Transcription

If You Can’t Take the HeatUtilizing Heat Recovery EffectivelyPresented byBrent SigmonSales ManagerCarrier Corporation 2014 Carrier Corporation

AGENDA What is Waste Heat?How Waste Heat is capturedBenefits of Heat ReclaimHeat Reclaim definitionsSystemsProductsExampleHeat Reclaim misapplied4

WHAT IS WASTE HEAT?Chilled Water HVAC System Heat is released to the atmosphere through cooling towerUnwanted heat is drawn from space or process5

HOW WASTE HEAT IS CAPTURED?Primary/Secondary Chilled Water System with the Heat Machine [3] Heat machine captures some of the wasted heat for useful purposes.Remainder is released through the cooling tower6

WHY IS HEAT RECOVERY IMPORTANT?100%USA Energy Consumption (BTU)25% Other28%Transportation9% IT / electronics10% Water heating32%Industry16% Lighting40% HVAC40%Buildings*Space and Water Heating is 50% of Total Building EnergySource: U.S. DOE, Buildings Energy Data Book, Mar. 2011* Includes Commercial and Residential buildings7

HEAT RECLAIM – WHY?ASHRAE 90.1-2010Heat Recovery for Service Water Heating, Section § 6.5.6.2 Operates 24 hours a day Total heat rejection exceeds 400 tons of chiller capacity (6,000,000 Btu of heat rejection) Service water-heating load exceeds 1,000,000 Btu/hCapacity to provide the smaller of: 60% of the peak heat rejection load at design conditionsor Preheat of the peak service hot water draw to 85 F.Exceptions: Use minimum 30% of peak condenser load at designconditions for space heating.or 60% or more of service water heating from site solar orcogeneration, condensate subcooling, or solar panels.Helps to earn LEED points under EAc 1Maintain ASHRAE 90.1 complianceLEED is a registered trademark of the U.S. Green Building Council.8

QUESTION #1According to the Department of Energy whatpercentage of the US building energyconsumption is space and water heating(HVAC and space heating)?A. 25% B. 50%C. 75%D. 10%9

QUESTION #2According to ASHRAE 90.1, what are the minimumbuilding conditions that Heat Recovery is required inthe building?A. 200 tons of chiller capacity and service water-heating loadexceeds 5,000 Btu/hB. 500 tons of chiller capacity and service water-heating loadexceeds 2,000,000 Btu/hC. 400 tons of chiller capacity and service water-heating loadexceeds 1,000,000 Btu/hD. ASHRAE 90.1 recommends, but does not require heatrecovery10

HEAT RECLAIM BENEFITS Uses waste heat to save energy Consumes less power during simultaneous heating and cooling– Using less boiler power consumption Has many uses– Heating building– Heating service water– Heating process water Capable of producing potable water Viable applications include– Hotels, college dormitories, indoor swimming pools,commercial laundries, hospitals LEED Project, EAc1 Points– Optimized energy performanceLEED is a registered trademark of the U.S. Green Building Council.11

HEAT RECOVERY FUNDAMENTALSCoefficient of Performance, the ratio of the output heatto the supplied work orWhere Q is the useful heat supplied by the condenserand W is the work consumed by the compressor.Heat recovery not only captures sufficient heat for usefulpurposes, it also produces the additional benefit ofchilled water.12

HEAT RECOVERY FUNDAMENTALSHeat OutWork In(Electricity)Heat In13

COP EXAMPLECOPHeat HR Chiller742.0 kW 185.2 kW4.0*1 kWCOPHeat Electric Boiler 1 kW 1.0COPHeat Gas Boiler.95 MBH .951HR Chiller uses refrigeration effect togain efficiency/savings versus a boiler*Chiller at 130 F leaving condenser Water and 44 F leaving chilled water14

HEAT RECOVERY COMPARISONSimultaneous heating and cooling: Electric HWheaters/boiler add heat(3.51 IkW / Ton) Chillersremove heat(0.6 IkW)Total(4.11 IkW / Ton)Heat reclaim can chill water to 44F, while heating hot water to 140F for 1.48 kW/TonFocus energy conservation effort on the bigger consumers: BOILERSOver 2.6 kW/ton Savings!15

HEAT RECOVERY FOCUSSimultaneous heating and cooling: Gas Boilers add heat(4.4 IkW / Ton) Chillers remove heat(0.6 IkW)Total(5.0 IkW / Ton)Heat reclaim can chill water to 44F, while heating hot water to 140F for 1.48 kW/TonFocus energy conservation effort on the bigger consumers: BOILERSOver 3.5 kW/ton Savings!Heat Machine saves as much as VFD Chillerif just 10% of ton hours are heat recovery16

CHILLER DEFINITIONS Cooling-Only– Standard water or air-cooled chiller Leaving chilled water temp is controlled Heat Reclaim– Standard water or air-cooled chiller Leaving chilled water temp is controlled Reclaimed heat from condenser is used to producehot water – not controlled– Reclaimed heat a function of cooing process Heat Machine– Water-cooled chiller option Leaving hot water temp typically higher than cooling-only chiller Leaving chilled water temp by-product ofheating function – not controlled– Chilled water temp controlled by primary chiller downstream17

HEAT RECOVERY DEFINITIONSTwo common ways toperform heat recovery1. Desuperheater– Refrigerant-to-water heat exchanger betweencompressor and condenser Captures heat from superheated refrigerant– Provides uncontrolled hot water temp Allows chiller to produce higher hot water temps– Transfer heat at discharge temp Only small quantity of heat is available since only superheatis removed from refrigerant (25% heat of compression)18

HEAT RECOVERY DEFINITIONSTwo common ways toperform heat recovery2. Full Condensing– Refrigerant-to-water heat exchanger Captures heat from refrigerant condensing process– Provides uncontrolled hot water temp– Hot water temp a function of the condensing temp Larger quantity of heat is available compared to desuperheater19

HEAT RECOVERY EXAMPLE 550,000 sq.ft. Medical use space(hospital and office space) Efficiency key matrix– Maintain operability– Local Energy Incentives Simultaneous Heating and Coolingyear around Humidity control with chilled water/ reheat for hospitalSwedish Issaquah Hospital Peak CHW load 800 tons Peak HW Demand 5,000 MBH*ASHRAE Journal. June 2013. Pgs 36-44. Jeremy McClanathan, PE20

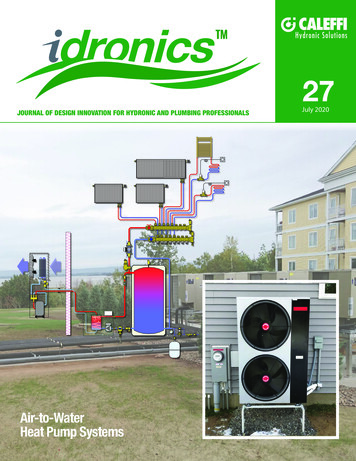

HEAT RECOVERY SEASONALITYHeating LoadPotable WaterCooling 0Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov DecTonsHeating (MBH)40000What sizeHR chiller?Size tomaximize use,not peakdemand.Boilers augmentHR chiller forpeak load021

HEAT RECOVERY EXAMPLEHeating LoadPotable WaterUsed a 300 ton HR chillerCooling Load900600080060040005003000400Produces approximately 4,500 MBHof heating at maximum nJulAugSepOctNovDecHeating (MBH)5000Enhancesavings withHW storagetanks0Increase the Mechanical budget byaround 6%, 500k savings per yearSix year simple payback(without external incentives)Less than one year paybackwith incentives22

HR CHILLER OPTIONSProduction / Distribution LoopCH-1HDCH-2Owner request redundancy for 260 ton chilled water plantInstall two (2) identical High Efficiency (HE) chillers, each 260 tons.What is the payback on CH-2?23

HR CHILLER OPTIONSProduction / Distribution LoopCH-1 (HE)HDCH-2 (HR)Owner request redundancy for chilled water plantInstall one (1) HE, one (1) Heat Recovery (HR) chiller.What is the payback on CH-2? 24

HR CHILLER OPTIONSProduction / Distribution LoopCH-1 (HR)HDCH-2 (HR)Install two (2) HR chillers.What is the payback on CH-2?Plant efficiency when you cannot utilize heat?25

HR CHILLER EXAMPLEBaseline47%Savings10% Add CostTwo HE chillers are the baseline for energy use.Using a HE and HR chiller together sized appropriatelysaved 47% yearly energy consumption (in )Two HR chillers actually cost more in energy. Why?Optimize lift in the machine (1.5 kw/ton vs. .35 kw/ton)26

CHILLER LIFTLift Amount of compressor workneeded to overcome differencesbetween leaving condensing waterand leaving chilled watertemperaturesLift (f) of SCT – SSTLower Lift Less Work Lower kWMinimize energy consumptionMaximizes energy savings!27

HIGHER LCWT LOWER EFFICIENCYChiller Efficiency at Various LeavingCondenser Water TemperaturesFull Load Chiller CWT ( F)Minimize LCWT, Maximize Efficiency28

SAVINGSSavings vary by application according to: Gas rate vs. electric rateAmount of heat recovery hoursHot water temperatureBoiler efficiency and typeHydronic system design29

CONDENSER PIPINGDual Heat / Cool Piping SchematicChiller can operatein cooling or heating.Control to T4in HEAT mode.Control to T1in COOL mode.Meet low winter loadswith our tower orcondenser pumps.30

EVAPORATOR PIPINGVariable speed dedicated evaporator pump regulateschilled water temperature while chiller tracks heat load.AutomaticIsolation ValvesControlValve, sizedfor minimumchiller flowP-1CH-1BypassCH-2P-2CH-3P-3Flow MeterEquipmentControl ToCH-1, CH-2LCWT Set PointCH-3LCdWT Set PointP-1, P-2Differential PressureP-3CH-3 LCWT31

HEAT RECLAIM CHILLER32

SIZING HEAT MACHINESHot water demand profile:Use ASHRAE Applications manual “Chapter 50”Service Water Heating.Table 7 provides HW demands for various types of buildings.Demand profile from Energy AnalysisSize per lowest HW demandSize larger with storage tank (preferred)Process load from customer.33

HOW TO SIZE A HEAT MACHINEHot Water Demand ProfileSizing the Heat Reclaim Chiller (one way): Dedicated reclaim chiller Size always allows it toreject all heat intoheat demand Trim heat demand withhot water heaters34

HOW TO SIZE A HEAT MACHINEHot Water Demand ProfileSizing the Heat Reclaim Chiller (a better way): A larger dedicatedheat reclaim chiller withpreheat storage tank Size allows storage ofheat during low demandfor use at periods ofhigh demand35

ONBOARD CONTROLSThe Heat Reclaim Chiller in Heating Mode Controls the Leaving Hot Water Temperature and prevents overcoolingof chilled water “Low Source Protection” feature prevents overcooling by reducingcompressor stage if necessary Captures maximum heat while maintaining stable chiller plant operation Why is chiller plant stability important?36

QUESTION #3When using a desuperheater heat exchanger forheat recovery, you are maximizing your heatrecovery potential.TrueFalseA full condensing heat exchanger maximizesyour heat recovery potential37

QUESTION #4The following are benefits of heat recoveryexcept.A. Energy SavingsB. Potential LEED pointsC. Can provide domestic or heating hot waterD. Makes steam efficiently from the chillerLEED is a registered trademark of the U.S. Green Building Council.38

IF YOU CAN’T TAKE THE HEATREMEMBER TO FILL OUT AND TURN IN THE EVALUATION FORMReminder: If you are registered in Florida, New York, or North Carolina,you must also sign the sheets in the back at the end of the session.Please print your name, include your registration number, and sign the sheet.39

Hot Water Demand Profile Sizing the Heat Reclaim Chiller (a better way): A larger dedicated heat reclaim chiller with preheat storage tank Size allows storage of heat during low demand for use at periods of high demand HOW TO SIZE A HEAT MACHINE 35. The Heat Reclaim Chiller in Heating Mode