Transcription

BACKUP WALL SYSTEMSBW UNIVERSAL SYSTEM & BW STRETCH SYSTEM

BACKUP WALL SYSTEMSBW Systems are the ultimate backup wall systems, providing superior air, water, thermal and vapor protection in an allin-one barrier component compared to traditional multi-component wall systems. They can be vertically and horizontallyinstalled with nearly any type of exterior rainscreen system. These unique insulated metal wall panel systems introducenew standards in cost savings, design integrity and sustainability. Easily and quickly installed in a single step, the BWSystems eliminate the need for multiple work crews, expediting close-in/dry-in building times and reducing the likelihoodof improper installation.BENEFITS OF BW APPLICATION: Provides an air barrier, vapor barrier and moisture control, drain plane and superior thermal performance in onecomposite assembly. Encloses the building faster in all weather conditions. Works well for all building types in all climates. Assembly thermal performance achieves u-factors that exceed International Energy Conservation Code (IECC)requirements in all climate zones. BW with different wall assemblies meets the requirements for the NFPA 285 multi-story fire test. Fully tested for air, water infiltration, vapor and thermal performance.SINGLE COMPONENT VS. MULTI-COMPONENTWith its single component construction, BW is a vast improvement over traditional multi-component building technology.A single component means a single source of responsibility, including less coordination, fewer scheduling and interfaceissues, and one-step installation by one contractor. Together, this adds up to a faster, more efficient construction process.TRADITIONAL BACKUP WALL SYSTEMS ARE INSTALLED IN THREE OR FOUR STEPS, REQUIRING MULTIPLE LAYERSAND MULTIPLE CONTRACTORS. Multiple layers equals more potential for installation errors, including issues with the connections between the framingand exterior façade. Multiple layers can lead to moisture entrapment in the wall cavity, resulting in wet insulation, mold and mildew.BW SYSTEMSTRADITIONAL BACKUP SYSTEM1. Exterior Rainscreen1. ExteriorRainscreen2. Zs Support& VerticalSubgirts2. Subgirts1233. BW with integralattachmentsystem1234563. Insulation4. Air and VaporBarrier5. ExteriorSheathing6. Cavity Insulation2BW SYSTEMS

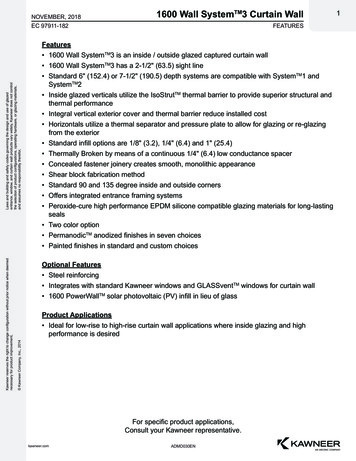

BW SYSTEM IS FULLY TESTED AND CODE COMPLIANTBuilding and energy code compliance are critical parts of any construction project. BW provides a superior solution for theserequirements and outperforms multi-component wall assemblies.MULTI-COMPONENT WALLTHERMOGRAPHSThe images to the left comparethermally equivalent wall assemblies.R-10 Continuousinsulation outboardof gypsumR-21 Batt Insulationbetween 6-inch steelstuds at 16-inchcenters; Effective R-7.4The multi-component wall with continuousinsulation still requires supplemental steelframing (Zs) to convey the wind load from theGypsum Boardrainscreen to the supports.Required supplemental framing for the multicomponent wall leads to a loss in thermalperformance and leads to a greater potential2-inch deep, 18 GAsteel Z-shapedsub-framing at24-inch centersAverage SurfaceTemperature 15 FColder away fromframing; warmer nearfor condensation in the cavity.0.5 7.9 16.4 24.8 33.3 41.8 50.2 58.7 67.1 COLOR LEGEND ( F)BW System exceeds IECC energy performancerequirements based on u-factors tested inaccordance with ASTM C1363. BW System3” BW SYSTEM3-inch BW SystemPanelNo insulation between6-inch Steel Studs at16-inch centers;Effective R-0.91compliance is based on using the u-factorAlternative Method as published in a table byclimate zone in the IECC.Gypsum BoardBW has several wall assemblies that passNFPA 285 and it meets the most rigorousstandards in IBC Chapter 26.Coldest SurfaceTemperature 50 FFraming impactis minimal.Rail through fastenersat 16-inch centersBW’s single component design provides asimpler, faster and more thermally efficientsolution.0.0 8.4 16.8 25.2 33.5 41.9 50.3 58.7 67.1 COLOR LEGEND ( F)Exterior Temperature (0 F), Interior Temperature (70 F)3

BACKUP WALL SYSTEMSBW SYSTEMSBW UNIVERSAL SYSTEM BW STRETCH SYSTEM Width: 32”*, 36”Width: 30”, 36”Thickness: 2”, 3”Thickness: 2”, 23/4”, 4”Length: 12’-0” or 20’-0”Length: 12’-0” or 20’-0”Orientation: HorizontalOrientation: VerticalExterior Profile: No Profile, unembossedExterior Profile: No Profile, unembossedExterior Face: AZ-50 aluminum-zinc coatedsteel in 29 Ga. with epoxy primer finishExterior Face: G-90 galvanized steel in 22 Ga.with epoxy primer finishInterior Profile: Shallow Planked, nominal 3/64”deep, unembossedInterior Profile: Shallow Planked, nominal 3/64”deep, unembossedInterior Face: AZ-50 aluminum-zinc coatedsteel in 29 Ga. with epoxy primer finishInterior Face: G-90 galvanized steel in 26 Ga.with epoxy primer finishCore: Foamed in-place polyisocyanurateCore: Foamed in-place polyisocyanurateJoint: Tongue-and-groove withconcealed face fasteningJoint: Double tongue-and-grooveSpan Capabilities: Up to 24” o.c.Attachment Method: Panel Clips, pre-punchedrails integrated with the panel joineryand integrated brick tie clips.Sealing Method: Joint has factory appliedsealant. Panel ends and marriage beads tofactory sealant applied during installation.Exterior Cladding Attachment Method:Subgirts attached to panel clips. IntegratedBWUH Rail and BWUV Rail. Integrated brickties for brick installation.* Primarily for brick application4BW SYSTEMSSpan Capabilities: Greater than 24” and up to6 ft. o.c.Attachment Method: Panel ClipsSealing Method: Joint has factory appliedsealant. Panel ends and marriage beads tofactory sealant applied during installation.Exterior Cladding Attachment Method:Subgirts attached into panel joint.

BW UNIVERSAL SYSTEMRAINSCREEN SELECTION GUIDERAINSCREENBWUH RAIL*Horizontal Profile PanelsBWUV RAILBRICK TIESPANEL CLIPS*XXVertical Profile PanelsXBrickXTerra CottaXACM PanelsX-horiz.X-vert.Honeycomb PanelsX-horiz.X-vert.StuccoXPerforated PanelsX*Additional subgirts are required.BRICKTERRA COTTAMETALACMBW STRETCH SYSTEMRAINSCREEN SELECTION GUIDERAINSCREENPANEL/GIRTS*Horizontal Profile PanelsXVertical Profile PanelsX*Additional subgirts are required.5

BW UNIVERSAL SYSTEM BW Universal System achieves energy efficiency goals with its integrated composite panel design. This constructioneliminates the need for conventional batt or board insulation, exterior gypsum, air barriers, vapor retarders andbuilding wraps. Metal Liner Provides Airand Vapor Barrier Durable Metal Drain Plane Factory Applied Sealant Tongue-and-Groove withconcealed face fastening BWU HorizontalRainscreen Rail IntegralAttachment System R-13.6 or R-20.4 TestedAssembly InsulationBW Universal System6BW SYSTEMS

BW UNIVERSAL SYSTEM TESTINGDESCRIPTIONTESTMETHODRESULTSASTM E84Flame Spread 25Smoke Developed 450NFPA 259Potential heat of foam plastic insulationcontained in the assembly tested inaccordance with NFPA 285NFPA 285Representative mockup tested inaccordance with NFPA 285. Requiresone layer of ⅝-inch Type X gypsumboard on the interior side of the steelframing of the panels. ContactMetl-Span for complying wall assemblies.ASTM E72See Load Span TablesASTM C518ASTM C1363ASTM C1363u-FACTOR(BTU/h*ft2* F)Panel Width: 36”75 2”0.0733”0.050Fire USThe BW insulated composite back-up panel system provides outstandingfire resistance. BW has been tested to the most rigorous industrystandards noted in IBC Chapter 26.StructuralA foamed-in-place core and two steel skins offer strength, durability andan excellent drain plane. BW can be applied horizontally to achieverequired span capabilities.Thermal PerformanceThermal Performance utilizes strong, composite construction withthermally broken panel joinery and places the thermal envelope onthe outside of the framing cavity.ASTM C518R-VALUE(h*ft2* F/BTU)Panel Width: 36”75 2”13.63”20.4Air InfiltrationWith so much attention to thermal and water performance, air infiltrationis often the most overlooked aspect of wall performance. BW addressesair infiltration by providing a continuous air barrier via a formed metal linerwith a combination of field-applied and factory applied sealants.ASTM E2357No uncontrolled leakage when testedto a static pressure of 15 psf for 15 min.Water PerformanceBW utilizes a joinery system that eliminates moisture build up andentrapment within panel joinery, thus ensuring the highest level ofwater performance.Maximum Air Infiltration Rate of0.004 cfm/sq. ft. at a static-airpressure difference of 1.57 psfASTM E331No uncontrolled leakage when testedat a differential pressure of 6.24 psffor 2 hours (per IBC - Chapter 14)OPTIONAL WARRANTYMetl-Span backs its BW System with a weathertight 10-year warranty. When any cladding isused with BW, you get the extra quality and performance assurance that no other backupwall with multiple components and layers can offer.7

BW UNIVERSAL SYSTEM DESIGN FLEXIBILITYMetl-Span BW Universal System provides you design flexibility to support a variety of rainscreen applications, as well asaccessories. The rainscreen systems provide aesthetics as well as a performance barrier to compliment any project under anyclimate condition.BWU HORIZONTALBWU VERTICALRAINSCREEN RAILRAINSCREEN RAILBW UNIVERSAL SYSTEMRAINSCREEN SELECTION GUIDERAINSCREENHorizontal Profile PanelsBWUH RAIL*BWUV RAILXVertical Profile PanelsXBrickTerra CottaXACM PanelsX-horiz.X-vert.Honeycomb PanelsX-horiz.X-vert.StuccoXPerforated Panels*Additional subgirts are required.8BW SYSTEMS

Integrated Panel Clipand Pintle for BrickMid-Span Face AttachmentClip and Pintle for BrickBRICK TIESPANEL CLIPBW UNIVERSAL SYSTEMRAINSCREEN SELECTION GUIDERAINSCREENBRICK TIESHorizontal Profile PanelsPANEL CLIPS*XVertical Profile PanelsBrickXTerra CottaACM PanelsHoneycomb PanelsStuccoPerforated PanelsX*Additional subgirts are required.9

BW STRETCH SYSTEM The BW Stretch System can be vertically installed with multiple types of exterior rainscreen systems and can span up to 6 ft. o.c. Thisunique insulated metal panel wall system can be easily and quickly installed in a single step. The BW Stretch System eliminates theneed for multiple work crews, expediting close-in/dry-in building times and reducing the likelihood of improper installation. R-13.6, R-18.7, or R-27.2Tested Assembly Insulation Durable MetalDrain Plane Offset DoubleTongue-and-Groove Joint Factory Applied SealantBW Stretch System10BW SYSTEMS

BW STRETCH SYSTEM TESTINGDESCRIPTIONFire US/ Fire CanadaTESTMETHODASTM E84Flame Spread 25Smoke Developed 450NFPA 259Potential heat of foam plasticinsulation contained in the assemblytested in accordance with NFPA 285NFPA 285Representative mockup tested inaccordance with NFPA 285. ContactMetl-Span for complying wall assemblyCAN/ULC S101Meets Acceptance Criteria per theNational Building Code of CanadaCAN/ULC S102Meets Acceptance Criteria per theNational Building Code of CanadaCAN/ULC S134Meets Acceptance Criteria per theNational Building Code of Canada.Testing performed on panel only.The BW insulated composite back-up panel system provides outstandingfire resistance. BW has been tested to the most rigorous industrystandards noted in IBC Chapter 26RESULTSStructuralA foamed-in-place core and two steel skins offer strength, durabilityand an excellent drain plane. BW can be applied vertically to achieverequired span capabilities.ASTM E72See Load Span TablesASTM C518ASTM C1363ASTM C1363u-FACTOR(BTU/h*ft2* F)Panel Width: 36”75 2”0.0762¾”0.0564”0.041Thermal PerformanceThermal Performance utilizes strong, composite construction withthermally broken panel joinery and places the thermal envelope onthe outside of the framing cavity.ASTM C518R-VALUE(h*ft2* F/BTU)Panel Width: 36”75 2”13.62¾”18.74”27.2k-Factor of 0.147 BTU/h·ft2· F at75 F mean coreAir InfiltrationWith so much attention to thermal and water performance, air infiltrationis often the most overlooked aspect of wall performance. BW addressesair infiltration by providing a continuous air barrier via a formed metal linerwith a combination of field-applied and factory applied sealants.ASTM E2357Meets acceptance criteria per theInternational Energy ConservationCode and the National Energy Codeof Canada.No uncontrolled leakage when testedto a static pressure of 15 psf for 15 min.Water PerformanceBW utilizes a joinery system that eliminates moisture build up andentrapment within panel joinery, thus ensuring the highest level ofwater performance.Maximum Air Infiltration Rate of0.004 cfm/sq. ft. at a static-airpressure difference of 1.57 psfASTM E331No uncontrolled leakage when testedat a differential pressure of 6.24 psffor 2 hours (per IBC - Chapter 14)OPTIONAL WARRANTYMetl-Span backs its BW System with a weathertight 10-year warranty. When any cladding isused with BW, you get the extra quality and performance assurance that no other backupwall with multiple components and layers can offer.11

Metl-Span: All-In-One Performance1720 Lakepointe Drive, Suite 101, Lewisville, Texas 75057 (p) 877.585.9969 metlspan.com ️ 2020 Metl-Span, part of the Cornerstone Building Brands family. All Rights Reserved. Printed in the U.S.A.Reference BWS NJ/PO 5 2012

Multiple layers can lead to moisture entrapment in the wall cavity, resulting in wet insulation, mold and mildew. BW SYSTEMS TRADITIONAL BACKUP SYSTEM 1. Exterior Rainscreen 2. Subgirts 3. BW with integral attachment system 1. Exterior Rainscreen 2. Zs Support & Vertical Subgirts 3. Insulation 4. Air and Vapor Barrier 5. Exterior Sheathing .