Transcription

SULLAIR SX Filtration Series25 – 21,000 scfm

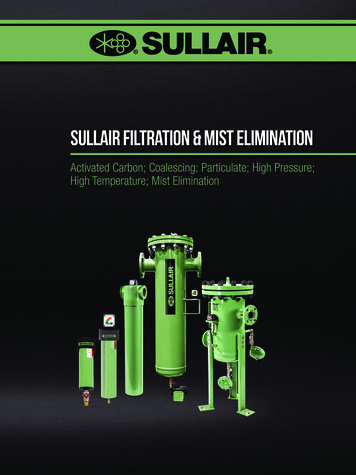

The Importance ofReliable FiltrationContaminants are introduced at various stages of the air compression cycle. Removing thesecontaminants is vital to help ensure part quality, avoid machine damage and protect employees.Sullair SX Filters reliably help remove contaminants plus humidity and oil from the compressedair stream.How?Compressed air enters the filter housing inlet.The unique curved inlet design helps minimizeflow resistance as the compressed air flows intophysical medium of the filter element.Then, untreated compressed air passesthrough an innovative high bed depth filtermaterial specifically designed for maximumretention of particles such as liquid oil,oil aerosols, dirt and scale.Finally, the treated, clean compressed air flowsdownstream to other inline components orpoint-of-use.Removed condensate moves to a collectionzone to help ensure it remains filtered fromthe treated air and can be easily drained.2

SULlAIR SX FILTRATION SERIESSullair SX Filters are built for maximum reliability, simplifiedmaintenance and superior performance. Engineeredfor energy efficiency Ultra-low differential pressure across the range Advance eco series pleated elements Fully optimized housing Unique curved inlet design engineered for the lowest possibledifferential pressure—helps reduce flow resistance up to 75% Versatile housing connections for easy installation Easy-open hexagonal profile housing base for simplified elementchanges and maintenance Simple, push-fit element design for easy changeoutSULLAIR SX SERIES FILTRATIONSXT THREADED FILTERSParticulate & Coalescing FiltersFlow Rates scfmMax Operating Pressure psigStandard Pipe Connection SizesHousing MaterialDrainsAvailable OptionsActivated Carbon Filters25–1900SXF FLANGED SERIESParticulate, Coalescing & Activated Carbon Filters1900–21,000232200 8 –3 NPT4 –12 ANSI FlangeAnodized, Powder-Coated AluminumPowder-Coated Carbon SteelFloat DrainSULLIMAX Zero Air Loss Drain3SULLIMAX Zero Air Loss DrainDifferential Pressure GaugeOil Check IndicatorManual ValvePowder-Coated Carbon Steel3

SULLAIR SXT Threaded Particulate, Coalescing & Activated Carbon FiltersModelPipe Size (NPT)Flow Rate (scfm)Element Size*Dimension Sizes (See Line Drawings Below for Reference)A (in)C1 (in)C2 (in)C3 (in)C4 (in)D (in)Weight (lbs)SXT00253 8 2504*2.957.099.6515.5518.115.911.65SXT00301/2 3004*2.957.099.6515.5518.115.911.65SXT00501/2 5005*2.958.2710.8316.7319.295.911.87SXT00801/2 8006*2.9510.4312.9918.921.465.912.65SXT01003/4 10007*3.9411.0213.5819.4922.055.913.75SXT01251 12507*3.9411.0213.5819.4922.055.914.18SXT01601 16010*3.9413.7816.3422.2424.85.914.63SXT02001 20012*3.9415.1617.7223.6226.185.914.85SXT025011/2 25015*5.7514.1716.7322.8325.396.39.04SXT033011/2 33018*5.7516.4619.0224.9227.486.39.92SXT045011/2 45020*5.7518.4320.9926.8929.456.310.61SXT05002 50020*5.7518.4320.9926.8929.456.311.24SXT06002 60022*5.7522.2424.830.7133.276.313.45SXT08002 80023*5.7526.8929.4535.3537.916.315.65SXT100021/2 /2 130027*10.2430.5133.0738.9841.547.8749.82SXT15003 150030*10.2435.2437.839.7642.327.8757.1SXT19003 190032*10.2441.1443.749.6152.177.8765.92* See element type chartElement TypeMicron Rating (µm)Oil Carryover (mg/m³)Dry Pressure (psid)Wet Pressure e.01.01Activated Carbon Element.01.0032.91.02Correction FactorsOperating Pressure ion .872.13Advanced SX eco series elementsValidated in accordance with ISO 12500-1 and 3Max operating pressure psig232Max operating temperature F140Options (Particulate & Coalescing):Float Drain or SULLIMAX Zero Loss DrainDifferential pressure gaugeOptions (Activated Carbon):Oil Check IndicatorManual Valve4

SULLAIR SXF Flange Particulate, Coalescing & ACTIVATED CARBON FiltersModelPipe Size (ANSI)Flow Rate (scfm)Element Size*Dimension Sizes (See Line Drawing Below for Reference)A (in)B (in)C1 (in)D (in)13Weight (lbs)SXF19004 190021.256.8846.5SXF28004 280021.257.1347.38266SXF38006 380023.5846.8828323.758.2550.38289.553SXF65006 6500SXF75008 750088*19532853418SXF93008 930030.319.7556.34623SXF1300010 13,00034.659.8860.18727SXF2100012 21,00038.9810.8764.26825* See element type chartMicron Rating (µm)Oil Carryover (mg/m³)Dry Pressure (psid)Wet Pressure (psid)CoarseElement Type255Oil Vapor 2.9Activated Carbon Element.01.003ApprovalsASME CodedVessel with "UM"stamp standard(CRN optional)1.45Correction FactorsOperating Pressure (psig)2040608090100110120130140160180200Correction .87SULLIMAX Zero Loss DrainConnection kit with differential pressure gaugeAdvanced SX eco series elementsValidated in accordance with ISO 12500Designed according to ASME Sec. VII, Div. 1UM Stamp Standard and CRN optionalMax operating pressure psig232Max operating temperature F1405

About SullairFor more than 50 years, Sullair has been on the leading edge of compressed air solutions.We were one of the first to execute rotary screw technology in our air compressors, andour machines are famous all over the world for their legendary durability. As the industrymoves forward, Sullair will always be at the forefront with quality people, innovative solutions,and air compressors that are built to last.Sullair was founded in Michigan City, Indiana in 1965, and has since expanded with a broadinternational network to serve customers in every corner of the globe. Sullair has offices in Chicagoand manufacturing facilities in the United States, China and India — all ISO 9001 certified toensure the highest quality standards in manufacturing. In addition, Sullair Suzhou and Shenzhenfacilities are ISO 14001 and OHSAS 18001 certified.Sulliar is A Hitachi Group Company6

RELIABILITY.DURABILITY.PERFORMANCE.These are the pillars that drive the qualityof Sullair compressed air solutions. It’s apromise we keep with every machinewe make.RELIABILITYCustomers who work with Sullair have found that the intangibles makeall the difference — things like trust, confidence, and peace of mind.They go to work every day having full faith in their equipment, as well asthe knowledge that dedicated distributors and Sullair personnel have theirback every step of the way.DURABILITYBulletproof. Built to last. However you spin it, Sullair compressedair solutions are in it for the long haul, driven by innovative designspioneering the air treatment industry. And ready to stand the test of time.PERFORMANCESullair is constantly innovating to improve our compressed air solutions.For our compressed air treatment line, this means more energy efficiency.With air treatment being a vital part of your entire compressed air system,Sullair is committed to helping you protect your equipment and manageyour operating expenses.7

2019 Sullair, LLC. All rights reserved. Specifications subject to change without notice. SAPATSX201901-1The Sullair symbol and Sullair wordmark are registered trademarks of Sullair, LLC. SULLIMAX is a trademark of Sullair, LLC.

Sullair is constantly innovating to improve our compressed air solutions. For our compressed air treatment line, this means more energy efficiency. With air treatment being a vital part of your entire compressed air system, Sullair is committed to helping you protect your equipment and manage your operating expenses.