Transcription

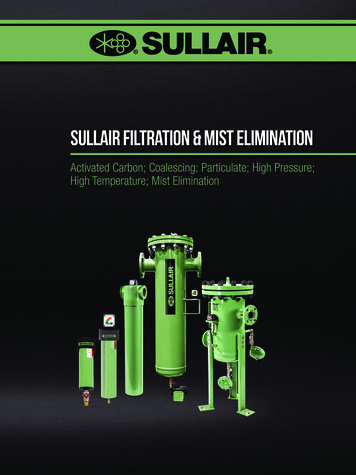

SULLAIR Filtration & Mist EliminationActivated Carbon; Coalescing; Particulate; High Pressure;High Temperature; Mist Elimination

The Importance ofReliable FiltrationContaminants are introduced at various stages of the air compression cycle. Removing thesecontaminants is vital to help ensure part quality, avoid machine damage and protect employees.Sullair filters reliably help remove contaminants plus humidity and oil from the compressedair stream.How?Compressed air enters the filter housinginlet. The inlet design helps optimize air flowas compressed air moves into the physicalmedium of a filter element.Then, untreated compressed air passesthrough filter material designed for retentionof particles such as liquid oil, oil aerosols,dirt and scale.Finally, the treated, clean compressedair flows downstream to other inlinecomponents or point-of-use.Removed condensate moves from thetreated air to be easily drained.

SULlAIR FILTRATION SERIESSullair filters are built for reliable operation and designed to help you save money. Engineered for energy efficiency — helps reduce operating costsDurable housing construction for corrosion resistanceBroad filtration from general purpose to highly stringent applicationsOptimized air flow design to help increase efficiency and reduce pressure lossBuilt for safe and easy maintenanceSULLAIR FILTRATIONTHREADED FILTERSSX SERIESFLANGE FILTERSFH SERIESFXFRHTHighPressureParticulateHigh 01500–17,700Max Operating Pressure psig232725290232290Max Operating Temperature F140176350140350³ 8 –3 NPT1/4 –21/2 NPT1/2 –3 NPT4 –12 ANSI Flange3 –14 ANSI FlangeAluminumDiecast AluminumManual DrainManual DrainFilter TypeCoalescingFlow Rates scfmStandard ConnectionHousing MaterialDrainsParticulateActivatedCarbonAnodized, Powder-Coated AluminumFloat DrainManual DrainSULLIMAX Zero Loss Drain optionalon SX Series Threaded Coalescing unitsSX wder-Coated Carbon SteelSULLIMAX Zero Air Loss DrainManual DrainParticulate HighTemperatureSteelExternal Float Drain

Sullair ELM Mist EliminatorsSullair ELM Series Mist Eliminators are engineered for reliable performance in varying load conditions,long service life and to stand up to harsh environments — all while ensuring extremely low pressure drop.Sullair ELM Series Helps You Save EnergyELM Series Mist Eliminators have a .05 psi pressure drop — 4 psi lower than conventional filters.Generally, reducing pressure drop by 2 psi saves 1% in compressor energy consumption.4 psi 2% compressor power savingsAnnual Energy Savings on 100 hp System 0.05/kWh x 8760 hours x 74.6 kW x 2% 653 0.08/kWh x 8760 hours x 74.6 kW x 2% 1046 0.10/kWh x 8760 hours x 74.6 kW x 2% 1307Annual energy savings based on assumptions of normal operating conditions. Your results may vary.ElementUltra-low differential pressure—.05 psi High load factor compared to conventional hand-packed media 9–10x greater surface area, dirt holding capacity and pressure drop Special machine pleated element construction Increases stability under changing loads Reduces specific surface tension DESIGNED FOR ALONGER SERVICE LIFEFrameEngineered to stand up to harsh environments Strong stainless steel support sleeve construction — helps eliminate rust and corrosion 4

Additional SullairAir Treatment SolutionsSullair COMPRESSED Air DryersRefrigerated; DesiccantSULLIMAX Condensate DrainsSULLIPRO &SP Oil/Water SeparatorsVisit Sullair.com for more information.5

AboutSullairFor more than 50 years, Sullair has been on the leading edge of compressedair solutions. We were one of the first to execute rotary screw technology in our aircompressors, and our machines are famous all over the world for their legendarydurability. As the industry moves forward, Sullair will always be at the forefront withquality people, innovative solutions, and air compressors that are built to last.Sullair was founded in Michigan City, Indiana in 1965, and has since expanded with a broadinternational network to serve customers in every corner of the globe. Sullair has offices inChicago and manufacturing facilities in the United States and China — all ISO 9001 certifiedto ensure the highest quality standards in manufacturing. In addition, Sullair Suzhou andShenzhen facilities are ISO 14001 and OHSAS 18001 certified.Sullair is A Hitachi Group CompanyRELIABILITY.DURABILITY.PERFORMANCE.These are the pillars that drive the qualityof Sullair compressed air solutions. It’s apromise we keep with every machinewe make.RELIABILITYCustomers who work with Sullair have found that the intangibles make all the difference— things like trust, confidence, and peace of mind. They go to work every day having fullfaith in their equipment, as well as the knowledge that dedicated distributors and Sullairpersonnel have their back every step of the way.DURABILITYBulletproof. Built to last. However you spin it, Sullair compressed air solutions are init for the long haul, driven by innovative designs pioneering the air treatment industry.And ready to stand the test of time.PERFORMANCESullair is constantly innovating to improve our compressed air solutions. For ourcompressed air treatment line, this means more energy efficiency. With air treatmentbeing a vital part of your entire compressed air system, Sullair is committed to helpingyou protect your equipment and manage your operating expenses.6

SXseriesThreaded FiltersDimensions & WeightFlow Rate(scfm)Connection Size(NPT)AvailableElement TypesWidthTop of Housing (in)Housing HeightIncludes Gauge & Float Drain (in)Housing HeightIncludes Gauge & Zero Loss Drain (in)Weight(lbs)253 8 2.9510.7517.151.65301/2 2.9510.7517.151.65501/2 2.9511.9318.331.87801/2 2.9514.120.492.651003/4 3.9414.6921.083.751251 3.9414.6921.083.751601 3.9417.4423.844.632001 3.9418.8225.224.8525011/2 5.7517.6824.439.0433011/2 45011/2 500CoarseFineSuperfineActivated Carbon5.7519.7626.529.925.7521.7328.4911.242 5.7521.7328.4911.246002 5.7525.5532.313.448002 5.7530.236.9515.65100021/2 10.2429.4136.4443.87130021/2 10.2433.540.5349.8215003 10.2438.2345.2657.119003 10.2444.0651.1865.92Element TypesElement Type DesignatorElement TypePackage DescriptionCoarseCoarse FilterFFineGeneral Purpose FilterHSuperfineOil Removal FilterCActivated Carbon ElementActivated Carbon Filter0.01CSMicron Rating (µm) Oil Carryover (mg/m³) Dry Pressure (psig) Wet Pressure �1.02Correction FactorsOperating Pressure ion .872.13Validated in accordance with ISO 12500-1 and 3CRN certifiedMax operating pressure: 232 psigMax operating temperature: 140 FStandard Features:Versatile housing connectionsSimple, push-fit element designHigh-pitch safety alarmDifferential pressure gauge (Not available on activated carbon units)Float drain (Manual drain ball valve standard on activated carbon units)Options:SULLIMAX Zero Air Loss Drain (Not available on activated carbon units) 2019 Sullair, LLC. All rights reserved. Specifications including appearance subject to change without notice. SAPATSX201907-2The Sullair symbol and Sullair wordmark are registered trademarks of Sullair, LLC. SULLIMAX is a trademark of Sullair, LLC.

SXseriesPARTICULATE THREADED FILTERSDimensions & WeightFlow Rate (scfm)Connection Size (NPT)25Available Element TypesWidth — Top of Housing (in)Housing Height (in)Weight (lbs)2.9510.441.65 8 3301/2 2.9510.441.65501/2 2.9511.621.87801/2 2.9513.782.651003/4 3.9414.373.751251 3.9414.373.751601 3.9417.134.632001 3.9418.514.8525011/2 5.7517.729.0433011/2 5.7519.819.9245011/2 5.7521.7811.245002 5.7521.7811.24Fine6002 5.7525.5913.448002 5.7530.2415.65100021/2 10.2429.7343.87130021/2 10.2433.0249.8215003 10.2438.5557.119003 10.2444.4765.92Element TypesElement Type DesignatorElement TypePackage DescriptionMicron Rating (µm)Oil Carryover (mg/m³)Dry Pressure (psig)Wet Pressure (psig)FineReverse Flow GP Filter10.10.731.9FCorrection FactorsOperating Pressure ion .872.13Validated in accordance with ISO 12500-1 and 3CRN certifiedMax operating pressure: 232 psigMax operating temperature: 140 FStandard Features:Versatile housing connectionsSimple, push-fit element designHigh-pitch safety alarmManual drain ball valve 2019 Sullair, LLC. All rights reserved. Specifications including appearance subject to change without notice. SAPATSX201907-2The Sullair symbol and Sullair wordmark are registered trademarks of Sullair, LLC. SULLIMAX is a trademark of Sullair, LLC.

FHseriesHIGH PRESSURE THREADED FILTERSDimensions & WeightFlow Rate (scfm)Connection Size (NPT)60Dimension A (in)Dimension B (in)Dimension C (in)Dimension D (in)Weight (lbs)1/4 4.464.541.016.171751/2 4.464.541.016.2473503/4 4.34.541.268.1495001 5.235.431.479.84147001 95011/2 Available Element TypesFineSuperfineActivated Carbon5.235.431.4712.36185.035.431.7414.482115002 5.76.222.0215.4725175021/2 6.2972.2615.1928Element TypesElement TypeDesignatorFElement TypePackage DescriptionMicron Rating (µm)Oil Carryover (mg/m³)Dry Pressure (psig)Wet Pressure (psig)FineGeneral Purpose Filter10.50.61.2HSuperfineOil Removal Filter0.010.011.22.3CActivated Carbon ElementActivated Carbon Filter0.010.0032.32.3Correction FactorsOperating Pressure (psig)290363435508580653725Correction Factor0.630.070.780.830.90.951Validated in accordance with ISO 8573-1ASME certifiedCRN certifiedManual drain ball valveMax operating pressure: 725 psigMin operating temperature: 36 FMax operating temperature: 176 F 2019 Sullair, LLC. All rights reserved. Specifications including appearance subject to change without notice. SAPATSX201907-2The Sullair symbol and Sullair wordmark are registered trademarks of Sullair, LLC. SULLIMAX is a trademark of Sullair, LLC.

FXFRHTseriesParticulate High Temperature Threaded FiltersDimensions & WeightFlow Rate (scfm)Pipe Size (ANSI)251/2 451/2 Available Element TypesDimension A (in)Dimension B (in)Dimension C (in)Weight (lbs)487341093653/4 5101141301 51514624011/2 51917735011/2 5211984752 62422127002 62725129253 829212313503 829272616003 8424027FineElement TypeElement Type DesignatorElement TypePackage DescriptionMicron Rating (µm)Oil Carryover (ppm)Dry Pressure (psig)Wet Pressure (psig)FineReverse Flow GP Filter10.50.61.2FCorrection FactorsOperating Pressure (psig)Correction ed in accordance with ISO 8573-1ASME certifiedCRN certifiedDifferential pressure gaugeManual drain ball valveMax operating pressure: 290 psigMin operating temperature: 36 FMax operating temperature: 350 FFXFRHT 2019 Sullair, LLC. All rights reserved. Specifications including appearance subject to change without notice. SAPATSX201907-2The Sullair symbol and Sullair wordmark are registered trademarks of Sullair, LLC. SULLIMAX is a trademark of Sullair, LLC.

SXseriesFlange FiltersDimensions & WeightFlow Rate (scfm)Pipe Size (ANSI)1900Available Element TypesDimension A (in)Dimension B (in)Dimension C (in)Dimension D (in)Weight (lbs)4 21.256.88471319528004 21.257.1347.381826638006 23.5846.881828365006 23.755.2550.381832875008 93008 13,00010 21,00012 CoarseFineSuperfineActivated 81872738.9810.8764.2618825Element TypeElement TypeDesignatorElementTypeMicron Rating(µm)CSCoarse25FFine1Oil Carryover(mg/m³)Dry Pressure(psid)Wet 871.7CActivated Carbon Element.01.0031.45—ApprovalsASME CodedVessel with "UM"stamp standard(CRN optional)Correction FactorsOperating Pressure (psig)2040608090100110120130140160180200Correction .87SULLIMAX Zero Loss Drain (Manual drain ball valve standard on activated carbon units)ASME certifiedSelect models CRN certifiedConnection kit with differential pressure gauge (Not available on activated carbon units)Validated in accordance with ISO 12500Max operating pressure: 232 psigMax operating temperature: 140 F 2019 Sullair, LLC. All rights reserved. Specifications including appearance subject to change without notice. SAPATSX201907-2The Sullair symbol and Sullair wordmark are registered trademarks of Sullair, LLC. SULLIMAX is a trademark of Sullair, LLC.

FWFRHTseriesPARTICULATE HIGH TEMPERATURE FLANGE FILTERSDimensions & WeightFlow Rate (scfm)Pipe Size(ANSI)1500Available ElementTypesDimension A (in)Dimension B (in)Dimension C (in)Dimension D (in)Dimension E (in)Weight (lbs)3 17.7511129.525.523019004 17.752.21130.325.524625004 20.953.211.130.425.532438006 22.856.413.131.425.545050006 25.657.113.2531.5625.558065008 29.559.614.532.625.5752Fine83008 31.560.71532.725.586610,00010 33.56416.333.8425.5114812,40012 33.56617.534.825.5121415,00014 39.469.718.935.825.5171617,70014 39.469.718.935.825.51730Element TypeSullair ModelNomenclatureFElement TypePackage DescriptionMicron Rating (µm)Oil Carryover (mg/m³)Dry Pressure (psig)Wet Pressure (psig)FineReverse Flow GP Filter10.50.61.2ASME certifiedCRN certifiedExternal float drainMax operating pressure: 290 psigMax operating temperature: 350 FDifferential pressure gaugeFloat drainFWFRHT 2019 Sullair, LLC. All rights reserved. Specifications including appearance subject to change without notice. SAPATSX201907-2The Sullair symbol and Sullair wordmark are registered trademarks of Sullair, LLC. SULLIMAX is a trademark of Sullair, LLC.

ELMseriesMist EliminatorsDimension SizesInlet–OutletPort Size (flange)WidthMin. Clearance forElement Change (in)Drain PortSize (NPT)Weight (lbs)ininELM-1502 19.7039.87131/2 250ELM-3002 ELM-6002 19.7043.87171/2 26419.7057.87311/2 304ELM-8003 19.7065.27371/2 343ELM-12003 23.6060.17311/2 436ELM-16003 23.6066.17371/2 460ELM-21004 27.5662.42311/2 682ELM-27504 27.5668.42371/2 713ELM-42006 31.5065.67311/2 858ELM-60006 31.5075.67411/2 940ELM-80008 33.5079.42411/2 1188ELM-10,00010 39.4083.47411/2 1642ELM-12,00012 39.40105.92611/2 1914ModelHeightASME certifiedCRN certifiedPressure drop: .05Micron rating: .01 μmDifferential pressure gaugeFloat drain 2019 Sullair, LLC. All rights reserved. Specifications including appearance subject to change without notice. SAPATSX201907-2The Sullair symbol and Sullair wordmark are registered trademarks of Sullair, LLC. SULLIMAX is a trademark of Sullair, LLC.

For more information, contact your local authorized Sullair distributor. 2019 Sullair, LLC. All rights reserved. Specifications subject to change without notice. SAPATSX201907-2The Sullair symbol and Sullair wordmark are registered trademarks of Sullair, LLC. SULLIMAX and SULLIPRO are a trademark of Sullair, LLC.

SULlAIR FILTRATION SERIES. Sullair filters are built for reliable operation and designed to help you save money. Engineered for energy efficiency — helps reduce operating costs Durable housing construction for corrosion resistance Broad filtration from general purpose to highly stringent applications