Transcription

Ford Motor CompanyAdvanced Product Quality Planning (APQP)Status Reporting GuidelineAny questions regarding this document, or the content therein,should be directed to:VO Quality Office(313) 248-6538This document is located on the Ford Intranet at:http://www.dearborn2.ford.com/apqpcntrThis Guideline is published by Ford Motor Company, Quality OfficeCopyright 2001 Ford Motor Company.All rights reservedAdvanced Product Quality PlanningRelease Level: 3.0Ford APQP Guideline (copyright , 2001)Page 1 of 83March 2001Uncontrolled Copy

ForewordFord Motor Company launched an Advanced Product Quality Planning StatusReporting Guideline (APQP) Fast Start Initiative in December 1994. A crossfunctional APQP team formed to review the existing FAO Procedures and targetbest practices. The 1994 version of this document was created at that time, tobe in line with the AIAG Advanced Product Quality Planning and Control PlanManual.Since that time, the external suppliers to Ford Motor Company, and internalsuppliers within Ford have used the FAO APQP Status Reporting Guideline tomonitor their own systems with regard to APQP.With the experience that has been acquired since 1994, it has becomenecessary to update this manual to reflect current practices, and successes. Inaddition, the Ford Product Development System (FPDS) has become thedocumented system for the Product Development processes within Ford(replacing World Class Timing).A cross-functional team was formed in 1999/2000 to review the 1994 FAO APQPmanual and practices, and this guideline has been updated to reflect generictiming with respect to the FPDS system. It also contains references (at the timeof publishing) to the FPDS Process Sheets. All of this is to clarify further theappropriateness of the APQP process, and its direct tie to the existingsystems/process Ford currently has in place.Furthermore, it is intended that the updated APQP process and FPDS timinginformation will assist the external supply base in understanding the differencesbetween their own timing requirements, and those which need to be met by theentire Vehicle Program in the delivery of a new vehicle.This Guideline documents the Ford APQP evaluation and status reportingprocess and is intended to be used for 2004 MY Programs and beyond. ThisGuideline does not replace the AIAG Advanced Product Quality Planning andControl Plan Reference Manual as the basis for quality planning.Advanced Product Quality PlanningRelease Level: 3.0Ford APQP Guideline (copyright , 2001)Page 2 of 83March 2001Uncontrolled Copy

Table of ContentsFOREWORD. 2APQP FUNDAMENTALS. 5APQP Process Flow Map . 6Fundamentals of the APQP Process. 7APQP REPORTING PROCESS. 10APQP Status Reporting Process Flow Chart . 11APQP Status Report. 12APQP Status Report Form . 13Filling Out the Status Report Form . 14Quality of Event Checklists. 15Risk Assessment . 15APQP TIMING . 17Ford / Supplier Systems "V" Model . 18APQP Generic Program Timing Gantt Chart. 19APQP ELEMENTS . 21Sourcing Decision. 22Customer Input Requirements . 23Craftsmanship . 24Design Failure Mode and Effects Analysis (DFMEA). 25Design / Manufacturing Reviews . 27Design Verification Plan & Report (DVP&R) . 28Sub-Contractor APQP Status . 29Facilities / Tools / Gauges . 30Prototype Build Control Plan . 32Prototype Builds . 33Drawings & Specifications . 34Team Feasibility Commitment . 36Manufacturing Process Flow . 38Process Failure Mode and Effects Analysis (PFMEA) . 40Measurement System Evaluation. 42Pre-Launch Control Plan . 44Operator Process Instructions . 45Packaging Specifications. 46Production Trial Run. 47Production Control Plan. 48Preliminary Process Capability. 49Production Validation Testing. 50Part Submission Warrant (PSW). 51APPENDIX SECTION. 52APPENDIX A:APQP ROLES & RESPONSIBILITIES. 53Powertrain Roles and Responsibilities Matrix . 54Advanced Product Quality PlanningRelease Level: 3.0Ford APQP Guideline (copyright , 2001)Page 3 of 83March 2001Uncontrolled Copy

Powertrain Roles and Responsibilities Matrix. 55Powertrain Program Review Process. 56(PTPRP) . 56STA Roles & Responsibilities . 57EXTERNAL SUPPLIERS . 67APPENDIX B:RELATED FORMS. 69APPENDIX C:GLOSSARY OF TERMS. 72APPENDIX D:REFERENCES AND WEBSITES . 79REFERENCES & WEB SITES . 80Advanced Product Quality PlanningRelease Level: 3.0Ford APQP Guideline (copyright , 2001)Page 4 of 83March 2001Uncontrolled Copy

APQP FundamentalsAdvanced Product Quality PlanningRelease Level: 3.0Ford APQP Guideline (copyright , 2001)Page 5 of 83March 2001Uncontrolled Copy

APQP Process Flow MapAPQP PROCESS FLOWC R A F T S M A N S H IPD R A W IN G S / S P E C IF IC A T IO N SP - D ia g r a mS O U R C IN GD E C IS IO ND E S IG N /M A N U F A C T U R IN GR E V IE W SF a ilu r e M o d e s &E r r o r S ta te sC U STO M ERIN P U TR E Q U IR E M E N T STEA MF E A S IB IL IT YC O M M IT M E N T(a ff e c t a ll A P Q Pe le m e n ts )S p e c if ic a t io n s &T a r g e ts(V D S /S D S /C D S )D E S IG N F A IL U R EM O D E EFFEC TA N A L Y S IS(D F M E A )D e s ig n in g o f th eV e h ic le / S y s te m /S u b s y s te m /C om ponentF E E D IN F O R M A T IO NFO R W A R DF E E D IN F O R M A T IO NB A C KD E S IG NV E R IF IC A T IO NP L A N (D V P )D R A W IN G S /S P E C IF IC A T IO N S(P a p e r / E le c tr o n ic )F A C IL IT IE S /TO O LS/G A U G ESM A N U F A C T U R IN GPR O C ESS FLO WM EA SU R EM EN TS YS TE ME V A L U A T IO N(D i m e n si o n a lC o n tr o l )O PER A TO RPR O C ESSIN S T R U C T IO N S(P r o c e s sD e fin itio n )PR O C ESSF A IL U R E M O D EEFFEC TA N A L Y S IS(P F M E A )P R O TO TYP EB U IL D C O N T R O LPLA NP R O TO TYP EB U IL DP R E -L A U N C HC O N TR O L PLA NTIMEP R O D U C T IO NT R IA L R U NO PER A TO RPR O C ESSIN S T R U C T IO N S( V e r if ic a t io n &T r a in in g )P R O D U C T IO NC O N TR O L PLA NP R E L IM IN A R YPR O C ESSC A P A B IL IT YP R O D U C T IO NV A L ID A T IO NT E S T IN GPA R TS U B M IS S IO NW A R R A N T(P S W )Advanced Product Quality PlanningRelease Level: 3.0Ford APQP Guideline (copyright , 2001)Page 6 of 83March 2001Uncontrolled Copy

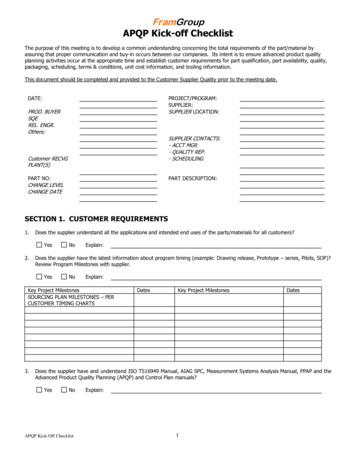

Fundamentals of the APQP ProcessAdvanced Product Quality Planning (APQP)Advanced Product Quality Planning (APQP) is a structured method for defining andexecuting the actions necessary to ensure a product satisfies the customer. APQP isprogram and supplier-led and is required of all system, subsystem and componentmanufacturing locations. This includes both internal and external suppliers to Ford.The Goal of APQPThe goal of APQP is to facilitate communication between all persons and activitiesinvolved in a program and ensure that all required steps are completed on time, with ahigh quality-of-event, at acceptable cost and quality levels.The Purpose of APQPThe purpose of this status reporting guideline is to establish:!"Common APQP expectations for the internal and external suppliers to FordMotor Company!"Common APQP process metrics!"A common program status reporting format!"Roles and responsibilities for APQP elements!"A better understanding of how the APQP elements relate to the Ford ProductDevelopment System (FPDS), specific FPDS milestones, and their timingThe Approach of APQPThis status reporting guideline describes 23 key APQP disciplines. Ford MotorCompany expectations are defined for these key disciplines in definitions, and detailedchecklists. The status for these disciplines is summarized using metrics described inthe Reporting section.This status reporting guideline is written from a supplier standpoint. A supplier is aninternal or external supplier of materials, components, subsystems, systems, designs orprocesses that will be delivered to a customer. A customer is the recipient of thesupplier's product or process. Besides customers, every supplier will havesubcontractors. A subcontractor is the provider of material or parts to a supplier.The Applicability of APQPAPQP status reporting is a requirement of all internal and external suppliers to Ford(including Ford Product Development). APQP must be done for new programs/partsand major part changes as appropriate. In addition, Product Development Teams are tomonitor the status of internal and external engineering and process developmentdisciplines and assess the "Quality-of-Event" as well as the timing and completi

Ford APQP Guideline (copyright , 2001) March 2001 Uncontrolled Copy Foreword Ford Motor Company launched an Advanced Product Quality Planning Status Reporting Guideline (APQP) Fast Start Initiative in December 1994. A cross-functional APQP team formed to review the existing FAO Procedures and target best practices. The 1994 version of this document was created at that time, toFile Size: 584KBPage Count: 83