Transcription

Best practices for HP 10000 Series and HP 10000 G2Series Racksbest practiceAbstract. 110000 G2 Series overview . 1Product availability . 3Specifications. 3Dimensions. 4Additional Resources . 6Certification and regulatory compliance . 6Product certification. 6HP General Specification for Environment compliance. 6Information Technology Equipment. 6Waste Electrical and Electronic Equipment directive . 6Integration services and software. 7HP Factory Express. 7Additional resources . 7HP eCo-Enterprise Configurator . 7Additional resources . 7HP UPS Sizing Tool . 7Additional resources . 7Rack documentation CD. 8Rack deployment considerations . 8Levels of rack security . 8HP 10000 G2 Series rack front doors . 8HP 10000 G2 Series rack rear doors . 8HP Side Panel Option Kit. 8Stabilization requirements . 8Leveling feet. 8HP 10000 Baying Kit . 9HP 10000 Stabilizer Kit . 9HP 10000 Ballast Option Kit . 10Stabilization for seismic activity . 10HP 10000 Series Plinth Option Kit . 11

HP 10000 G2 Series Tie Down Option Kit . 11Space and cable management requirements . 11Extension kits . 11Cable management kits. 12Thermal requirements . 12Additional resources. 13Rack assembly guidelines . 13Additional resources. 13Installation and maintenance precautions . 14Moving racks with casters . 14Connecting and disconnecting power to hot-pluggable power supplies. 14Rack-mountable products. 15Data Center planning and considerations . 16Environmental considerations . 16Thermal considerations . 16Third-party thermal considerations. 18Power considerations. 19Power redundancy . 19Non-redundant. 19High line voltage versus low line voltage. 19Grounding and Earth leakage current . 20Additional resources . 20Equipment clearance and floor loading . 20Rack and accessory footprints. 21Front door clearance . 22Qualified shipping . 23Qualification of rack components for shipping. 24Rack shipping enclosures . 24Standard shipping pallet . 24CTO shock pallet. 24Horizontal crate . 25Vertical crate for rack options . 25Shipping specifications . 2610000 and 10000 G2 Series Rack packing materials . 27Preparation for shipment . 27Site preparation for receiving Integrated Racks . 28General considerations (all shipments). 28Special shipping considerations. 29Door Height Clearances . 30Modes of shipment. 30Airfreight . 31International Air Transport Association labeling . 31Mode of receiving and delivery . 3310000 and 10000 G2 Series Rack packing and shock pallet assembly. 34Dismounting a 10000 G2 Series Rack from a shock pallet. 42Installation service. 43Spares kits . 43Additional tools and equipment . 43Battery decals and boxes . 43Appendix a: glossary . 44Appendix b: torque values. 45

AbstractThis document outlines recommended practices for configuring, installing, transporting, andestablishing a work environment for the HP 10000 and HP 10000 Generation 2 (G2) Series Racks,which includes the following models: 10000 Series rack models–S10614 10000 G2 Series rack G2G2G210000 G2 Series overview10000 G2 Series racks (see Figure 1) provide an integrated platform for mounting computingsolutions and are designed for strength and durability.Figure 1. 10000 G2 Series rack1

HP racks and rack accessories ease the centralization, protection, organization, and access tohardware for servicing and upgrading. HP racks are flexible, secure, and designed to industrystandards. HP racks are designed be populated with the following HP products: HP ProLiant servers HP BladeSystem servers HP 9000 servers HP Integrity servers HP StorageWorks products HP rack mount power protection products HP rack mount switches HP rack mount monitorsThe 10000 G2 Series racks are designed for greater ease-of-use. The 10000 G2 Series rack designis based on the original 10000 Series racks.Table 1 lists the key features of the 10000 G2 Series racks.Table 1. 10000 G2 Series rack key featuresComponentFeaturesFront doorThe front door is designed to allow for air flow of 65 percent. The majorchange in the front door is the look; the front door design has beenupdated to reflect the evolving Industrial Design tastes of high value andhigh volume customers. Based on the 10000 Series rack door, it maintainsthe airflow capabilities of its predecessors, while the handle and closingmechanisms have been improved and a new, modernized visual effect hasbeen implemented.Rear doorsThe rear doors have been modified to maximize the perforations supportingairflow requirements. The rear door handle is designed to provide a moreergonomically pleasing design.Side panelsThe side panel design has been updated in favor of a lighter, easier toinstall three-part solution.Vertical ElAmounting railsThese e-coated black rails with white U-markings provide greater contrast toaid in the installation of product to the rails. The ESD grounding locationprovides a more readily available solution.Rear extension kitAn optional rear extension is available for Models 36U and 42U forimproved cable management,Standard andheavy-dutystabilizersNew, improved standard and heavy duty stabilizers which also addressease of installation.Grounding kitNew universal grounding kit supports the 9000, 10000, and 10000 G2Series racks.Rack tie-down kitFor stability needs, the rack tie-down kit is available for the 10000 G2Series racks.2

Product availabilityThe 10000 Series rack Model S10614 is available.NOTEThe following 10000 Series rack models are discontinued: 10622 10636 10642 10647 10842SpecificationsThe 10000 and 10000 G2 Series racks are graphite-metallic in color and are available in the rackheights listed in Table 2. The racks are one-meter deep allowing more room for cable managementand for accommodating deeper server and storage equipment.Additional cable management features are as follows: Wide (or 800-mm) rack models can accommodate network cabling on the sides of the rack. A cable egress in the top of the rack allows for overhead data center cabling. Split rear doors provide greater efficiency with respect to service access. A removable access panel on the rear door provides added flexibility for cable routing out the rearand bottom of the rack. Velcro straps for bundling cables within the rack are included in the hardware kit and alsoavailable as an option.3

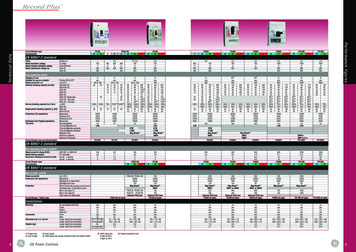

DimensionsTable 2 lists the dimensions of the 10000 and 10000 G2 Series rack models.Table 2. 10000 and 10000 G2 Series rack dimensionsRack modelU heightWidthDepth14U600 mm /1,000 mm /23.62 in.39.37 in.600 mm /1,000 mm /23.62 in.39.37 in.10000 Series rack models:S1061410000 G2 Series rack models:10622 G210636 G210636 G222U36U36Uwith rear extension10642 G210642 G242U42Uwith rear extension10647 G210842 G247U42U600 mm /1,000 mm /23.62 in.39.37 in.600 mm /1184.9 mm /23.62 in.46.65 in.600 mm /1,000 mm /23.62 in.39.37 in.600 mm /1184.9 mm /23.62 in.46.65 in.600 mm /1,000 mm /23.62 in.39.37 in.800 mm /1,000 mm /31.49 in.39.37 in.4

Table 3 lists the 10000 G2 Series rack specification details.Table 3. 10000 G2 Series rack specification detailsRack DetailsHP 10000 G2 Series racksRack Model10622 G210636 G210642 G210647 G210842 G2EIA-310 typeType DType DType DType DType D1735.78 mm2003.5 mm2285 mm2000 mm( /- 3 mm)36U42U47U42UD 1520#S 2000#D 2000#S 2000#D NotapplicableS 2000#D 1000#S 2000#597.3mm597.3mm597.3mm604.3 mm604.3 mm604.3 mm1015 mm1015 mm1015 mm65%65%65%915.36 mm915.36 mm915.36 mm451.3 mm(per EIA)451.3 mm(per EIA)451.3 mm(per EIA)452 mm(per EIA)452 mm(per EIA)452 mm(per EIA)465 mm(per EIA)465 mm(per EIA)465 mm(per EIA)Rack height max.Rack U heightMax. weight capacityD Dynamic/S Static1113.48 mm22UD 1045#S 1045#Rack width: no sidepanels597.3 mmRack width: with sidepanels612.77 mmRack depth: front torear door1015 mmFront door percentageopen space63%Nominal distance fromfront mtg flange toinside of rear door915.36 mmMin. front equipmentopening width451.3 mm(per EIA)Nominal FrontEquipment openingwidth452 mm(per EIA)Nom Ctr-to-ctr distancefor equipment465 mm(per EIA)Std equipmentmounting hardwarefor rack (example, clipnuts)Cage nutsMounting hardwaresize (example, M5)M6 supplied;M5&10-32supportedNominal front/backmounting distance742 mmOverallrack/extension depthNotapplicableNominal distance fromfront mtg flange toinside of rear doorwith extensionNotapplicable800mm815.47mm1015 mm63%915.36 mm451.33 mm(per EIA)452mm(per EIA)465mm(per EIA)Cage nutsCage nutsCage nutsCage nutsM6 supplied;M6 supplied;M6 2supported742 mm742 mm742 mm1184.9 mm/46.65 in.1184.9 mm/46.65 cable1060.87 mm1060.87 mmM6 supplied;M5&10-32supported742 mm5

Additional ResourcesAdditional resources are available as follows: For a complete list of HP rack options and accessories, go to the main rack page atwww.hp.com/products/racks or to the main rack options page at www.hp.com/products/rackoptions. For a list of ProLiant servers and options, go to www.hp.com/products/proliant. For a list of HP power products such as UPS and PDU, go to www.hp.com/products/ups. For a complete list of HP server storage equipment, go to www.hp.com/products/serverstorage.Certification and regulatory complianceProduct certificationThe10000 and 10000 G2 Series racks are defined as non-functional mechanical storage bays andtherefore, are not certified individually as a stand-alone product. The rack does not serve as anoverall safety or EMI rated enclosure nor does it carry any other Agency compliant rating. However,any product intended for use in an HP rack should be individually certified as a stand-alone product.For example, HP Power Distribution products, such as uninterruptible power supplies (UPSs) andpower distribution units (PDUs) are fully certified as stand-alone products.Certain third-party products may not be fully certified as stand-alone products. Any product that doesnot meet stand-alone certification is not included in any HP-specified rack configuration and shouldnot be installed in an HP rack.HP General Specification for Environment complianceHP General Specification for Environment (GSE) specifications prohibit or restrict the use of certainchemical compounds in products or in the manufacture of products. HP complies with the GSEspecifications and restricts the use of these compounds in the development or manufacture of any HPproduct (including third-party supplier product).Information Technology EquipmentThe 10000 and 10000 G2 Series racks are designed to comply with the applicable safetyrequirements for Information Technology Equipment (ITE) when the rack is configured with properlycertified equipment. The 10000 and 10000 G2 Series racks are considered ITE compliant when thefollowing conditions are met: The rack is populated with individually certified products All installation guidelines and instructions are followedWaste Electrical and Electronic Equipment directiveThe directive on Waste Electrical and Electronic Equipment(WEEE) requires manufacturers to finance the take back andrecovery of waste from electrical and electronic equipment atthe end of its useful life.Figure 2. WEEE disposal symbolAny product or product packaging marked with the symbolin Figure 2 must not be disposed of with other householdwaste. The customer must dispose of the product bydelivering the product to a designated collection point forthe recycling of waste electrical and electronic equipment.For more information about locations to drop off equipmentfor recycling, please contact a local city office, the6

household waste disposal service, or the business where the product was purchased.Integration services and softwareSeveral resources are available for planning rack configurations.HP Factory ExpressFactory Express is a robust portfolio of flexible, pre-priced, configured, customized and integratedfactory solutions and deployment services – supporting HP products from the desktop to the datacenter with Windows , Linux, and HP-UX 11i.Additional resourcesFor specific information, please see the HP Factory Express link: www.hp.com/go/factory-express.In addition to this available integration option, HP also provides information links and contacts forproblem solving of rack and product compatibility in support of Build to Order on site locationsthrough several venues. Please refer to the following resources: Frequently Asked Questions about Rack and Power products and rkgroup/rackandpower/download/Rack 20System 20faqs.doc Contact your sales representative for the Interoperability guide to fit and HP ProLiant servers into HPRack System/E and 9000/10000 ckandpower/interoperability.asp To specifically request help on rack and power p/rackandpower/requestform.aspHP eCo-Enterprise ConfiguratorIf you require factory default racking for our HP hardware portfolio, you may still use the HP eCoEnterprise Configurator. If you require "custom" rack configuration capabilities, please contact the HPCustomer Business Center or an HP Authorized Partner for assistance.Additional resourcesFor more information on the eCO Custom Builder tool, refer to the following HP websites: eCO-Enterprise Configurator: http://h30099.www3.hp.com/configurator/ eCO-Enterprise Configurator features: p Frequently asked questions: http://h30099.www3.hp.com/configurator/docs/eCo FAQ.doc What's new: http://h30099.www3.hp.com/configurator/about.asp Technical support: HP UPS Sizing ToolThe UPS Sizing tool is an online tool that collects information on power consumption requirements andthen provides the correct UPS product for those requirements.Additional resourcesFor additional information on the UPS Sizing tool, refer to http://www.upssizer.com/selector.asp.7

Rack documentation CDThe Documentation CD shipped with the rack provides documentation for installing and optimizingthe rack.Rack deployment considerationsThe following sections describe the components and HP options available for the 10000 and 10000G2 Series racks that may be necessary to achieve safety, regulatory compliance, or functionalityrequirements.Levels of rack securityEither of the following conditions may be necessary for compliance with certain safety certifications: Racks must be located in a restricted access area that is only accessible to trained personnel.-Or Racks must be configured with lockable hardware.HP rack front doors, rear doors, and side panels support this locking requirement. Rear split doors arestandard on 10000 and 10000 G2 Series racks. (The 10000 Series rack Model S10614 is notconfigured with split rear doors).HP 10000 G2 Series rack front doorsAll 10000 and 10000 G2 Series rack Models ship with front doors. The 42U and 36U front doors(and necessary hardware) are available as option kits are backwards compatible with the 10000Series racks of the same heights; this enables customers to have all racks standardized with the sameupdated look, if desired.NOTEThe front door option kit is not compatible with the 9000 Series racks.HP 10000 G2 Series rack rear doorsAll 10000 and 10000 G2 Series rack models ship with rear doors as part of the standardconfiguration. The 10000 G2 rear door has been upgraded to provide a more ergonomically andcosmetically pleasing handle.HP Side Panel Option KitSide panels aid in providing proper front to rear airflow and a first level of security. 10000 Seriesrack Models S10614 and 10622 ship with side panels installed. Side Panel Option kits are availablefor all other rack models.Stabilization requirementsRack stability is of special concern when equipment is routinely installed, removed, or accessed withinthe rack. Stability is addressed through the use of leveling feet, baying kits, fixed stabilizers, and/orballast.Leveling feetLeveling feet are adjustable stabilizers that provide leveling of the rack at the installation site and shipinstalled to the racks. HP 10000 and 10000 G2 Series racks ship with leveling pads for stabilization;these parts are found in the hardware kit – also shipped with each rack.8

HP 10000 Baying KitBaying kits are used to physically connect adjacent racks to create a row of two or more units. Racksthat are bayed together with a baying kit are more stable and reduce the potential tipping of therack. The same baying kit supports the 10000 and 10000 G2 Series Racks.HP 10000 Stabilizer KitFixed stabilizers are anti-tip feet (front and side) that provide stability and support when equipment isinstalled, removed or accessed within the rack.The following stabilizers are available: HP 10000 G2 600 mm Stabilizers HP 10000 G2 Heavy Duty 600-mm Stabilizer HP 10000 G2 800-mm StabilizerNOTEThe 600-mm and 800-mm stabilizer designs are different between the10000 and 10000 G2 Series racks and have different part numbers.If racks are secured together with baying kits, the side feet installed on each end of the row of racksare considered optional.Rack rows with four or more bayed racks do not need a stabilizer kit installed. Single racks or bays ofthree racks, with no component exceeding 100 kg (220 lbs.), a standard 600-mm stabilizer isrequired.HP recommends that stabilizer option kits be used when one or more of the following situations occur: If a standard 600-mm (23.62-in.) or 800-mm (31.50-in.) front stabilizing foot is installed on a standalone rack, the side feet, provided with the fixed stabilizer kit, should also be installed to stabilizestand-alone racks from the side. A heavy duty 600-mm (23.62-in.) front stabilizer foot is required in either of the followingsituations:– A single rack-mountable component weighing 100 kg (220 lbs.) (or greater) is installed in astand-alone rack.– A rack row of three or fewer racks are bayed together– Side feet, which are included in the stabilizer kits, should also be installed to stabilize the rackWARNINGTo reduce the risk of personal injury or damage to the equipment, be surethat: The leveling feet are extended to the floor. The full weight of the rack rests on the leveling feet. The stabilizing feet are attached to the rack if it is a single-rackinstallation. The racks are coupled together in multiple-rack installations. Only one component is extended at a time or the rack may becomeunstable.9

HP 10000 Ballast Option KitBallast plates add weight to a rack and therefore improve side-to-side and front-to-back mechanicalstability for stand-alone racks or a row of three or fewer racks bayed together. Ballast plates fit in thezero-U space at the interior sides of the rack and should be installed into the rack prior to installationof any other equipment.NOTEThe 10000 Ballast option kit is compatible with all 10000 and 10000 G2Series racks.Increasing rack weightA rack with a light static load (less than 95 kg / 210 lbs.) should have ballast plates installed toprovide extra weight, thus reducing the possibility of the rack tipping over if a significant force whereto be applied to the rear or side of the rack. Racks with a heavier static load (greater than 95 kg /210 lbs.), depending on the particular configuration involved, may not require ballasts.Multiple Ballast kits may be necessary to provide sufficient weight. Each kit contains two 40-lb. (18kg) ballast plates. Ballast plates should be added to the rack until the total weight of componentsinstalled into the rack is 210 lbs. (95 kg) (minimum).For example, a lightly loaded rack configured with 50 lbs. (23 kg) of equipment requires two ballastkits (four ballast plates). The total weight of four ballast plates is 160 lbs. (72 kg). Therefore, the totalinstalled weight of the rack components would be 210 lbs. (the minimum recommended rack installedcomponent weight):Should any rack component weigh more than 100 lbs. (46 kg), there must be and additional 210 lbs.(91 kg) of equipment weight in the rack (excluding the weight of the component) to provide balanceand maintain rack stability when the component is extended on its rails. In this instance, ballast platesshould be added until the total rack component weight is300 lbs. (or greater).Total weight of installed equipment total weight of ballast plates total rack component weightWARNINGTo reduce the risk of personal injury or damage to equipment, extend onlyone component at a time. The rack may become unstable if more than onecomponent is extended.Stabilization for seismic activityRack installations in geographical areas where there is a risk of seismic activity require specialconsiderations for stabilization of the rack.IMPORTANTThe 10000 and 10000 G2 Series racks are not qualified as a Zone 4 orOSHPOD solution.An equipment integrator will need to determine the requirements for which, if any, ballast andstabilizer kits are required. If the rack is bolted to the floor or to adjacent racks that have sufficientcombined weight, additional stabilization products may not be required.10

HP 10000 Series Plinth Option KitThe Plinth Option kit provides a means for meeting building code guidelines to anchor a 10000Series rack to the floor in geographical areas pron

Front door The front door is designed to allow for air flow of 65 percent. The major change in the front door is the look; the front door design has been . rack models can accommodate network cabling on the sides of the rack. . 1,000 mm / 39.37 in. 10000 G2 Series rack models: 10622 G2 22U 600 mm / 23.62 in. 1,000 mm /