Transcription

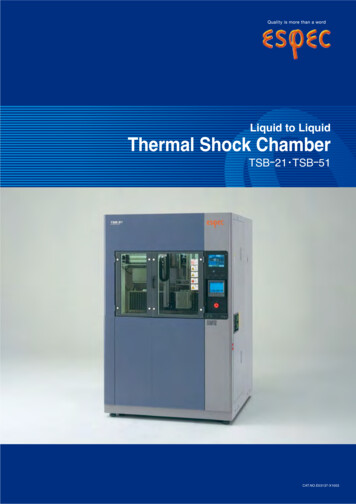

Liquid to LiquidThermal Shock ChamberTSB 21・TSB 51CAT.NO.E03137-X1003

Key technology for ensuring reliabilitySupports the current trend toward higher stress.High accuracy is increasingly demanded in the pursuit of reliability in the field of electronics.“Liquid-to-liquid” type thermal shock testing is now attracting attentionfor its ability to impose higher thermal stress on specimens than“air-to-air” type testing, and to deliver test results quickly.ESPEC has successfully developed next-generationliquid-to-liquid thermal shock chambers that satisfy the demandfor environmental conservation and lower running costs from brine andpower consumption, which have traditionally been regarded as stumbling blocks withliquid-to-liquid thermal shock chambers.ESPEC takes great pride in offering this cutting-edge chamber as a key technologyin ensuring higher reliability.TSB 511* The paperless recorder, external alarm terminal emergency stop switch and casters are optional items.

UtilityA number of mechanisms fordrastically reducing brineconsumptionTo reduce br i ne consu mpt ion, t heairtightness of the test area has beenenhanced to prevent vapor leakage andbrine evaporation. Numerous mechanisms have also been adopted, includinga water separation filter for removingbrine from water for the purpose ofbrine recycling. As a result, these newchamber models have reduced brineconsumption by approximately 65 %compared to the preceding model (TSB-5).Both single-liquid anddouble-liquid brine applicableEither single-liquid brine or doubleliquid brine can be selected simply byswitching the valve.Test Area Brine Consumption (In 1 Cycle)4(g)3.9gTwo models available to suitthe specimen size and weightTwo different models are available:TSB-21 can hold specimens weighingup to 1.0 kg, while TSB-51 can holdspecimens weighing up to 2.0 kg.Capable of handling a wide variety ofelectronic parts, from ICs to printedcircuit boards.Smooth transfer ofspecimens realized3Former modelTSB-5Reduced by65%ConditionsPower: 200V AC 60HzAmbient temp.: 23 H 155 : 5 minutesL 70 : 5 minutes100 cyclesSpecimen: TSB-5 1.5kgTSB-51 2.0kgBrine: Galden (DO2-TS)211.4gTSB-510An air cylinder system that suppressesvibration of the specimens and a newspecimen loading system that preventsunnecessary stress to the specimensduring transfers between the hot bathand the cold bath.Recorder terminals asthe standard deviceThermal shock chamber has one pieceof the recorder terminal that outputs thetemperature of the specimens.*A d d i t i o n a l l y, t h e t h e r m a l s h o c kchamber has a specimen power supplycontrol terminal and a time signal.The external alarm terminal is optional.*Up to 5 pieces of the recorder terminals canbe added as an option.2

Utility Comparison of power consumptionConditions : 20 cyclesH : 155 L : 70 Specimen : TSB-51TSB-5Energy savings achievedDramatic energy savings have beenachieved through the adoption of a newr ef r ige r a t io n c i r c u it , w it h p owe rconsumption slashed by as much as 52%(compared to former ESPEC models).5 min.5 min.2.0 kg1.5 kgReduced by 52.4%TSB-51Former model (TSB-5)10.0*Above values are references.Installation environment improvedthrough reduced operation noise20.030.040.0Power consumption (kWh)The operation noise level of the chamber has been reduced to as low as 65 dB(A-characteristic) by providing soundproofing panels for the noise-emittingmachine compartment, including therefrigerator.Paperless recording (optional)The paperless recorder makes it easyrecord the temperatures of differentcomponents, such as the chamber temperature, on a memory card (CompactFlash).Remote control from your PCPaperless recorder (optional)3Please contact us for details on using aPC to monitor and remotely control theequipment.

Control operationVisibility and ease of use improved through interactive inputusing a touch-screen system and color LCD screenUses a color LCD interactive touchpanel system employed throughoutthe Thermal Shock Chamber SeriesA color LCD panel design allows settings to be made simply by touching thescreen in accordance with the display.The test pattern, test area temperature,number of temperature cycles, trendgraph display, etc., are all displayed onthe screen.SettingsystemInteractive input system usinga touch panelDisplayColor TFT LCD panel (6.5 inch) Test area exposure temperature Hot bath preheating temperature Cold bath precooling temperatureTemperature Liquid temperature recovery forcontrolhot bath Liquid temperature recovery forcold bathTemperature- High-temperature side: 60 to 200 setting range Low-temperature side: 75 to 0 Setting resolution 1 InputThermocouple T (JIS C 1602)ControlsystemPID control Detailed test monitoring Selection of operating modes Test pattern editing Error descriptionTime-setting1 sec. to 99 min. 59 sec.rangeCycle-setting1 to 9999 cyclesrangeProgramsRAM mode: Max. 40 patterns (writable)ROM mode: 10 standard test patterns (registered)Auxiliaryfunctions Timer preset Test continuity selection Overheat/overcool protection Stable time control Power-saving operation Power-failure/ recovery operation selection Liquid temperature recovery Recycling operation Automatic preheating/ precooling setting Time signal Program memory Automatic power shutoff Programmed time display Test starting point selection Test halt preset Test completion mode selection Trend graph Alarm history display Sensor calibration RS-485 communication4

SPECIFICATIONSModelTSB 21TSB 51Two-liquid bath system with specimen basket transferBrineSingle-liquid or double-liquid fluorine deactivated brineUtility requirementSystemPower supply(within 10% of the rated voltage)Maximum load current200V AC, 3φ, 3W, 50/60Hz25A43AOperating temperature0 to 40 ( 32 to 104 )Air-source pneumatic pressure0.4 to 0.7MPa (4 to 7kgf/ cm2)Air-source piping connection sizeφ8mmRequired air-flow quantity15L/ min. (ANR)〈3.6L/ cycle (ANR)〉Performance *1Temp. rangeHot bath 70 to 200 ( 158 to 392 )Temp. fluctuation *2 2 ( 3.6 )Temp. heat-up rate *3Ambient temp. to 150 ( 302 ): within 90 min.Temp. pull-down rate *3 150 to 60 ( 302 to 140 ) Within 60 min. 150 to 60 ( 302 to 140 ) Within 100 min.Temp. rangeCold bath 65 to 0 ( 85 to 32 )Temp. fluctuation *2Temp. heat-up rate *3 2 ( 3.6 ) 65 to 0 ( 85 to 32 ) Within 60 min. 65 to 0 ( 85 to 32 ) Within 65 min.Test performanceTemp. pull-down rate *3 Ambient temp. to 65 ( 85 ) Within 120 min. Ambient temp. to 65 ( 85 ) Within 90 min.Hot bathLiquid temp. 150 100 ( 302 180 ) (Galden DO2-TS)Cold bath Liquid temp. 65 100 ( 85 180 ) (Galden DO2-TS)Exposure timeHigh and low temperatures 5 min. eachNumber of cyclesSpecimenSpecimen transfer time15 cyclesPlastic molded ICs 1.0kgNoise level *465 dB or lessConstructionExterior materialStainless steel plate (18-8 Cr-Ni)InsulationGlass wool, foamed polyurethaneHeaterSheathed heaterCoolerCooling-pipe coilAgitatorRefrigerator unit2 units (one each for the hot and cold baths)Refrigeration system: Mechanical cascade refrigeration system (Air-cooled condenser)CompressorRotary compressorRefrigerantR508A, R404ADrive unit for specimen transferCondensation circuitComponentsSpecimen basket dimensions (mm)Test area loading capacitySpecimen basket load capacity(evenly distributed load)Inside bath dimensions (W H D mm)Outside dimensions (W H D mm) *5Chamber (overall) weight *65Painted steelInternal tankFluid recovery circuit*1*2*3*4*5*6Plastic molded ICs 2.0kgWithin 10 sec. (Time of transfer between hot and cold baths)Horizontal and vertical air drive systemMethod: Condensed recovery through refrigerator coolingRefrigerator: Cold bath cooling refrigeratorMethod: Condensation by refrigeratorRefrigerator: Cold bath cooling refrigeratorLiquid-level indicator, chamber lamp, specimen transfer-area door, adjuster,specimen power-supply control terminal, time signal, recorder terminal, integrating hour meterW120 H150 D120 (W4.7 H5.9 D4.7 in.)W150 H150 D200 (W5.9 H5.9 D7.8 in.)Approx. 2.1 LApprox. 4.5 L1.0 kg2.0 kg260 350 440 (10.2 13.8 17.3 in.) (Approx. 40 L) 290 350 520 (11.4 13.7 20.4 in.) (Approx. 55 L)1140 1785 1240 (44.9 70.3 48.8 in.)1200 1785 1320 (47.2 70.3 52 in.)Approx. 650 kgApprox. 790 kgPerformance at an ambient temperature of 23 Performance indications conforming to JTM K01-1998Performance when each bath is operated individuallyValue measured in an anechoic room at 1m from the chamber front and at a height of 1.2 m above the floor (A-characteristic: Compliant with JIS-Z-8731)Protrusions from the machine sides excluded. Leveller height not included.Weight of the liquid not included

TEST STANDARDS (satisfied by all models in the TSB Series)Test StandardMIL-STD-883E(Method No. 1011.9)MIL-STD-202G(Method No. 107G)JIS C 0025TestConditionExposure TemperatureExposure TimeHighTemp.AmbientTemp.LowTemp.A 10 100 2—0 2 10B 10 125 0— 55 0 10C 10 150 0— 65 0 10A 10 100 2—B 12 100—C 10 150 0—— 100 —High/ LowTemp.—Over 2 min.,up to 5 min.—— 2 10 Varies by specimenweightLess than 1.4 g:0.5 min.1.4 to 14 g:02 min. 65 10 Over 14 to 140 g:5 min.0 0 TemperatureTestNumber ofRecoveryStartingTestCyclesAmbientTimePointTemp.5 min. to20 min.Temperatureof thespecimenunder worstcaseconditions,recoveredwithin 5 min.Min.15 cyclesLow temp.orhigh temp.—5 cycles15 cycles25 cyclesLow temp.—————10 cycles unlessotherwiseLow temp.specified6

SAFETY DEVICES Leakage breakerCircuit breaker for wiringMotor reverse prevention relayCompressor thermal relayCompressor temperature switchElectric parts compartment door switchSpecimen transfer area door switchRecycling circuit fan temperature switchRefrigerator high-pressure switchHot bath agitator temperature switchCold bath agitator temperature switchAir-pressure switchHot bath boil-dry protectorCold bath boil-dry protectorOverheat protector for hot bathOvercool protector for cold bathOverheat/ overcool protector for the hot bath(built into the controller)Overheat/ overcool protector for the cold bath(built into the controller)Drive unit transfer time (built into the controller)Test area overheat/overcool protector(built into the controller)Specimen power supply control terminalFuseLow-liquid-level alarmLocking mechanism for specimen transfer area doorDANGERACCESSORIES Specimen basket(18-8 Cr-Ni stainless steel 5-mesh wire net)Specimen basket coverCartridge fuse (5 A)Fluid drain hose Inner dia.: 12 mmInner dia.: 8 mmFunnel for fluid supplyFluid injection pipe (with rubber cork)Connector (Terminal for temperature recorder)Shutter open attachmentWater absorption matThermocoupleUser’s manual Do not use specimens that are explosive or inflammable, or thatcontain such substances. Doing so may lead to fire or explosion. Do not use as specimens substances or creatures that may emitinflammable or corrosive gases, or substances that may exceedpermissible heating values. Correctly clean the brine in use. Use of the incorrect liquid willsignificantly reduce the service life of the chamber and may producenoxious decomposition products. Before using a brine, consult withthe brine manufacturer. Be sure to read the user’s manual before operations.CAUTION11 set1211112111 copy7

OPTIONSPaperless recorderThermocoupleBuilt-in air compressorRecords temperature of each sectionsuch as the temperature inside thechamber.Number of inputs:PL1S: 1 (5 more channels can be turned ON)Data saving cycle: 1 secPL3S: 3 (3 more channels can be turned ON)Data saving cycle: 1 secPL3L: 3 (3 more channels can be turned ON)Data saving cycle: 5 secTemperature range: 100 to 220 External recording media :CF memory card (128 MB)Language support: ENG, JPNUsed to measure specimen temperature, etc.・T JIS C 1602 with ball attachedEquipped when there is no air supplysource.Specimen basketTemperature recorder terminalTerminal for specimen temperatureoutput.・Five terminals(six in total, incl. one for standard supply)Equivalent to standard accessory.・Material Stainless steel (5-mesh)CasterExternal alarm terminalInstalled for mobility.・Free wheels: 4If the safety device of the chamberactivates, the external alarm terminalwill relay the alarm to distant place.Fixture for securing the bodyUsed to bolt the chamber to the floor.Power cableFor supplies electricity to the chamber.・5, 10mTemperature recorder 100 to 220 / 100 mmRK-61: 1-penRK-63: 3-pensRK-64: 6-dotsCommunication functionEmergency stop switchStops the chamber immediately.Connected to a PC directly to controlthe chamber (standard equipment:RS-485).・GPIB・RS-232CFor future installation of a recorderIf the user elects to prepare a customtemperature recorder or plans to addone at a later date, the necessarypower cable, temperature sensor,and grounding wire are available asoptions. Some photographs listed in this catalog contain Japanese display.8

http://www.espec.co.jp/englishHead Office3-5-6, Tenjinbashi, Kita-ku, Osaka 530-8550, JapanTel : 81-6-6358-4741Fax : 81-6-6358-5500ESPEC NORTH AMERICA, INC.Tel : 1-616-896-6100 Fax : 1-616-896-6150ESPEC EUROPE GmbHTel : 49-89-1893-9630 Fax : 49-89-1893-96379ESPEC ENVIRONMENTAL EQUIPMENT (SHANGHAI) CO., LTD.Head OfficeTel : 86-21-51036677 Fax : 86-21-63372237BEIJING BranchTel : 86-10-64627025 Fax : 86-10-64627036TIANJIN BranchTel : 86-22-26210366 Fax : 86-22-26282186GUANGZHOU BranchTel : 86-20-83317826 Fax : 86-20-83317825SHENZHEN BranchTel : 86-755-83674422 Fax : 86-755-83674228SUZHOU BranchTel : 86-512-68028890 Fax : 86-512-68028860ESPEC TEST TECHNOLOGY (SHANGHAI) CO., LTD.Tel : 86-21-68798008 Fax : 86-21-68798088ESPEC (MALAYSIA) SDN. BHD.Tel : 60-3-8945-1377 Fax : 60-3-8945-1287ESPEC CORP.ESPEC CORP. has been assessed by andregistered in the Quality Management Systembased on the International Standard ISO9001:2008 (JIS Q 9001:2008) through theJapanese Standards Association (JSA).W3E22C02 (The contents of this catalog is as of March, 2010.) Specifications are subject to change without notice due to design improvements. Corporate names and trade names mentioned in this catalog are trademarks or registered trademarks.

Thermal shock chamber has one piece of the recorder terminal that outputs the temperature of the specimens.* Additionally, the thermal shock chamber has a specimen power supply control terminal and a time signal. *Up to 5 pieces of the recorder terminals can be added as an option. Test Area 0 1 (g) 2 3 4 Reduced by 65% TSB-51 3.9g 1.4g