Transcription

TELEDYNE CONTINENTAL AIRCRAFT ENGINECRITICAL SERVICE BULLETINCATEGORY 2CSB 01-1Compliance Necessary To Maintain SafetyTECHNICAL PORTIONSFAA APPROVEDSUBJECT:FUEL PUMP INSPECTION and SEAL LEAK TESTPURPOSE:To Provide A Leak Test Procedure To Insure Integrity Of Basic Fuel Pump FuelSeal On Fuel Pump Assemblies Manufactured Between July 1, 1998 And May 31,2000.COMPLIANCE: 1. At the earliest opportunity, but within the next 25 hours of engine operation forfuel pump assemblies with less than 300 hours total time in service, perform theseal leak test per Part A.2. Anytime fuel flow indications fluctuate or engine fuel flows do not meet theAFM/POH published specifications, perform the fuel pumpseal leak test per Part A.MODELSAFFECTED:IO-240, IO-360, IO-346, O-470-G7, O-470-G10, O-470-GCI, IO-470,GIO-470, IO-520, LIO-520, IO-550, GIO-550, LTSIO-360, TSIO-360,TSIO-470, TSIO-520, TSIO-550, TSIOL-550, GTSIO-520 modelengines with P/N 642932-1, 2, 3 & 4 basic fuel pump manufacturedbetween July 1, 1998, and May 31, 2000 - .Any of the above listed engine models that have had a new or rebuiltengine driven fuel pump installed between July 1, 1998, andNovember 26, 2000.Any of the above listed engine models that have had an engine drivenfuel pump overhauled using a new P/N 642932-1, 2, 3, or 4 basic fuelpump between July 1, 1998, and November 26, 2000. Refer to Figures 1 and 2- Engines delivered from TCM between July 1, 1998, and November 26, 2000. See GENERALINFORMATION section of this CSB.GENERAL INFORMATION :Teledyne Continental Motors has receivedreports of fuel being discharged from the enginedriven fuel pump seal overboard drain.Additionally, isolated reports of engine fuel flowfluctuations and/or a reduction in engine fuelflow have been received.Fuel pump seal drain leak observations havebeen noted during operation of the aircraft fuelboost pump during engine priming, prior toISSUEDengine start. Once the engine has started and isoperating, with the aircraft fuel boost pump OFF,fuel does not leak from the engine driven fuelpump seal overboard drain.However, significant fuel flow fluctuations orreductions in engine fuel flow may result in areduction of engine performance due to airingestion if the basic fuel pump seal has movedfrom its originally installed and seated positionor has been mechanically damaged.REVISEDPAGE NO REVISIONTMMODAYYEAR04252001MODAYYEAR 2001 TELEDYNE INDUSTRIES, INC.C O N T IN E N T A L M O T O R SA Teledyne Technologies CompanyP.O. BOX 90 MOBILE ALABAMA 36601 334-438-34111 of 5CSB 01-1

COMPLETE FUELPUMP ASSEMBLYBASIC FUEL PUMPFIGURE 1FUEL PUMP ASSEMBLY-COMPLETE(TYPICAL)BASIC FUEL PUMP-EXPLODED VIEWFIGURE 2FUEL PUMP ASSEMBLY-EXPLODED VIEW(TYPICAL)ISSUEDREVISEDPAGE NOTMMODAYYEAR04252001MODAYYEARC O N T IN E N T A L M O T O R SA Teledyne Technologies CompanyP.O. BOX 90 MOBILE ALABAMA 36601 334-438-34112 of 5CSB 01-1REVISION

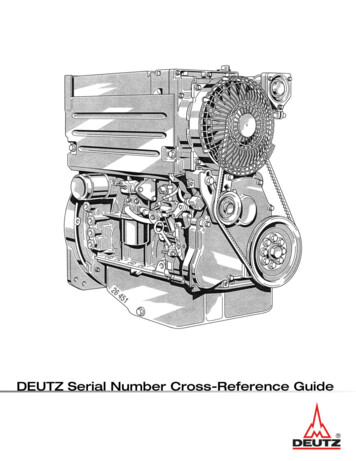

WARNINGFailure to comply with this service bulletinmay result in a reduction in or loss of enginepower.GENERAL INFORMATION:This Service Bulletin provides instructions forperforming a fuel seal leak test on engine driven fuelpump assemblies installed on engines listed in the“Models Affected” section of this Service Bulletin.One Round BossAffected fuel pump assemblies were manufacturedbetween July 1, 1998, and May 31, 2000. Theaffected fuel pump assemblies may be installed onnew and rebuilt engines delivered from TCMbetween July 1, 1998, and November 26, 2000.Additionally, affected fuel pump assemblies weresold individually as a service spare part or wereincluded as a component part of a complete fuelinjection system or EQ Kit.If your engine driven fuel pump assembly wasreplaced, repaired, or overhauled during the dateslisted above, this Critical Service Bulletin may affectyou.Affected engine driven fuel pump assemblies weremanufactured utilizing basic fuel pumps P/N’s642932-1, 642932-2, 642932-3 and 642932-4. Thesebasic fuel pumps may be identified by the presence oftwo (2) round bosses located on opposite sides of thebasic fuel pump housing. Refer to Figure 3.New basic fuel pumps P/N’s 655243-1, 655243-2,655243-3 and 655243-4 having only one round bossare not affected by this service bulletin. Refer toFigure 4.FIGURE 4Current Production Basic Fuel PumpP/N’s 655243-1,-2,-3,&-4(basic fuel pumps with one round boss are notaffected by this service bulletin)PART A: BASIC FUEL PUMP SEAL LEAKTEST PROCEDURENOTE:Refer to the appropriate aircraftmanufacturer’s maintenance manual forthe location of the fuel injection systemconnections and drains.The following procedure should be used to checkintegrity of engine driven fuel pump assembly basicpump fuel seal. An assistant will be required tovisually inspect the induction system drains for fuel.1.Locate the engine driven fuel pump assemblybasic fuel pump seal overboard drain tube thatexits the engine lower cowling.OVERBOARD DRAIN TUBETwo Round BossesFIGURE 5FIGURE 3Affected Basic Fuel PumpP/N’s 642932-1, -2, -3, & -4ISSUEDFuel Pump Overboard Drain Tube(Typical)REVISEDPAGE NOTMMODAYYEAR04252001MODAYYEARC O N T IN E N T A L M O T O R SA Teledyne Technologies CompanyP.O. BOX 90 MOBILE ALABAMA 36601 334-438-34113 of 5CSB 01-1REVISION

NOTE: The engine driven fuel pump assemblybasic fuel pump seal drain may be teed intothe induction system drain(s) prior toexiting the engine lower cowling.2.3.Place the Throttle in the CLOSED position andthe Mixture Control in IDLE CUTOFF.Insure that the Ignition Switch is in the OFFposition.4.5.Insure that all electrical equipment is OFF.On aircraft with retractable landing gear, insurethat landing gear selector is in the DOWNposition.WARNINGDO NOT PERFORM THIS TEST ON A HOTENGINE.PERFORMING THIS TEST WILLRESULT IN FUEL BEING INJECTED INTOTHEENGINECYLINDERS.DONOTATTEMPT TO START THE ENGINE FOR ATLEAST 15 MINUTES AFTER COMPLETINGTHIS TEST TO ALLOW SUFFICIENT TIMEFOR FUEL TO DRAIN FROM CYLINDERSAND INDUCTION SYSTEM. FAILURE TOADHERE TO THIS WARNING MAY RESULTIN AN ENGINE FIRE OR CYLINDERHYRDOSTATIC LOCK.6.7.Turn the aircraft Master Switch ON.Turn the aircraft electric fuel boost pump ON, tothe high position.8.Have an assistant observe the engine driven fuelpump assembly basic fuel pump seal overboarddrain tube for evidence of fuel discharge. SeeFigure 5.If there is no visible indication of fuel beingdischarged from the fuel pump assembly basicfuel pump seal overboard drain tube make anengine logbook entry verifying compliance withTCM CSB 01-1.9.10. If there is visible discharge of fuel from theengine driven fuel pump assembly basic fuelpump seal overboard drain tube proceed to step11.11. Locate the engine driven fuel pump assemblybasic fuel pump seal drain tube connection at theengine driven fuel pump. Refer to Figure 6.Basic Fuel PumpSeal DrainFIGURE 6Fuel Pump Seal Drain Connection (Typical)12. Isolate the basic fuel pump seal drain bydisconnecting the seal drain tube at the fitting.Refer to Figure 6.13. Repeat steps 6 and 7 having the assistant observethe fuel pump assembly basic fuel pump sealdrain fitting at the fuel pump assembly forevidence of fuel discharge.14. If no fuel discharge is noted, reconnect the fuelpump assembly basic fuel pump seal drain tube.Make an engine logbook entry indicatingcompliance with CSB 01-1.NOTE: Refer to TCM SB 95-5 for correctprocedures for loosening and torquing fuelsystem lines and hose “B” nuts.15. If fuel discharge is noted, proceed to Part B.PART B: FUEL PUMP ASSEMBLYREPLACEMENTNOTE: To expedite compliance with this CriticalService Bulletin, all orders for replacementfuel pump assemblies are to be placed withthe TCM Customer Support Center,Fairhope, Al. Orders may be place bycalling 1-888-200-7565. Please have thefuel pump assembly part number, fuel pumpassembly serial number (from the fuel pumpassembly data plate attached to the vaporseparator housing), engine model and serialnumber, total time on fuel pump and engineavailable when placing your order.Refer to the aircraft manufacturer’s maintenancemanual and the applicable engine overhaul manualfor specific instructions for removing and replacingthe engine driven fuel pump assembly.ISSUEDREVISEDPAGE NOTMMODAYYEAR04252001MODAYYEARC O N T IN E N T A L M O T O R SA Teledyne Technologies CompanyP.O. BOX 90 MOBILE ALABAMA 36601 334-438-34114 of 5CSB 01-1REVISION

Special consideration may be given to operators inremote areas to allow repair of affected fuel pumpsby an approved accessory overhaul facility. In thissituation, the overhaul facility is directed to referencethe latest revision of TCM’s Fuel Injection OverhaulManual form X30593A and TCM service bulletinsfor specific instructions, dimensional limits and fuelpump flow specifications. Refer to SB 00-10 forspecific dimensional limits for fuel seal installation.After installation of any engine fuel injection systemcomponent perform a complete fuel injection systemset up and adjustment prior to returning the engineand aircraft to service. Refer to the latest revision ofTCM Service Information Directive SID 97-3.Make an engine logbook entry of fuel pumpreplacement and compliance with TCM CSB 01-1.PART C: WARRANTYIn the event an affected fuel pump assembly requiresreplacement as a result of this CSB rator or FBO the invoiced cost of areplacement Factory Rebuilt fuel pump upon receiptof the removed, affected fuel pump assembly atTeledyne Continental Motors.PART D: SPECIAL INSTRUCTIONS FORRETURNING FUEL PUMPS:Replacement fuel pumps assemblies are shipped witha special green return label. To insure promptprocessing of your warranty claim and the fuel pumpassembly core deposit, place the fuel injection pumpassembly removed from the engine in the containerthat held the replacement fuel pump assembly. Placegreen labels on two sides of the container. Completeany hazardous material documents required prior toshipment.NOTE: Insure that all residual fuel has been purgedfrom the fuel pump assembly prior to shipment.Return the removed fuel pump assembly via surfacefreight to:TCM Customer Support CenterFairhope Airport8600 County Road 32Fairhope, AL 36532Warranty labor coverage for fuel pump removal,installation and system adjustments will be limited tothe number of man hours of labor specified in Table1 “Approved Labor Allowance” by engine model.TABLE 1Approved Labor AllowanceENGINE -550’sTSIO-550’sTSIOL-550’sGIO-550’sALLOW LABOR ISEDPAGE NOTMMODAYYEAR04252001MODAYYEARC O N T IN E N T A L M O T O R SA Teledyne Technologies CompanyP.O. BOX 90 MOBILE ALABAMA 36601 334-438-34115 of 5CSB 01-1REVISION

fuel pump seal overboard drain tube make an engine logbook entry verifying compliance with TCM CSB 01-1. 10. If there is visible discharge of fuel from the engine driven fuel pump assembly basic fuel pump seal overboard drain tube proceed to step 11. 11. Locate the engine driven fuel pump assembly basic fuel pump seal drain tube connection at the