Transcription

ADVANCED PRODUCT QUALITY PLANNING (APQP) AND PRODUCTIONPART APPROVAL PROCESS (PPAP)JENNIFER COX - SPIRIT AEROSYSTEMSELIZABETH WALTERS – THE BOEING CO.July 2019 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)

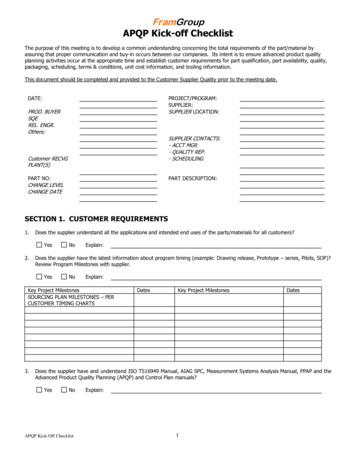

9145 APQP & PPAPThe purpose of this presentation is to: Introduce the key concepts of APQP and PPAP and thebenefits of application Communicate availability of guidance material andtraining Implementation – First steps 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)2

APQP and PPAP Webinar SeriesWebinar ObjectivesDesign RiskAnalysisPPAPAdvancedProduct QualityPlanningOverviewProcessCapability &ControlProcess FlowDiagram &ProcessFMEAControl Plan Provide high level understanding Introduce APQP and PPAP andshow relation to 9145 Share benefits & best practices Provide sources of additionalinformationMeasurementSystemsAnalysis 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)3

Introduction to 9145 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)4

What is 9145?9145 applies Advanced Product Quality Planning (APQP) andProduction Part Approval Process (PPAP) to Product Development in theAviation Space And Defense (AS&D) industrySuccess Drivers5-Phase Product Development Process1.2.3.4.5.PlanningProduct Design and DevelopmentProcess Design and DevelopmentProduct and Process ValidationOn-Going Production, Use, and Post-DeliveryService 2018 IAQG Management commitmentIntegrated cross-functional teamsEffective project managementDefined deliverables & outputs for each phaseThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)5

Why 9145?Improve Quality and Reduce Cost Early achievement of product maturity Reduced overall life-cycle costs Prevention tools for risk reduction Provides foundation for successful work transfersProgressive companies have incorporated APQP into their Product Development Process 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)6

Companies incorporating APQP into their PDP andflowing these requirements to their suppliersAirbus GroupHoneywellEmbraerBoeingHensoldtOshkoshGE AviationLockheed MartinRolls RoyceRaytheonSafran GroupWoodwardSpirit AeroUTCMHIRockwell CollinsBombardierParker AerospaceTextronEatonNot intended to be a comprehensive list 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)7

What does 9145 do for AS&D?Standardizes requirements for Product Development across AS&D Integrated multifunctional approach to ensure effectivecollaboration Structured proactive life-cycle approach Phased/gated process to ensure on-time quality products Strengthens production verification process (PPAP)Based on proven methodology for Product Development 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)8

How are 9145 Benefits achieved? Early understanding of Customer ExpectationsReduce overall cost by identifying & eliminating risksAchieve robust Product and Process DesignsMinimize required changesEffective implementation through program managementCross-functional teams collaborate on all aspects of the programMeet Customers requirementsAchieve reliability and cost targets 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)9

9145 Benefits from Proactive ApproachNon-conformances reduced through PPAP(actual AS&D example)Work TransfersNew Product IntroductionDefective items per items received40 % reduction80 % am to program comparison201420152016Across programsFirst benefits of APQP can be achieved through PPAP deployment 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)10

APQP Overview 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)11

What is Advanced Product Quality Planning?APQP is a structured phased Product Development methodology that assuresCustomer satisfaction by: Ensuring that all activities are completed on-time and on-quality Facilitating effective communication Providing timely escalation and resolution of delays and risksCustomerSatisfaction 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)12

APQP PrinciplesCustomer SatisfactionEffective ProjectPlanningCross FunctionalTeamOrganizationalCommitment &ManagementSupportOn-Time, On-Quality, Shorter lead timesAPQP PRINCIPLESPillars of success 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)13

APQP PrinciplesTop Management demonstratescommitment by On-Time, On-Quality, Shorter lead timesEffective ProjectPlanningManagement engagement &commitment from launch toclosure is key!Customer SatisfactionCross FunctionalTeamCompleting APQP trainingAllocating and training resourcesLeading reviewsStandardizing APQP practicesRemoving roadblocksOrganizationalCommitment &ManagementSupport APQP PRINCIPLESPillars of success 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)14

APQP PrinciplesCross functional teams enableeffective communications and fasterproduct developmentTeams should consist of Customer SatisfactionEffective ProjectPlanningCross FunctionalTeamOrganizationalCommitment &ManagementSupportOn-Time, On-Quality, Shorter lead times pliersCustomersCustomer SupportAPQP PRINCIPLESPillars of success 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)15

APQP PrinciplesEffective project planning and management Schedule tasks, assignresponsibility and drive ontime completionEffective ProjectPlanningOn-Time, On-Quality, Shorter lead timesCross FunctionalTeam The APQP plan cascadesprogram key targetsthrough the value streamCustomer SatisfactionOrganizationalCommitment &ManagementSupport Continually monitor plan,communicate risks andremove roadblocksCommitment to a firm APQP planis a critical success factor!CustomerInternal OperationsAPQP PRINCIPLESSuppliers 2018 IAQGPillars of successThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)16

PDP and APQP Phase AlignmentPhase MilestonesAPQP has 5 phases starting with product concepts and extending through the product life cycleKick OffEnd of Concept(PDR)Initial ProductionProduction LaunchApprovalDesignRelease(CDR)Product DevelopmentProcess (PDP)1. PlanningPhases of Advanced ProductQuality Planning (APQP)APQP MilestoneADB2 – Product Design and DevelopmentC4 – Product and ProcessValidationE3 – Process Design and DevelopmentProduct conceptDesign validation & verification 2018 IAQG5 – On-going Production, Use and Postdelivery Service1st Article Inspection(FAI)Production Part ApprovalProcess (PPAP)Process validationProduction Readiness ReviewThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)17

APQP – Phase 1Phase 1 –Planning Identifies and gathers all the inputs applicable to the productCollects the technical and non-technical requirements applicable to the project/productDefines the product and project goalsEnsures that the organization makes the key make-buy decisionsEstablishes timing for deliverables for each APQP elementOutput The product concept is finalized (milestone A) and a pre-design is available Concurrent product design and process design can startAAPQP Milestone 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)18

APQP – Phase 2Phase 2 –Product design & development Turns product specifications into a robust product definition Design risk analysis (DFMEA) Provides a verified product design Team commits to product manufacturabilityOutput Design record and BOM are available The product design is verified and validated (milestone B) by the design organization ABAPQP Milestone 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)19

APQP – Phase 3Phase 3 –Process design & development Creates a robust manufacturing process that meets requirements in terms of quantity and quality ofproduct Defines the means to control the manufacturing process and its outputsOutput The process is defined, established, verified (Production Readiness Review - milestone C) and ready forvalidation. ABAPQP Milestone 2018 IAQGCThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)20

APQP – Phase 4Phase 4 –Product & process validation: Launches the initial production run Collects data to demonstrate the manufacturing and assembly processes can produce conforming productat the required rate Management determines process readiness for entry into serial production by reviewing the results of:– Product and process design as validated by the organization– Production readiness evaluation– Corrective actions taken for any issues identified to date ABAPQP Milestone 2018 IAQGCThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)21

APQP – Phase 4Phase 4 –Product & process validation:Output Start of production & FAI (milestone D) verify that the initial product made using all full production meansconforms to specified requirements First Article Inspection (FAI) is compiled, approved and available for customer review Production Part Approval Process (PPAP) (milestone E) is compiled, approved and available for customerreviewDABAPQP Milestone 2018 IAQGECThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)22

APQP – Phase 5Phase 5 –Production Evaluate if project objectives have been achieved Record Lessons Learned to drive robust product realization processes Implement actions to increase customer satisfactionOutput Project goals are achieved, including reliability, quality, and customer satisfaction On-time, on-quality, on-cost production and serviceDABEC 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)23

PPAP Overview 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)24

PPAP OverviewPPAP is an aerospace APQP element finalizing “Product and Process Validation”5 – On-going Production, Useand Post-delivery Service1. Planning2 – Product Design andDevelopment4 – Product andProcess ValidationPPAP3 – Process Design and DevelopmentPPAP combines First Article Inspection and Process Validation 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)25

What is Production Part Approval Process?PPAP confirms.that the production process has demonstrated the potential toproduce products .that consistently fulfill all requirements .while operating at the customer demand rate 2018 IAQGThe IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)26

PPAP Elements & Phase AlignmentPPAP elements are the output and evidence of APQP executionPPAP ELEMENT* Responsibility of designresponsible organization 2018 IAQGAPQP PHASE1. Design Records*22. Design Risk Analysis*23. Process Flow Diagram34. PFMEA35. Control Plan36. MSA47. Initial Process Capability Studies48. Packing, Preservation and Labeling Approvals39. FAIR410. Customer Specific Requirements411. PPAP Approval Form (or equivalent)4The IAQG is a legally incorporated international not for profit association (INPA) with membership from the Americas, Europe and the Asia Pacific Region (Rev. 08-2015)27 page

PDP and APQP Phase Alignment Phase Milestones APQP has 5 phases starting with product concepts and extending through the product life cycle Production Launch Phases of Advanced Product Quality Planning (APQP) Product Development Process (PDP) Kick Off End of Concept (PDR) Initial Production Approval Design Release (CDR) 1. Planning 4 –Product and Process