Transcription

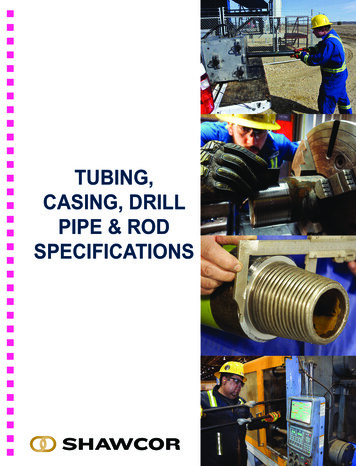

TUBING,CASING, DRILLPIPE & RODSPECIFICATIONS

USED DRILL PIPE INSPECTION SPECIFICATIONSIMPERIAL (in) / (lbs/ft)METRIC (mm) / (kg/m)MATERIALNEW PIPEPREMIUMCLASSCLASS MinimumWall30%MinimumWall2 7.110.896.221.425.692.134.982 489.191.158.051.847.362.766.443 906.764 38.1012.701.5911.112.5410.163.818.895 67.386 6.44Page 1

OD GAUGING CHARTIMPERIAL (in) / (lbs/ft)METRIC (mm) / (kg/m)O.D.NominalWeightWallThickness1/32” Equiv. to% of Wall3% of O.D. in1/32”4% of O.D. in1/32”5% of O.D. in1/32”2 3/860.32 7/873.03 0.610.610.64101.64 1/2114.35127.05 1/2139.76 5/8168.3Page 2

DRILL PIPE & DRILL COLLAR CLASSIFICATIONSSTANDARD DRILL PIPE, DRILL COLLAR, HEAVY WEIGHT & SUBS COLOR CODESO.DREDUCTIONREMAINING WALLCUTS AND GOUGES(EXCLUDING SHARPBOTTOM TRANSVERSE)CLASS 1NEWMINIMUMWALLTHICKNESSMASHESSTRETCHSLIP AREA87½%One WhiteBandPREMIUM CLASSPREMIUM CLASS80%80%3% OF O.D.One PunchMarks2 WhiteBandsOne PunchMarks3 WhiteBands3% OF O.D.80%Heavy Wall Premium Class Tube70%CLASS 280%70%4% OF O.D.Two Punch (Yellow Band)MarksCLASS 3ANY IMPERFECTIONS OR DAMAGESWHICH EXCEEDS CLASS IIThree Punch (Orange Band)MarksCLASS 4CRACKEDFour PunchMarks(Red Band)1 GreenUltrasonic End / Slip Area Inspection Performed1 BlueX95 Grade2 BlueSS95 Grade1 PurpleG105 Grade2 PurpleSS105 Grade1 PinkS135 GradeCustomer Specification Shall Override These Identification Bands Where ApplicableForm No. CC-3 DP Colour ChartRev. Date: October 2017Rev. 001Page 3

DRILL PIPE & TOOL JOINT IDENTIFICATION INFORMATIONSTANDARD DRILL PIPE, DRILL COLLAR, HEAVY WEIGHT & SUBS COLOR CODES1 WhiteMPI Inspection - No Damage1 GreenDamaged Seal (Field Repairable)2 GreenDamaged Seal / Threads (Shop Repairable)1 BlueUndersize Tooljoint OD1 YellowIncorrect Bevel Diameter1 RedCracked or Severe Damage - Do not Use1 PurplePoor / Undercut Hardband(Place Next To Hardband On Drill Collars)1 BlueShort Tool Joint / Insufficient Tong Space1 OrangeRequires ID Cleaning(Approx. 3 Ft. from Box End)2 OrangePlugged ID(Approx. 3 Ft. from Box End)1 WhiteBent / Crooked Tube(Approx. 3 Ft. from Box End)SILVERSerial Number HighlightingCustomer Specification Shall Override These Identification Bands Where ApplicableForm No. CC-3 DP Colour ChartPage 4Rev. Date: October 2017Rev. 001

DRILL PIPE & TOOL JOINT IDENTIFICATION INFORMATIONMARKINGEXAMPLETool joint manufacturer’s symbolZZ indicates ZZ company (fictionalfor example only)Month welded (1 to 12)3 indicates MarchYear welded (last two digits ofyear)02 indicates 2002Pipe manufacturer’s symbolN indicates United States SteelCompanyDrill-pipe grade symbolaDrill-pipe weight codeba - Drill Pipe Grade G105VV-150b - Pipe Manufacturers:Pipe Mills or XArmcoABritish Steel-American SeamlessAISeamless Tubes LTDBB&WWDalmineDCF&ICKawaskiHJ&LJNipponILone StarLKMannesmannMOhioORepublicRNKKReynolds ecUS SteelVallourec & MannesmannUsedGrant PridecoVMUGPOmscoOMSTexas Steel ConversionTSCTIVoestWheeling PittsburghGrant TFWPridecoZTUVVAPTFWPIPage 5

DRILL PIPE & TOOL JOINT IDENTIFICATION INFORMATIONa) Standard groove and mill-slot locations for Egrade standard-weight drill pipeb) Standard groove and mill-slot locations for Egrade heavy-weight drill pipec) Standard groove and mill-slot locations for highstrength standard-weight drill piped) Standard groove and mill-slot locations for highstrength heavy-weight drill pipe31SIZEO.D.INCHES2 3/82 7/83 1/244 1/2KEY1. Mill slot location for pipe grade code2. Mill slot location for pipe weight code3. Mill slot location for optional serial number2NOMINALWEIGHT LBPER WEIGHT LBPER .36234 1/255 1/26 5/8NOTE: Designates standard weight for drill pipe sizePage 6

STANDARD HEAVY-WEIGHT SPECIFICATIONS(OMSCO)IMPERIAL (in) / (lbs/ft)METRIC (mm) / (kg/m)NOMINALO.D.3 1/1677.83 1/879.43 1/288.94101.64 1/2114.351275 1/2139.76 5/8168.3WEIGHT14.9 lb/ft22.17 kg/m15.8 lb/ft23.51 kg/m23.7 lb/ft35.27 kg/m29.9 lb/ft44.49 kg/m40.8 lb/ft60.72 kg/m50.0 lb/ft74.41 kg/m46.7 lb/ft69.5 kg/m83.4 lb/ft124.11 kg/mTUBEI.D.2 1/8542 1/8542 1/457.22 9/1665.22 13/1671.4376.24101.64101.6NOM. 1.431.00025.400.75019.051.31333.35CENTERO.D.3 3/885.73 3/885.74101.64 1/2114.351275 1/2139.76152.47 1/8181.0TOOL JOINTCONNECTION NEW O.D.I.D.2 7/8 SLH902 7/8 SLH90NC 383 1/2 IFNC 404 FHNC 464 1/2 XHNC 504 1/2 IF5 1/2 FH6 5/8 FH3 3/495.33 3/495.34 3/4120.75 1/4133.46 1/4158.86 1/2165.17 1/4184.158203.2BEVEL DIAM.2 1/8542 1/8542 1/457.22 9/1665.22 13/1671.4376.24101.64101.63 23/3294.53 23/3294.54 37/64116.35 1/64127.45 23/32145.36 1/161546 23/32170.77 45/64195.7NOTE: This table is a guideline only. Contact customer and/or customer spec. for current information includingminimum wall thickness and tool joint O.D.sSTANDARD HEAVY-WEIGHT SPECIFICATIONS(GRANT PRIDECO)NOMINAL O.D.WEIGHT3 1/288.93 1/288.94101.64 1/2114.351275 1/2139.76 5/8168.323.5 lb/ft34.97 kg/m25.7 lb/ft38.25 kg/m29.9 lb/ft44.50 kg/m41.5 lb/ft61.76 kg/m50.4 lb/ft75.00 kg/m61.6 lb/ft91.67 kg/m71.4 lb/ft106.25 kg/mTUBEI.D.2 1/457.22 1/1652.42 9/1665.22 3/469.9376.23 1/482.54 1/2114.3NOM. 5.401.12528.581.06327.00CENTERO.D.4101.64101.64 1/2114.351275 1/2139.76152.47 1/4184.2CONNECTIONNC 383 1/2 IFNC 383 1/2 IFNC 404 FHNC 464 1/2 XHNC 504 1/2 IF5 1/2 FH6 5/8 FHIMPERIAL (in) / (lbs/ft)METRIC (mm) / (kg/m)TOOL JOINTNEWI.D.O.D.4 3/42 5/16120.758.74 3/42 3/16120.755.65 1/42 5/8133.466.76 1/42 7/8158.8736 5/83 1/16168.377.87 1/43 5/16184.2084.184 1/2203.2114.3BEVELDIAM.4 37/64116.34 37/64116.35 1/64127.45 23/32145.36 1/161546 23/32170.77 45/64195.7NOTE: This table is a guideline only. Contact customer and/or customer spec. for current information includingminimum wall thickness and tool joint O.D.sPage 7

STANDARD HEAVY-WEIGHT SPECIFICATIONS (DRILCO)IMPERIAL(in) / (lbs/ft)IMPERIALMETRICMETRIC(mm) / (kg/m)NOMINALO.D.3 1/1677.83 1/288.94101.64101.64 1/2114.351275 1/2139.76 5/8168.3WEIGHTTUBEI.D.NOM. WALL17.3 lb/ft25.75 kg/m23.2 lb/ft34.53 kg/m29.9 lb/ft44.50 kg/m27.2 lb/ft40.48 kg/m41.0 lb/ft61.01 kg/m49.7 lb/ft73.96 kg/m57.0 lb/ft84.83 kg/m70.8 lb/ft105.36 kg/m250.82 1/457.22 9/1665.22 9/1665.22 3/469.9376.23 3/885.74 87522.231.00025.401.06327.001.06327.00CENTERO.D.3 7/898.44101.64 1/2114.34 1/2114.351275 1/2139.76152.47 1/8181.0TOOL JOINTCONNECTION NEW O.D.I.D.2 7/8 SLH90NC 383 1/2 IFNC 404 FHNC 383 1/2 IFNC 464 1/2 XHNC 504 1/2 IF5 1/2 FH6 5/8 FH3 7/898.44 3/4120.75 1/4133.451276 1/4158.86 5/8168.37177.88203.2250.82 3/860.32 11/1668.32 1/263.52 7/8733 1/1677.83 1/288.94 1/2114.3BEVELDIAM.3 23/3294.54 37/64116.35 1/64127.44 37/64116.35 23/32145.36 1/161546 23/32170.77 45/64195.7NOTE: This table is a guideline only. Contact customer and/or customer spec. for current information includingminimum wall thickness and tool joint O.D.sPage 8

NEW & USED TUBING INSPECTION SPECIFICATIONSIMPERIAL (in)/ (lbs/ft)IMPERIALMETRIC (mm)/ (kg/m)METRICMATERIALO.D. 2.90.14548.264.323.683.730.2005.555.082 1/163.250.15652.394.843.962 3/84.70.19060.336.994.835.950.2548.856.452 2.957.823 37519.279.5315.50.47623.0712.0949.50.226101.60 14.145.74110.26216.376.654 1/212.750.271114.30 18.976.8815.50.33723.078.56InsideDia.DriftDia.NEW A.P.I. SPECS.5%Min. 12.50% Min.Red. .0330.830.0340.860.0421.0 0.0340.860.0391.000.0411.030.0511.28USED PIPE SPECS.Min. Wall 30% Red. Min. 4.660.1904.820.2365.99Page 9

NEW & USED CASING INSPECTION SPECIFICATIONSIMPERIAL(in) / (lbs/ft)IMPERIALMETRICMETRIC(mm) / (kg/m)O.D.4 1/2114.35127.005 1/2139.706 .9428.000.41741.6710.5932.000.47547.6212.07Page 2 924150.475.796147.225.666143.925.550140.97NEW A.P.I. SPECS.5%Min.12.50%Min.Red.WallRed.WallUSED PIPE 80.2

CASING, DRILL PIPE & ROD SPECIFICATIONS. Page 1 USED DRILL PIPE INSPECTION SPECIFICATIONS IMPERIAL METRIC (g) MATERIAL NEW PIPE PREMIUM CLASS CLASS 2 O.D. Nomia Weig Wall Thicknes 12.5% Minimum Wall 20% Minimum Wall 30% Minimum Wall 2 3/8 6.65 0.280 0.035 0.245 0.056 0.224 0.084 0.196 60.3 9.90 7.11 0.89 6.22 1.42 5.69 2.13 4.98 2 7/8 10.40 0.362