Transcription

AGILENTROTARY VANE PUMPS2-3Features and Benefits4-5Typical Applications6-19Pump Models20Accessories21HS Series Pumps Features and Benefits22-25 HS Series Pump Models26-27 MS 40 Pump Features and Benefits28-29 MS 40 Pump Model

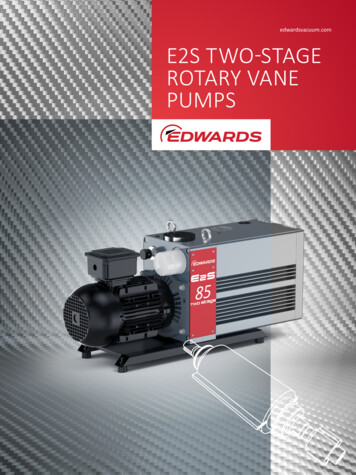

ROTARY VANE PUMPSAGILENT ROTARY VANE PUMPS FEATURES AND BENEFITS Thanks to a very simple and highly reliable design, these field provenrotary vane pumps provide excellent vacuum performance. Agilent’squality and manufacturing standards ensure that the DS Rotary VanePumps provide high pumping stability for light gases, low noise, minimaloil backstreaming, and a long operating life. Agilent’s DS Rotary Vane Pumps conform with CE and RoHSrequirements, and all pumps are UL and CSA approved. Agilent’s worldclass technical support organization makes the DS Rotary Vane Pumpcost-effective and well suited for a wide range of applications.The newMS 40 Mono StageRotary Vane PumpHS Series“smart”pumps withgreen technology High capacity pumping speed withthe smallest footprint Proven inverter technology Ideal for mass spectrometry andelectron microscopy Lowest noise, highest throughput In 2004 Varian, now Agilent,introduced the first rotaryvane pumps with truly “smart”capabilities Employ an innovative frequencyinverter technology to deliveroptimal and consistentperformance Encompasse the worldwide rangeof voltage and frequency conditions Enviromentally friendly thanks toreduced power requirements andlow start up currentDual Stage PumpsDS Series: the two stage design allows: Low 10-3 mbar operation Low operating temperature Minimal backstreaming at low pressure Good pumping efficiency and gas ballastin the low 10-2 mbar regionWorldwide Motors Pump motors, available as 1-phase or3-phase, are suitable for all voltages andfrequencies worldwide Operational voltages are easilyselectable, allowing greater flexibility,easy planning and inventory reductionAnti-suckback Valve and Vent DeviceSocket Type IEC320 This valve isolates the pump should itstop or be idle Permits use of standard power cable Eliminates the need to open box andwire the motor Prevents inadequate venting and oilcontamination of the vacuum systemwhen the pump is switched off, or incase of power failForced Oil CirculationGas Ballast Valve The dedicated oil circulation gear pumpensures efficient and reliable lubricationof the pump from atmospheric pressurethroughout the entire vacuum operatingrange The opening of this valve injects dry airinto the second stage of the pump This action increases the temperatureof the module which facilitates theoutgassing and clean up of water vaporor other condensable gases from the oilBuilt-in Oil ShieldAlignment Pins on Pump Module This feature minimizes the oil mist at thepump exhaust The pump module components areassembled and positioned by built-inalignment pins Drastically reduces the oil consumptionover long periods of operation Reduction of air pollution limiting theimpact on the environment2Rotary VanePumpsA reliable line of pumps to cover the mostdemanding industrial and scientific applications These speed up the assembling andmaintenance process, avoiding any errorForced Air VentilationThe cooling fan between the motor andthe pump: Reduces the pump operatingtemperature Lowers the oil vapor partial pressure Minimizes oil backstreaming and vacuumsystem contamination3

ROTARY VANE PUMPSRotary VanePumpsAGILENT ROTARY VANE PUMPS TYPICAL APPLICATIONSICP-MS. Photo courtesy Agilent Scientific Instruments.Freeze Drying equipment.Analytical Instrumentsand Mass SpectrometryRotary Vane Pumps are the most common primaryvacuum pumps used on GC-MS, LC-MS, ICP-MS, andMALDI-TOF Instruments.GC-MS typically uses our smallest pump, the DS42; thepump is needed to rough the system and back the highvacuum Turbo or Diffusion pump.LC-MS and ICP-MS use a medium capacity pump on thesample injection/system interface, typically a DS402 or aDS602, and a smaller pump to back the system Turbo pumps.MALDI-TOF depending on system size, uses the DS102 tothe DS602 as roughing or interface pumps.Nowadays high-end instruments, such as LC-MS andICP-MS, can take advantage of the benefits of HS 452,HS 652 and MS 40 : Large pumping capacity Consistent worldwide performance thanks to universalvoltage and frequency Single phase Low power requirements and start up current Remote control and diagnostic Adjustable performance, low noise Green technologyElectron MicroscopesIndustrial Vacuum ProcessesSmall pumps, typically the DS202 and the DS302,are still used in competition with dry pumps to roughthe system and the high vacuum Turbo or Diffusion pump.condensable vapor.Vacuum coatings, Metallurgy Vacuum Furnaces, Lamps andTV Tube manufacture, Sterilizers, Freeze Dryers, Glove Boxes,High Speed Centrifuges, and Flywheels (for energy storage)represent the main Industrial applications for Dual StageRotary Vane pumps. In the first four fields of applicationthe Rotary Pumps are used as roughing and backing pumpsfor High Vacuum Turbo or Diffusion pumps, while in theothers the Rotary Pumps are typically the only vacuum pumpson the system.Leak DetectionPumps in the DS102, DS202 and DS302 range aretypically used to back the Helium Mass Spectrometer Turboor Diffusion pump.The roughing pump is usually bigger, typically up to theDS402/DS602, and can still be installed on the Leak Detectoritself, while bigger pumps can be used to pump down highthroughput Leak Detection systems.4Distillation apparatus. Photo courtesy University of Torino, Italy.High Energy Physics and ResearchLaboratoriesIn these applications the Rotary Vane pumps are mainly usedin combination with Turbo pumps. The combination istypically used to rough and pump High Vacuum experimentalchambers or to start Ion Pumps in ultra high vacuum systems.OLED-Lab. Photo courtesy PNNL.5

DS 40MDS 102DS 202DS 302DS 402DS 602HS 452HS 652MS 40 36 (1.27)43 (2.58)114 (4)95 (5.7)192 (6.8)160 (9.6)285 (10)237 (14.2)410 (14.5)342 (20.5)605 (21.4)504 (30.2)456 (16.1)456 (27.3)672 (23.8)672 (40.3)828 (29.2)828 3223.540–10-410-410-410-410-410-410-4N/A6.7 x 10-32 x 10-32 x 10-32 x 10-32 x 10-32 x 10-32 x 10-32 x 10-35 x 10-2Ultimate total pressure with gas ballast* (mbar)–2 x 10-22 x 10-22 x 10-21 x 10-21 x 10-21 x 10-21 x 10-2N/ANo gas ballast portWater vapor tolerance (mbar)–15152030303030N/ANo gas ballast portWater vapor capacity (g/h)–60100160350550350550N/ANo gas ballast port0.37 750.900.750.500.500.75Free air displacement60 Hz l/min (cfm)50 Hz l/min (m3/h)Pumping speed*60 Hz (cfm)50 Hz (m3/h)Ultimate partial pressure* (mbar)Ultimate total pressure* (mbar)Oil capacity min/max (l)Motor rating 1 ph60 Hz (kW)50 Hz (kW)Motor rating 3 ph60 Hz (kW)50 Hz (kW)Nominal rotation speed60 Hz (rpm)50 Hz 500200020001450Weight kg (lbs)9.3 (20.5)22 (48)25 (55)25 (55)35 (77)35 (77)33 (73)33 (73)33 (73)Inlet flange16KF DN25KF DN25KF DN25KF DN25KF DN25KF DN25KF DN25KF DN25KF DN - 40KF DNExhaust flange16KF DN25KF DN25KF DN25KF DN25KF DN25KF DN25KF DN25KF DN25KF DN*According to PNEUROP 660267Rotary VanePumpsROTARY VANE PUMPSAGILENT ROTARY VANE PUMP MODELS

ROTARY VANE PUMPSAGILENT ROTARY VANE PUMP MODELS Agilent DS 40MDS 40M - Pumping Speed Curve107 (4.21) 120 (4.72)RUBBERFEETØ5 (0.19)120 (4.72)86,5 (3.40)7.8 (0.30)288.8 (11.37)INLET FLANGE 16KF DN100 (3.93)10-211011021.76572.01.17711.00.80.5885(m3/h) 0.60.29420.40.110 -323.5 (0.92)(cfm)0.17650.229 (1.14)OUTLET FLANGE 16 KF DN0.117710 -210 -1OIL INLET PLUG 3/4G1(mbar)10110 210 30.0588Pressure50 HzDimensions: millimeters (inches)Technical SpecificationsFree air displacementPumping speed*Ultimate partial pressure*Ultimate total pressure*Ultimate total pressure with gas ballast*Noise levelOil capacity maxMotor rating 1phNominal rotation speedWeightInlet flangeExhaust flange(Torr)10-1Rotary VanePumpsPumping Speed202.4 (7.96)154.2 (6.07)36.9 (1.45)157.8 (6.21)OIL DRAINPLUGPOWERSWITCH163.3 (6.43)POWER INLET(EN 60320)OIL LEVEL3.010-360 HzOrdering Information60 Hz: 36 l/min (1.27 cfm)60 Hz: 1.27 cfm60 Hz: 46 dB(A)60 Hz: 0.1 kW60 Hz: 3300 rpm50 Hz: 43 l/min (2.58 m3/h)50 Hz: 1.8 m3/h–6.7 x 10-3 mbar–0.37 l9.3 kg (20.5 lbs)16KF DN16KF DNDual Stage Rotary Vane PumpDS 40M 100-120 Vac - 50/60HzDS 40M 200-240 Vac - 50/60HzPart NumberX3703-64000X3703-64001Oil and AccessoriesRotary vane fluid, AVF 20S type, 0.5 literDS 40M oil mist trap 3/4 GDS 40M oil mist trap cartdrige (pkg. of 2)DS 40M maintenance kitDS 40M oil drain extensionNW 16 centering ring vitonNW 16 aluminum clamp50 Hz: 45 dB(A)50 Hz: 0.1 kW50 Hz: 2600 rpm* According to PNEUROP 6602DS 42 - Pump Speed Curve89Part X3703-64007KC16AVKQ16AWP

ROTARY VANE PUMPSAGILENT ROTARY VANE PUMP MODELS Agilent DS 102DS 102 - Pumping Speed Curve(Torr)30 (1.18)35 (1.38)3 (0.12)3 (0.12)35 (1.38)212 (8.3)212 (8.3)104 (4.1) (2)104 (4.1)132 (5.2)(2)245 (9.6) (1)245 (9.6)132 (5.2)10-210-1110150165 (6.5)(1)105 (4.13) 105 (4.13)430 (16.9) 430 (16.9)Effective Pumping Speed 50 Hz30 (1.18) 30 (1.18)30 (1.18)165 (6.5)10-3Rotary VanePumps10010105(m3/h)(cfm)110.50.10.1Alternative mounting holes are also available,with (1) 226 (8.9) and (2) 98 (3.8), with hole Ø 7 (0.3)10 -310 -210 -1110 110 2(mbar)PressureDimensions: millimeters (inches)Technical SpecificationsFree air displacementPumping speed*Ultimate partial pressure*Ultimate total pressure*Ultimate total pressure with gas ballast*Water vapor toleranceWater vapor capacityOil capacity min/maxMotor rating 1phNominal rotation speedWeightInlet flangeExhaust flangeOrdering Information60 Hz: 114 l/min (4 cfm)60 Hz: 3.5 cfm60 Hz: 0.55 kW60 Hz: 1800 rpm10-4 mbar2 x 10-3 mbar2 x 10-2 mbar15 mbar60 g/h0.2/0.5 l22 kg (48 lbs)25KF DN25KF DN50 Hz: 95 l/min (5.7 m3/h)50 Hz: 5 m3/hDual Stage Rotary Vane PumpDS 102 with 1 phase worldwide motor*Part Number9499315Oil and AccessoriesRotary vane fluid, DS19 type, 1 literRotary vane fluid, DS19 type, 1 liter (USA)*Rotary vane fluid, DS19 type, 1 gallon (USA)Oil mist eliminatorOil mist replacement cartridge (pkg. of 2)NW 25 oil exhaust filterNW 25 oil exhaust replacement cartridgeOil return kitOil drain extensionEuropean plug power cable 2 meters 1 phUSA plug power cable 2 meters 1 phUK plug power cable 2 meters 1 phNW 25 centering ring VitonNW 25 aluminum clamp* 1 phase motors (100-120 / 200-230) V 10%, 50/60 Hz.All motors comply with CE and UL/CSA standards.50 Hz: 0.45 kW50 Hz: 1500 rpmMinor Maintenance KitContains all the valves, O-rings and sealsto refurbish the pump to vacuum integrityPart NumberMajor Maintenance KitIncludes all the items of the minor kit plus the vanesPart Number94993809499370* According to PNEUROP 6602Part 25AWP* When these pumps are used in Leak Detectors applications, werecommend the use of Rotary Vane Fluid (Elite-Z mechanical),P/N 695409005 as it features a lower vapor pressure.1011

ROTARY VANE PUMPSAGILENT ROTARY VANE PUMP MODELS Agilent DS 202DS 202 - Pumping Speed Curve(Torr)10-310-210-1110150Rotary VanePumps1003 (0.12)35 (1.38) 35 (1.38)212 (8.3)212 (8.3)3 (0.12)30 (1.18) 30 (1.18) 30 (1.18) 30 (1.18)104 (4.1) (2)104 (4.1) (2)245 (9.6) (1)245 (9.6) (1) 105 (4.13) 105 (4.13)132 (5.2) 132 (5.2)467 (18.4) 467 (18.4)Effective Pumping Speed 50 Hz205 (8.1) 205 (8.1)10105(m3/h)(cfm)110.50.10.1Alternative mounting holes are also available,with (1) 226 (8.9) and (2) 98 (3.8), with hole Ø 7 (0.3)10 -310 -210 -1110 110 2(mbar)PressureDimensions: millimeters (inches)Technical SpecificationsFree air displacementPumping speed*Ultimate partial pressure*Ultimate total pressure*Ultimate total pressure with gas ballast*Water vapor toleranceWater vapor capacityOil capacity min/maxMotor rating 1phNominal rotation speedWeightInlet flangeExhaust flangeOrdering Information60 Hz: 192 l/min (6.8 cfm)60 Hz: 5.8 cfm60 Hz: 0.55 kW60 Hz: 1800 rpm50 Hz: 160 l/min (9.6 m3/h)50 Hz: 8.3 m3/h10-4 mbar2 x 10-3 mbar2 x 10-2 mbar15 mbar100 g/h0.25/0.6 l25 kg (55 lbs)25KF DN25KF DNDual Stage Rotary Vane PumpDS 202 with 1 phase worldwide motor*Part Number9499320Oil and AccessoriesRotary vane fluid, DS19 type, 1 literRotary vane fluid, DS19 type, 1 liter (USA)*Rotary vane fluid, DS19 type, 1 gallon (USA)Oil mist eliminatorOil mist replacement cartridge (pkg. of 2)NW 25 oil exhaust filterNW 25 oil exhaust replacement cartridgeOil return kitOil drain extensionEuropean plug power cable 2 meters 1 phUSA plug power cable 2 meters 1 phUK plug power cable 2 meters 1 phNW 25 centering ring VitonNW 25 aluminum clamp* 1 phase motors (100-120 / 200-230) V 10%, 50/60 Hz.All motors comply with CE and UL/CSA standards.50 Hz: 0.45 kW50 Hz: 1500 rpmMinor Maintenance KitContains all the valves, O-rings and sealsto refurbish the pump to vacuum integrityPart NumberMajor Maintenance KitIncludes all the items of the minor kit plus the vanesPart Number94993819499370* According to PNEUROP 6602Part 25AWP* When these pumps are used in Leak Detectors applications, werecommend the use of Rotary Vane Fluid (Elite-Z mechanical),P/N 695409005 as it features a lower vapor pressure.1213

ROTARY VANE PUMPSAGILENT ROTARY VANE PUMP MODELS Agilent DS 302DS 302 - Pumping Speed Curve(Torr)10-310-210-1110150Rotary VanePumps1003 (0.12)35 (1.38) 35 (1.38)212 (8.3)212 (8.3)3 (0.12)30 (1.18) 30 (1.18) 30 (1.18) 30 (1.18)104 (4.1) (2)104 (4.1) (2)245 (9.6) (1)245 (9.6) (1) 105 (4.13) 105 (4.13)132 (5.2) 132 (5.2)467 (18.4) 467 (18.4)Effective Pumping Speed 50 Hz205 (8.1) 205 (8.1)10105(m3/h)(cfm)110.50.10.1Alternative mounting holes are also available,with (1) 226 (8.9) and (2) 98 (3.8), with hole Ø 7 (0.3)10 -310 -210 -1110 110 2(mbar)PressureDimensions: millimeters (inches)Technical SpecificationsFree air displacementPumping speed*Ultimate partial pressure*Ultimate total pressure*Ultimate total pressure with gas ballast*Water vapor toleranceWater vapor capacityOil capacity min/maxMotor rating 1phNominal rotation speedWeightInlet flangeExhaust flangeOrdering Information60 Hz: 285 l/min (10 cfm)60 Hz: 8.2 cfm60 Hz: 0.55 kW60 Hz: 1800 rpm50 Hz: 237 l/min (14.2 m3/h)50 Hz: 11.6 m3/h10-4 mbar2 x 10-3 mbar2 x 10-2 mbar20 mbar160 g/h0.25/0.6 l25 kg (55 lbs)25KF DN25KF DNDual Stage Rotary Vane PumpDS 302 with 1 phase worldwide motor*Part Number9499325Oil and AccessoriesRotary vane fluid, DS19 type, 1 literRotary vane fluid, DS19 type, 1 liter (USA)*Rotary vane fluid, DS19 type, 1 gallon (USA)Oil mist eliminatorOil mist replacement cartridge (pkg. of 2)NW 25 oil exhaust filterNW 25 oil exhaust replacement cartridgeOil return kitOil drain extensionEuropean plug power cable 2 meters 1 phUSA plug power cable 2 meters 1 phUK plug power cable 2 meters 1 phNW 25 centering ring VitonNW 25 aluminum clamp* 1 phase motors (100-120 / 200-230) V 10%, 50/60 Hz.All motors comply with CE and UL/CSA standards.50 Hz: 0.45 kW50 Hz: 1500 rpmMinor Maintenance KitContains all the valves, O-rings and sealsto refurbish the pump to vacuum integrityPart NumberMajor Maintenance KitIncludes all the items of the minor kit plus the vanesPart Number94993819499370* According to PNEUROP 6602Part 25AWP* When these pumps are used in Leak Detectors applications, werecommend the use of Rotary Vane Fluid (Elite-Z mechanical),P/N 695409005 as it features a lower vapor pressure.1415

ROTARY VANE PUMPSAGILENT ROTARY VANE PUMP MODELS Agilent DS 402DS 402 - Pumping Speed Curve(Torr)10-310-210-1110150Rotary VanePumps1006 (0.24)40 (1.57) 40 (1.57)242 (9.5)242 (9.5)6 (0.24)40 (1.57) 40 (1.57) 40 (1.57) 40 (1.57)130 (5.1) 130 (5.1)261 (10.3) 261 (10.3) 100 (3.9) 100 (3.9)164 (6.5) 164 (6.5)541 (21.3) 541 (21.3)Effective Pumping Speed 50 Hz230 (9.0) 230 (9.0)10105(m3/h)(cfm)110.50.10.110 -310 -210 -1110 110 2(mbar)PressureTechnical SpecificationsFree air displacementPumping speed*Ultimate partial pressure*Ultimate total pressure*Ultimate total pressure with gas ballast*Water vapor toleranceWater vapor capacityOil capacity min/maxMotor rating 1phMotor rating 3phNominal rotation speedWeightInlet flangeExhaust flangeOrdering Information60 Hz: 410 l/min (14.5 cfm)60 Hz: 12.3 cfm60 Hz: 0.55 kW60 Hz: 0.90 kW60 Hz: 1800 rpm50 Hz: 342 l/min (20.5 m3/h)50 Hz: 17.4 m3/h10-4 mbar2 x 10-3 mbar1 x 10-2 mbar30 mbar350 g/h0.5/1 l35 kg (77 lbs)25KF DN25KF DN50 Hz: 0.75 kW50 Hz: 0.75 kW50 Hz: 1500 rpmDual Stage Rotary Vane PumpPart NumberDS 402 with 1 phase worldwide motor*9499330DS 402 with 3 phase worldwide motor**9499331* 1 phase motors (100-120 / 200-230) V 10%, 50/60 Hz.** 3 phase motors (200-220 / 380-415) V 10% at 50 Hz or(200-230 / 460) V 10% at 60 Hz.All motors comply with CE and UL/CSA standards.Minor Maintenance KitContains all the valves, O-rings and sealsto refurbish the pump to vacuum integrityPart NumberMajor Maintenance KitIncludes all the items of the minor kit plus the vanesPart Number9499382Oil and AccessoriesRotary vane fluid, DS19 type, 1 literRotary vane fluid, DS19 type, 1 liter (USA)*Rotary vane fluid, DS19 type, 1 gallon (USA)Oil mist eliminatorOil mist replacement cartridge (pkg. of 2)NW 25 oil exhaust filterNW 25 oil exhaust replacement cartridgeOil return kitOil drain extensionEuropean plug power cable 2 meters 1 phUSA plug power cable 2 meters 1 phUK plug power cable 2 meters 1 phNW 25 centering ring VitonNW 25 aluminum clamp9499371* According to PNEUROP 6602Part 25AWP* When these pumps are used in Leak Detectors applications, werecommend the use of Rotary Vane Fluid (Elite-Z mechanical),P/N 695409005 as it features a lower vapor pressure.1617

ROTARY VANE PUMPSAGILENT ROTARY VANE PUMP MODELS Agilent DS 602DS 602 - Pumping Speed Curve(Torr)10-310-210-1110150Rotary VanePumps1006 (0.24)40 (1.57) 40 (1.57)242 (9.5)242 (9.5)6 (0.24)40 (1.57) 40 (1.57) 40 (1.57) 40 (1.57)130 (5.1) 130 (5.1)261 (10.3) 261 (10.3) 100 (3.9) 100 (3.9)164 (6.5) 164 (6.5)541 (21.3) 541 (21.3)Effective Pumping Speed 50 Hz230 (9.0) 230 (9.0)10105(m3/h)(cfm)110.50.10.110 -310 -210 -1Alternative mounting holes are also available, with thread 1/4-20UNC110 110 2(mbar)PressureDimensions: millimeters (inches)Technical SpecificationsFree air displacementPumping speed*Ultimate partial pressure*Ultimate total pressure*Ultimate total pressure with gas ballast*Water vapor toleranceWater vapor capacityOil capacity min/maxMotor rating 1phMotor rating 3phNominal rotation speedWeightInlet flangeExhaust flangeOrdering Information60 Hz: 605 l/min (21.4 cfm)60 Hz: 17.6 cfm60 Hz: 0.90 kW60 Hz: 0.90 kW60 Hz: 1800 rpm50 Hz: 504 l/min (30.2 m3/h)50 Hz: 25 m3/h10-4 mbar2 x 10-3 mbar1 x 10-2 mbar30 mbar550 g/h0.5/1 l35 kg (77 lbs)25KF DN25KF DN50 Hz: 0.75 kW50 Hz: 0.75 kW50 Hz: 1500 rpmDual Stage Rotary Vane PumpPart NumberDS 602 with 1 phase worldwide motor*9499335DS 602 with 3 phase worldwide motor**9499336* 1 phase motors (100-120 / 200-230) V 10%, 50/60 Hz.** 3 phase motors (200-220 / 380-415) V 10% at 50 Hz or(200-230 / 460) V 10% at 60 Hz.All motors comply with CE and UL/CSA standards.Minor Maintenance KitContains all the valves, O-rings and sealsto refurbish the pump to vacuum integrityPart NumberMajor Maintenance KitIncludes all the items of the minor kit plus the vanesPart Number9499382Oil and AccessoriesRotary vane fluid, DS19 type, 1 literRotary vane fluid, DS19 type, 1 liter (USA)*Rotary vane fluid, DS19 type, 1 gallon (USA)Oil mist eliminatorOil mist replacement cartridge (pkg. of 2)NW 25 oil exhaust filterNW 25 oil exhaust replacement cartridgeOil return kitOil drain extensionEuropean plug power cable 2 meters 1 phUSA plug power cable 2 meters 1 phUK plug power cable 2 meters 1 phNW 25 centering ring VitonNW 25 aluminum clamp9499371* According to PNEUROP 6602Part 25AWP* When these pumps are used in Leak Detectors applications, werecommend the use of Rotary Vane Fluid (Elite-Z mechanical),P/N 695409005 as it features a lower vapor pressure.1819

AGILENT HS SERIES PUMPSFEATURES AND BENEFITS Exhaust Filters - Oil Mist Eliminator Foreline Roughing TrapsThe exhaust filters (below, left) and the oil mist eliminator(right), retain the oil vapors which would otherwise beexpelled into the atmosphere during pumpdown and gasballast operation.Some models feature an oil return line to allow condensed oilor fluid to return to the pump reservoir.Agilent’s new traps are designed to prevent the backstreamingof mechanical pump fluids. Copper and stainless steel gauzeinserts are designed to reduce oil backstreaming. Molecularsieve inserts are available for applications where it is desirableto increase water vapor pumping speed while eliminatingbackstreaming above the trap.ROTARY VANE PUMPS Agilent’s HS 452 and HS 652 rotary vanepumps employ an innovative frequency invertertechnology that delivers optimal and consistentperformance throughout the worldwide range ofvoltage and frequency conditions. Operating with low power requirements, themicroprocessor-controlled frequency inverter,combined with a 3-phase motor, is an efficientdriving unit capable of delivering the high startingtorque required for a dual-stage oil pump. Green technology: environmentally friendly thanksto reduced power requirements, low start upcurrent, minimum oil mist at pump exhaust.Rotary VanePumpsAGILENT ROTARY VANE PUMP ACCESSORIESI/O and RS232/RS485 Communication Adjustable pumping speed from 45 to 68Hz permits easy integration and reducesnoise levels.Ordering InformationNW25 oil exhaust filter (left)Oil mist eliminator DS 102 - DS 602 (right) Pump performance can be tailoredo specific applications to reducessystem costs.Ordering InformationPN 9499392PN 9499395Foreline/Roughing Traps: please call Agilent for ordering informationUniversal Input VoltageFor any further details on our rotary vane pump accessories,please contact Agilent Vacuum Products. Truly universal single-phase voltage andfrequency provide worldwide compatibility. Constant performance at different inputfrequencies.Remote DiagnosticsAgilent Oil, GP Type Mechanical Pump FluidAgilent GP Type Fluid is a mechanical pump fluidrecommended for use in non-corrosive applications. As aresult of molecular distillation, it has low vapor pressure and,therefore, backstreams less than undistilled refinery products. Remote monitoring and control of oilconsumption, power and current. Reduces maintenance costs, improvesuptime and offers higher reliability.Ordering InformationDescription1 liter bottle1 gallon bottlePart NumberK7516301K7516302Reduced Power RequirementsShipping Weight lbs (kg)3.5 (1.6)14.0 (6.4) Inverter technology reduces the powerrequired compared to traditional singlephase motors. Circuit-breakers are no longer required,resulting in reduced system costs.Higher Nominal Rotational Speed(2000 rpm) The pump is ideally suited for steady andhigh gas-load applications.2021

ROTARY VANE PUMPSAGILENT ROTARY VANE PUMP MODELSHS 452 - Pumping Speed CurveKF25 EXHAUST FLANGE40 (1.6)271 (10.7)245 (9.6)(m3/h)199 (7.8)164 (6.5)261 (10.3)The first rotary vane pumps with truly “smart” capabilities. Agilent’s HS 452 and HS 652 pumps employ an innovativefrequency inverter technology that delivers optimal andconsistent performance while encompassing the worldwiderange of voltage and frequency conditions. Operating with low power requirements, themicroprocessor controlled frequency inverter, combinedwith a 3-phase motor, is an efficient driving unit capableof delivering the high starting torque required of a dualstage oil pump. HS 452 and HS 652 technology solves the commonproblems inherent in traditional single-phase motors. SmartPumps start with inrush current about 7 times lower thanthat of equivalent traditional pumps.Technical SpecificationsFree air displacementPumping speed*Ultimate total pressure*Ultimate total pressure with gas ballast*Operating voltageInverter maximum output powerNominal rotation speedWeight10110210 35051-21010-199 (3.9) Unlike traditional pumps, Smart Pump’s software drivenstartup procedure recognizes faulty pumps within seconds,and so avoids uncontrolled load conditions. The result isvery easy pump integration. The 3-phase inverter output is constant and independent ofsingle-phase input frequencies and voltages. Motorefficiency and power factors remain optimal and as a resultmotor and pump wo asy to drive the pump. Pumpperformance can be tailored by setting the rotational speedfor specific applications. The software monitors and logspump parameters making it possible to perform pump andsystem diagnostics.110515 (20.3)Dimensions: millimeters (inches)(Torr)10110-3130 (5.1)10-1Pressure (mbar)KF25 INLET FLANGE10-2(cfm)75 (2.9)Pumping Speed10010-3HS 452 - Pump Down Curve1(mbar)Pressure10110210 1110 -110 -21030* 200 liters chamber60120180240300Time (sec)Ordering InformationPumpHS 452 Smart Pump 1 phase worldwide motorIP44 accessory connector KitPart Number94993609499367AccessoriesNW25 oil exhaust filterOil return kitOil drain extensionRotary vane fluid, DS19 type, 1 literEuropean plug power cable 2 meters 1 phUSA plug power cable 2 meters 1 phUK plug power cable 2 meters 1 phMinor maintenance kitMajor maintenance kitPart 9939894993719499382Application NoteSteady state high gas load applications exploit the majorbenefits of the smart technologies. When operated atpressures lower than the auto-tuning pressure, the HS 452 andHS 652 outperform the equivalent traditional DS 402 and DS602 pumps by 10% at 60 Hz and by 30% at 50 Hz.The Smart Pumps can run below auto-tuning pressure at theirfull speed of 2000 rpm. As shown in the pumping speed curveat top right, the HS 452 has an auto-tuning pressure of 100mbar while the HS 652 has an auto-tuning pressure of 40 mbar.Despite the lower power requirements of 780 W max, theSmart Pumps deliver good performance in the roughing phase.Fast cycling or inrush applications need to be evaluated on acase by case basis with our application engineers.27 m3/h (16 cfm)22 m3/h (13 cfm)2 x 10-3 mbar1 x 10-2 mbar100-120/200-240 V 10%, 50/60 Hz780 W2000 rpm33 kg (73 lbs)* According to PNEUROP 66022210 2Rotary VanePumps Agilent HS 45223

ROTARY VANE PUMPSAGILENT ROTARY VANE PUMP MODELSHS 652 - Pumping Speed CurveKF25 EXHAUST FLANGE40 (1.6)271 (10.7)245 (9.6)(m3/h)199 (7.8)164 (6.5)261 (10.3)The first rotary vane pumps with truly “smart” capabilities. Agilent’s HS 452 and HS 652 pumps employ an innovativefrequency inverter technology that delivers optimal andconsistent performance while encompassing the worldwiderange of voltage and frequency conditions. Operating with low power requirements, themicroprocessor controlled frequency inverter, combinedwith a 3-phase motor, is an efficient driving unit capableof delivering the high starting torque required of a dualstage oil pump. HS 452 and HS 652 technology solves the commonproblems inherent in traditional single-phase motors. SmartPumps start with inrush current about 7 times lower thanthat of equivalent traditional pumps.Technical SpecificationsFree air displacementPumping speed*Ultimate total pressure*Ultimate total pressure with gas ballast*Operating voltageInverter maximum output powerNominal rotation speedWeight10110210 35051-21010-199 (3.9) Unlike traditional pumps, Smart Pump’s software drivenstartup procedure recognizes faulty pumps within seconds,and so avoids uncontrolled load conditions. The result isvery easy pump integration. The 3-phase inverter output is constant and independent ofsingle-phase input frequencies and voltages. Motorefficiency and power factors remain optimal and as a resultmotor and pump working temperatures remain low andconstant worldwide. Smart Pumps can be remotely driven via discrete I/O orRS232/RS485 interfaces. Agilent’s T-plus NavigatorSoftware facilitates communication making it very easy todrive the pump. Pump performance can be tailored bysetting the rotational speed for specific applications.The software monitors and logs pump parameters makingit possible to perform pump and system diagnostics.110515 (20.3)Dimensions: millimeters (inches)(Torr)10110-3130 (5.1)10-1Pressure (mbar)KF25 INLET FLANGE10-2(cfm)75 (2.9)Pumping Speed10010-3HS 652 - Pump Down Curve1(mbar)Pressure10110210 1110 -110 -21030* 200 liters chamber60120180240300Time (sec)Ordering InformationPumpHS 652 Smart Pump 1 phase worldwide motorIP44 accessory connector KitPart Number94993659499367AccessoriesNW25 oil exhaust filterOil return kitOil drain extensionRotary vane fluid, DS19 type, 1 literEuropean plug power cable 2 meters 1 phUSA plug power cable 2 meters 1 phUK plug power cable 2 meters 1 phMinor maintenance kitMajor maintenance kitPart 9939894993719499382Application NoteSteady state high gas load applications exploit the majorbenefits of the smart technologies. When operated atpressures lower than the auto-tuning pressure, the HS 452and HS 652 outperform the equivalent traditional DS402 andDS602 pumps by 10% at 60 Hz and by 30% at 50 Hz.The Smart Pumps can run below auto-tuning pressure at theirfull speed of 2000 rpm. As shown in the pumping speed curveat top right, the HS 452 has an auto-tuning pressure of 100mbar while the HS 652 has an auto-tuning pressure of 40 mbar.Despite the lower power requirements of 780 W max, theSmart Pumps deliver good performance in the roughing phase.Fast cycling or inrush applications need to be evaluated on acase by case

Oil and Accessories Part Number Rotary vane fluid, AVF 20S type, 0.5 liter X3703-64006 DS 40M oil mist trap 3/4 G X3703-64003 DS 40M oil mist trap cartdrige (pkg. of 2) X3703-64004 DS 40M maintenance kit X3703-64005 DS 40M oil drain extension X3703-64007 NW 16 centering ring viton KC16AV NW 16 aluminum clamp KQ16AWP