Transcription

VOL. 232, SEPTEMBER 2019WISCONSIN WASTEWATER OPERATORS’ASSOCIATION, INC.Aerial view of NEW Water’s Green Bay Facility, Green Bay, WI53rd Annual W.W.O.A. ConferenceOctober 8-11KI Convention Center, Green Bay

4VOL. 232, SEPTEMBER 2019The ClarifierNEW Water, the brand of the Green Bay MetropolitanSewerage District - “The Perfect Storm”: How one utility isadapting to extreme weatherBy: Hannah Malmberg, Public affairs & education intern, NEW Water“Heavy Rains Impact Wastewater Treatment”“Torrential Rain Leads to Release of Untreated Wastewater”“Floodwaters Cause Sewage Treatment Plant to Overflow”lies, as a whole suffered as a result of this weather causingBrown County Executive Troy Streckenbach to issue adisaster declaration.These are just a few headlines from around Wisconsinin the recent past, and similar events are occurring topartners in the clean water industry around the U.S. Wetweather events are hitting wastewater treatment plantshard, and with 2018 being the wettest year on record inseveral parts of Wisconsin, plants around the state knowthis impact well.Storm Events of March 2019: A Case StudyNEW Water, the brand of the Green Bay MetropolitanDistrict, also felt the impacts of this wet weather event thatTreatment Leader Jacob Becken described as “the perfectstorm:” Rapid thawing of snow in one-to-two days’ time,a fair amount of rain, and excessive amounts of Inflow &Infiltration (I&I).In Green Bay, extreme weather events continued into2019. On March 14th and 15th 2019, heavy rainscombined with several inches of rapid snow melt causedflooding throughout the community. The flooding was sosevere it led to Governor Tony Evers declaring a state ofemergency. Brown County, the county in which Green BayThe I&I phenomenon is more significant during extremeweather events, when excess clear water from customercommunities gets into the system, takes up capacity, andthreatens operations and infrastructure. I&I is impactingthe entire clean water industry.continued on page 6

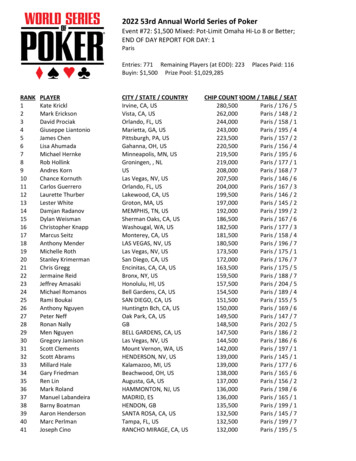

6VOL. 232, SEPTEMBER 2019The Clarifiercontinued from page 4Green Bay Facility Design DataDesign Flow, million gallons per dayAverage Flow30Maximum Daily112Design Loadings, thousand poundsBiochemical Oxygen Demand (BOD5)DesignSuspended Solids (SS) DesignPhosphorus (mg/l as P) DesignInfluent PumpsNumber4Total Installed Capacity, MGD 160Horsepower each pump900Primary ClarifiersNumber4Diameter, Feet 120Volume, MG1.25Activated Sludge SystemAnoxic BasinsNumber6Volume, MG (North Plant) 1.32Volume, MG (South Plant) 0.91Contact BasinsNumber6Volume, MG (North Plant) 2.69Volume, MG (South Plant) 1.84Final Clarifiers – North PlantNumber8Diameter, Feet125Volume, MG1.7746415Thickening—Gravity Belt ThickenersNumber3Capacity each unit (GPM)750Thickening—CentrifugeNumber1Capacity, GPM1,250Dewatering—CentrifugeNumber3Capacity each unit, GPM 150DryerNumber1Capacity, dry tons/day 51Incinerator (Fluid Bed)Number1Capacity each unit, dry tons/day 51Anaerobic DigestersNumber2Volume, MG 2.2Height110 ft.Bio-Gas GeneratorsNumber2Capacity each unit, MW 2.0Final Clarifiers – South PlantNumber2Diameter, Feet135Volume, MG1.93Emergency GeneratorsNumber2Capacity each unit, MW 2.0Return Activated Sludge PumpsNumber16Capacity Each Pump, GPM 4,500Plant Effluent Quality RequirementsC-BOD, mg/l25Suspended Solids, mg/l30Phosphorus, mg/l1.0Fecal Counts /100 ml400Process Air CompressorsNumber4Capacity Each unit (SCFM) 21K—55KOver the course of the March 2019 weather event, flowsat NEW Water’s De Pere Facility (average of eight milliongallons per day (MGD) rose from 11.9 MGD to around 50MGD with all six influent pumps running at max capacityfor 18 hours straight. The Green Bay Facility (average 30MGD) rose from 78 MGD to over 100 MGD with 5 milliongallons being transferred from De Pere. NEW Water staffworked day and night to facilitate continuous service atboth treatment plants and throughout the interceptorsystem.While both facilities were pushed to the limit, the De PereFacility in particular posed a challenge to Treatment andOperations staff. “We had to do things we had never reallydone before,” Becken said. Hydraulically, the plant couldnot handle pumping that much for that long of a periodtime and they risked washing microorganisms out of thesystem, which would take weeks to recover from. Theteam had to stop the aeration basin blowers allowing forthe microorganisms to settle into the basins until the flowscame down. “We had to think long term. Sure, it’s going tobe bad for a little bit -- but we have to protect the plant,”Becken said.continued on page 8Collection System Mysteries SolvedUNIQUE INVESTIGATIONS, ASSESSMENTS AND IMPROVEMENTS TO Provide direction and transparency Reduce risk Optimize spendingUNDERSTAND PROBLEMS AND DEVELOP SOLUTIONS TO Too much flow Backups/SSOs Structural defectsPLAN, DESIGN AND CONSTRUCT EFFICIENTLYAsk us about green infrastructure for storm water management!EXPERTS WHO WORK WITH YOU TO IMPROVE YOUR SYSTEM - CONTACT US!800.748.7423 : symbiontonline.com

8VOL. 232, SEPTEMBER 2019The Clarifiercontinued from page 6De Pere Facility Design DataDesign Flow, million gallons per day (MGD)Average Dry Weather Flow8.0Design Flow14.2Maximum Hourly - Dry Day Flow23.8Maximum Hourly - Wet Day Flow30Return Activated Sludge PumpsNumber5Capacity Each Pump, gpm 3125Design Loadings, thousand pounds per dayWaste Activated Sludge PumpsNumber2Capacity Each Pump, gpm 650Biochemical Oxygen Demand (BOD5) Design 41Suspended Solids (SS) Design28.9Phosphorus (mg/l as P) Design15Total Available Ammonium (mg/l as N)22.2MaximumInfluent PumpsNumber6Total Installed Capacity, MGD55Horsepower each pump150Two pumps conveying metro waste to100,150GBhpOf course, what impacts the treatment plant is alsoimpacting the interceptor system. And they had their ownshare of woes during this event.Mill Waste Conveyance PumpsNumber2Capacity Each Pump, gpm 750Preliminary Treatment UnitsNumber2Size, Feet50x50Final ClarifiersNumberDiameter, FeetSide Water Depth, FeetOverflow Rate at Design Flow, gpd/ft2Activated Sludge SystemAnoxic BasinsNumber2Volume, MG (Both Basins) 2.2Return Activated Sludge PumpsNumber5Capacity Each Pump, gpm 2500Contact BasinsNumber2Volume, MG (Both Basins) 4.4Tertiary Filtration Sand FiltersNumber5Hydraulic Loading at Design Flow, gpm/ft2 5HST Turbo CompressorsNumber6Capacity each unit (SCFM) 5300Horsepower each unit322UltraViolet DisinfectionNumber of Channels2Design Flow per Channel, MGD 15.0Average Dose mWs/cm230Intermediate ClarifiersNumberDiameter, FeetSidewater Depth, FeetOverflow Rate at Design Flow, gpd/ft2210013.71000Plant Effluent Quality RequirementsC-BOD mg/lSuspended Solids SS, mg/lPhosphorus P, mg/lFecal Counts/100 ml312510.94209.0101.0400Field Services opening up a siphon barrel to allow more flowcapacity to NEW Water’s DePere facilityBecken and the Operations staff were in constant contactwith the Field Services team throughout the night as theplant is always interested in whether they have crested inthe collection system. The plant can then judge what needsto done based off of what Field Services is seeing out in thefield.continued on page 10

10VOL. 232, SEPTEMBER 2019The Clarifiercontinued from page 8While Operators were handling the situation at the plant,Field Services Technicians were handling critical situationsat two locations. The East River Lift Station (ERLS) notonly had high flow alarms, but the flooding of the EastRiver was encroaching on the lift station. While there wereflood gates in the doorways, there was nothing to protectthe transformers and power was at risk of being lost. Withthe help of Maintenance staff, along with workers fromBrown County Emergency Management, Brown CountyPublic Works, Ledgeview Public Works, Brown CountySheriff’s Office, and Wisconsin Public Service, emergencysand berms were built around the transformers. Thissituation was a first not only for Field Services TeamLeader Duane Fish, but the entire Field Services team. “Inmy time here, this is the first time I’ve ever heard of watergetting up close to the transformers, which are about 10yards from the building,” he said.Fish entering a confined space to evaluate the equipment in oneof our service area list stations.RELIABLE WATER& SEWER PRODUCTSSINCE 1976ADAPTOR was founded by water and sewercontractors with the mission of providing qualitysolutions to common challenges in the field.Our American-made water and sewer productssave municipalities time andmoney, and have proveneffective time and again.adaptorinc.comGrasland waterways afterThe East Bay Shore (EBS) system was also seeing high flowrates. The EBS system includes a series of interconnectedlift stations that requires significant intervention by theField Services team and Maintenance team at high flowrates in order to operate without overflows and backups.Four people were needed at all times at the EBS lift stationsand septic haulers were called in to pump out wet wells inorder to prevent sanitary sewage overflows and basementbackups as the pumps couldn’t keep up with flows. Theloads were then brought to the Green Bay Facility.For the future, Field Services Manager Sharon Thieszensaid NEW Water is evaluating improvements to the ERLSincluding constructing a berm.Furthermore, a reduction in I&I would help mitigatestorm event impact. During these events, water volumeflowing to NEW Water can increase upwards of fivetimes the average – and that’s not because people areflushing their toilets five times as often. Leaky pipesin the interceptor system are coming from customercommunities, with up to 80% of that coming from thehomeowner pipes, according to industry statistics. Truly awicked problem, tackling I&I will require communitycontinued on page 12

12VOL. 232, SEPTEMBER 2019The Clarifiercontinued from page 10buy-in, and community partnership. NEW Water hasalready begun to engage customer communities in the I&Iproblem.Meanwhile, Becken noted that “it appears as though theintensity of some of these storms has changed. Rainfallamounts have been happening in a shorter period oftime, which almost forces a change in the way we managecertain things.”As NEW Water looks at the long-term, understanding thedifferent flow impacts to the facilities during rain events iscritical. Becken went on to note that as NEW Water goesthrough a Liquids Facility planning process, peak flowswill be analyzed, including how those flows trend, andhow they have looked historically over the past ten yearsor more. “Based off of that, we’ll look at what we needto do as an organization to make sure that we can handlewhat’s going to come our way in the future,” Becken said.Meanwhile, Becken said he is proud of the way the NEWWater team has handled events like March’s flooding.“Overall, I am very proud of the way we’ve all handled alot of these big rain events recently, especially the powerNEW Water’s Green Bay facility with the Bay of Green Bay inthe backgroundoutages,” Becken said. “Some situations could have beenterrible, and we could have been in the news big time, butwe didn’t let it get to that point.”Added Operator Mike Gardner: “I think it’s impressive thateverybody is in here working extra hard, doesn’t matterwhat time of day it is.”continued on page 14We move water.Full Service Process Control Integration and Service Expertisefor Fresh Water and Wastewater Treatment PlantsAerationAlarm SystemsCalibrationsChemical Feed SystemsControlsCross ConnectionsInstrumentation DevicesLevel MeasurementLift StationsProcess EquipmentPumps/Rotary EquipmentRemote MonitoringSCADA/Telemetry PanelsB&M Technical Service, Inc.715.228.7604bmtechservice.com

14VOL. 232, SEPTEMBER 2019The Clarifiercontinued from page 12He added that no two challenges are alike: “It’s always alearning opportunity. It seems we learn something neweach time we go through these events.”Being Prepared: NEW Water’s Proactive ApproachFor Field Services, there is little that can be done toprepare for extreme weather events as they, Fish notes, areat the mercy of gravity systems and I&I. However, FieldServices Technicians conduct weekly station checks tomake sure pumps are in good condition. If not, the pumpsare deconstructed and more often than not, “rags,” whichinclude wipes, fats, oil, grease, dental floss and other“unflushable” material, are removed. The one-to-two weekaftermath of an extreme weather event is an importanttime to check for “unflushables” in pumps as everything isbeing washed out through the system.Additionally, cleaning and televising are used in theinterceptor system to identify possible problem areas.Thieszen believes weekly station checks and maintenanceare very important preventative steps to take. “If youalready have a plugged pump going into a wet weatherevent, you are really behind,” Thieszen said.“Unflushable”–wipes, fat, oil, grease, dental floss, etc.,-are posing an increasing challenge for equipment. These photos depict“unflushables” in NEW Water’s influent pump station wet well.Jacob Becken and Craig Lawniczak examining the inside ofthe digester.The Treatment and Maintenance teams take several stepsto prepare for extreme weather events as well. Going into a rain event, the team likes to have full redundancy atboth facilities. Additional aeration basins are examined tomake sure that they are ready go and staff makes sure thattwo aeration basins are never down for maintenance at thesame time.Weather radar is monitored in the control room and ifthe storm looks as though it will be bad, the process oflooking at who is on staff to help begins. With eventsthat can happen any time of the day, knowing the crewswell is an important step of this process. Knowing who isworking, who is available, and who worked last is criticalin managing people’s wellbeing and time to sleep during along-lasting event.continued on page 16

16VOL. 232, SEPTEMBER 2019The Clarifiercontinued from page 14Knowing the structure of the plant well is also vital inan extreme weather situation. “When I first got there [inMarch], we were physically sprinting from one place to thenext because you have to do things pretty timely, becauseit happened quick and you have to make sure that certainparts of the plant can take the flow,” Becken said.When the Storms Hit: Adaptation is KeyWhen an extreme weather situation occurs, alarmsinstalled at pump stations will alert NEW Water’s controlroom when flow levels begin to rise and the pumps areunable to keep up. The control room will contact FieldServices and a minimum of two technicians, due toconfined space requirements, will be sent to monitor thesituation. The technicians will remain in contact with theplant and if the pumps are unable to keep up, the back-upplan is to call septic haulers to suck out of the wet wells.Both Thieszen and Fish agree that communication is vitalin an extreme weather situation, not only among the FieldServices team but also with the plant, back up resourcesin the community like septic haulers, and the NEW Waterteam as a whole.NEW Water staff collaborating in the control room.“We pretty much don’t let ourselves get in that position,”Becken said. “You always have to think worst case. If weget this much rain, what are we going to do?”However, given the trend of weather events coming onwith little advance notice, there is often little time toprepare. Teamwork, therefore, is key, as are experience,knowledge, and skill.Gardner said this means all hands on deck. “Whoever ishere will get together and come up with a game plan,” hesaid. However, even with preparation, storm events likethe one in March call for everyone to have to adapt quicklyon their feet.Looking to the future, NEW Water is planning tocollaborate with the community to reduce I&I, to attackcontinued on page 18Anaerobic digesters, part of NEW Water’s Resource Recoveryand Electrical Energy (R2E2) project. Launched in 2018, R2E2embraces sustainability principles to manage solids handling.The project incorporates a number of new technologies into onesystem: Anaerobic digestion, fluid bed incineration, and nutrient harvesting. By the end of 2018, NEW Water was producingnearly 40% of its own electricity for the Green Bay Facility,well on its way to the goal of 50%, reducing the need for purchased energy. To learn more, visit www.newwater.us/R2E2.

18VOL. 232, SEPTEMBER 2019The Clarifiercontinued from page 16the “unflushables” problem through enhanced publiceducation and community engagement, and continue toaddress and mitigate risk caused by these extreme weatherevents.NEW Water Executive Director Thomas W. Sigmund,P.E., praised the efforts of the staff to rally to the callwhenever needed, in order to serve the community.“Our staff demonstrate dedication and commitment atevery turn – and these extreme weather events are posingchallenges we’ve never seen before,” Sigmund said. “Iam so proud of their tireless efforts to protect our mostvaluable resource, water.”The Clarifier needs you,your stories, your opinionsDo you havesomethingto say?Have you solved aunique problem atyour plant?Won recognitionfor a job welldone?Hired someonenew?Wish to share your opinion on an issue?How about telling us about in the Clarifier?NEW Water staffThe front cover of every issue includes the followingstatement:“The Clarifier is the publication of theWisconsin Wastewater Operator’s Associationand is intended to inform and educate themembership on issues related to the treatmentand control of wastewater.All members are encouraged to contribute tothe mission of the Clarifier.”Submitting an article can be as easy as mailing a letteror sending an email. Perhaps you are not a typist ordo not have access to a computer? No problem, justwrite your thoughts down on a piece of paper and wewill do the rest.Or give me a call and we will figure something out.Jon Butt, Clarifier Editorc/o Symbiont6737 W. Washington St., Suite 3440Milwaukee, WI 53214Jon.butt@symbiontonline.comOffice: 414-291-8840

Over the course of the March 2019 weather event, flows at NEW Water's De Pere Facility (average of eight million gallons per day (MGD) rose from 11.9 MGD to around 50 MGD with all six influent pumps running at max capacity for 18 hours straight. The Green Bay Facility (average 30 MGD) rose from 78 MGD to over 100 MGD with 5 million