Transcription

REFURBISHMENTCONCRETE REPAIRSITE HANDBOOKHAND PLACED AND SPRAYED APPLICATIONS

CONCRETE REPAIR SITEHANDBOOKCONTENTBEFORE APPLICATION4Health and Safety5Technical and Safety Information6Bag Layout7Climate Conditions8EquipmentCONCRETE REPAIR PROCEDURE1234101 Substrate Preparation122 Reinforcement Preparation133 Reinforcement Corrosion Protection144 Bonding Primer155a Repair Application by Hand165b Repair Application by Spray176 Smoothing MortarAFTER APPLICATION18Curing Protection / Curing MethodsADDITIONAL INFORMATION1. Sika MonoTop /SikaTop Armatec Reinforcement corrosion protection and bonding primers2. Sika MonoTop , SikaTop Repair and profiling mortars3. Sika MonoTop , SikaTop Pore sealer/ smoothing mortars4. Sikagard Protective coatings and hydrophobic impregnations19Mixing One-, Two-, and Three-Component Products20Overhead Application21Cleaning Tools / Environment / AccidentsSIKA REPAIR SYSTEMS22242Concrete OverviewWE ARE SIKASika is on Your Project Site3

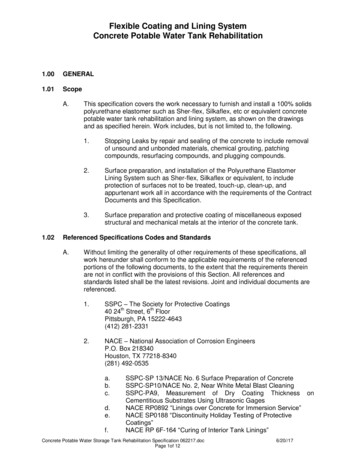

HEALTH AND SAFETYTECHNICAL AND SAFETYINFORMATIONWORK SAFELY!SICHERHEITSDATENBLATTgemäß Verordnung (EG) Nr. 1907/2006Sika MonoTop -412 EcoÜberarbeitet am 24.11.2016Version 1.0Druckdatum 24.11.2016ABSCHNITT 1: Bezeichnung des Stoffs beziehungsweise des Gemischs und des Unternehmens1.1 ProduktidentifikatorHandelsname:Sika MonoTop -412 Eco1.2 Relevante identifizierte Verwendungen des Stoffs oder Gemischs und Verwendungen, von denen abgeraten wirdProduktverwendung: Zement / Mörtel1.3 Einzelheiten zum Lieferanten, der das Sicherheitsdatenblatt bereitstelltFirma: Sika Österreich GmbHBingser Dorfstraße 236700 Bludenz: 4350610: EHS@at.sika.comTelefonEmail-AdresseMETHOD STATEMENTRepairing Concrete Using Sika Readyto use Mortars1.4 Notrufnummer: 0043 1 4064343 (Giftinformationszentrale Wien)EHS@at.sika.comNotrufnummerABSCHNITT 2: Mögliche Gefahren2.1 Einstufung des Stoffs oder GemischsJULY 2014 / V2 / SIKA SERVICES AG / D TAYLORProduktart:GemischEinstufung (VERORDNUNG (EG) Nr. 1272/2008)FOR LOCAL TRANSLATIONReizwirkung auf die Haut, Kategorie 2Schwere Augenschädigung, Kategorie 1Spezifische Zielorgan-Toxizität - einmalige Exposition, Kategorie 3, AtmungssystemH315: Verursacht Hautreizungen.H318: Verursacht schwere Augenschäden.H335: Kann die Atemwege reizen.2.2 KennzeichnungselementeKennzeichnung (VERORDNUNG (EG) Nr. ahrenhinweise:H315H318H335Verursacht Hautreizungen.Verursacht schwere Augenschäden.Kann die Atemwege reizen.Sicherheitshinweise:P101Ist ärztlicher Rat erforderlich, Verpackungoder Kennzeichnungsetikett bereithalten.Land AT 100000015001METHOD S TATEMENT́ Repairing ConcreteUsing Sika Readyto use Mortarś Detailed stepby-step guide toconcrete repairPRODUCTDATA SHEET́ Product useś Substrate qualitý Substratepreparatioń Mixing ratió Application conditions and toolś Pot lifé Curing treatment́ Limitations1 / 12SAFETYDATA SHEET́ Hazardś First aid́ Emergencý EcologyCONSULT PRODUCT DATA SHEET AND SAFETYDATA SHEET BEFORE STARTING WORK.45

BAG LAYOUTCLIMATE CONDITIONSEXAMPLESTORAGÉ Dry and cool conditionś Undamaged original packaging1. PRODUCT NAME2. MAIN DESCRIPTION AND PRODUCTCHARACTERISTICS123. BAG SIZEAPPLICATIONProtect area from:́ Direct sunlight́ Wind́ Raiń Frost3TEMPERATURECheck acceptable limits:́ Ambient temperaturé Substrate temperatureDO NOT MIX AND APPLY THEPRODUCT IN DIRECT SUNLIGHT.67

EQUIPMENTSPRAY EQUIPMENTHAND TOOLSWET SPRAY PROCESSMixing toolsMixing containerWet mixCompressed airHydraulic conveyance(dense stream)TrowelsCompressed airAir stream conveyance(thin stream)VariableSpongeDRY SPRAY PROCESSDry mixBrushesCompressedairMAKE SURE TOOLS AND EQUIPMENTS ARECLEAN AND WELL MAINTAINED.Air stream conveyance(thin stream)Compressed airand Water feed8Variable9

1 SUBSTRATE PREPARATIONSURFACE PREPARATIOŃ Mark defective concreteEXTENT OF CONCRETE REMOVAĹ Remove concrete minimum 15 mmbehind main barsCONCRETE REMOVAĹ Using a high pressure water jet, 1,100bar (large area)Minimum15 mmoŕ With a hammer drill (medium area)CORRECT SUBSTRATE PREPARATIOŃ Rough surface (2 mm minimum)́ Cut sides more than 90 to avoidundercutting and maximum 135 toreduce debonding around edgeś Substrate shall be sound with no loosematerialoŕ Hammer and chisel (small patch repairs)REMOVE TIE WIRES, NAILS ETC.REMOVE ONLY DEFECTIVE CONCRETEAS INSTRUCTED.INFORM A SUPERVISOR IMMEDIATELYIF THERE ARE ANY CRACKS IN THE SUBSTRATE.DO NOT REDUCE STRUCTURAL INTEGRITY.1011

2 REINFORCEMENTPREPARATION3 REINFORCEMENTCORROSION PROTECTIONCLEANING REINFORCEMENTRemove ALL:APPLICATION OF CORROSION PROTECTIOŃ Apply two 1 mm thick coats(total 2 mm minimum)́ Tie wireś Mortar/concreté Rust/scalé Other loose materialREMOVAL TECHNIQUES1. Steel wire brush or hand/power toolsTechnique applicable only in carbonated concrete and under environmental constraintswhere techniques 2 and 3 cannot be used.́ Reinforcement uniformly cleaned2. Abrasive blast cleaning techniqueś Reinforcement uniformly cleanedFIRST COAT MUST BE HARDENED BEFORE ITIS READY FOR THE SECOND COAT. PRIOR TOAPPLYING THE REPAIR MORTAR, THE CORROSION PROTECTION MUST BE DRY.APPLICATION TECHNIQUEŚ Hopper spray for large applicationś If chlorides are present reinforcementshould be cleaned with water afterwards3. High pressure water jetting (1100 bar min)́ Reinforcement uniformly cleanedINFORM A SUPERVISOR I MMEDIATELY OF ANYBADLY DAMAGED REINFORCEMENT.12oŕ Brush for small applicationś Inspect bars after to ensure full coverageUSE TWO BRUSHES SIMULTANEOUSLY TOENSURE FULL APPLICATION BEHIND BARS.13

4 BONDING PRIMER5a REPAIR APPLICATIONBY HANDAPPLYING BONDING PRIMER(if specified)́ Wet the substrateSURFACE PREPARATION(if no bonding primer applied)́ Wet the substraté Wipe away excess wateŕ Wipe away excess waterSmall area:with spongeSmall area:with spongeLarge area:with air pressureAPPLICATION TECHNIQUEŚ For small patches brush firmly onto surfaceLarge area:with air pressureAPPLICATION TECHNIQUEŚ Press the repair mortar firmly into the repairarea using a trowel and/or handAPPLY SECOND COAT, WHEN FIRST COAT ISDRY (IF APPLICATION DEPTH EXCEEDS PRODUCT’S MAXIMUM COAT THICKNESS).́ For large areas spray on with hopper guń Profile the surface and finish with a trowelPOINT GUN AT DIFFERENT ANGLES ON THESURFACE TO ENSURE EVEN APPLICATIONBEHIND THE BARS.FOR BEST RESULTS, FINISH THE SURFACEWITH A PVC OR W OODEN TROWEL.DO NOT SPRAY A DDITIONAL WATER OVERTHE SURFACE.1415

5b REPAIR APPLICATIONBY SPRAY6 SMOOTHING MORTARSURFACE PREPARATIOŃ Wet the substrate(if no bonding primer applied)SURFACE PREPARATIOŃ Wet and clean the surface with water(180 bar)́ Wipe away excess waterSMOOTHING OR LEVELLING MORTAŔ Apply vertically using toothed troweĺ Apply with trowel approximate 45 to surfaceSmall area:with spongeLarge area:with air pressureAPPLICATION TECHNIQUÉ Point nozzle 200 mm to 500 mm fromsurfacé Finish with a PVC or wooden trowelMAKE SURE VOIDS ARE FILLED BEHINDBARS. POINT SPRAY NOZZLE AT DIFFERENTANGLES TO THE SURFACE.IF SECOND COAT IS REQUIRED, SURFACESHOULD NOT BE TOO SMOOTH.16USE DIFFERENT SIZE TOOTHED TROWEL FORREQUIRED COAT THICKNESS.́ When the first coat is hard, apply second coat́ After product has set, smooth surface usinga wooden trowel0.25 – 4 hours17

AFTER APPLICATIONADDITIONAL INFORMATIONMixingCURING PROTECTIONProtect application from:́ Frost́ Rain*́ Wind*́ Sun*ONE-COMPONENT SYSTEM(e.g. Sika MonoTop )́ Add powder to water and mix at least for3 minutes with a low speed mixer* Apply as soon as possible after application to avoid surfacecracking / crazingDO NOT MIX POWDERS FROM DIFFERENTPRODUCTS. DO NOT ADD MORE WATER THANRECOMMENDED.CURING METHODŚ Plastic sheetinǵ Fabric and wateŕ Other membranesTWO-COMPONENT SYSTEM (e.g. SikaTop )́ Shake component A thoroughly and pour intoa clean containeŕ Add in powder component B and mix at leastfor 3 minutesABDO NOT ADD EXTRA WATER.́ If no subsequent coating is to be applied onthe surface an approved curing agent (e.g.Sika A ntisol ) could be used.BTHREE-COMPONENT SYSTEM(e.g. SikaTop Armatec EpoCem )́ Shake component A B separatelý Mix components A B togetherADO NOT CONTAMINATE MIXTURE WITH OTHERCHEMICALS.́ Add A B to powder component C and mixfor at least 3 minutes with a low speed mixerADJUST CONSISTENCY TO SUIT CONDITIONSUSING POWDER C OMPONENT C. REFERTO PRODUCT DATA SHEET FOR MORE INFORMATION.18A BC19

ADDITIONAL INFORMATIONHINTS AND ADVICEOverhead applicationCleaning tools / environment / accidentś Apply mortar tightly behind reinforcementuntil bars are coveredCLEANING TOOLŚ Clean immediately with water after use.Hardened material can only be removedmechanically.́ Press firmly to ensure pores in concretesubstrate are filledENVIRONMENT́ Dispose of waste responsiblý Separate recycling materialś From same end apply second coat in samedirection as first́ Repeat coats until void is filledACCIDENTŚ Seek immediate medical attention in theevent of an injurý Smooth surface using a wooden trowel2021

SIKA CONCRETE REPAIR SYSTEMSPRODUCTTYPEAPPLICATION METHODSDESCRIPTIONSika MonoTop -352 NFGLight Weight Structural Repair MortarHandWet sprayedR3 Normal setting, 4-75mmSika MonoTop -412 NFGStructural Repair MortarHandWet sprayedR4 Normal setting, 6-50mmSika MonoTop -612NStructural Repair MortarHandWet sprayedR4 Normal setting, 5-100mmSika MonoTop -436NStructural Repair MortarForm PourR4 Normal setting, 30-300mmSikaQuick -2500 (au)Rapid Hardening MortarHandVery rapid hardening, gain early strength, 5-150mmSikaGunite -GPStructural Repair MortarDry SprayGeneral purpose gunite dry spray, 20-150mmSika MonoTop -FCFairing CoatHandWet sprayedUp to 3mmSika MonoTop -723NSmoothing MortarHandWet sprayedR3 mortar, 1-5mmSikaGard -720 Epocem Damp Substrate Pore SealerHandWet sprayedR4 Epoxy cementSika MonoTop -910NBonding primer and reinforcementcorrosion protectionHandWet sprayedNormal useSikaTop -110 Epocem Bonding primer and reinforcementcorrosion protectionHandWet sprayedDemanding useSikadur 32Bonding primerHandWet sprayedLong open life2223

EVERYDAY, EVERYWHERESIKA IS ON YOURPROJECT SITEYOU CAN RELY ON our experienced construction expertsavailable in every phase of the construction process forvaluable advice: from the initial consultation phase,through the project planning phase, the detailed designphase, application on site and finishing with qualitycontrol, completion and final handover.Our knowhow in projects is based on more than 100 years of onsiteexperiences, which enables us to provide recommendations andlong-lasting solutions for any project you have, no matter how largeor small. Such projects include:CIVIL ARCHITECTURE Residential buildings Educational buildings Office buildings Transportation buildings Cultural buildings Sports facilities Commercial buildings Healthcare facilities Communication facilities Judiciary buildings Landscape architecture Mixed-use highrise buildings Other domestic buildings /structures24INDUSTRIAL FACILITIES Research / lab / testbuildings Industrial buildings Other industrial structuresINFRASTRUCTURE Water infrastructure Transportation infrastructure Power plants Mining Other infrastructure25

GLOBAL BUT LOCAL PARTNERSHIPSWE ARE SIKASika is a specialty chemicals company with a leading position in thedevelopment and production of systems and products for bonding, sealing,damping, reinforcing and protecting in the building sector and the motorvehicle industry. Sika's product lines feature concrete admixtures, mortars,sealants and adhesives, structural strengthening systems, flooring as well asroofing and waterproofing systems.

SITE HANDBOOK HAND PLACED AND SPRAYED APPLICATIONS. 2 3 1. Sika MonoTop / SikaTop Armatec Reinforcement corrosion protec-tion and bonding primers 2. Sika MonoTop , SikaTop Repair and profiling mortars 3. Sika MonoTop , SikaTop . ́ Substrate shall be sound with no loose material. 12 13 2 REINFORCEMENT PREPARATION