Transcription

Victor Reinz Sealing Solutions for Industrial Applications.We are Your Industrial Sealing Expert.

2

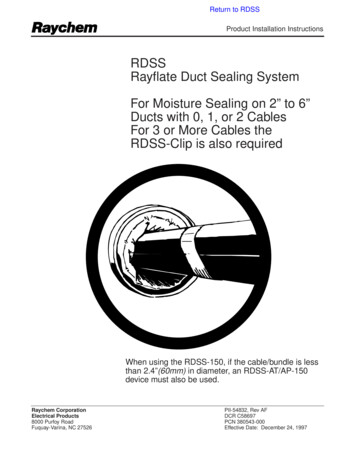

We Are Ready for the Sealing Future.Nearly 100 years of gasket technology inspired by the claim of alwaysproducing the best gasket material of the time. We are developing thegasket material of the future today.Contents4 Benefits6 Gasket Solutions7 Materials8 High-Performance Compressed Sheet10 General Service Compressed Sheet11 Soft Range Compressed Sheet12 Table 1 Material Overview14 High-Performance Metal Reinforced Gaskets15 Controlled Swell Gaskets15 High-Temperature Metal Reinforced Mica Gaskets16 Table 2 Material Overview18 Special Gaskets Solutions20 Sealants21 Tested Quality22 Practical Tips for Gaskets 3

Major manufacturers trust Victor Reinz gasket materials. Across the country and around the world, webring to the table high-quality, innovative products, backed by service you can depend on. 4

Use the Benefits.Victor Reinz gaskets and gasket materials meet any industrial challenge: wecarry exactly the right gasket material for your business and have the gasketknow-how for your industry. This enables us to support you as our partner inchoosing the best material. The world’s best gasket fabricators trust Dana tosupply the perfect fit for your needs.Specialized in IndustrialSealing Applications.Refrigeration compressors andevaporators, chemical and foodstuffproduction: Victor Reinz gasketmaterials are absolutely temperatureresistant and withstand the highestmechanical stresses and pressures.Made in Germany.Victor Reinz gasket materials areGerman-engineered and made at ourplant in Neu-Ulm, Germany, underrigorous quality assurance to provideyou with consistent top quality – allaround the world, wherever you arepresent.Quality Makes the Difference.High-quality materials and world classproduction, certified and environmentally safe: Victor Reinz gasketsand gasket materials meet top qualitydemands. All gaskets and materialsundergo comprehensive tests and testroutines.At Home in Your Country.Excellent availability and shortest delivery times: we have an experiencedsales partner in the U.S. gasket industry providing an excellent service.We Are Ready for the SealingFuture.Traditional and innovative: we’ve beenin the gasket business for almost100 years and know the field like fewothers. We continually look toward innovations to come – whatever gasketyou might need in the future. 5

Gasket Solutions for Industrial Applicationsand Everyday Challenges.Our Industrial Applications expertsdevelop and produce high-techmaterials for gaskets as well ascomplete gasket solutions under thebrand name Victor Reinz – from theclassic flange gasket to the customdesigned high-pressure gasket.The customers are companies in allsectors of the manufacturing industry:from the Heating, Ventilation, Air Conditioning and Refrigeration Industry(HVAC/R Industry) to the ChemicalIndustry and on to the FoodstuffsIndustry. Victor Reinz gaskets sealwherever uncompromising safety isrequired. 6Partner of the Industry and GasketFabricators.Dana provides professional support toindustrial end customers and to gasketfabricators. We provide the idealmaterial and gasket know-how for thedevelopment and production of yourgaskets.Distribution and Logistics on Site.Our distributor Target Industrial Productsin the United States stocks ample supplies of our products for fast, on-demand delivery. Assistance and adviceare never more than a phone call or ane-mail away.Dana. The Global Technology Leader.Dana is a world leader in highly engineered solutions forimproving the efficiency, performance, and sustainability ofpowered vehicles and machinery. Dana supports the passenger vehicle, commercial truck, off-highway, and industrial markets as well as industrial and stationary equipmentapplications. Founded in 1904, Dana employs more than30,000 people in 33 countries on six continents who arecommitted to delivering long-term value to customers.Under the brand name Victor Reinz, Dana in Neu-Ulm,Germany, has been developing and producing innovativesealing solutions for more than half a century. For practically every industrial application, Dana’s sealing conceptsand gasket materials provide the most reliable solutions.

Materials.We Have what You Need.We have the right answer for allindustrial gasket challenges. Whenit comes to your specific application,we provide the ideal gasket solution atthe best value for your money. A widerange of materials is available.The Victor Reinz Material Range High-Performance Compressed Sheet General Service Compressed Sheet Soft Range Compressed Sheet Controlled Swell Gaskets High-Performance Metal Reinforced Gaskets High-Temperature Metal Reinforced Mica GasketsIn addition, we produce innovativegasket solutions for challenging applications. Solutions range from eyeletedgaskets with stainless steel eyelet, viagraphite materials on tanged steelcore, on to ePTFE material. Rubbercoated metal materials and sealingcompounds complete the range ofproducts.We Produce the Gasket Materials you Need! 7

High-Performance Compressed Sheet.VR 100VR 100 is a compressed sheet materialmade from carbon fibers and otherhigh-temperature-resistant substances.Due to its resistance to temperaturesup to 520 F (temporarily even up to ashort-term peak of 825 F) in combinationwith high chemical resistance, it isused especially by the oil processingindustry. Another special feature of VR100 is its excellent capability to sealalkaline solutions, e.g. brine in the pulpand paper industry.Universally applicable and extremelydurable! We count on high performance fibers and high quality elastomers as binders: the product groupHigh-Performance CompressedSheet. VR 100 VR 90 VR 85 VR 80Leading companies in the Heating, Ventilation, AirConditioning and Refrigeration Industry (HVAC/R Industry) in the US have been trusting the VR 90 materialand other Victor Reinz products for decades – used,for example, in refrigeration compressors, evaporators, condensers, chillers, valves, etc.212 8VR 90VR 90 is the most successful VictorReinz gasket material of all time. Thearamid fiber based classic is physiologically harmless and comes withnumerous approvals (among others:TA Luft/German Clean air Act) as wellas FDA conformity for all types offoodstuffs. Universally usable, thisgasket material is the perfect sealingsolution for a large number of fluidsand withstands high temperatures andoperating pressures.VR 90 – like no other compressed sheeton the market – combines a variety ofexcellent properties such as ultimatetensile strength, excellent gas-tightness, ultimate chemical resistance,and superior creep resistance evenunder elevated temperatures.VR 90 CO: consisting of VR 90 topped with aninnovating surface coating.1 VR 90: aramid fiber based material2 CO: extremely thin, highly adaptable surface coating

The areas of application include thechemical industry, foodstuffs production, the oil and gas industry, theHVAC/R industry on to engine construction and mechanical engineering,and many more.VR 90 COIn cases where VR 90 is the idealmaterial but surface irregularities orimperfections might lead to surfaceleakage, VR 90 CO is the answer. Itfeatures a special coating, called “COcoating”, that compensates for smallirregularities to prevent leakage.VR 85VR 85 is suitable for sealing jointsunder high mechanical-thermalstresses where stability and tensilestrength are required. Because of itsgood adaptability it seals oils, water,and gases very well. It is widely used,for example, in combustion enginesand marine applications.VR 80VR 80 features excellent gas tightnesscoupled with high tensile strengthand excellent creep resistance. It istherefore especially used for sealingtasks in the gas industry and forcompressors, but also to seal fluidsin pumps, transmissions and smallengines, to name just a few. 9

General Service Compressed Sheet.Sound quality at a good price for awide range of applications! An important part of our productline: theGeneral Service Compressed Sheetproduct group. VR 70 VR 60VR 70VR 70 is a sturdy gasket material andprovides an excellent value for money.Used in demanding applications suchas, e.g. in HVAC/R, oil & gas, pumps,compressors, and trans-formers.VR 60Because of its great adaptabilityand physiological safety, VR 60 coversa wide range of applications fromgeneral mechanical engineeringthrough sanitary installations on topotable water applications.As a standard, all of our materials featureanti-bake properties, facilitating removal ofthe gasket. Additionally we offer a number ofspecial-purpose material coatings. Pleasecontact us for further details. 10

Soft Range Compressed Sheet.Low bolt load? We have just the rightgasket material: the Soft Range Compressed Sheet product group. VR 55 VR 40VR 55VR 55 shows excellent sealability andadaptability already at low bolt load.Its good tensile strength makes it idealfor use in easily deformable construction components that are subjectedto high mechanical stress. Accordingly, it is used in a broad range ofapplications, e.g. in housings, covers,gear boxes, HVAC/R, engines, marineapplications and hydraulics, to namejust a few.VR 40VR 40 shows excellent adaptabilityand sealability already at low bolt load.It is our well-priced material for lightweight applications, e.g. in HVAC/R,gear boxes and motors, housings,covers, etc. 11

MaterialFeaturesTypical ApplicationsTechnical data (typical values refer to1/16" thick material unless otherwise specified)StandardTensile strength, transverseASTM F 152High-Performance Compressed SheetVR 100VR 90VR 85 Highest TemperatureResistance Superior Creep Resistance Carbon and Inorganic Fibers Nitrile Binder Ultimate Chemical andMechanical Resistance FDA-compliant for all kinds ofFoodstuffs Superior Creep Resistancecombined with UltimateTensile Strength Aramid and Inorganic Fibers Nitrile Binder High Tensile StrengthCombined with GoodAdaptability Excellent Creep Resistancecombined with Very HighTensile Strength Aramid and Inorganic Fibers Nitrile BinderOil Processing Industry,Pulp and PaperChemical Industry, Food &Beverage, HVAC/R, Water,Oil & Gas, Engines, MarineApplications, MechanicalEngineeringCombustion Engines, MarineApplications 2180 psi / 15 MPa 2610 psi / 18 MPa 2180 psi / 15 MPaCreep relaxation (1/ 32" unless otherwise specified) ASTM F 38 B15 %15 %17 %Sealability (1/ 32"), NitrogenASTM F 37 B0.25 ml / h0.12 ml / h0.15 ml / hGas permeabilityDIN 3535 / 6 0.1 mg / (s*m) 0.02 mg / (s*m) 0.1 mg / (s*m)CompressibilityASTM F 36 J6 – 10 %5–8%7 – 12 %RecoveryASTM F 36 J 60 % 55 % 50 %Thickness decrease at 68 F (20 C)9%6%13 %Thickness decrease additional, at maximumcontinuous application temperature11 % (520 F / 270 C)8 % (480 F / 250 C)7 % (480 F / 250 C)IRM 903 Oil, 5 h, 300 F0 – 10 %0–7%0–8%ASTM Fuel B, 5 h, 73 F0 – 10 %0 – 10 %0–7%Water/antifreeze 1:1, 5 h, 212 F0–7%0 – 10 %0–5%IRM 903 Oil, 5 h, 300 F10 % maximum7 % maximum12 % maximumASTM Fuel B, 5 h, 73 F10 % maximum10 % maximum10 % maximumWater/antifreeze 1:1, 5 h, 212 F7 % maximum10 % maximum15 % maximumDensity109 –122lb/ft³/1.75 –1.95 g/cm³112 – 125 lb / ft³ / 1.8 – 2 g / cm³100 – 112 lb / ft³ / 1.6 – 1.8 g / cm³VR-Hot compression test (@7250 psi ):Increase in thickness after immersion in:Increase in weight after immersion in:ASTM F 146ASTM F 146ASTM line call-outASTM F 104,respectively F 868for metal 2K7M6F712120-A9B3E12M6Operating temperature, max. 1)continuous520 F / 270 C480 F / 250 C480 F / 250 Ctemporary (peak)825 F / 440 C750 F / 400 C750 F / 400 Cmax.1880 psi / 130 bar2180 psi / 150 bar2180 psi / 150 barSheet size respectively coil width1.5 x 1.5 m (approx. 60 x 60")to 1.5 x 4.5 m1.5 x 1.5 m (approx. 60 x 60")to 1.5 x 4.5 m1.5 x 1.5m (approx. 60 x 60“)to 1.5 x 4.5 mThickness1/ 64" to 1/ 8"1/ 64" to 1/ 8"1/ 64" to 1/ 8"Operating pressure 1)Standard formats1)2)2)Maximum operating pressure and maximum operating temperature must not occur simultaneously.Special sheet sizes and material thicknesses on request. 12

General Service Compressed SheetSoft Range Compressed SheetVR 80VR 70VR 60VR 55VR 40 High-Performance Sheetwith Excellent Gas Tightness Excellent Creep Resistancecombined with High TensileStrength Aramid and Inorganic Fibers Nitrile Binder Multi-Purpose GeneralService Sheet Very Good Creep Resistancecombined with Good TensileStrength Aramid and Inorganic Fibers Nitrile Binder Good General Service Sheet Good Creep Resistance Aramid and Inorganic Fibers Nitrile Binder Excellent Sealability andAdaptability already at LowBolt Load Good Tensile Strengthcombined with Good CreepResistance Aramid and Inorganic Fibers Nitrile Binder Excellent Adaptability andSealability already at LowBolt Load Good Creep Resistance Aramid and Inorganic Fibers Nitrile BinderGas Industry, Compressors,Pumps, Transmissions, SmallEnginesHVAC/R, Oil & Gas, Pumps,Compressors, TransformersPotable Water, SanitaryInstallations, PumpsHousings, Covers, Gear Boxes,HVAC/R, Engines, MarineApplications, HydraulicsHVAC/R, Gear Boxes andMotors, Housings, Covers 1740 psi / 12 MPa 1160 psi / 8 MPa 1015 psi / 7 MPa 1160 psi / 8 MPa 1015 psi / 7 MPa15 %16 %21 %19 %22 %0.22 ml / h0.14 ml / h0.11 ml / h0.02 ml / h0.05 ml / h 0.05 mg / (s*m) 0.1 mg / (s*m) 0.05 mg / (s*m) 0.01 mg / (s*m) 0.01 mg / (s*m)7 – 15 %7 – 15 %9 – 18 %14 – 23 %15 – 25 % 50 % 50 % 55 % 50 % 60 %11 %10 %12 %17 %15 %8 % (480 F / 250 C)17 % (480 F / 250 C)22 % (430 F / 220 C)28 % (390 F / 200 C)26 % (390 F / 200 C)0 – 10 %0 – 10 %10 – 25 %0 – 10 %0 – 10 %0 – 10 %0 – 10 %10 – 25 %0 – 15 %0 – 15 %0–5%0–5%0 – 10 %0–5%0–5%10 % maximum15 % maximum20 % maximum20 % maximum20 % maximum10 % maximum10 % maximum20 % maximum20 % maximum15 % maximum10 % maximum10 % maximum10 % maximum15 % maximum15 % maximum109 – 122 lb / ft³ / 1.75 – 1.95 g / cm³119 – 131 lb / ft³/ 1.9 – 2.1 g / cm³109 – 122 lb / ft³ / 1.75 – 1.95 g / cm³87 – 106 lb / ft³ / 1.4 – 1.7 g / cm³94 – 106 lb / ft³ / 1.5 – 1.7 g / E35M4F714130-A9B3E33M4F714130-A9B4E23M4480 F / 250 C480 F / 250 C430 F / 220 C480 F / 250 C390 F / 200 C750 F / 400 C750 F / 400 C570 F / 300 C660 F / 350 C570 F / 300 C1450 psi / 100 bar1450 psi / 100 bar870 psi / 60 bar1160 psi / 80 bar725 psi / 50 bar1.5 x 1.5 m (approx. 60 x 60")to 1.5 x 4.5 m1.5 x 1.5 m (approx. 60 x 60")to 1.5 x 4.5m1.5 x 1.5 m (approx. 60 x 60")to 1.5 x 4.5 m1.5 x 1.5 m (approx. 60 x 60")to 1.5 x 4.5 m1.5 x 1.5 m (approx. 60 x 60")to 1.5 x 4.5 m1/ 64" to 1/ 8"1/ 64" to 1/ 8"1/ 64" to 1/ 8"1/ 64" to 1/ 8"1/ 64" to 1/ 8" 13

High-Performance Metal Reinforced Gaskets.High mechanical and thermal load?Applications with vibrations? Noheadache for us: the High-Performance Metal Reinforced Gasketsproduct group. VR 640 VR 108 VR 99 VR 98VR 640VR 640 is a metal reinforced fiberbased gasket material featuring agalvanized tanged steel core. It exhibits very high mechanical strengthtogether with high pressure and superior temperature resistance, yet it stillconforms well to sealing surfaces. Thematerial is resistant to oils, fuels, andmixtures of water and antifreeze orcorrosion inhibitors. Areas of application: e.g. intercoolers, compressors,engines, marine applications, HVAC/R.VR 108VR 108 is the metal reinforced variantof our carbon fiber material VR 100,wired with a mesh of galvanized car- 14bon steel. It is ideal for applicationswith fluctuating temperatures andpressures or vibrations, for examplein the oil & gas and pulp and paperindustry.VR 99VR 99 is our VR 90, reinforced withan expanded stainless steel. Thestrong metal reinforcement ensures ahigh degree of blowout safety andmechanical strength. Areas of application: e.g. chemical industry, HVAC/R,water, oil & gas.VR 98VR 98 is the wire mesh reinforcedvariant of VR 90. The reinforcementconsists of a galvanized carbon steelmesh. Its sturdiness makes it idealfor use in compressors,pumps, HVAC/R, oil & gas.

Controlled Swell Gaskets.VR 30 CSVR 30 CS is a high-performancecontrolled swell material with hightensile strength. The dimensionallystable gasket material swells in oil ina controlled manner. Because of itsspecific properties the material isespecially suitable for sealing oil pans,valve covers and transmissions.High-Temperature Metal Reinforced Mica Gaskets.VR -XVR-X is the most heat-resistant material among the VictorReinz gasket materials. The premium grade mica material,reinforced with a special heat-resistant tanged stainlesssteel, resists temperatures up to 1740 F. Wherever thingsget extremely hot, VR-X demonstrates its enormous sealingpotential: engines, exhaust systems, turbo chargers, marineapplications, burners and ovens, etc. 15

MaterialControlled Swell GasketsVR 30 CSFeatures High-Performance Controlled Swell Material Very Good Creep Resistance combined withHigh Tensile Strength Aramid and Inorganic Fibers Special Controlled Swell BinderOil Pans, Valve Covers, TransmissionsTypical ApplicationsHigh-Performance MetalReinforced GasketsVR 640 Metal Reinforced with Galvanized TangedSteel Core Ultimate Creep Resistance Superior Temperature Resistance Inorganic Fibers Nitrile BinderIntercoolers, Compressors, Engines, MarineApplications, HVAC/RTechnical data (typical values refer to1/16" thick material unless otherwise specified)StandardTensile strength, transverseASTM F 152 2030 psi / 14 MPa 7250 psi / 50 MPaCreep relaxation (1/32" unless otherwise specified)ASTM F 38 B21 %14 % [valid for t 1 mm]Sealability (1/32"), NitrogenASTM F 37 B0.40 ml / h-Gas permeabilityDIN 3535 / 6 0.1 mg / (s*m)-CompressibilityASTM F 36 J8 – 15 %7 – 13 %RecoveryASTM F 36 J 55 % 55 %Thickness decrease at 68 F (20 C)11 %9%Thickness decrease additional, at maximumcontinuous application temperature10 % (390 F / 200 C)4 % (570 F / 300 C)IRM 903 Oil, 5 h, 300 F10 – 30 %0 – 10 %ASTM Fuel B, 5 h, 73 F10 – 30 %-Water/antifreeze 1:1, 5 h, 212 F-0–7%IRM 903 Oil, 5 h, 300 F30 % maximum-ASTM Fuel B, 5 h, 73 F20 % maximum-Water/antifreeze 1:1, 5 h, 212 F--nominal thickness 1.3 mm unless otherwise specifiedVR-Hot compression test (@7250 psi ):Increase in thickness after immersion in:Increase in weight after immersion in:ASTM F 146ASTM F 146Density97–109 lb / ft³ / 1.55 – 1.75 g / cm³-ASTM line call-outASTM F 104,respectively F 868for metal reinforcedmaterialsF712440-A9B4E35M60FMF1; F F702100-B2E00M8Operating temperature, max.1)continuous390 F / 200 C570 F / 300 Ctemporary (peak)750 F / 400 C750 F / 400 COperating pressure1)max.1740 psi / 120 bar-Sheet size respectively coil width1.5 x 1.5 m (approx. 60 x 60")to 1.5 x 4.5 mcoil width max. 0.5 m (approx. 20")Thickness1/ 64" to 1/ 8"0.75 to 1.8 mmStandard formats2)1)2)Maximum operating pressure and maximum operating temperature must not occur simultaneously.Special sheet sizes and material thicknesses on request. 16

High-Temperature MetalReinforced Mica GasketsVR 108VR 99VR 98VR-X Metal Reinforced with GalvanizedSteel Mesh Superior Creep Resistance Very High Temperature Resistance Carbon and Inorganic Fibers Nitrile Binder Metal Reinforced with ExpandedStainless Steel Core Ultimate Chemical Resistance Superior Creep Resistance Highest Pressure Resistance Aramid and Inorganic Fibers Nitrile Binder Metal Reinforced with GalvanizedSteel Mesh Superior Creep Resistance High Temperature Resistance Aramid and Inorganic Fibers Nitrile Binder Metal Reinforced with Special HeatResistant Tanged Steel Core Excellent Creep Resistance Ultimate Temperature Resistance upto 1740 F (950 C)“ Mica MaterialOil Processing Industry, Pulp and PaperChemical Industry, HVAC/R, Water,Oil & GasCompressors, Pumps, HVAC/R, Oil & GasEngines, Exhaust Systems, TurboChargers, Marine Applications, Burnersand Ovens 3335 psi / 23 MPa 7540 psi / 52 MPa 2900 psi / 20 MPa 7250 psi / 50 MPa18 %22 % [valid for t 1 mm]23 %26 % [valid for t 1.2 mm]---- 0.25 mg / (s*m) 0.05 mg / (s*m) 0.25 mg / (s*m)-6–9% 5% 5%5 – 15 % 50 % 60 % 60 % 40 %9%6%7%18 %8 % (520 F / 270 C)5 % (480 F / 250 C)7 % (480 F / 250 C)11 % (570 F / 300 C)0 – 10 %0 – 10 %0 – 10 %0–5%0 – 10 %0 – 10 %0 – 10 %0–5%0–7%0–5%0–5%5 – 20 %10 % maximum10 % maximum10 % maximum15 % maximum10 % maximum10 % maximum10 % maximum10 % maximum7 % maximum5 % maximum5 % maximum20 % maximum122 – 134 lb/ft³ / 1.95 – 2.15 g / cm³ 153 lb / ft³ / 2.45 g / cm³125 – 137 lb / ft³ / 2 – 2.2 g / cm³-0FMF9; F F711110-B3E12M70FMF9; F F711110-B4E12M80FMF9; F F711110-B4E12M60FMF1; F F702120-B5E11M8520 F / 270 C500 F / 260 C480 F / 250 C1740 F / 950 C825 F / 440 C750 F / 400 C750 F / 400 C-2320 psi / 160 bar3625 psi / 250 bar2465 psi / 170 bar-1.5 x 1.5 m (approx. 60 x 60")1.25 x 1.5 m (approx. 50 x 60")1.5 x 1.5 m (approx. 60 x 60")coil width max. 0.5 m (approx. 20")1/ 32" to 1/ 8"1.0, 1.5 and 2.0 mm1/ 32" to 1/ 8"1.2 and 1.6 mm 17

Special Gasket Solutions.Eyeleted Gaskets.Special requirements under extremely difficult conditions?Our answer: the Special Gasket Solutions productgroup. Eyeleted Gaskets Graphite Materials ePTFE-Material Rubber Coated MaterialsAFM 34 CO METM.Thanks to our innovative coating (CO) in combination withan easily adaptable metal eyelet (ME), AFM 34 CO ME gaskets provide ultimate sealing already at low bolt load. Theflange gasket with stainless steel eyelet is used especiallyin the chemical, petro-chemical and natural gas industry.AFM 34Surface sealabilitySurface stressInnovative coating (CO)thin and highly adaptableto the flange surfaceMetal eyelet (ME)AFM 34 CO MESurface sealabilitySurface stressSurface stress distribution across the width ofan eyeleted gasket, comparing an unfavourableconventional design with the innovative VictorReinz AFM 34 CO ME gasket. 18Conventionaldesign Coating

Graphite Materials.ePTFE-Material.Rubber Coated Materials.Chemotherm SPTM andChemotherm SPETM.Made of expanded graphite on atanged steel core, Chemotherm SP isthe special material for quick-changingthermal-mechanical operating conditions. Its excellent material propertiesgive proof especially in the exhaustarea or as a cylinder head gasket.REINZOFLON ETM.REINZOFLON E consists of pureexpanded PTFE (ePTFE) – a materialwith excellent chemical resistance toaggressive fluids. Because of itsspecial structure, ePTFE is mechanically very strong and stable as well assoft and very adaptable.REINZOFLON E is used whereversealing against highly aggressivefluids, e.g. acids, is required.MatriCSTM and MatriCS plusTM.MatriCS defines a new generation ofrubber coated materials. It consistsof a carbon steel core with fiberreinforced rubber coating; it is verycompressible and features good recovery. MatriCS is the ideal solutionfor sealing joints that have to meetstringent mechanical and thermalrequirements simultaneously.Our Chemotherm SPE features atanged stainless steel core. Thus, theSPE version expands the range ofapplications to sealing aggressivefluids, e.g. in piping construction andapparatus engineering.MatriCS plus, compared to MatriCS,features stainless steel as metal coreand a thicker fiber reinforced elastomer coating – for applications withhigh dynamics and/or where corrosionresistance is of importance. 19

Sealants.No space for a flat gasket andextremely narrow web width? Oursolution: the Sealing Compoundsproduct group. REINZOPLAST REINZOSIL REINZOSIL-t RE-MOVEREINZOPLASTREINZOPLAST is a solvent-free,permanently plastic, non-curingpolyurethane sealants with very goodflow properties. It is ideal for sealingjoints subjected to great static loadswith vibrations.REINZOSILREINZOSIL is a quick-hardeninguniversal silicone sealants for sealingeven large gaps – also without component disassembly. It features hightemperature and fluid resistance.REINZOSIL-tREINZOSIL-t is the transparent version of REINZOSIL. Because of itstransparency, it is primarily used atexposed sealing joints when visualappearance matters.RE-MOVERE-MOVE is a highly effective sealantremover based on ether solvent with apropellant. The agent removes anykind of gasket residues and sealingcompounds quickly and easily.Beyond this, it can also be used toremove adhesives, resin and paintresidues.TIP FROM THE EXPERTSFor sealing gaps smaller than 0.006 inches between thetwo sealing surfaces, REINZOPLAST is the right choice. Forgaps of 0.006 inches and larger our product REINZOSILseals quickly and reliably. 20

Tested Quality. Your Advantage.For example RPM 511 measures the deformation (compressibility and recovery)as a function of surface stress (alsoknown as LDC load deflectioncurves). RPM 510 hot compression testmeasures creep relaxation undertemperature for different surfacestress levels.With all these tests we ensure thatyou receive materials that are idealfor your applications. Naturally, wehave all required ISO certifications,e.g. ISO/TS 16949.Strict Testing Methods, International Certificates, WorldwideReferences.Rest assured that you’re alwaysreceiving the best quality.Gasket material is our business –and we know it as few others do.Of course, we test our materials according to DIN and ASTM standards,but even these do not cover all properties essential in practical application.For this reason we always go one stepfurther. We use our own additionalstandards, designated as RPM (Reinztest methods), which guarantee highest quality – for your safety’s sake. 21

Practical Tips for Gaskets. Retorqueing of bolts is recommended before commissioning tocompensate for potential settling ofthe gasket. Retorqueing of fiber or PTFE basedgaskets that have been in operationmust only be done under ambienttemperature. Retorque with greatcare in several steps to avoid damage to the gasket.InstallationCorrect installation is a basic requirement for the reliable function of a gasket. The surface stress at assemblyhas to be in between the minimumrequired and maximum permissible forthe respective gasket material. Use only new, undamaged, anddry gaskets. Please consider ourstorage recommendations, providedbelow. Clean the sealing surfaces carefullywithout scratching them. Make surethat the sealing surfaces are dry. Center the gasket. Do not applyany additional sealing compound,grease, releasing agent or similarsubstance to the gasket or the sealing surfaces. Do not use corroded bolts, nutsor washers. The calculated surface stress must match the actually achieved stress. Therefore, thebolts and nuts should be lubricatedslightly. Align the two sealing surfaces andtighten the bolts by hand. In order to achieve an even distribution of the surface stress, the boltsmust be torqued to the specifiedvalue in star pattern using at leastthree steps. Example:- Step 1:20% of the specified torque- Step 2:60% of the specified torque- Step 3:100% of the specified torque All bolts must be torqued to thesame specified value.Storage recommendationsPlease consider the following storageconditions for fiber based gaskets andgasket material sheets:Recommended maximum storageperiod is two to three years under thefollowing conditions: Temperature: below 68 F Relative humidity: 30.60 % No direct sunlight No artificial lighting with highUV content No ozone Stress-free storageAny significant deviation from theabove will reduce the maximumstorage period. When critical (e.g.toxic) gases are to be sealed, thestorage period should not exceedone year. If necessary, the gaskets orgasket material sheets must be storedin airtight and lightproof packaging.WarningProperties/applications shown throughout this brochure are typical. Your specific application should not be implementedwithout independent study and evaluation for suitability. For specific application recommendations please consult us.Failure to select the proper sealing products could result in material damage and/or serious personal injury. Performancedata published in this brochure is based on field tests, customer field reports and/or in-house testing. Field conditions willaffect gasket performance. While utmost care has been taken while compiling this brochure,we assume no responsibilityfor errors. Specifications are subject to change without notice. We point out that this method for gasket selection is merelya general guide and should not be the sole means for selecting or rejecting a product. 22

At Home in Your Country.Excellent availability and shortest delivery times: we have an experiencedsales partner in the U.S. gasket industry providing an excellent service. 23

Dana IncorporatedDana is an integral partner for virtuallyevery major vehicle and engine manufacturerworldwide. Dana is a leading supplier ofdrivetrain, sealing, and thermal technologiesto the global automotive, commercial-vehicle,off-highway markets and for industrial applications. Founded in 1904, Dana employsthousands of people across six continents.What Can Dana Do For You?This lineup of technologies from one sourceis designed to offer flexibility to vehiclemanufacturers around the world – whetherin automotive centers or emerging markets– and ensures that customers get the lateststate-of-the-art technologies, as well asproducts adjusted for specific local markets.With technology centers strategically locatedthroughout the world, Dana engineers havethe superior resources to develop, design,test, and manufacture to suit individual customer needs. This close collaboration allowsDana to create everything from advancedsingle components to fully integrated modularsystems.AxlesDriveshafts«Off-Highway» TransmissionsGaskets and SealsCylinder-Head Cover ModulesThermal-Acoustic Protective ShieldingTransmission Oil CoolersEngine Oil CoolersVictor Reinz Sealing Solutions.We are Your Industrial Sealing Expert.Seal & DesignC

The worldÕs best gasket fabricators trust Dana to supply the perfect fit for your needs. We Are Ready for the Sealing Future. Traditional and innovative: weÕve been in the gasket business for almost 100 years and know the field like few others. We continually look toward in-novations to come Ð whatever gasket you might need in the future. Â 6 Gasket Solutions for Industrial Applications .