Transcription

SULLAIR INDUSTRIALAIR COMPRESSOR3000, 3700, 4500,3000V, 3700V, 4500V30, 37 & 45 KW/40, 50 & 60HPAir-Cooled Standard & 24 KTPART NUMBER:02250155-601KEEP FORFUTUREREFERENCE SULLAIR CORPORATIONStarting Serial Number:003-139556O PERATO R’S M ANU AL AND PARTS LIST

AIR CARESEMINAR TRAININGSullair Air Care Seminars are courses that provide hands-on instruction in the proper operation, maintenanceand service of Sullair equipment. Individual seminars on Industrial compressors and compressor electricalsystems are presented at regular intervals throughout the year at a dedicated training facility at Sullair'scorporate headquarters in Michigan City, Indiana.Instruction includes discussion of the function and installation of Sullair service parts, troubleshooting of themost common problems, and actual equipment operation. The seminars are recommended for maintenanceand service personnel.For detailed course outlines, schedule and cost information contact:Sullair Corporate Training Department: 1-888-SULLAIR or219-879-5451 (ext. 5363)www.sullair.com- Or Write Sullair Corporation3700 E. Michigan Blvd.Michigan City, IN 46360Attn: Service Training Department

SULLAIR 3700 Operator’s Manual and Parts ListTABLE OF CONTENTS1 - SAFETY . 1General. 1Personal Protective Equipment . 1Pressure Release. 2Fire and Explosion. 2Moving Parts . 3Hot Surfaces, Sharp Edges and Sharp Corners . 3Toxic and Irritating Substances . 3Electrical Shock. 4Lifting. 4Entrapment. 52 - DESCRIPTION. 7Introduction. 7Description of Components . 8Sullair Compressor Unit, Functional Description. 8Compressor Cooling and Lubrication System, FunctionalDescription . 10Compressor Discharge System, Functional Description . 10Control System, Functional Description . 11START MODE - 0 TO 50 PSIG(0 TO 3.5 BAR). 11FULL LOAD MODE - 50 TO 100 PSIG (3.4 TO 6.9 BAR). 12MODULATING MODE - 100 TO 110 PSIG (6.9 TO 7.6 BAR) . 12UNLOAD MODE - IN EXCESS OF 110 PSIG (7.6 BAR) . 13LOAD/NO LOAD CONTROL . 13AUTOMATIC OPERATION . 13Air Inlet System, Functional Description. 133 - SPECIFICATIONS . 15Table of Specifications . 15Lubrication Guide . 17 SULLAIR 3700 Operator’s Manual and Parts Listiii

Application Guide . 17Lubrication Change Recommendations and Maintenance Fluid Filter and Separator. 184 - INSTALLATION. 25Mounting of Compressor . 25Ventilation and Cooling . 25Air-Cooled Compressors . 25Service Air Piping .Pipe Sizing .Use of Auxiliary Receiver / Sump.Isolation Valve(s).Fluid Containment .2626262627Coupling Alignment Check . 27Fluid Level Check. 27Electrical Preparation . 27Motor Rotation Direction Check . 28Fan Motor Rotation Check . 285 - WS Controller . 29Controller Layout . 29Controller Keypad. 29LED Display. 29LED Lights. 316 - MAINTENANCE . 33General. 33Daily Operation. 33Maintenance After Initial 50 Hours of Operation . 33Maintenance Every 2000 Hours . 33Fluid Maintenance . 34Filter Maintenance. 34Fluid Filter Element Replacement . 34Air Filter Maintenance . 34Air Filter Element Replacement. 35Separator Maintenance .Separator Element Replacement .Oil Return/Sight Glass Maintenance .Pressure Regulator Adjustment .Water Condensate Drain Maintenance .Control Line Strainer .Shaft Coupling Maintenance .35353536363637Troubleshooting - Introduction. 37Troubleshooting Guide . 38iv3700 Operator’s Manual and Parts List SULLAIR

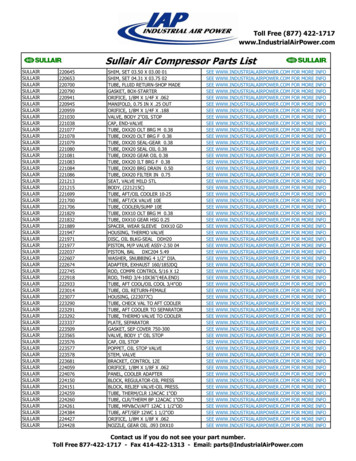

TABLE OF CONTENTS7 - PARTS LISTS. 41Procedure For Ordering Parts . 41Recommended Spare Parts List . 43Compressor, Frame and Drive - 3000 and 3700 Models . 44Compressor, Frame and Drive - 4500 Model . 46Air Inlet System . 48Air Piping - Air-Cooled. 50Fluid Piping - Air-Cooled . 52Cooling and Lubrication System - Air-Cooled 18"/60HzFan, Standard Cooler . 54Discharge, Sump and Piping System. 56Moisture Drain . 58Pneumatic Control System - Standard . 60Pneumatic Control System - With Sequencing . 62Control System and Electric Parts - 230/460WYE-Delta. 64Enclosure - Air-Cooled . 66Decal Section - Air-Cooled . 68 SULLAIR 3700 Operator’s Manual and Parts Listv

This Page Intentionally Left Blankvi3700 Operator’s Manual and Parts List SULLAIR

SULLAIR 3700 Operator’s Manual and Parts ListSection 1SAFETYInstall, use and operate the compressor only in fullcompliance with all pertinent OSHA regulations and/orany applicable Federal, State, and Local codes,standards and regulations.NOTEDO NOT modify the compressor and/or controls in anyway except with written factory approval.OPERATOR IS REQUIRED TOREAD ENTIRE INSTRUCTIONMANUAL.SU 00000051.1 GENERALSullair Corporation and its subsidiaries design andmanufacture all of their products so they can beoperated safely. However, the responsibility for safeoperation rests with those who use and maintain theseproducts. The following safety precautions are offered asa guide which, if conscientiously followed, will minimizethe possibility of accidents throughout the useful life ofthis equipment.The compressor should be operated only by those whohave been trained and delegated to do so, and who haveread and understood this Operator’s Manual. Failure tofollow the instructions, procedures and safetyprecautions in this manual may result in accidents andinjuries.While not specifically applicable to all types ofcompressors with all types of prime movers, most of theprecautionary statements contained herein areapplicable to most compressors and the conceptsbehind these statements are generally applicable to allcompressors.1.2 PERSONAL PROTECTIVEEQUIPMENTPrior to installing or operating the compressor, owners,employers and users should become familiar with, andcomply with, all applicable OSHA regulations and/or anyapplicable Federal, State and Local codes, standards,and regulations relative to personal protectiveequipment, such as eye and face protective equipment,respiratory protective equipment, equipment intended toprotect the extremities, protective clothing, protectiveshields and barriers and electrical protective equipment,as well as noise exposure administrative and/orengineering controls and/or personal hearing protectiveequipment.NEVER start the compressor unless it is safe to do so.DO NOT attempt to operate the compressor with aknown unsafe condition. Tag the compressor and renderit inoperative by disconnecting and locking out all powerat source or otherwise disabling its prime mover soothers who may not know of the unsafe condition cannotattempt to operate it until the condition is corrected. SULLAIR 3700 Operator’s Manual and Parts List1

SECTION 11.3 PRESSURE RELEASEA. Install an appropriate flow-limiting valve betweenthe service air outlet and the shut-off (throttle)valve, either at the compressor or at any otherpoint along the air line, when an air hoseexceeding 13mm inside diameter is to beconnected to the shut-off (throttle) valve, toreduce pressure in case of hose failure, perOSHA Standard 29 CFR 1926.302(b)(7) and/orany applicable Federal, State and Local codes,standards and regulations.B. When the hose is to be used to supply a manifold,install an additional appropriate flow-limiting valvebetween the manifold and each air hoseexceeding 13mm inside diameter that is to beconnected to the manifold to reduce pressure incase of hose failure.C. Provide an appropriate flow-limiting valve at thebeginning of each additional 23m of hose in runsof air hose exceeding 13mm inside diameter toreduce pressure in case of hose failure.D. Flow-limiting valves are listed by pipe size andflow-rated. Select appropriate valves accordingly,in accordance with their manufacturer’srecommendations.E. DO NOT use air tools that are rated below themaximum rating of the compressor. Select airtools, air hoses, pipes, valves, filters and otherfittings accordingly. DO NOT exceedmanufacturer’s rated safe operating pressures forthese items.F. Secure all hose connections by wire, chain orother suitable retaining device to prevent tools orhose ends from being accidentally disconnectedand expelled.G. Open fluid filler cap only when compressor is notrunning and is not pressurized. Shut down thecompressor and bleed the sump (receiver) to zerointernal pressure before removing the cap.H. Vent all internal pressure prior to opening any line,fitting, hose, valve, drain plug, connection or othercomponent, such as filters and line oilers, andbefore attempting to refill optional air line anti-icersystems with antifreeze compound.I. Keep personnel out of line with and away from thedischarge opening of hoses or tools or otherpoints of compressed air discharge.J. Use air at pressures less than 2.1 bar for cleaningpurposes, and then only with effective chipguarding and personal protective equipment perOSHA Standard 29 C

Sullair Corporate Training Department : 1-888-SULLAIR or 219-879-5451 (ext. 5363) www.sullair.com - Or Write - Sullair Corporation 3700 E. Michigan Blvd. Michigan City,