Transcription

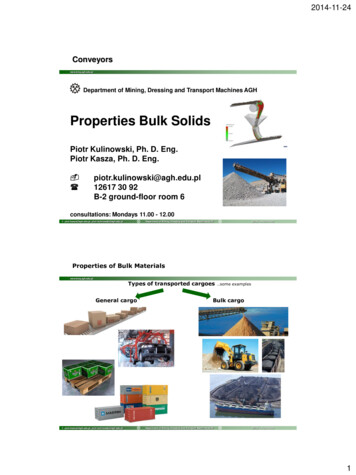

2014-11-24Conveyorswww.kmg.agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHProperties Bulk SolidsPiotr Kulinowski, Ph. D. Eng.Piotr Kasza, Ph. D. Eng.(piotr.kulinowski@agh.edu.pl12617 30 92B-2 ground-floor room 6consultations: Mondays 11.00 - 12.00 piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHtel/fax 48126335162Properties of Bulk Materialswww.kmg.agh.edu.plTypes of transported cargoesGeneral cargo piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl some examplesBulk cargoDepartment of Mining, Dressing and Transport Machines AGHtel/fax 481263351621

2014-11-24Properties of Bulk Materialswww.kmg.agh.edu.plGeneral cargo – single objects (boxes, containers, packages, machines, etc ).Classified according to their dimmensions, shape, weight and others, such as:inflammability, toxicity, explosivness, corrosivity, fragility, humidity resistanceetc Bulk cargo – grainy or dusty bulk material (coal, ore, gravel, sand, cement,flour etc ).Bulk materials are characterized by: granulation or dustiness,density,natural angle of repose,internal friction,static and kinetic friction,hardness,attrition,crushing sensivity,change of properties due to vibrations, temperature, water or humidity,adhesion,plasticity,electrostatic properties. piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHtel/fax 48126335162Properties of Bulk Materialswww.kmg.agh.edu.plGranulation – numerical definition of material particles according to their size.The size of a single particle is defined by the maximum value of dimensionmeasured by diagonal of cuboid as a contour of the particle.Transpotred material is: sorted, when:amax 2.5amina* amax amin2 unsorted, when:amax 2.5amina* amaxa* 3 a1 a2 a3where: a* - average size of a particle piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHtel/fax 481263351622

2014-11-24Properties of Bulk ding to particle size cllasification is as follows: massive a* 300 mm lumpy 160 a* 300 mm middling lumpy 60 a* 160 mm fine lumpy 10 a* 60 mm grained 2 a* 10 mm fine grained 0.5 a* 2 mm powdery 0.05 a* 0.5 mm dusty a* 0.05 mmGranulation is characterized byparticle size distribution chart piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHtel/fax 48126335162Properties of Bulk Materialswww.kmg.agh.edu.plBulk Density – mass of a cubic meter freely poured bulk, contains someleeks.ρ [kg/m3]According to bulk density cllasification is as follows: light: 0,6 t/m3 average: 0,6 1,1 t/m3 heavy: 1,1 2,0 t/m3 very heavy: 2,0 t/m3 piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHtel/fax 481263351623

2014-11-24Properties of Bulk Materialswww.kmg.agh.edu.plAngle of Repose – angle between the surface of a piled-up bulk material andthe horizontal plane.staticalφdynamical 0 (0.5 0.7) 1mφ0 piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHtel/fax 48126335162Angle of repose and surchargewww.kmg.agh.edu.pl The angle of repose of a material is the acuteangle which the surface of a normal, freelyformed pile makes to the horizontal. The angle of surcharge of a material is theangle to the horizontal which the surface of thematerial assumes while the material is at rest ona moving conveyor belt.This angle usually is 5degrees to 15 degrees less than the angle ofrepose, though in some materials it may be asmuch as 20 degrees less. piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHtel/fax 481263351624

2014-11-24Properties of Bulk Materialswww.kmg.agh.edu.plSome examples piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHtel/fax 48126335162Properties of Bulk nternalFriction between bulk particles insidelayer as a result of acting forces.KineticBulk friction coefficient againstwalls or conveyors surface can bestatic mst or kinetic mkintg m stαValues of external and internal frictioncoefficients must be obtained inexperimental tests. piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHtel/fax 481263351625

2014-11-24Properties of Bulk Materialswww.kmg.agh.edu.plShearing efixedframem piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plP P arctanP P Department of Mining, Dressing and Transport Machines AGHtel/fax 48126335162Properties of Bulk Materialswww.kmg.agh.edu.plInternal friction shearing forcechart: 1 – black coal with sand,2 – dry coal, 3 – polytroksane,4 – dusty ligniteExternal friction shearing forcechart piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHtel/fax 481263351626

2014-11-24Definitions and Symbolswww.kmg.agh.edu.pl Angle of repose - angle between the surface of a piled-up bulk solidand the horizontal plane ( r). Effective angle of internal friction - angle between the abscissa andthe tangent of the curve representing the relationship of shearingresistance to normal stress ( i). Static angle of internal friction - the angle at which the bulk solidwill begin to slide on itself when subjected to stress acting onto theshearing surface ( st). Surcharge angle - dynamic angle of the material conveyed ( , ): - [ISO] angle formed with the horizontal by the tangent to the materialcross - section at the intersecting point with the belt in motion - [DIN] equivalent surcharge angle( 0.67 ) piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHtel/fax 48126335162Flowability–angle of surcharge–angle of reposewww.kmg.agh.edu.pl piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHtel/fax 481263351627

2014-11-24Characteristics of BuIk Solid Materials - CEMAwww.kmg.agh.edu.plMaterial CharacteristicsCodeSizeVery fine—100 mesh and underFine—1/8 inch and underGranular—Under 1/2 inchLumpy—containing lumps over 1/2‘ inchIrregular—stringy, interlocking, mats togetherABCDEFlowabilityAngle of ReposeVery free flowing—angle of repose less than 19 Free-flowing—angle of repose 20 to 29 Average flowing—angle of repose 30 to 39 Sluggish—angle of repose 40 and over1234AbrasivenessNonabrasiveAbrasiveVery abrasiveVery sharp—cuts or gouges belt covers5678Miscellaneous Characteristics(Sometimes more than one ofthese characteristics mayapply)Very dustyAerates and develops fluid characteristicsContains explosive dustContaminable, affecting use or saleabilityDegradable, affecting use or saleabilityGives off harmful fumes or dustHighly corrosiveMildly corrosiveHygroscopicInterlocks or matsOils or chemical present—may affect rubber productsPacks under pressureVery light and fluffy—may be wind-sweptElevated temperatureLMNP0RSTUVWXVZ piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plExample: A very fine material that is freeflowing, abrasive, and contains explosive dustwould be designated:Class A26N.Department of Mining, Dressing and Transport Machines AGHtel/fax 48126335162Material characteristics and weight per cubic foot - CEMAwww.kmg.agh.edu.plMaterialAverageweight(lbs/cu ft)Angle ofrepose(degrees)Recommendedmaximum inclination(degrees)CodeAshes, fly40-454220-25A37Cement, Portland72-9930-4420-23A36M603518B35TYCoal, lignite40-453822D36TCopper ore120-15030-4420*D37Dolomite, lumpy80-10030-4422D36Gravel, dry, sharp90-10030-4415-17D37Coal, anthracite, river, or culm, ⅛inch and underRice, hulled or polished45-48198B15100-11030-4422D36Salt, common dry, fine70-802511D26TUWSandstone, broken85-9030-44Wood chips10-3045Rock, soft, excavated with shovel piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHD3727E45WYtel/fax 481263351628

2014-11-24CharacteristicParticie SizePowderyGranular: FineGranular: CoarseModularLumpyMassiveParticle SizeVariation(d dmax) 10%: d to d/2; rest: d/2 25%:d to d/2; rest: d/2 95%: d to d/2; rest: d/10 10%:d to d/2; 15%: d/10; rest d/10 to d/2 10%: d; rest: d/10www.kmg.agh.edu.plCharacteristicsof BuIk Solid Materials- ISOParticle ShapeFlowability /Cohesion piotr.kasza@agh.edu.pl, max 0.42 mm 3 mm 12 mm 40 mm 200 mm 200 mmS1S25354S5S6SV1SV2SV3SV4SV5Sharp edged - with three dimension similar- with one dimension clearly greater- with one dimension clearly smallerRound edged — globularRound edged—with one dimension clearly greaterlrregular - fibrous, stringy, curly, indescribableIIIIIIIVVVIE1E2E3E4E5E6Fluid-like floodingVery free flowingFree flowingAyerage flowingPoor flowing, compact productSluggish, non-collapsible, entangled123456F1F2F3F4F5F6Department of Mining, Dressing and Transport Machines AGH0 r 3030 r 4545 r 60 r 60tel/fax 48126335162www.kmg.agh.edu.plCharacteristicsof BuIk Solid Materials- sNon-/sIightly abrasiveMildly abrasiveModerately abrasiveExtremely y corrosiveHighly corrosiveppClC2C3Non-dustyVery dustyHarmful to lifeSusceptibIe to explosionttrDlD2D3D4DustLowTendency to degradeMediumor weatherHigh piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHqG1G2G3tel/fax 481263351629

2014-11-24Properties of Bulk Materialswww.kmg.agh.edu.plDEM – DISCTERE ELEMENT METHODA discrete element method (DEM), also called a distinct elementmethod is any of family of numerical methods for computing the motion andeffect of a large number of small particles. Though DEM is very closely relatedto molecular dynamics, the method is generally distinguished by its inclusionof rotational degrees-of-freedom as well as stateful contact and oftencomplicated geometries. With advances in computing power and numericalalgorithms for nearest neighbor sorting, it has become possible to numericallysimulate millions of particles on a single processor. Today DEM is becomingwidely accepted as an effective method of addressing engineering problemsin granular and discontinuous materials, especially in granular flows, powdermechanics, and rock mechanics. piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHtel/fax 48126335162Properties of Bulk Materialswww.kmg.agh.edu.plDEM Solutions piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHtel/fax 4812633516210

2014-11-24Properties of Bulk Materials - DEMwww.kmg.agh.edu.plTransfer Chutes piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.plDepartment of Mining, Dressing and Transport Machines AGHtel/fax 48126335162Department of Mining, Dressing and Transport Machines AGHtel/fax 48126335162DEM - applicationswww.kmg.agh.edu.pl piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl11

Bulk materials are characterized by: granulation or dustiness, density, natural angle of repose, internal friction, static and kinetic friction, hardness, attrition, crushing sensivity, change of properties due to vibrations, temperature, water or humidity, adhesion, plasticity,