Transcription

GratingProducts

Our GratingProductsHave YourFlooringNeedsCovered2GRATINGOur grating consists of load-bearing bars in avariety of depths and thickness’s, with lateralrestraint provided by 6mm square twisted crossbars.These are then forge-welded to the upper edgesof the load-bearing bars, producing a productof one-piece construction with a high strengthto weight ratio, which in turn meets therequirements of Australian Standard AS1657.Serrated GratingHas a serrated edge bar for enhanced anti-slipproperties. Serrated load bars are not availablefor 20mm deep grating.Below are examples of applications wheregrating can be used: Power plants Petrochemical facilities Mining operations Industrial construction Ship building Paper mills transportation (highway and rails) Wastewater treatment plantsNote: For sloping walkways 10mm x 10mm squarebar can also be welded on the top of the gratingto meet requirements of AS1657. Metallurgical plantsHow to Specify Grating Profiles Communication facilitiesWhen ordering, use the code break up belowto detail your chosen grating profile: Commercial facilities and other commercial,industrial and infrastructure projects Flooring in corrosive locationsWe can supply grating in standard and fabricatedpanels or customised to project specifications,ready for immediate installation.Types of GratingOur grating is available in either a plain surfacefor standard applications or serrated, oftenutilised when higher slip resistance is required.Plain (Standard) GratingHas a plain edge load bar and twisted cross rods.Rapid PerforatingPart No: R 30 A 325 MPURRapid grating30 Load bar pitchACross bar pitchA 100mm orB 50mmMMild steelPPlainP Plain orS SerratedUUntreated325 Bar size32 x 5Need Help?With over 60 years of combined experience,our team are the experts when it comes to findingthe right product for you.3

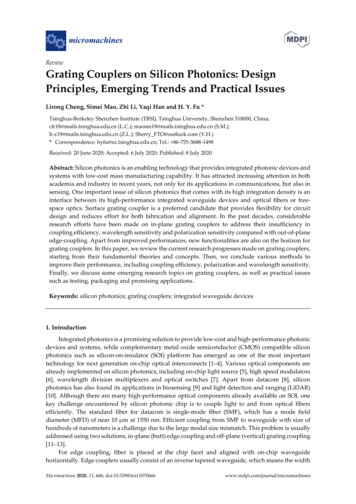

R40 ProfileNon-Standard – 50mm CrossbarNon-Standard – 50mm Crossbar50mm crossbar centers100mm crossbar centers30 loadbar centers30 loadbar centers30 loadbar centers30 loadbar centersStandard – 100mm CrossbarNon-standard50mm crossbar centers40 loadbar mcrossbarcentersStandard100mm crossbar centers40 loadbar centersStandard – 100mm CrossbarNote: All 50mm crossbar centres, to be ordered.When to use R30Note: All 50mm crossbar centres, to be ordered.Quick Selection ChartR30 can be utilised in projects that requirea high load-carrying capacity.Maximum span (mm)For various loads with 5.00mm deflectionRapid Grating TypeWalkway SafetyWhen choosing this product for your projectconsider using serrated for areas that requiresuperior walkway safety.High Impact LoadTo ensure this product meets your high impactload requirements utilising profile with crossbars at 50mm centres is favourable.2.5 kPa4.0 kPa5.0 kPa7.5 0A-7563830340032202900When to use R40Quick Selection ChartPerfect for use as conveyor walkways,mezzanine floors and walkways.10018.8R30B - 2035021.8R30A - 20510029.5R30B - 2055032.5R30A - 25310022.8R30B - 2535025.8R30A - 25510036.2R30B - 2555039.2R30A - 32310028.4R30B - 3235031.4R30A - 32510045.5R30B - 3255048.5R30A - 40310034.9R30B - 4035037.9R30A - 40510056.2R30B - 4055059.2R30A - 45510062.9R30B - 4555065.9R30A - 50510069.6R30B - 5055072.6R30A - 55510076.2R30B - 5555079.2R30A - 65510089.6R30B - 6555092.9R30A - 756100122.9R30B - 75650An economical choice when price is a priority,load bars spaced further apart giving you alighter alternative to other profiles withoutseverely compromising strength.Walkway SafetyWhen choosing this product for your projectconsider using serrated for areas that requiresuperior walkway 565X575X62.5 kPa4.0 kPa5.0 kPa7.5 cal application loadings: 2.5 kPa – Conveyor walkways and light accessplatforms, 4 kPa – Standard Australian pedestrian platform, 5 kPa – Britishstandard pedestrian platform, 7.5 kPa – Boiler house platform (e.g. Power 5120013501500165018001950210024002700NOT 264.6117.566.442.3625.313.78.02U Safe uniformly distributed load inkPa (or kN/m2)NOT RECD Deflection (mm) at mid-spancaused by .2410.126.320.876Spans shown have maximum 5mmdeflection, which is limiting deflectionfor pedestrian 24.12555550.951N/AR40A - 20310014.6R40B - 2035017.6R40A - 20510022.5R40B - 2055022.5R40A - 25310017.5R40B - 2535020.5R40A - 25510027.4R40B - 2555030.4R40A - 32310021.7R40B - 3235024.7R40A - 32510034.2R40B - 3255037.2R40A - 40310026.4R40B - 4035029.4R40A - 40510042.1R40B - 4055045.1R40A - 45510047R40B - 4555050R40A - 50510051.9R40B - 5055054.9R40A - 55510056.8R40B - 5555059.8R40A - 65510066.6R40B - 5X565X5Spans rated EdgeConversionFactor60046Nom.load barsize (mm)450101Mass kg/m2300UCross Bar Pitch(mm)Spans (mm)Grating TypeSafe Load and Deflection TableSerrated EdgeConversionFactorNom.load barsize (mm)Mass kg/m2Cross Bar Pitch(mm)Grating TypeSafe Load and Deflection TableMaximum span (mm)For various loads with 5.00mm deflectionRapid Grating TypeTypical application loadings: 2.5 kPa – Conveyor walkways and light accessplatforms, 4 kPa – Standard Australian pedestrian platform, 5 kPa – British standardpedestrian platform, 7.5 kPa – Boiler house platform (e.g. Power stations).R30A - 203GRATINGR30 ProfileNOT 52.9429.919.0411.36.14U Safe uniformly distributed load inkPa (or 519.0310.26NOT RECD Deflection (mm) at mid-spancaused by .937.560.876Spans shown have maximum 5mmdeflection, which is limiting deflectionfor pedestrian .991.552.233.033.96555555550.9430.951Note: for galvanised fabricated grating add 12% to massNote: for galvanised fabricated grating add 12% to mass4Rapid Perforating5

Metal Grating Finish OptionsCustom Orders OnlyGRATINGR60B Profile60 LOADBAR CENTERS50mm CROSSBAR CENTERSWhen to use R60BQuick Selection ChartLarge openings make this profile the ideal flooringchoice for areas where material spillage build upis a concern.Maximum span (mm)For various loads with 5.00mm deflectionRapid Grating Type2.5 kPaLoad bars spaced further apart giving you a lighteralternative to other profiles however not suitable forhigh impact loadsWalkway SafetyWhen choosing this product for your project,consider using serrated for areas that requiresuperior walkway safety.4.0 kPa5.0 kPa7.5 45244523302090Typical application loadings: 2.5 kPa – Conveyor walkways and light accessplatforms, 4 kPa – Standard Australian pedestrian platform, 5 kPa – Britishstandard pedestrian platform, 7.5 kPa – Boiler house platform (e.g. Power stations).501915.720X525X3R60B - 2555022.325X5R60B - 3235018.532X3R60B - 325502732X5R60B - 4035021.740X3R60B - 4055032.340X5R60B - 4555035.745X5R60B - 505503950x5R60B - 555R60B - 655505042.44955x565x5Serrated EdgeConversionFactorNom.load barsize (mm)Mass kg/m2Cross Bar Pitch(mm)Grating TypeR60B - 25350Floor Plate10x10sq BarGrating can also be suppliedwith flattened expanded metalwelded to the underside to preventtools and small objects fromfalling through.Grating can be supplied with a5mm floor plate welded to the top.Grating can be offered with 10x10sqbar welded at 300mm centres (nominal).This is ideal on walkways, with an inclineof 7 degrees or greater as it will reducethe chance of slipping.How to order:1. Select your grating.This option is used in applicationssuch as wet areas where wateris directed to a specific drainagelocation.How to order:How to order:1. Select your grating.2. Decide on material type, andfinish/coating if required.2. Decide on material type, andfinish/coating if required.3. Select a required expandedmesh profile. The most commonprofile is EX1220F (Flattened).This option is also beneficial as it meetsthe requirements of AS1657.3. Select floor plate.1. Select your grating.2. Decide on material type, andfinish/coating if required.3. Request square bar.HeelguardSafe Load and Deflection TableR60B - 205Expanded MetalSpans 23.2355105012001350150016501800195021002400NOT 55U209.993.3252.4533.5823.3213.928.15U Safe uniformly distributed load inkPa (or kN/m2)NOT RECD Deflection (mm) at midspancaused by U0.876Spans shown have maximum 5mmdeflection, which is limiting deflectionfor pedestrian 03.866.446.1133.8822.6714.159.276.33Heelguard Mild Steel and HDG Grating is the ideal solutionfor areas with frequent pedestrian access as it is aestheticallypleasing, it’s also a perfect choice for wine tank platforms.Featuring a 9mm gap between the bars set at 12.5mm centres,our grates are ideally suited to public spaces, parks, plazas,railway stations, viewing platforms, and outdoor shoppingcentres. It’s also constructed with your safety in mindcomplying with the new Australian Standards.We can also offer drainage items made from Heelguardsuch as trench grates and pit covers.Load Charts0.9224.46This table is theoretical and is based on a uniformly distributed load of 300 kg/m2 (5 500Stress (kg/mm2)0.901.131.351.652.162.733.37Deflection 560.991.552.233.033.9655555550.9370.943This table is theoretical and is based on a uniformly distributed load of 500 kg/m2 (5 kPa)Note: for galvanised fabricated grating add 12% to massSpan600750900105012001350Stress (kg/mm2)1.501.882.252.763.604.5615005.63Deflection (mm)0.220.420.721.202.063.305.03Stock Sheet Size: 993mm x 4000mm LB (197.55 kg/sheet)Code: Heelguard R12.5A-253 (Load Bar 25x3 FB @ 12.5mm pitch, cross bar @ 100mm pitch)6Rapid Perforating7

Fixing AccessoriesGRATINGMetal Step TreadsRG Clip – GalvanisedOur Galvanised EX Clip is the most common method of securinggrating to the structural supports. Using a minimum of 4 clipsper m2, these clips are installed from the top of the grating.T1T2T3Welded fixing, no nosing.Bolted fixing, no nosing.Welded fixing, floor plate nosing.Metal Drain GratesT5T6Bolted fixing, floor plate nosing.Welded fixing, abrasive nosing.Bolted fixing, abrasive nosing.Dim ‘A’457575Series 30T2 - T6125155185Series 40T2 - T6125165Series 60T2 - T6155215100100100100215205245275305245285325Series 6027525 & 32mm Grating EndplateLoad Bar Size25 x 532 x 540 x 5Series 3090013001600Series 4075012001500500800130040mm Grating EndplateWidth varies5mm plateØ14 holesDim A2525Dim A25NosingOur nosing options can be retrofitted to gratingstair treads, as opposite: AS/NZS 1594:2002Hot rolled steel flat productsPlease have theopposite informationready before you do.8Ᏼ Tread size e.g.750 x 215mm.D Grate DepthB Grate SizeE Frame DepthNominal WheelLoading (Kg)ServiceabilityDesign Load (kN)Ultimate LimitDesign Load (kN)Class A – Extra Light DutyAreas include footways, accessible only to pedestrians and pedal cyclists and closed toother traffic.3306.710Class B – Light DutyAreas including footways and light tractor paths accessible to vehicles (excludingcommercial vehicles) or livestock.26705380Class C – Medium DutyMalls and areas open to slow moving commercial traffic.5000100150Class D – Heavy DutyCarriageways of roads and areas open to commercial vehicles.8000140210LoadBarLarge CarWheel LoadWheel load 495kg130x130 tyre contactarea.Ᏼ Grating type andload bar surface e.gR30A-325 serrated.A Clear OpeningC Overall Frame ISO/IEC 17025:2005Competence of testing andcalibration laboratoriesCodesReadyto Order?A AS/NZS 4680:2006Hot-dip galvanisingTraffic Conditions15251006075505mm plateØ14 holesCB Weld one side every load barWidth Varies1565 AS 3996-2006Access covers and gratesRecommended maximum lengthHole CentresOverall c 200mm100ERecommended standard widthsDrain Gate DimensionsOur drainage grates are availablemade to order and comply withAustralian Standards as follows:DT4Ᏼ Bolt in or weldin treads.Ᏼ Nosing typerequired.Ᏼ Quantity oftreads required.Ᏼ Material finishe.g. galvanisedor mill finish.RDG30-2552 Tonne Forklift5 Tonne Forklift5 Tonne TruckWheel load 1865kg130x140 tyre contactarea.Wheel load 1690kg170x170 tyre contactarea.Wheel load 1690kg170x170 tyre contactarea.---Axle Load9.8 TonneDual Wheel14.3 TonneDual WheelEach axle end wheelload 2450kg 200x200contact area.Each axle end wheelload 3580kg 250x200tyre contact 530395685590555Rapid Perforating9

Quoting RequirementsOverall DimensionsLet us do the Hard Work175182517524017216131952265017297165075 typical stanchion 51611840175463Customer LayoutAll safe load tables were calculated in accordancewith the following criteria:1. Loading code AS1170-1 (load combination1.25 x dead load and 1.5 x live load)End Flat Lean25mmEdge bars and attachments are welded witha minimum 3mm fillet weld to one side of: Every 3rd load bar on R6010mm nominal gapTransverse BowLongitudinal BowLoadbars1mm per 200mm of widthPanel Width9455. Load calculated with allowablebending stress of 171.6 MPa (0.66 Fy)1106Marking PlanOrder ExampleLoadbarsLoadbars1mm per 100mm of width9957. Spans based on maximum 5mmdeflection, which is a limiting deflectionfor pedestrian comfortPanel Length1mm per 100mm of width9954. Minimum yield strength of steel 260 MPa6. Load bars assumed to be simplysupported and unserrated Every 4th load bar on R40Cutout taken to nearest loadbar9953. Mass calculated on untreatedand un-edged gratingFabrication Welding1mm11472. Steel structures code AS4100 Every 5th load bar on R30Panel Width880Design Criteria 5mm crossbars bow10mm nominal gap175ABRASIVE NOSING1050D1 d 6mmPanel Length1635175Width (w) 3mmW1 w 6mmWidth (w) 6mmLoadbar length 6mm751150By sending through your floor plan, our experiencedestimating team will provide you with a detailedmarking plan and panel drawings for your finalapproval. Our team is committed to working closelywith you on every project regardless of size toensure we offer you the most economical layoutwhich in turn saves you time and money.Length 0mm, —3mmd620075863Cross Bars Spacing & AlignmentGRATINGMetal Grating TolerancesLoadbars1mm per 200mm of widthOne Platform – 2000mm Load Bar Span x 5380mm WideThe illustration below shows a typical layout. The platform is split up intostandard stock panel widths of 995mm, plus a cut and joined end panel withthe width taken to the nearest load bar to match the required dimension.Note: Make-up panels of less than 400mm in width will be welded to theadjacent panel.5380995Radius cutouts to have minimum 25mm clearance25mm boaringminimum (typical)KickplateAngle thickness109951013601010mm nominalCUT & JOINED10mm100mm minimum10mmKickplate1010mm nominal25mm boaringminimum (typical)10mm nominalLoadbars (typical)10mm nominal10mm nominal100mm minimumLoadbars (typical)1099515mm nominal200010mm nominal99510mm nominalRapid Perforating11

Our fibreglass grating is a one mesh patternutilising a 38x38mm grid, with an open area of70%. The 6mm load-bearing bars mean that ourfibreglass grating is bi-directional, so no loadbar direction is required, making it a simple yetversatile flooring option.Fibreglass Step TreadsBenefits of Fibreglass: Strength vs weight – Fibreglass grating islight-weight yet still retains its ability to evenlydistribute applied loads to adjoining bars Non-sparking, non-magneticand non-conductiveOur fibreglass grating is available in either 25mmor 38mm thick and can also be supplied witha diamond cover or gritted top when greatertraction is required. Easy to cut on site using standard cutting toolsOur fibreglass grating treads are madeto order and can be manufactured to suityour requirements.These treads are manufactured with the attributesof a T5 grating step tread.Fibreglass grating treads are the perfect solutionwhen the treads are required to be:GRATINGFibreglass GratingReadyto order?Please have tread size& quantity requiredready before you do. Corrosion resistant Corrosion resistant No load bar direction required (bi-directional) Strong Fire resistant25mm Square Mesh38mm Square Mesh25mm Deep, 38mm SquareNote: Stock panels available in an industrystandard size of 310 x 3660mm.38mm Deep, 38mm SquareFixing AccessoriesWeight: 52kg OA: 70% Load Bar Thickness: 6mmStock Panel Size: 1220 x 3660mmFRP Clip – 316 Stainless SteelWeight: 83kg OA: 70% Load Bar Thickness: 6mmStock Panel Size: 1220 x 3660mmOur EX Clip in 316 Stainless Steel is the most commonmethod of securing fibreglass grating to the structuralsupports. Using a minimum of 4 clips per m2, the clipsare installed from the top of the fibreglass grating.Load Charts3 kPa - This table is theoretical and is based on a uniformly distributed load of 300 kg/m2 (3 kPa)Product CodeMass kg/m2ColourResinFRP25MM12.1Green or YellowFRP38MM18.6Green or YellowSpan (mm) vs Deflection 0.10.61.84.312008.95 kPa - This table is theoretical and is based on a uniformly distributed load of 500 kg/m2 (5 kPa)Product CodeMass kg/m2ColourResinFRP25MM12.1Green or YellowFRP38MM18.6Green or YellowSpan (mm) vs Deflection 2007.114.8Mini Mesh38mm Deep, 19mm SquareWeight: 70kgs / 105kgs OA: 40% Load Bar Thickness: 6mm Stock Panel Size*: 1220 x 2440mm & 1220 x 3660mm*Contact your local branch for availabilityLoad ChartThis table is theoretical and is based on a uniformly distributed load of 350 kg/m2 (3.5 kPa) & 500 kg/m2 (5 kPa)Product CodeSpan (mm) vs Deflection (mm)Mass kg/m2ColourResinkPa300450600750900FRP38 MINIMESH23.5Dark GreyIsopthalic3.5 kPa 0.260.340.911.134.666.2FRP38 MINIMESH23.5Dark GreyIsopthalic5 kPa0.320.451.31.626.198.2121200Rapid Perforating13

Have Questions?We are Here to Help!Victoria – EppingNew South WalesSouth AustraliaP 03 8405 3609E sales@rapidperf.com.auP 02 8292 1104E sales.nsw@rapidperf.com.auP 08 7078 5922E sales.sa@rapidperf.com.au26 Yale DriveEpping VIC 307629 Broadhurst RoadIngleburn NSW 25655 Woodlands TerraceEdwardstown SA 5039Victoria – CoolarooQueenslandHead OfficeP 03 8592 9444E grating@rapidperf.com.auP 07 3063 1202E sales.bris@rapidperf.com.auP 03 8405 3609E admin@rapidperf.com.au42 Maffra StreetCoolaroo VIC 30482/17 Learoyd RoadAcacia Ridge QLD 411071 Yale DriveEpping VIC 3076Product KeyPerforated MetalGratingHandrailExpanded Metalrapidperf.com.au

Types of Grating Our grating is available in either a plain surface for standard applications or serrated, often utilised when higher slip resistance is required. Plain (Standard) Grating Has a plain edge load bar and twisted cross rods. R Rapid grating 30 Load bar pitch A Cross bar pitch A 100mm or B 50mm 325 Bar size 32 x 5 M Mild steel