-83674228SUZHOU BranchTel : 86-512-68028890 Fax : 86-512-68028860ESPEC TEST TECHNOLOGY (SHANGHAI) CO., LTD.Tel : 86-21-68798008 Fax : 86-21-68798088ESPEC SOUTH EAST ASIA SDN.BHD.Tel : 60-3-8945-1377 Fax : 60-3-8945-1287Quality Management System Assessedand RegisteredESPEC CORP. has been assessed by andregistered in the Quality Management Systembased on the International Standard ISO9001:2008 (JIS Q 9001:2008) through theJapanese Standards Association (JSA).*Registration : ESPEC CORP.(Overseas subsidiaries not included)TW3E24C03 (The contents of this catalog is as of March, 2012.)Environmental Management System Assessedand RegisteredESPEC CORP. Specifications are subject to change without notice due to design improvements. Corporate names and trade names mentioned in this catalog are trademarks or registered trademarks.

the TSD Thermal Shock Chamber from ESPEC can test specimens under a uniform thermal stress, and is ideally suitable for a wide range of applications, from research and development to inspection or production. 1 TSD_e_120328.indd 1 12.3.28 10:22:33