Transcription

Plateflow Plate and FrameHeat Exchangers Efficient Heat Transfer.Compact Design.ITT Standard

Exceptional Choice.No other technology is more compact, efficient, or flexible than Plateflow.Easy to install and maintain Easy to install and move Readily expandable and easy to inspect or clean Opening and closing a standard unit does not require disconnecting the piping Platefow has vertical flow, so inlet and outlet connections are aboveand below each other and on the same plane for easy installation No special tools are needed to open and close the unit Tightening bolt design allows opening and closing the unit from the frame plate Studded connections withstand higher piping loads than nozzles With studded connection no welding is requiredSupport ColumnCarry BarPressure PlatePlate PackFrame PlateGuide BarTightening BoltsGasketHeat Transfer Plate2

Compact Design.Big on heat transfer.Small on space.Plateflow heat exchangers provide more heat transfer inless space. The Plateflow design is compact and efficient. Plateflow models have higher surface area tovolume ratios than conventional shell and tubeheat exchangers. Plateflow offers superior heat transfercoefficients compared to shell and tube heatexchangers. This is obtained through the uniqueplate designs that generate high turbulence. Plateflow offers “true” countercurrent flow.This maximizes the mean temperature differencebetween the fluids.These attributes allow Plateflow to perform with one-third to one-fifth the surface area of a conventional shelland tube heat exchanger for the same application. The superior heat transfer capabilities make Plateflow anexceptional choice for heat transfer applications like heat recovery, applications with viscous fluids and largetemperature cross situations.ITT offers a numerous choice of models and options to suit your particular heat transfer requirements.Efficient.HowPlateflow works.Plateflow uses a combination of chevron-style heat transfer plates sequenced between a frame plate and pressureplate. The heat transfer plates have holes at the four corners. These holes form a header that distributes the respective fluids to the opposite sides of each plate when the plates align. The fluids are confined to the heat transfersurface of the plate or the port as appropriate with elastomer gaskets.Countercurrent flow is obtained with a given fluid traveling up one side of a plate and the otherfluid down the opposite side of the plate. The plate’s chevron patterns create metal to metalcontact points between adjacent plates for added strength. This allowsdifferential pressures equal to the design pressure. The entire assembly isheld together with tightening bolts.Carry/guide bars are used to obtainthe proper alignment. The Plateflowdesign is extremely flexible.3

A D VA N C E D P L A TGaskets.Low maintenance.Plateflow models include a one-piece molded gasket. Thisstandard gasket is designed with two rings to confine eachfluid to the appropriate port region of the plate, a field regionof the gasket to confine the fluid to the heat transfer area ofthe plate and a vented region in between. This design createsa double gasket with a leak path to atmosphere through the Double gasketing preventscross-contamination.vented region to prevent any cross contamination of the fluidsdue to a gasket failure. A leak due to a gasket failure isdetected as a leak to atmosphere prior to any chance for crosscontamination. ITT offers various options of glueless gasketsas well as glued gaskets. Glueless gasket option.Welded Plate.Heavy duty.The semi-welded Plateflow design expands the applicationenvelope of plate heat transfer technology to applications thatare aggressive to standard elastomers and other applicationswhere leak prevention is critical.The semi-welded Plateflow design utilizes twoplates laser welded together to form a cassette.The cassettes form channels within which theRing Gasketwelded-side fluid flows. Two ring gaskets anda field gasket are used between adjacentWelded Plateflow unitsare ideal for handlingaggressive fluids.cassettes in the same fashion as a typicalgasket in the standard Plateflow design.The ring gaskets confine the welded side fluidbetween the adjacent cassettes and can bemade of highly resistant Teflon or moretraditional elastomer gasket materials. Thedesign eliminates the welded-side’s exposedCassettesgasket surface by approximately 90%. Thesemi-welded Plateflow is exceptional forFieldGasketrefrigerant, aggressive chemical, or any applicationswhere reducing the fluid’s contact with elastomers is desired.4Non-AggressiveFluidAggressiveFluid

TETECHNOLOGYDouble-Wall.Built forprotection.The nature of the basic Plateflow design includes a double gasketing feature for extra protection against gasketfailure. With double-wall units, that additional protection is extended to guard against plate failure as well. Twoplates are positioned together with a unique sealing mechanism at the port holes to form one assembly with air spacebetween the plates. There are noGasketDouble-wall thermal platewelds. This unique feature protectsagainst contamination of one fluid byEffluentanother. If one of the plates shouldcorrode and develop a leak, the fluidDomestic Waterwould enter the air space and exit tothe atmosphere, instead of enteringthe opposing tAir spaceLeak in plateWorry free.Free-flow units offer the same features of basicPlateflow models, with the added benefit ofexceptional clog-resistance for high-fiber orcoarse-fiber applications. The ITT Freeflow models feature minimum or no metalto-metal contact points between adjacentplates to reduce points for particles tocatch on the plates. Free-flow models canhandle fluids with particulate, pulp orfibrous materials up to 2mm in diameterand 5mm long. The free-flow feature isideal for heat reclamation in pulp andpaper or chemical processing, wherewash water, white water, fibrous waterslurries or high viscosity fluids are used.5

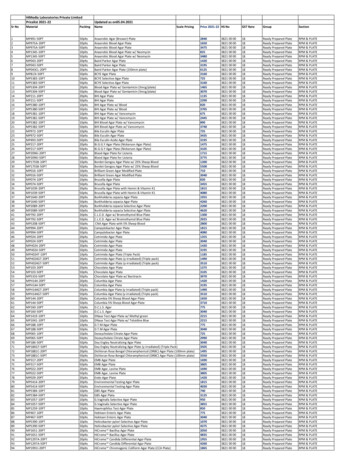

Versatility.Adaptableconstruction.A wide variety of plate construction materials are available, including 304 or 316 stainless steel, titanium, Hastelloy, Incolloy, and other metals. Various connection types are available to match the application requirements. Gasketedsemi-welded, double wall, and free flow plates are designed to meet a wide variety of applications.Technical DataPerformance: Maximum Flowrate (GPM)up to 23,500 GPMMax. Heat Transfer Area (Ft 2)up to 20,000 Ft 2Connections: NPT Nozzles—Size (IN)1 inch to 3 inchANSI Studded Connections—Size (IN)4 inch to 18 inchConnection MaterialsEpoxy painted carbon steel, stainless steel, titanium, Hastelloy, rubberConstruction: Plate Materials304 and 316 stainless steel, titanium, SMO 254, Hastelloy,Incolloy, palladium-titaniumGasket MaterialsNitrile, EPDM, viton, neoprene, high temperature EPDM & nitrileFrame Design PressuresStandard designs of 150 psi and 300 psi*Design Temperatures- 31 F to 338 F* Frame designs exceeding 300 psiavailable upon requestVariety.Wide ProductBreadth.Gasketed Plates6

Multiple Connection TypesStandard threaded connection.Threaded connection withalloy nozzle.Standard studded connection.Studded connection withalloy lining.OptionalVariable Thermal Length PlatesFlanged connection.Sanitary Quick-Disconnectnozzle.(2) Thermal Long Plates“TL” Channel(1) Thermal Long &(1) Thermal Short Plate“TM” ChannelFree Flow Plates(2) Thermal Short Plates“TK” ChannelSemi Welded Plates7

Pre-engineeredITTSTANDARDPRODUCTS.shell-and-tube heatexchangers for generalheating and cooling.Efficiency.DESIGNEDTO MEETVIRTUALLYEngineered/customized heatEVERY HEATexchangers for process andTRANSFERother .Brazepak compact,vacuum-brazed,FanEx air/oil,general purposeair/air, or air/waterheat exchangers.heat ransfercoils.ITT StandardRepresented by:175 Standard ParkwayCheektowaga, New York 14227tel 800.447.7700In New York State: 716.897.2800Fax: 716.897.1777www.ittstandard.comLit# 104-75Formerly AMERICAN-STANDARD HEAT TRANSFER DIVISION 2000 ITT Standard920220.20M.1200.BLPrinted on recycled paper.

ITT STANDARD PRODUCTS. DESIGNED TO MEET VIRTUALLY EVERY HEAT TRANSFER APPLICATION REQUIREMENT. Pre-engineered shell-and-tube heat exchangers for general heating and cooling. Lit# 104-75 2000 ITT Standard 920220.20M.1200.BL Printed on recycled paper. 175 Standard Parkway Cheektowaga, New York 14227 tel 800.447.7700 In New York State: 716.897.2800