Transcription

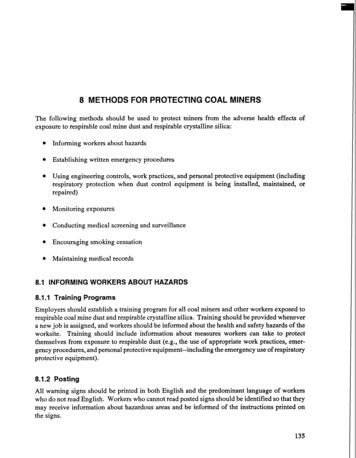

8 METHODS FOR PROTECTING COAL MINERSThe following methods should be used to protect miners from the adverse health effects ofexposure to respirable coal mine dust and respirable crystalline silica:Informing workers about hazardsEstablishing written emergency proceduresUsing engineering controls, work practices, and personal protective equipment (includingrespiratory protection when dust control equipment is being installed, maintained, orrepaired)Monitoring exposuresConducting medical screening and surveillanceEncouraging smoking cessationMaintaining medical records8.1 INFORMING WORKERS ABOUT HAZARDS8.1 .ITraining ProgramsEmployers should establish a training program for all coal miners and other workers exposed torespirable coal mine dust and respirable crystalline silica. Training should be provided whenevera new job is assigned, and workers should be informed about the health and safety hazards of theworksite. Training should include information about measures workers can take to protectthemselves from exposure to respirable dust (e.g., the use of appropriate work practices, emergency procedures, and personal protective equipment--including the emergency use of respiratoryprotective equipment).8.1.2 PostingAll warning signs should be printed in both English and the predominant language of workerswho do not read English. Workers who cannot read posted signs should be identified so that theymay receive information about hazardous areas and be informed of the instructions printed onthe signs.

Coal Mine Dust8.2 ESTABLISHING WRITTEN EMERGENCY PROCEDURESThe employer should formulate a set of written procedures covering fire, explosion, asphyxiation,and any other foreseeable emergency that may arise during coal mining or in other occupationswhere workers are exposed to respirable coal dust. All potentially affected workers shouldreceive regular training in fire or emergency evacuation procedures and the proper use ofself-contained self-rescuer (SCSR) and other rescue and evacuation equipment. Selected workersshould be given training in first aid, cardiopulmonary resuscitation, and fire control. Proceduresshould include prearranged plans for transportation of injured workers and provisions foremergency medical care. At least two trained persons in every work area should have receivedextensive emergency training. Necessary emergency equipment, including appropriate respirators and other personal protective equipment, should be stored in readily accessible locations.8.3 ENGINEERING CONTROLSEngineering controls should be the principal method for minimizing exposure to respirable coalmine dust and respirable crystalline silica in the workplace. Engineering control measures includediluting the dust generated (by adequate ventilation at the coal face), controlling the respirabledust generated and entrained (e.g., with improved shearer drum design), and suppressing the dustgenerated (e.g., by water application).8.3.1 Dust ControlTo be effective, the dust control system in a mine should be evaluated as soon as possible afterany change in geological conditions, production, processes, or controls that might increase theconcentrations of respirable coal mine dust or respirable crystalline silica.Jobs that require rock drilling (e.g., roof bolters) can generate dust containing respirable crystalline silica. Wet drills (including use of surface-active agents) or drills with attached dustcollectors are advisable [Olishifski 1971; NIOSH 19921. Dry drilling without dust controlsshould be prohibited. Appendix C contains further information about reducing respirable dustconcentrations during overburden drilling in surface coal mining operations.8.3.2 VentilationUnderground coal mines are required to be mechanically ventilated [30 CFR 75.300-75.3301.The purpose of mechanical ventilation is to provide fresh air to the underground miners and tocarry off toxic and explosive gases and dusts. The primary purposes of ventilation are to diluterespirable coal dust, to remove explosive concentrations of coal dust and methane from theworking faces, and to remove methane from mined-out areas. In addition to supplying fresh airand exhausting noxious and explosive gases and dusts, mine ventilation systems must furnishpaths of escape in the event of an underground fire. Ventilation and escape considerations relatingto fire safety are extremely complex.The portions of the mine used as part of the ventilation system are sometimes referred to as "aircourses" [McAteer 198 11. Air courses are often described as follows:

8 Methods for Protecting Coal MinersIntake air courses, which bring in fresh air to the working faceReturn air courses, which exhaust air from the working faceThe number of entries available for ventilation vary with the mining method used and thegeological characteristics of the rock strata mined.Exhaust fans are commonly used to ventilate underground coal mines. Positive-pressure fans areused infrequently-usually where the mine is close to the surface and there is leakage to thesurface through the air intakes. The volume of air flow through an underground mine is a functionof the fan capacity and the "resistance" of the mine ventilation configuration WcAteer 19811.Because of the multiple functions imposed on underground coal mine ventilation systems and thewide variations in underground mining methods, no general statements can be made about theavailability of intake air to dilute respirable dust at the working face. Current ventilationtechniques are largely dictated by regulations relating to available types of air courses, escapewayrequirements, and methane regulation. The ventilation plan for each underground coal mine mustbe approved by MSHA [30 CFR 75.3 161.Guidelines for the design of mine ventilation systems may be found in Mine Ventilation and AirConditioning [Hartman et al. 19821. Principles for the design and operation of local exhaustsystems are presented in Industrial Ventilation-A Manual of Recommended Practice [ACGIH19951; American National Standard: Fundamentals Governing the Design and Operation ofLocal Exhaust Systems, 29.2 (1971) [ANSI 19791; and Recommended Industrial VentilationGuidelines, published by NIOSH [Hagopian and Bastress 19761.8.4 WORK PRACTICES8.4.1 Worker IsolationIf feasible, workers should be isolated from work areas where the concentration of respirable coalmine dust or respirable crystalline silica exceeds the REL. This can be done by using automatedequipment operated from a closed control booth or room. The control room should be maintainedat a positive pressure so that air flows out of rather than into the room. However, personalprotective clothing and equipment (including respiratory protective equipment) may be necessarywhen workers must perform process checks, adjustments, maintenance, or other related operations in work areas where respirable dust concentrations exceed the RELs.8.4.2 Sanitation and HygieneTobacco products should not be smoked, chewed, or carried into work areas. Workers should beprovided with and advised to use facilities for showering and changing clothes at the end of eachwork shift. Tools and protective clothing and equipment should be cleaned as needed to maintainsanitary conditions. The work area should be kept free of flammable debris. Flammable workmaterials (rags, solvents, etc.) should be stored in approved safety cans.

Coal Mine Dust8.5 PERSONAL PROTECTIVE EQUIPMENT8.5.1 Protective Clothing and EquipmentWorkers should wear work uniforms, coveralls, or similar full-body coverings that are launderedeach day. Employers should provide lockers or other closed areas for workers to store their streetclothes separately. Employers should also ensure that protective clothing is inspected andmaintained to preserve its effectiveness. At the end of each workshift, employers should collectwork clothing and provide for its laundering. Laundry personnel should be informed about thepotential hazards of handling contaminated clothing, and they should be instructed aboutmeasures to minimize their health risk.Workers and persons responsible for worker health and safety should be informed that protectiveclothing may interfere with the body's heat dissipation, especially during hot weather (e.g., insurface coal mines) or in hot work situations (e.g., in confined spaces). Additional monitoringis required to prevent heat-related illness when protective clothing is worn under these conditions[NIOSH 19861.8.5.2 Respiratory Protection8.5.2.1 The Need for Respiratory ProtectionThe need for respiratory protection in U.S. coal mines has changed considerably since 1969. Theuse of sophisticated extraction machines has greatly increased coal production and the quantityof dust generated. New chemicals have also been introduced for use in dust control systems, andviable biological matter has been discovered in the mining environment. Other potentiallyhazardous exposures include diesel exhaust, coal tar pitch volatiles from creosote-treated timbers,and polyurethane resins used in some roof support systems. The current MSHA regulations forrespiratory equipment are contained in 30 CFR 70.300-70.305- 1.Engineering controls should be the primary method used to control exposures to airbornecontaminants. Respiratory protection is the least preferred method of controlling worker exposures and should not be used routinely to prevent or minimize exposures. Respirators should beused by workers only in the following circumstances:During the development, installation, or testing of required engineering controlsWhen engineering controls are not feasible to control exposures to airborne contaminantsduring short-term operations such as maintenance and repairDuring emergencies8.5.2.2 Selection of RespiratorsSeveral factors in the mine environment affect the selection of respirators. Safety factors are aparticular concern, and impairment of vision must be avoided. For example, the use of watersprays to suppress dust may result in dirty water droplets that can quickly obscure vision infull-facepiece respirators. Silt can also collect around respirator face seals and irritate the skin.

8 Methods for Protecting Coal MinersThe particulate filter in the respirator can become saturated and change its filtration and breathingresistance characteristics.The NIOSH Respirator Decision Logic [NIOSH 1987bl should be followed to select the correctrespirator. The following issues should be evaluated:Other available means of reducing exposure, such as increased or redirected ventilation andimproved dust and vapor control systemsThe nature of the task to be performed (location, physical demands, industrial processesinvolved, and frequency and duration of respirator use)The space restrictions within the work locationThe physical nature of the air contaminant, including odor threshold, eye irritation, andother warning propertiesThe interaction of contaminants with the respirator filter mediumThe concentrations of respirable coal mine dust, respirable crystalline silica, and other toxiccontaminants in the miner's breathing zoneToxicological data, RELs, and PELSThe required use of protective devices for the eyes and faceThe level of respiratory protection needed by the minerThe worker's fitness to wear a respirator as determined by his or her health, potentialhypersensitivity to a substance, type of respirator, fit testing, training, and conditions ofrespirator use (this issue is particularly important with the use of self-contained breathingapparatus)The performance characteristics, capabilities, and limitations of different types of respirators8.5.2.3 Respiratory Protection ProgramWhen respirators are used, employers should institute a complete respiratory protection programthat includes, at regular intervals, worker training in the use and limitations of respirators, routineair monitoring, and the inspection, cleaning, maintenance, and proper storage of respirators. Anyrespiratory protection program must, at a minimum, meet the requirements of 29 CFR 1910.134.Respirators should be used according to the manufacturer's instructions.Each respirator user should be fit-tested and the wearer's physical ability to wear a respiratorshould be periodically evaluated by a physician [Appendix H of NIOSH 1991b; NIOSH 1994dl.

Coal Mine DustThe miners should be informed annually about the hazard of dust exposure, and they should betrained in the use and care of the respirators. In addition, the program should be periodicallyreviewed, and if necessary, corrective action should be taken to maintain program effectiveness.For additional information about the use of respiratory protection, refer to the NIOSH Guide toIndustrial Respiratory Protection [NIOSH 1987al or the NIOSH Respirator Decision Logic[NIOSH 1987bl.Table 8- 1 lists the recommended minimum respiratory protection for respirable coal mine dustand respirable crystalline silica. The NIOSH Respirator Decision Logic [NIOSH 1987b (orsubsequent revised editions)] should be consulted if a certain condition requires a specific typeof respirator other than those listed in Table 8-1.When respirators are indicated, the employer should provide them at no cost to the worker andshould assure the appropriate respirator is used. The employer should select respirators that areapproved under the new NIOSH respirator certification regulation (42 CFR 84).*8.6 EXPOSURE MONITORINGRoutine environmental monitoring is an important part of an occupational health programdesigned to protect workers from the adverse effects of exposure to respirable coal mine dust andrespirable crystalline silica. Such monitoring provides a means of assessing the effectiveness ofengineering controls and work practices. The environmental monitoring (including both theinitial and periodic surveys) should be conducted by competent industrial hygiene and engineering personnel. Chapter 5 and Appendices I and J contain additional information about samplingrespirable coal mine dust and respirable crystalline silica.The concentration of respirable coal mine dust or respirable crystalline silica shall be determinedas a time-weighted average (TWA) by collecting samples over an 8- or 10-hr shift for up to a40-hr workweek. For extended workshifts, Brief and Scala [I9751 present a method for estimating an exposure-limit reduction factor. When the mine environment contains concentrations thatexceed the REL for respirable coal mine dust or respirable crystalline silica, workers must wearrespirators for protection until adequate engineering controls or work practices are instituted.8.7 MEDICAL SCREENING AND SURVEILLANCEFirst priority should be given to primary prevention of occupational respiratory diseases throughthe reduction of exposures. However, a secondary program of medical screening and surveillanceis necessary to identify miners who develop respiratory diseases as a result of their workplaceexposures. Chapter 6 contains provisions for preplacement and periodic medical examinationsand recommendations for medical intervention.*42 CFR 84 became effective July 10, 1995, and replaces the provisions under 30 CFR 11.140

See footnotes a t end of table.Entry into environmentscontaining respirable dustCondition10.05 (1 x REL)10.25 (5 x REL)10.5 (10 x REL)11.25 (25 x REL)12.5 (50 x REL)125 (500 x REL)1 5 (5 x REL)110 (10 x REL)125 (25 x REL)150 (50 x REL)1500 (500 x EL)**Respirable crystalline silica1 1 (1 x REL) ,*Respirable coal mine dustAirborne concentration (mg/m3*(continued)Any supplied-air respirator operated in a pressuredemand orother positive-pressure mode%5Any self-contained respirator equipped with a full facepieceand operated in a demand (negative-pressure) mode3zazr)aP .'a85.vii;caAny supplied-air respirator equipped with a tight-fittingfacepiece and operated in a continuous-flow mode, orAny supplied-airrespirator equipped witha full facepiece andoperated in a demand (negative-pressure) mode, orAny powered, air-purifying respirator equipped with a tightfitting facepiece and a high-efficiency filter,§ orAny air-purifying, full-facepiece respirator equipped with ahigh-efficiency filter,g orAny supplied-air respirator equipped with a hood or helmetand operated in a continuous-flow modeAny powered, air-purifying respirator equipped with a hoodor helmet and any type of particulate filter,t orAny supplied-air respirator equipped with a half mask andoperated in a demand (negative-pressure) modeAny air-purifying, half-mask respirator equipped with any typeof particulate fdter) orSingle-use or quarter-mask respirator equipped with any typeof particulate filtersNo respirator requiredMinimum respiratory protectionTable 8-1. NIOSH-recommended respiratory protection for workers exposed t o respirable coal mine dust a n d respirable crystalline silica

Respirable coal mine dustREL)or unknown' s s i n eprotectiondfactor (APF) times the NIOSH REL.The APF [NIOSH 1987bl is the minimum anticipated level of protection provided by each type of respirator.*The values in this table were computed using the NIOSH REL of 1 mg/m3for respirable coal mine dust measured according to cumnt MSHA methods (see Section 5.1).This REL of 1 mg/m3 is equivalent to 0.9 mg/m3when measured according to the international definition of respirable dust (see Sections 5.2 and 5.4). Thenew NIOSH respirator certification regulation (42 CFR 84) became effective July 10, 1995, and replaces the old regulation (30 CFR 11). High-efficiency is the** appropriate filter for respirable crystalline silica under 30 CFR 11; N100, R100, and PlOO are the appropriate filters for respirablecrystalline silica under 42 CFR 84.For airborne particulates, 500 x REL is the concentration above which only the most protective respirators are recommended [NIOSH 1994al.s he highest measured concentration of respirable coal mine dust or silica determines the minimum respiratory protection to be supplied to and worn by the miner.Any appropriate escape-type, self-contained breathingapparatus or self-contained self rescuer (SCSR)Any air-purifying, full-facepiece respirator with a highefficiency filter, orEscape onlyAny supplied-airrespirator equipped with a full facepiece andoperated in a pressuredemand or other positive-pressuremode in combination with an auxiliary self-containedbreathing apparatus operated in a pressure-demand or otherpositive-pressure modeAny self-contained breathing apparatus equipped with a fullfacepiece and operated in a pressure-demand or otherpositive-pressuremode, orMinimum respiratory protectionAny self-contained breathing apparatus equipped with a fullfacepiece and operated in a pressure-demand or otherpositive-pressuremodeconcentrations 25 (500xRespirable crystalline silicaFirefightingPlanned or emergency entry 500 (500x REL)or unknowninto environments containingconcentrationsrespirable dustConditionAirborne concentration (mg/m3*Table 8-1 (Continued). NIOSH-recommended respiratory protection for workers exposed t orespirable coal mine dust a n d respirable crystalline silica

8 Methods for Protecting Coal Miners8.8 SMOKING CESSATIONOverwhelming evidence exists for the adverse health consequences of smoking, the number ofworkers affected, and the additive effects of smoking and dust exposures on the development ofoccupational respiratory diseases (e.g., chronic bronchitis, emphysema, and lung cancer). Because of this evidence, NIOSH and the Association of Schools of Public Health cosponsored aProposed National Strategy for the Prevention of Occupational Lung Diseases, which recommended the elimination of smoking in the workplace as an important strategy for preventingoccupational lung diseases [ASPH 19861. The recommendation was further supported by theNIOSH conclusion that nonsmokers exposed to environmental tobacco smoket in the workplacehad an increased risk of lung cancer [NIOSH 1991a].NIOSH recommends the following regarding smoking in the workplace:Workers should be prohibited from smoking in the workplace.Information about health promotion and the harmful effects of smoking should be disseminated.Smoking cessation classes should be offered to workers at no cost to the participant.Therefore, in addition to the MSHA prohibition of smoking in all underground mines and insurface mines where fire or explosion may result [30 CFR 75.1072 and 77.171 11, NIOSHrecommends that smoking be prohibited in all underground and surface coal mines and all otherwork areas associated with coal mining to prevent exposure to environmental tobacco smoke, apotential occupational carcinogen [NIOSH 1991al. NIOSH also recommends that all miners whosmoke participate in a smoking cessation program.8.9 RECORDKEEPINGMedical records must be maintained for workers as specified in Section 1.11 of this document.They must be kept for at least 40 years after termination of employment. Copies of environmentalexposure records for each worker must be included with the medical records. These records mustbe made available to past or present workers or to anyone having the specific written consent ofa worker, as specified in 42 CFR 37.80.8.10 PROTECTING CONTRACT MINERSSome provisions of the standard recommended in this criteria document may be difficult to applyto a special category of miners known as contract miners. Coal miners who are contracted towork on specific jobs at various mines for relatively short periods may not gain the full benefitsof exposure monitoring, medical surveillance, hazard training, and transfer programs normallyavailable to other mine workers. NIOSH recognizes the need to include these contract miners ina recommended standard and will continue to explore options that will address their occupationalsafety and health needs.'Environmental tobacco smoke is tobacco smoke in the ambient atmosphere composed of sidestream smoke and exhaledmainstream smoke [NIOSH199la].

9 RESEARCH NEEDSAdditional research and data analysis are needed for improvements in engineering controlmethods, respiratory protection, sampling devices and strategies, medical screening and intervention, adverse health effects of dust exposure, characterization of dust for future recommendedstandards, and training and education. The following is a list of such research needs:Engineering control methodsAssess current control technology in the coal mining industry by examining state-of-the-arttechnologies and work practices.Develop and recommend improved methods for keeping worker exposures below the RELsfor respirable coal mine dust and respirable crystalline silica in underground and surfacecoal mines.Respiratory protectionEvaluate the physiological stress placed on miners who must wear respiratory protection.Sampling devicesDevelop sampling devices with improved design for greater accuracy and precision andmore rugged construction.Develop continuous monitors for use in sampling respirable coal mine dust.Sampling strategyEvaluate sampling strategies for the accurate monitoring and control of worker exposures.Evaluate sampling strategies for effective enforcement of the standard.Medical screening and interventionEvaluate the effectiveness of the existing transfer program in preventing the progressionof simple CWP. The transfer program enables miners with CWP category 110 or greater

9 Research Needsto transfer to jobs in areas of the mine where mean concentrations of respirable coal minedust are 1 mg/m 3 .Identify early markers of disease to help identify adverse health effects of exposure torespirable coal mine dust and respirable crystalline silica and to prevent or impede diseaseprogression.Determine the factors affecting the incidence of PMF in miners without prior radiographicevidence of simple CWP. Determining these factors will facilitate early identification andintervention.Evaluate exposure-response relationships affecting lung function in surface coal miners.Evaluate the effectiveness of reducing or eliminating exposures to respirable coal mine dust(and tobacco smoke, if applicable) in halting or impeding decline in lung function.Determine the prevalence of miners who have normal spirometry values and chest X-raysbut abnormal gas exchange values. Knowledge of this prevalence would help determinethe need for lung function tests in addition to spirometry tests (FEV1 and FVC): DLCO ortranscutaneous measurements of arterial oxygen pressure, for example.Adverse health effects of dust exposureInvestigate exposure, dose, and response relationships-including the effect of exposurepatterns (intensity and duration) on the development of occupational respiratory diseasesin coal miners.Assess the influence of dust composition and characteristics (e.g., quartz concentration,thoracic dust) on the development of simple CWP, PMF, and COPD in coal miners.Evaluate the role of overloaded lung clearance mechanisms in the development of occupational respiratory diseases in coal miners.Evaluate the ways in which the statistical model may affect risk estimates for occupationalrespiratory diseases-particularly in the low-exposure regions of the exposure-responsecurves.Analyze the relationship between exposure to thoracic coal mine dust and COPD.Characterization of dustCompare the particle size distribution and the composition of airborne respirable dust inunderground coal mines, surface mines, and other worksites where workers are exposed tocoal dust.

Coal Mine DustTraining and educationDetermine the training and education needed to promote occupational safety and healthawareness in coal miners and coal mine operators, including safe work practices and useof engineering controls and personal protective equipment.

8.1 .I Training Programs Employers should establish a training program for all coal miners and other workers exposed to respirable coal mine dust and respirable crystalline silica. Training should be provided whenever a new job is assigned, and workers should be informed about the health and safety hazards of the worksite.