Transcription

Quick Startup GuideTPM(A)010 – 110BOSCH REXROTH(Indramat)ECODRIVE 03VersionDateFileDoc.No.::::1.2th19 October 20054091 D006343 3.doc4091-D006343-03Technical changes reserved!

Quick Startup Guide Bosch Rexroth EcoDrive 03Table of ContentsTABLE OF CONTENTS. 21GENERAL INFORMATION AND SAFETY INSTRUCTIONS . 32NAME PLATE DATA DETAILS . 43PARAMETERIZATION. 53.13.1.13.23.2.13.2.2RD3 PARTY MOTOR FILE . 5Selecting the motor parameter file during initial start-up drive . 5PARAMETER INPUT VIA SINGLE PARAMETER . 6Starting the dialog single parameter input . 6Parameter input . 64PARAMETERS TPM 025 - 1105PARAMETERS TPM 0106PARAMETERS TPMA 025 - 1107CONNECTION SCHEMATIC TPM / TPMA ECODRIVE 03 . 107.17.2600V AT ECODRIVE 03 DKC**.040. 7600V AT ECODRIVE 03 DKC**.016 . 8600V AT ECODRIVE 03 DKC**.040 . 9TPM / TPMA WITH RESOLVER FEEDBACK . 10TPM / TPMA WITH ABSOLUTE ROTARY ENCODER ECN 1313 / EQN 1325. 108DIAGNOSTIC MESSAGES DURING INITIAL START-UP . 119ASSIGNMENT TPM SERVO AMPLIFIER CABLE SET . 129.19.2TPM WITH RESOLVER FEEDBACK . 12TPM WITH ABSOLUTE ENCODER ECN 1313 / EQN 1325. 13Modification HistoryDocument Designation4091 D006343 1.doc4091 D006343 2.docVersion1.01.14091 D006343 3.doc1.2Date15.05.200319th March 2004NoteFirst editionCorrection wiring schemes and cable cross reference table. TPMA added.19th October 2005 Correction parameter S-0-0106 and S-0-0107for TPM010-110Contact address:WITTENSTEIN motion control GmbHWalter-Wittenstein-Strasse 197 999 IgersheimTel.FaxEmail: 07931 / 493-0: 07931 / 493-200: info@w-m-c.deDocument-No.: 4091-D006343-03Date: 19th October 2005Page 2 of 13

Quick Startup Guide Bosch Rexroth EcoDrive 031 General Information and Safety InstructionsThis guide serves as an aid during start-up and inspection of TPM motor gear units withservo amplifiers. It contains the following points: Start-Up informationParameter lists for the TPM seriesConnection schematic for TPMAssignment table TPM – Servo amplifier - cable setPlease be sure to carefully read through this document before starting up the TPM and alsobe sure to read the documentation provided by the manufacturer of the servo amplifier.WITTENSTEIN motion control will not be held liable for the consequences of theimproper, negligent, or incorrect installation or setting of the servo amplifier's operating parameters.All of the installation, operation, and safety information provided in the servo amplifier documentation is to be observed.Observe all of the national safety regulations and guidelines of the country where the deviceis being used. All transportation, installation, start-up, and service work is to be performed byqualified technicians. Qualified technicians are those who are completely familiar with the assembly, installation, and operating procedures, as well as all warnings and safety measuresin accordance with the country-specific regulations. Furthermore, they are trained, instructed,and authorised to set the electrical circuits and other devices into operation in accordancewith safety regulations.The drives are intended to be installed in machines being used in commercial applications.You may only operate the equipment if you comply to the national EMC regulations (refer tothe servo amplifier documentation for installation information pertaining to EMC) as they aredefined for the given application.Note: All of the product brand names which appear in this Quick Start Guide are trademarksof the relevant companies. If the and/or symbols are omitted, this does not imply thatthe name is a free brand name.Document-No.: 4091-D006343-03Date: 19th October 2005Page 3 of 13

Quick Startup Guide Bosch Rexroth EcoDrive 032 Name plate data detailsThe following specifications can be found on the identification plate. Please select the input parameters corresponding to the nameplate values of your drive.TPM 010–091 M–600 K–BP 1–015 IF STDSizeTPM 004 / 010 / 025 / 050 / 110TPMA 025 / 050 / 110Plug formSTD angleSEG straightXXX customRatio21 / 31 / 61 / 91 (TPM)110 / 154 / 220 (TPMA)StandardIF industry standardUL UL recognisedfile E220160Motor encoderR ResolverS Singleturn Heidenhain EnDat M Multiturn Heidenhain EnDat N Singleturn Stegmann Hiperface K Multiturn Stegmann Hiperface I Heidenhain incremental encoderStator lengthClearance specification1 Standard 3 arcmin(TPM 004: 5 arcmin)0 Reduced 1 arcmin(TPM 004: 3 arcmin)Intermediate voltage320600BrakeBP Permanent magneticbrakeOH Without brakeTemperature sensorP PTC STM 160 in accordance withDIN 44081 / 44082N NTCK KTY 84-130Document-No.: 4091-D006343-03Date: 19th October 2005Page 4 of 13

Quick Startup Guide Bosch Rexroth EcoDrive 033 ParameterizationTo operate the TPM together with a drive of the EcoDrive03-family the motor parameters need to beput in.The tables in section 4 resp. 5 contain all of the parameters that are required for the initial start-up ofa TPM motor-gear unit from WITTENSTEIN motion control together with a Bosch Rexroth EcoDrive.When the TPM and the servo amplifier are properly connected, these parameters guarantee that theTPM can be operated without load in speed control. Based on these default settings, the dynamics ofthe speed loop can be optimized depending on the application.rdTogether with the Drivetop-Software the data can either be loaded as a 3 party motor file or can beinput via single parameter dialog.3rd party motor file3.1rdWith this option the motor parameters are loaded as predefined 3 party motor parameter file. Youcan download matching parameter files for your TPM at www.w-m-c.de.3.1.1Selecting the motor parameter file during initial start-up drive Select the file corresponding to your TPM. Set the motor parameters. Configure the application to your requirements. During initial start-up parameter S-0-0091 will be set to 100 rpm. Depending on the selected scaling (reference to motor or load) the value needs to be changed to achieve maximum speed.Document-No.: 4091-D006343-03Date: 19th October 2005Page 5 of 13

Quick Startup Guide Bosch Rexroth EcoDrive 033.2Parameter input via single parameterWith this option each parameter number and each parameter value needs to be put in. In this case it isnecessary to use the parameters from table in section 4 or 5 depending on the TPM you use.3.2.1 Starting the dialog single parameter input3.2.2Parameter inputInput of p4014 is sufficient for selecting Parameter P-0-4014, s109 for S-0-0109.Put in the appropriate values.Document-No.: 4091-D006343-03Date: 19th October 2005Page 6 of 13

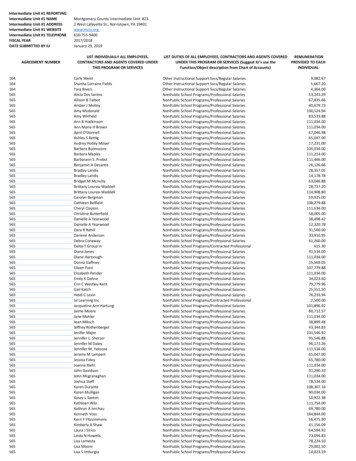

Quick Startup Guide Bosch Rexroth EcoDrive 034 Parameters TPM 025 - 110600V at EcoDrive 03 DKC**.040Data for combinations not shown here are available on criptionMotor typeSwitching frequency [kHz]Number of pole pairsCommutation offset Resolver1Commutation offset EnDatBipolar torque / force limit value [%]Torque / Force limit value. [%]Motor warning temperature [ C]Motor shutdown temperature [ C]Maximum motor speed [rpm] ResolverMaximum motor speed [rpm] EnDatVelocity loop control gain [As/rad]Velocity loop integral action time [ms]Velocity loop smoothing time constant [µs]Feedback 1 typeResolver / EnDatVelocity polarity parameterResolver / EnDatPosition polaritiesResolver / EnDatTorque / Force polarity parameterResolver / EnDatFeedback 1 resolution ResolverFeedback 1 resolution EnDatS-0-0116S-0-0116Ratio 21 / 31Stator lengthS-0-0109Motor peak current [Apeak]Ratio i 21Ratio i 31S-0-0111Motor current at standstill [Apeak]S-0-0106Current loop proportional gain 1 [V/A]S-0-0107Current loop integral action time 1 [ms]P-0-4047Motor inductance [mH]P-0-4048Stator resistance [Ohm]P-0-0051Torque / Force constant [Nm/Apeak]P-0-0511Brake current [A]P-0-0525Type of motor brakeP-0-0526Brake control delay [ms]P-0-0540Brake Torque / Force [Nm]Ratio 61 / 91Stator lengthS-0-0109Motor peak current [Apeak]Ratio i 61Ratio i 91S-0-0111Motor current at standstill [Apeak]S-0-0106Current loop proportional gain 1 [V/A]S-0-0107Current loop integral action time 1 [ms]P-0-4047Motor inductance [mH]P-0-4048Stator resistance [Ohm]P-0-0051Torque / Force constant [Nm/Apeak]P-0-0511Brake current [A]P-0-0525Type of motor brakeP-0-0526Brake control delay [ms]P-0-0540Brake Torque / Force 65101510500500130145430043000.21050010 / 80111 / 00001111 / 00000111 / 4.101.402.4000.3600.6401.1000010151It may be necessary to put in this parameter with the help from the commutation angle detection routine from the DriveTop Software.Document-No.: 4091-D006343-03Date: 19th October 2005Page 7 of 13

Quick Startup Guide Bosch Rexroth EcoDrive 035 Parameters TPM 010600V at EcoDrive 03 DKC**.016The DKC**.016 supports only motors with resolver.Data for combinations not shown here are available on Motor typeSwitching frequency [kHz]Number of pole pairsCommutation offset ResolverBipolar torque / force limit value [%]Torque / Force limit value. [%]Motor warning temperature [ C]Motor shutdown temperature [ C]Maximum motor speed [rpm] ResolverVelocity loop control gain [As/rad]Velocity loop integral action time [ms]Velocity loop smoothing time constant [µs]Feedback 1 typeResolverVelocity polarity parameterResolverPosition polaritiesResolverTorque / Force polarity parameterResolverFeedback 1 resolution ResolverS-0-0116Ratio 21 / 31Stator lengthS-0-0109Motor peak current [Apeak]Ratio i 21Ratio i 31S-0-0111Motor current at standstill [Apeak]S-0-0106Current loop proportional gain 1 [V/A]S-0-0107Current loop integral action time 1 [ms]P-0-4047Motor inductance [mH]P-0-4048Stator resistance [Ohm]P-0-0051Torque / Force constant [Nm/Apeak]P-0-0511Brake current [A]P-0-0525Type of motor brakeP-0-0526Brake control delay [ms]P-0-0540Brake Torque / Force [Nm]Ratio 61 / 91Stator lengthS-0-0109Motor peak current [Apeak]Ratio i 61Ratio i 91S-0-0111Motor current at standstill [Apeak]S-0-0106Current loop proportional gain 1 [V/A]S-0-0107Current loop integral action time 1 [ms]P-0-4047Motor inductance [mH]P-0-4048Stator resistance [Ohm]P-0-0051Torque / Force constant [Nm/Apeak]P-0-0511Brake current [A]P-0-0525Type of motor brakeP-0-0526Brake control delay [ms]P-0-0540Brake Torque / Force [Nm]Document-No.: 4091-D006343-03Date: 19th October 500.5000061.8Page 8 of 13

Quick Startup Guide Bosch Rexroth EcoDrive 036 Parameters TPMA 025 - 110600V at EcoDrive 03 DKC**.040Data for combinations not shown here are available on onMotor typeSwitching frequency [kHz]Number of pole pairsCommutation offset Resolver2Commutation offset EnDatBipolar torque / force limit value [%]Torque / Force limit value. [%]Motor warning temperature [ C]Motor shutdown temperature [ C]Maximum motor speed [rpm] ResolverMaximum motor speed [rpm] EnDatS-0-0100Velocity loop control gain [As/rad]S-0-0101Velocity loop integral action time [ms]P-0-0004Velocity loop smoothing time constant [µs]P-0-0074Feedback 1 typeResolver / EnDatS-0-0043Velocity polarity parameterResolver / EnDatS-0-0055Position polaritiesResolver / EnDatS-0-0085Torque / Force polarity parameterResolver / EnDatS-0-0116Feedback 1 resolution ResolverS-0-0116Feedback 1 resolution EnDatratio 110 / 154 / 220stator lengthS-0-0109Motor peak current [Apeak]Ratio i 110Ratio i 154Ratio i 220S-0-0111Motor current at standstill [Apeak]S-0-0106Current loop proportional gain 1 [V/A]S-0-0107Current loop integral action time 1 [ms]P-0-4047Motor indukance [mH]P-0-4048Stator resistance [Ohm]P-0-0051Torque / Force constant [Nm/Apeak]P-0-0511Brake current [A]P-0-0525Type of motor brakeP-0-0526Brake control delay [ms]P-0-0540Brake Torque / Force MA1107865102510500500130145450045000.2001050010 / 80111 / 00001111 / 00000111 / 004.101.402.4000.3600.6401.1000010152It may be necessary to put in this parameter with the help from the commutation angle detection routine from the DriveTop Software.Document-No.: 4091-D006343-03Date: 19th October 2005Page 9 of 13

Quick Startup Guide Bosch Rexroth EcoDrive 037 Connection schematic TPM / TPMA EcoDrive 03For detailed information about cable design and screening the documentaion of the drive manufacturer has to be consulted.7.1TPM / TPMA with resolver feedbackpower plugPEM3PEPE2A14A21A3UVW5Br 6Br -brake optionalBr Br -brake / temp.sensor(X6)3 BR 4 BR12signal plugRPTC5PTC6Ref 7Ref-8Sin 3Sin -4G1 8V/SIN0VG1Sin G1Sin-resolver plug(X4)3 G1Cos 10 G1Cos-9shield7.21213292Cos -TM TM-IndramatECODRIVE 031Cos powerterminalblock(X5)TPM / TPMA with absolute rotary encoder ECN 1313 / EQN 1325power plugPEM3UVWBr Br -PEPE1A12A26A345brake ata 3data -13clock 517SCclock P-Encoder5V SenseM-Encoder0V SenseDocument-No.: 4091-D006343-03TM TM-IndramatECODRIVE 038A B brake / temp. sensor(X6)3 BR 4 BR12signal plugPTCBr Br -powerterminalblock(X5)141016715Date: 19th October 2005G2Sin G2Sin0VG2Cos sincosG2Cos0VplugG2EnDat (X8)G2EnDat0VG2EnDatClk G2EnDatClkG2 5VG2 5VSen0VG2 0VSenPage 10 of 13

Quick Startup Guide Bosch Rexroth EcoDrive 038 Diagnostic messages during initial start-upDuring initial start-up faults may occure. Following diagnostic messages could appear with an correctlyworking TPM. For further investigations please consult the documentation from Bosch Rexroth.Diagnostic messagePossible causeSolutionF228 Excessive deviationCommutation anglenot correctCheck wiring of motor and motorfeedback. Verify that P-0-0508 wastaken over correctly by the drive. Ifnot please activate the commutation angle determination routine.Set absolute measurementCheck speed loop setting.If necessary check wiring of motorand commutation offset angle.F878 Velocity loop errorF879 Velocity limit S-0-0091 exceededF276 Absolute encoder out of windowF230 Max. signal frequency of encoder 1exceededInitial start-upCutoff frequency ofEnDat feedback interface is limited to200kHz. When using the 2048 linesthis results in amaximum speed of5859 rpm.E263 Velocity command value limit S-0- Speed command0091exceeds the valuefor bipolar limit in S0-091.Document-No.: 4091-D006343-03Date: 19th October 2005Adjust the value for S-0-0091 according your application.Verify the scaling of your application.Page 11 of 13

Quick Startup Guide Bosch Rexroth EcoDrive 039 Assignment TPM / TPMA servo amplifier cable set9.1TPM / TPMA with resolver feedbackTPM typeiFeedbacksizeController1recommendation WMC320V600V5mL10mSLSarticle code for power (L) and feedback (S) cables15m20m25m30mLSLSLSLS40mL50mSLS021031TPM 004061DKC 0x.3-040-7-DKC 0x.3-040-74000 76704000 74524000 76694000 76784000 76824000 76684000 61694000 38794000 60934000 76814000 76834000 8096-110, 154, 2204000 8095021, 031, 061, 0914000 8094DKC 0x.3-100-74000 7592-4000 7591021, 0314000 8093DKC 0x.3-040-7DKC 0x.3-040-74000 6135-4000 6143061, 091110, 154, 2204000 8092DKC 0x.3-040-74000 6134-4000 3878DKC 0x.3-040-7110, 154, 2204000 6142-4000 6133DKC 0x.3-016-7021, 031, 061, 0914000 3877DKC 0x.3-016-7-4000 6141-0914000 38760614000 8091TPM(A) 110DKC 0x.3-016-74000 8090TPM(A) 050DKC 0x.3-016-7-4000 6132TPM(A) 025-0314000 6140TPM 0100214000 8089Resolver0911WMC recommendation is based on use of a power stage with maximal PWM-frequency. Please refer to WMC or controller manufacture to select optimized controller size for the application. Possibly youare able to use a smaller controller.Power and Feedback cables for TPM with Resolverall cable complete and for dynamic layingpower cable TPM 004-050KABELL-TPM -xxINDE-RES015-STGstructure power cable:4 x 1,5mm2 2 x (2 x 1mm2), diameter 12,2mm, min. bending radius 122mmpower cable TPM 110KABELL-TPM -xxINDE-RES025-STGstructure power cable:4 x 2,5mm2 2 x (2 x 1mm2), diameter 15,1mm, min. bending radius 151mmfeedback cableKABELS-TPM -xxIND -RES000-STGstructure feedback cable:3 x (2 x 0,14mm2) 4 x 0,14mm2 4 x 0,25mm2 2 x 0,5mm2diameter 10mm; min. bending radius 100mm(xx cable length)Document-No.: 4091-D006343-03Date: 19th October 2005Page 12 of 13

Quick Startup Guide Bosch Rexroth EcoDrive 03TPM / TPMA with absolute encoder ECN 1313 / EQN 1325TPM typesizeiController1recommendation WMC320V600V5mL10mSLSarticle code for power (L) and feedback (S) cables15m20m25m30mLSLSLSLS40mL50mSLS021DKC 0x.3-040-714000 76554000 76874000 76544000 76864000 76534000 76854000 76524000 8088DKC 0x.3-040-7-4000 8087-110, 154, 2204000 8086021, 031, 061, 0914000 7684DKC 0x.3-100-74000 8085-4000 6139021, 0314000 6147DKC 0x.3-040-7DKC 0x.3-040-74000 8084-4000 6138061, 091110, 154, 2204000 6146DKC 0x.3-040-74000 6145DKC 0x.3-040-7-4000 8083TPM(A) 110-110, 154, 2204000 6137TPM(A) 050021, 031, 061, 0914000 8082TPM(A) 0250614000 6136TPM 0044000 6144Absolute Single-/Multiturn feedback with EnDat interfaceFeedback4000 80819.2WMC recommendation is based on use of a power stage with maximal PWM-frequency. Please refer to WMC or controller manufacture to select optimized controller size for the application. Possibly youare able to use a smaller controller.Power and Feedback cables for TPM with EnDat absolute feedback ECN1313 / EQN1325all cable complete and for dynamic layingpower cable TPM 004-050KABELL-TPM -xxINDE-END015-STGstructure power cable:4 x 1,5mm2 2 x 1mm2, diameter 12mm, min. bending radius 120mmpower cable TPM 110KABELL-TPM -xxINDE-END025-STGstructure power cable:4 x 2,5mm2 2 x 1mm2, diameter 15,1mm, min. bending radius 151mmfeedback cableKABELS-TPM -xxINDE-END000-STGstructure feedback cable:3 x (2 x 0,14mm2) 4 x 0,14mm2 4 x 0,25mm2 2 x 0,5mm2; diameter 10mmdiameter 10mm; min. bending radius 100mm(xx cable length)Document-No.: 4091-D006343-03Date: 19th October 2005Page 13 of 13

Quick Startup Guide Bosch Rexroth EcoDrive 03 Document-No.: 4091-D006343-03 Date: 19 th October 2005 Page 3 of 13 1 General Information and Safety Instructions This guide serves as an aid during start-up and inspection of TPM motor gear units with