Transcription

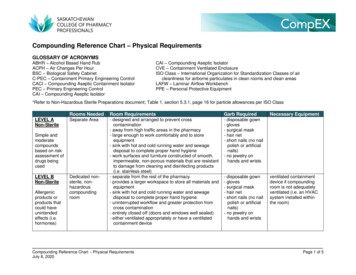

Compounding Reference Chart – Physical RequirementsGLOSSARY OF ACRONYMSABHR – Alcohol Based Hand RubACPH – Air Changes Per HourBSC – Biological Safety CabinetC-PEC – Containment Primary Engineering ControlCACI – Compounding Aseptic Containment IsolatorPEC – Primary Engineering ControlCAI – Compounding Aseptic IsolatorCAI – Compounding Aseptic IsolatorCVE – Containment Ventilated EnclosureISO Class – International Organization for Standardization Classes of aircleanliness for airborne particulates in clean rooms and clean areasLAFW – Laminar Airflow WorkbenchPPE – Personal Protective Equipment*Refer to Non-Hazardous Sterile Preparations document; Table 1, section 5.3.1, page 16 for particle allowances per ISO ClassLEVEL ANon-SterileRooms NeededSeparate AreaSimple andmoderatecompoundsbased on riskassessment ofdrugs beingusedLEVEL BNon-SterileAllergenicproducts orproducts thatcould haveunintendedeffects (i.e.hormones)Dedicated nonsterile, nonhazardouscompoundingroomRoom Requirements- designed and arranged to prevent crosscontamination- away from high traffic areas in the pharmacy- large enough to work comfortably and to storeequipment- sink with hot and cold running water and sewagedisposal to complete proper hand hygiene- work surfaces and furniture constructed of smooth,impermeable, non-porous materials that are resistantto damage from cleaning and disinfecting products(i.e. stainless steel)- separate from the rest of the pharmacy- provides a larger workspace to store all materials andequipment- sink with hot and cold running water and sewagedisposal to complete proper hand hygiene- uninterrupted workflow and greater protection fromcross contamination- entirely closed off (doors and windows well sealed)- either ventilated appropriately or have a ventilatedcontainment deviceCompounding Reference Chart – Physical RequirementsJuly 8, 2020Garb Required- disposable gown- gloves- surgical mask- hair net- short nails (no nailpolish or artificialnails)- no jewelry onhands and wristsNecessary Equipment- disposable gown- gloves- surgical mask- hair net- short nails (no nailpolish or artificialnails)- no jewelry onhands and wristsventilated containmentdevice if compoundingroom is not adequatelyventilated (i.e. an HVACsystem installed withinthe room)Page 1 of 5

NonHazardousSterile(Level A & BSterile)All sterilecompoundsnot involvingantineoplasticdrugsRooms NeededAnteroom andClean RoomRoom RequirementsBoth:- ALL surfaces, fixtures and furniture must beconstructed of smooth, impermeable, non-porousmaterials that are resistant to damage from cleaningand disinfecting products (i.e. stainless steel)- for low and medium risk compounding (sec 5.3.2.5 –Non-Hazardous Sterile Preparations) no wallseparation is needed, but there must bedisplacement air flow with a velocity of 40 feet /minute from clean-area to ante-areaAnteroom:- ISO Class 8 air quality must be maintained, unless itis a shared non-hazardous and hazardous druganteroom, in which case ISO Class 7 must bemaintained- separated into “dirty” area and “clean” area by avisible demarcation line- must have at least 20 ACPH- kept under positive pressure relative to noncontrolled area (pharmacy) adjacent to anteroom- storage space for PPE- hands-free sink with hot and cold running water andsewage disposal (large enough to wash hands andfore-arms without touching sides)- soap dispenser- nail picks- ABHR- hand drying system- mirror to verify garbing- clock- waste container- eyewash station- pass-through for transferring products into cleanroom and/or cart reserved for use in “clean” areaClean Room:- PEC is installed in the clean room- kept under positive pressure relative to anteroom- ISO Class 7 air quality must be maintained- at least 30 ACPH or moreCompounding Reference Chart – Physical RequirementsJuly 8, 2020Garb Required- disposable gownthat has longsleeves, closedfront, fitted cuffs- sterile gloves- surgical mask- hair net- beard cover- shoe covers-short nails (no nailpolish or artificialnails)-jewelry removedfrom fingers, wrists,forearms, face,tongue, ears andneckNecessary EquipmentPEC installed in cleanroom is either:- LAFW- CAIPage 2 of 5

LEVEL ooms NeededRoom dedicatedto hazardousdrug/materialcompoundingORSeparate room(non-hazardouscompoundingroom) withassurances that itis meticulouslycleaned so thereis no risk of crosscontaminationwith hazardousmaterials beforecompoundingother preparationsRoom Requirements- be under negative pressure- physically separate from other preparation rooms (ifnot having a shared hazardous and non-hazardousnon-sterile compounding room)- have an appropriate air exchange of at least 12ACPH- be externally vented through HEPA filtration- have a C-PEC- sink with hot and cold running water to completeproper hand hygiene as well as an eye wash station(water sources and drains must be at least 1 meteraway from C-PEC)*If sharing a compounding room with non-hazardousnon-sterile compounding Level C requirements mustbe in place for the shared roomCompounding Reference Chart – Physical RequirementsJuly 8, 2020PPE Required- disposable gownthat has longsleeves, closedfront, fitted cuffs,resists permeabilityby hazardousproducts- double glove(chemo gloves)- mask (surgicalmasks do notprovide respiratoryprotection. N95 orN100 will protectagainst airborneparticles)- hair net- shoe covers- goggles and faceshield, or a full-facerespirator- short nails (no nailpolish or artificialnails)- no jewelry on handsand wristNecessary EquipmentC-PEC installed- Either a Class IBSC or a CVE- A Class II BSCor CACI may beused- For occasional nonsterile hazardouscompounding, a CPEC used for sterilehazardouscompounding can beused but MUST bedecontaminated,disinfected andcleaned before andafter the non-sterilehazardous preparationPage 3 of 5

LEVEL CSterileCompoundsinvolvingantineoplasticdrugsRooms NeededAnteroom andClean Room- designated forhazardouscompoundingonlyOR- if spacelimitations, ananteroom may beshared forhazardous andnon-hazardouscompoundingRoom RequirementsBoth:- maintain ISO Class 7 air quality- air into rooms must go through HEPA filtration- must have at least 30 ACPH- one or more observation windows installed for visualverification steps in compounding- ALL surfaces, fixtures and furniture must beconstructed of smooth, impermeable, non-porousmaterials that are resistant to damage from cleaningand disinfecting products (i.e. stainless steel)Anteroom:*If Anteroom is shared between hazardous and nonhazardous sterile compounding Level C requirementsmust be in place for the shared room*- positive air pressure relative to main pharmacy area- separated into “dirty” area and “clean” area by a visibledemarcation line- storage space for PPE- hands-free sink (large enough to wash hands and forearms without touching sides)- soap dispenser- nail picks- ABHR- hand drying system- mirror or other means to verify garbing- clock- cytotoxic waste container- eyewash station- pass-through for transferring products into clean roomand/or cart reserved for use in “clean” areaCleanroom:- C-PEC is installed in the clean room- negative air pressure relative to anteroom- return air must be externally vented- return air exhausts at bottom of walls, forcing particlesto flow downward- large enough to facilitate compounding, allow forproper cleaning and disinfecting and proper workflowCompounding Reference Chart – Physical RequirementsJuly 8, 2020PPE Required- non-sheddingscrubs- disposable gownthat has longsleeves, closedfront, fitted cuffs,resists permeabilityby hazardousproducts- double glove(chemo gloves)- mask (surgicalmasks do notprovide respiratoryprotection.N95 or N100 willprotect againstairborne particles)- hair net- shoe covers- goggles and faceshield, or a full-facerespirator- beard cover- short nails (no nailpolish or artificialnails)- jewelry removedfrom fingers, wrists,forearms, face,tongue, ears andneckNecessary EquipmentC-PEC installed in cleanroom:- Must beexternallyventilated- Comply with ISOClass 5- Either Class II orIII BSC or CACIPage 4 of 5

Hazardous drugs require a specified storage room that: All air is exhausted outside Negative air pressure relative to adjacent rooms At least 12 ACPH (air changes per hour) Proper signage (“Hazardous Products Present”) Shelves with lips to prevent products from falling and breakingHazardous sterile preparations requiring refrigeration can be stored in a fridge kept in the hazardous clean room for this purpose only.Level A and B Risk Assessment:Factors to consider: Concentration of ingredients in product Physical characteristics of ingredients (liquid VS solid VS powders, water soluble VS lipid soluble) Quality of ingredients being handled Frequency of making the compound Exposure to compounding personnel Risk of microbial contamination Availability of appropriate facilities and equipment NIOSH/WHMIS classification of producto NIOSH List of Hazardous Drugs - 161.pdfo WHIMIS - http://whmis.org/Most simple or moderate non-sterile compounds can be made following Level A requirements. It would be possible to prepare a non-sterile simplepreparation, which contains a drug categorized by NIOSH as hazardous (i.e. Clonazepam, Carbamazepine) and follow Level A if the hazardousdrug is in a small quantity and has the physical characteristics conducive to minimizing contamination of the immediate area and risk to thecompounding personnel.Compounding Reference Chart – Physical RequirementsJuly 8, 2020Page 5 of 5

CACI - Compounding Aseptic Containment Isolator LAFW - Laminar Airflow Workbench PEC - Primary Engineering Control PPE - Personal Protective Equipment CAI - Compounding Aseptic Isolator . displacement air flow with a velocity of 40 feet / minute from clean-area to ante-area Anteroom: - ISO Class 8 air quality must be maintained .