Transcription

Construction Concerns: Job Site Fuel Storage, Part 1Article by Gregory HavelAugust 10, 2015Most construction job sites have power tools and equipment that use liquid or gaseousfuels. This article will discuss the storage of flammable and combustible liquids in smallquantities. Future articles will discuss the storage of flammable and combustible liquidsin larger quantities as well as the use of natural gas and liquefied propane (LP) gas.The requirements for the storage and dispensing of flammable and combustible liquidsmay be found in National Fire Protection Association (NFPA) 30, Flammable andCombustible Liquids Code, 2015 edition. This code—or an earlier edition—isincorporated by reference into many state and municipal building and fire codes.The U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA)regulations on the storage and dispensing of flammable and combustible liquids, in 29CFR 1910.106 and 1926.152, incorporate much of the language from an early edition ofNFPA 30. Although the details may not be identical when comparing present NFPAcodes with OSHA regulations, the principles and definitions are the same.According to the NFPA codes and OSHA regulations, safety cans are required forstorage and dispensing of small quantities of combustible and flammable liquids onconstruction job sites. The definitions below are quoted from NFPA 30 Flammable andCombustible Liquids Code, 2015 edition:3.3.33.1 Combustible Liquid. Any liquid that has a closed-cup flash point at orabove 100 F (37.8 C) as determined by the test procedures and apparatus setforth in Section 4.4. Combustible liquids are classified according to Section 4.3.3.3.33.2* Flammable Liquid. Any liquid that has a closed-cup flash point below100 F (37.8 C), as determined by the test procedures and apparatus set forth inSection 4.4, and a Reid vapor pressure that does not exceed an absolutepressure of 40 psi (276 kPa) at 100 F (37.8 C), as determined by ASTM[American Society for Testing and Materials] D 323, Standard Test Method forVapor Pressure of Petroleum Products (Reid Method). Flammable liquids areclassified according to Section 4.3.3.3.48* Safety Can. A listed container of not more than 5.3 gal (20 L) capacityAugust 10, 2015

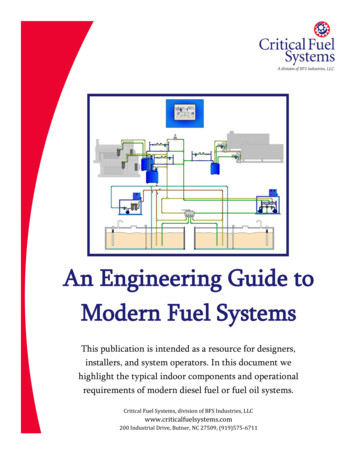

having a screen or strainer (flame arrester) in each fill-and-pour opening andhaving a spring-closing lid and spout cover designed to safely relieve internalpressure when exposed to fire.Metal safety cans (photo 1) are manufactured to comply with the standard AmericanNational Standards Institute (ANSI)/Underwriters Laboratories (UL) 30, Metal SafetyCans.(1)Safety cans are also made of high-density polyethylene (HDPE) with metal fill caps, pourspouts, and flame arresters. However, in larger sizes, these may not meet the OSHAand NFPA regulations for some flammable or combustible liquids. These plastic safetycans look like metal safety cans, except that the shell is plastic rather than paintedmetal. These must not be confused with the low-priced plastic Department ofTransportation containers for flammable and combustible liquids that are sold forhousehold use by hardware and home improvement stores, which have no flamearrester, no self-closing lids, and no pressure relief features; these are never acceptableAugust 10, 2015

for use on construction job sites or in manufacturing facilities or other commercialoccupancies.Any safety can must incorporate a flame arrester (photo 2) in both the fill opening andthe pour spout. A flame arrester is usually a tubular metal screen with a metal bottomthat is permanently attached to the safety can. Flame arresters may also be a flat metalscreen in the opening in some types of safety cans. The purpose of a flame arrester is toreduce the possibility of a spark igniting the vapors in the top of the safety can while it isopen for filling or dispensing liquid. A safety can from which the flame arrester has beenremoved is no longer a safety can.(2)Safety cans are constructed to reduce the chance of leaks and container failures, and toeliminate vapor release from the container under normal conditions by using self-closinglids and pressure-relief devices in case the cans are heated.Safety cans are also color-coded for certain common products by their classification asflammable or combustible liquids.August 10, 2015

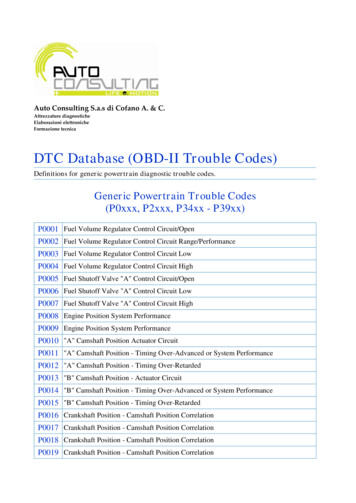

Flammable liquids (Class I) and combustible liquids (Class II and Class III) are classifiedaccording to NFPA 30, Chapters 4.3.1 and 4.3.2: Class IA (flammable) liquids are those with a flash point below 73 F (22.8 C)and a boiling point below 100 F (37.8 C); including ethers and other volatilesolvents.Class IB (flammable) liquids are those with a flash point below 73 F (22.8 C)and a boiling point at or above 100 F (37.8 C), including acetone and gasoline.Class IC (flammable) liquids are those with a flash point at or above 73 F(22.8 C), but below 100 F (37.8 C), including turpentine, and paint thinners.Class II (combustible) liquids are those with a flash point at or above 100 F(37.8 C) and below 140 F (60 C), including diesel fuel, naphtha, fuel oils, andStoddard solvent.Class IIIA (combustible) liquids are those with a flash point at or above 140 F(60 C), but below 200 F (93 C), including kerosene, some fuel oils, andnitrobenzene.Class IIIB (combustible) liquids are those with a flash point at or above 200 F(93 C), including formalin, motor oils, and some fuel oils.The common color coding of safety cans includes: Red: Class I flammable liquids, including gasoline and paint thinners.Yellow: Diesel fuel (photos 1, 2, and 3).Blue: Kerosene and light fuel oils.Green: heavy oils and heavy fuel oils.Safety cans must also be labeled with the name of their contents (photos 3 and 4)according to OSHA’s Hazard Communication regulations, 29 CFR 1910.1200.August 10, 2015

(3)(4)August 10, 2015

The key points in the storage of flammable and combustible liquids on construction jobsites and in commercial occupancies: Safety cans must be used, except for smaller quantities in manufacturer’s originalshipping containers (five-gallon, gallon, quart, pint).Safety cans must be metal unless the product is compatible with the materialused in plastic safety cans, and within the quantity limits listed in NFPA 30 forthat product.Safety cans must incorporate flame arresters, self-closing lids, and pressurerelief valves or pressure relief lids.Safety cans must be properly color-coded for their contents.Safety cans must be labeled with the name of and other information on theircontents.Since the same safety rules apply to fire stations and fire department operations asapply to construction job sites and commercial occupancies, you should ensure that themotor fuels and other flammable liquids at your station and on your apparatus are storedas our fire inspectors expect that they should be.NFPA codes and standards are available by subscription in both print and onlineeditions. Check with your fire prevention bureau or with your local technical college orregional fire training center library for access to these documents.OSHA regulations are available online at no cost: www.osha.govGregory Havel is a member of the Town of Burlington (WI) FireDepartment; retired deputy chief and training officer; and a 30-yearveteran of the fire service. He is a Wisconsin-certified fire instructorII, fire officer II, and fire inspector; an adjunct instructor in fireservice programs at Gateway Technical College; and safety directorfor Scherrer Construction Co., Inc. Havel has a bachelor's degreefrom St. Norbert College; has more than 30 years of experience infacilities management and building construction; and has presentedclasses at FDIC.CLICK HERE for more 'Construction Concerns' articles!MORE CONSTRUCTION CONCERNS Porches, Decks, and StairsFuels and Fire BehaviorBlocked Emergency ExitsTypes of Gypsum Drywall BoardRadiant Floor Heating PanelsVertical Rolling Fire DoorsAugust 10, 2015

Misleading MarketingFire DoorsSnow LoadElectrical NeedsHazard Communication in ConstructionFirewall PenetrationsRoofing Materials TestFire Extinguisher TestingAugust 10, 2015

in larger quantities as well as the use of natural gas and liquefied propane (LP) gas. The requirements for the storage and dispensing of flammable and combustible liquids may be found in National Fire Protection . (OSHA) regulations on the storage and dispensing of flammable and combustible liquids, in 29 CFR 1910.106 and 1926.152 .