Transcription

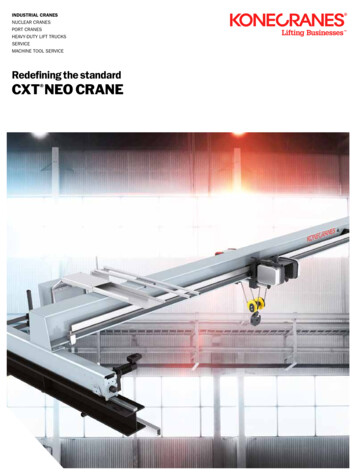

INDUSTRIAL CRANESNUCLEAR CRANESPORT CRANESHEAVY-DUTY LIFT TRUCKSSERVICEMACHINE TOOL SERVICERedefining the standardCXT NEO CRANE

2KonecranesCXT NEO craneCXT NEO CRANEAgilityPowerThis publication is for general informational purposes only. Konecranes reserves the right at any time, without notice, to alter or discontinue theproducts and/or specifications referenced herein. This publication creates no warranty on the part of Konecranes, express or implied, including but notlimited to any implied warranty or merchantability or fitness for a particular purpose. Konecranes standard terms and conditional apply to all orders.

Redefiningthe standardin general liftingErgonomicsPreventivemaintenance

4KonecranesCXT NEO craneFREEDOM TOMOVE ANDPOWER TO LIFTWhen it comes to lifting, CXT NEO crane is a powerfulmachine – but also an agile one. Its ergonomic design and newMiniJoystick radio enable faster operations. Inverter hoistingprovides power and accuracy with load positioning, and theTRUCONNECT Remote Service package seals the deal. That'swhat we mean by redefining the standard in general lifting.OPTIMIZEDMAINTENANCEACTIVITIESbased on usage datawith TRUCONNECTRemote Monitoring.

UP TO 12.5 TONSof lifting capacity and up to 25 tons with twosimilar hoists.IMPROVEDSAFETYwith energy chain, which protectsthe power and control cables frommechanical wear and reduces therisk of external damage.INCREASEDACCURACY INLOAD CONTROLthanks to stepless hoisting speed.LONGERLIFECYCLEthanks to inverter hoisting that reducesmechanical stress on structures.

6KonecranesCXT NEO craneHIDDENPOWEREnergy chain gives CXT NEO crane its sleek andmodern look and, more importantly, improves thesafety of the crane’s working environment.ENERGY CHAIN BENEFITSEnergy chain is an easy way to feed the primarypower and control cables along the crane bridge.It holds all the cables from the main electricalcubicle to the hoist in a composite chain. Improved safety in the workingenvironmentThe composite chain moves along a channel that isattached to the main girder of the crane. There areno visible electrical cables hanging from the crane. Reduced cable wear and risk ofexternal damageEnergy chain increases the working space underthe crane, protects the power and control cablesfrom mechanical wear and reduces the risk ofexternal damage. Increased working space A modern look to your crane

AgilityENERGY CHAIN’S simplified designeliminates the need for additional partsassociated with common festoon systems.SINGLE- AND DOUBLE-GIRDER CRANES WITH ENERGY CHAINEnergy chain protects the power and control cables from mechanical wear.

8KonecranesCXT NEO craneNEO PACKSMORE PUNCHBehind CXT NEO crane’s power is the energyefficient inverter hoisting technology thatprovides accuracy with load positioning andcontrolled slow-speed operation.Inverter hoisting enables stepless hoistingspeeds. It allows very slow speeds, whichare important in moments of load lift-off andlowering. It also enables faster lifting by as muchas 50%.With inverter hoisting, an empty load hook can bedriven at speeds of up to 50% faster comparedto a loaded hook, allowing the operator to choosethe most efficient way to operate the hoist.Inverter hoisting makes soft start-ups possibleand reduces the stress affecting the crane andthe structures. It means a longer lifetime for yourcrane and lower life cycle costs.INVERTER HOISTINGBENEFITS Up to 50% faster lifting Better accuracy with load positioning Controlled slow-speed operation Longer lifetime and lowerlife cycle costs

PowerINVERTER HOISTING (ASR)technology enables faster loadcycles, stepless speed controland precise load positioning.INVERTER HOISTING (ASR) TECHNOLOGY LOAD SPECTRUM & SPEEDSSpeed range forinverter hoisting100%Occasional full load liftsRegular partial loading125%100%Medium load spectrum per FEM:LoadSpeed150%Frequent handlingof light loads80%Normal speed of two-speed hoist60%75%40%50%25%20%0%Load0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%ASR Adaptive Speed RangeLifting Speed0%0%15%50%100%150%Inverter hoisting (ASR) motor characteristics:Fast speed for light loadsMedium speed for partial loadingSafety speed for heavy loads

10KonecranesCXT NEO craneTAKING ERGONOMICSTO THE NEXT LEVELAll of the lifting power in CXT NEO crane iseasy to control with the ergonomic KonecranesMiniJoystick radio.The MiniJoystick radio takes the ergonomicsof controlling cranes to the next level. It islightweight and easy to use.The joystick is for controlling the travelingmovement of the crane and hoist, whereas thebuttons are for lifting and lowering. The joystickallows the operator to control the load withjust a single grip and enables the operator toconcentrate fully on the load.MINIJOYSTICK BENEFITS Ease of use makes operations faster Single-grip control enables fullconcentration on the load Light weight and ergonomic controlsreduce operator fatigue

ErgonomicsMINIJOYSTICK RADIO providesfreedom to move and makesspeed adjustments easy.MINIJOYSTICK RADIOLIFTING ANDLOWERING MOVEMENTSPush-buttons are for controllingstepless hoisting movements.EMERGENCY STOPBRIDGE ANDTROLLEY MOVEMENTSThe joystick is for controllingthe traveling movement of thecrane and hoist.MULTIFUNCTION KEYThe rotatable function key makes itpossible to have multiple functionsfor just one control element.

12KonecranesCXT NEO craneNEO HELPS YOUMAKE INTELLIGENTMAINTENANCE DECISIONSA quality crane, properly used and wellmaintained, should provide years of troublefree lifting. If you start with a great crane andthen work with us to care for it professionally,predictability can improve, helping you makedecisions about maintenance and productivity.SERVICE PROGRAMS THAT FITYOUR NEEDSAn active preventive maintenance program isrecommended for your CXT NEO. We can createa maintenance plan based on your equipment,application and duty cycle.The CARE Preventive Maintenance Program isour most popular service offering and includespreventive maintenance inspections and routinemaintenance. If you need less, the CONDITIONInspection Program will help you comply withlocal statutory requirements and support yourin-house maintenance.BACKED BY A SOLID WARRANTYCombining preventive maintenance withTRUCONNECT Remote Monitoring givesyou an optimal safety and productionenvironment. And when you have aKonecranes Service program andRemote Monitoring in place, you canextend the CXT standard warranty –which includes replacement or repairof faulty parts and components duringregular hours – up to 10 years.

Get insightsinto yourcrane usageTRUCONNECT REMOTE MONITORING usessensors to collect data, such as running time,motor starts, work cycles and emergencystops, providing visibility to crane usage.The data is accessible on demand in theyourKONECRANES.com customer web portalwhere aggregated data can be viewed, analyzedand shared quickly, for a single asset or anentire fleet.TRUCONNECT REMOTE MONITORINGSensors gather usage data–running time, motorstarts, work cycles and brake condition.Data is transmitted to the Konecranes RemoteData Center.Usage and maintenance data can be viewed onyourKONECRANES.com.

14KonecranesCXT NEO craneCXT NEO CRANEFACTS AT A ASR inverter niJoystick y chain power feeding for CONNECT Remote Extended L7035 grey 28 yellow OOMDOUBLE-GIRDERFEATURESSTANDARD AND OPTIONAL COLORINGSTANDARD RAL7035 grey colorOPTIONAL RAL1028 yellow color

LOAD RANGE AND DUTY CLASSLoad range (tons)With CXT cranes you can go up to 160 tons with two CXT7 hoists80706356504034CXT73225201615With CXT NEO crane up to 12.5 ton with one 2&31.251Duty classesM41AmBM52mCM63mDWHEN YOU NEED MORE LIFTING CAPACITY,GET TO KNOW OUR CXT WIRE ROPE HOIST CRANES RANGECXT cranes can be implemented with a single-girder or double-girder construction,a fixed single-girder system (monorail) or with an under-running construction.With different trolley configurations, CXT wire rope hoist cranes maximize the lifting heightand easily fit into different kinds of buildings: Low headroom trolleys up to 12.5 tNormal headroom trolleys up to 40 tDouble-girder trolleys up to 80 tFive frame sizes up to 80 tFixed hoists up to 80 tISOFEMCMAA

NUCLEARCRANESPORTCRANESHEAVY-DUTY SERVICELIFT TRUCKSMACHINETOOLSERVICEKonecranes is a world-leading group of Lifting Businesses offering lifting equipment andservices that improve productivity in a wide variety of industries. The company is listed onNasdaq Helsinki Ltd (symbol: KCR1V). With almost 12,000 employees at 600 locations innearly 50 countries we have the resources, technology and determination to deliver on thepromise of Lifting Businesses . 2016 Konecranes Plc. All rights reserved. ‘Konecranes’, ‘Lifting Businesses’, ‘CXT’, ‘TRUCONNECT’, andregistered trademarks or trademarks of Konecranes Plc.are either2016INDUSTRIALCRANESkonecranes.com

Konecranes is a world-leading group of Lifting Businesses offering lifting equipment and services that improve productivity in a wide variety of industries. The company is listed on Nasdaq Helsinki Ltd (symbol: KCR1V). With almost 12,000 employees at 600 locations in