Transcription

In the name of god, the mercifulWIRE-ARC SPRAYING SYSTEM:Particle Production, Transport, and DepositionbyAmirHossein Pourmousa AbkenarA thesis submitted in conformity with the requirementsfor the degree of Doctor of PhilosophyGraduate Department of Mechanical and Industrial EngineeringUniversity of Toronto Copyright by AmirHossein Pourmousa Abkenar 2007

ISBN: 978-0-494-39723-7

AbstractWIRE-ARC SPRAYING SYSTEM: Particle Production, Transport, and DepositionAmirHossein Pourmousa AbkenarDoctor of PhilosophyGraduate Department of Mechanical and Industrial EngineeringUniversity of Toronto2007Protective coatings are important to metal working. Thermal spray is a rapidly growingmarket, and wire-arc spraying is gaining a significant share of this market because of its lowoperating/equipment costs and high material/energy efficiency. Although wire-arc spraying iswidely used, many of its underlying processes are not yet fundamentally understood. This workexamines and explains different aspects of a wire-arc system.In wire-arc spraying, two consumable wires are continuously fed into the gun. An electricarc is struck between the tips of these two wires and continuously melts their material. A crossflow gas removes the molten material from the wire-tips and accelerates them towards asubstrate, over which the detached particles form a protective coating layer.An imaging system was developed to take pictures of the arc, and determine its lengthand shape. Using the information extracted from such pictures, a computational fluid dynamicmodel of the wire-arc torch was developed to estimate the shear stresses on the wire-tips and alsosizes of primary breakups from the two electrodes.ii

Shortly after primary breakups, the detached particles break up into smaller particles(secondary atomization). The size and velocity of such particles were measured in-flight using aDPV-2000 system for a range of operating parameters. A technique was developed to identifyand separate the size distributions of particles produced by atomization of molten metal at eitherthe anode or cathode by assuming that both follow a log-normal distribution. (This assumptionwas also verified experimentally). It was shown that particles produced by the anode are almosttwo times larger than those originating from the cathode. Furthermore, effect of operatingparameters on size distribution of anodic and cathodic particles was investigated.Experiments were also conducted to study the effect of impact velocity and substratetemperature on the properties of individual wire-arc splats and coatings. Aluminum was sprayedonto polished stainless-steel coupons maintained at temperatures ranging from 25 C to 450 C.At low substrate temperature, droplets splashed, forming irregular splats; at higher temperaturesthere was no splashing and splats formed circular disks. The temperature at which the transitionoccurred decreased with increasing impact velocity.iii

To my love, Malahat without whom this work could have never been done,or could have been done much sooner.iv

AcknowledgementsI would like to take this opportunity to acknowledge my supervisors and mentors,Professor Javad Mostaghimi and Professor Sanjeev Chandra, for their invaluable guidance,encouragement, and support throughout this study. I would like to express my sincereappreciations to Professor Javad Mostaghimi for his patience and understanding. His concise butinsightful comments fueled me with ideas.I extend thanks to my supervisory committee members, Professor Bendzsak, ProfessorSullivan, Professor Ashgriz, and Professor Bussmann for their advice and helpful suggestions. Iam also grateful to Dr. Larry Pershin and Mr. Tiegang Li for their assistance in the lab, andMs. Brenda Fung for her excellent administrative support at the office of graduate studies.In addition, I would like to thank all my colleagues at the Center for Advanced CoatingTechnologies for making this journey enjoyable. My special thanks goes to Ali Abedini, my labpartner, Hanif Montazeri, my numerical handyman, Rajeev Dhiman, my heat transfer expert,Hamid Salimi, my industrial advisor, Fardad Azarmi, my political rival, Hamed Samadi, myfinancial advisor, and many more including Liming, Libing, Michelle, Bob, Ken, Ala, Mehdi,Afsoon, Nikoo, Andre, Reza, and many more friends in the department.I am grateful to my family, especially my parents for their never ending love and support.I would like to extend my special thanks to my father-in-law who was not only my teacher, butalso my mentor in difficult times.To my wife, Malahat: Without you, your energetic essence, enthusiastic support, andunconditional kindness, I could have never completed this work. I love you and I gladly dedicatethis thesis to you.v

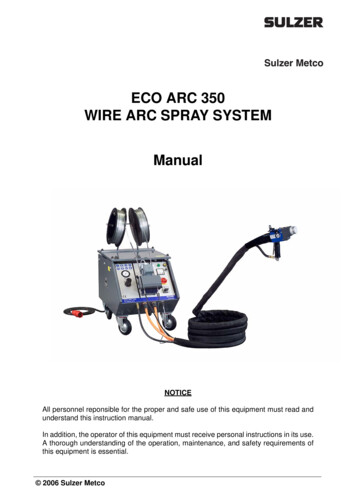

Table of ContentsABSTRACT .IIACKNOWLEDGEMENTS .VCHAPTER 1INTRODUCTION .11.1 BACKGROUND, MOTIVATION, AND LITERATURE SURVEY .11.1.1 Thermal spray.11.1.2 Twin-Wire-Arc Spray.51.1.2.1Description of the Wire-Arc spraying process. 51.1.2.2Operating parameters. 81.1.3 Brief Literature Review .101.1.3.1Previous Work on Droplet Production and Transport. 101.1.3.2Previous Work on Bimodal Size Distribution of In-flight Particles. 121.1.3.3Previous Work on Particle Deposition. 131.2 STATEMENT OF OBJECTIVES .141.3 SCOPE OF THE PRESENT WORK .151.4 OUTLINE OF THE THESIS .16CHAPTER 2EXPERIMENTAL APPARATUS AND PROCEDURES.172.1 COATING AND PROCESS DIAGNOSTICS .172.1.1 Coating Characterization.172.1.2 Process Characterization .182.2 VALUARC 200 SPRAYING SYSTEM AND ITS CHARACTERISTICS .262.2.1 Volume-Flow-Rate.322.2.2 Arc Current.33vi

CHAPTER 3PARTICLE BREAKUP: THERMAL SPRAY GUN .383.1 EXPERIMENTAL STUDIES .383.1.1 Imaging system .393.1.2 Current and Voltage Fluctuations.453.2 NUMERICAL STUDIES .493.2.1 Flow dynamics of the nozzle geometry .493.2.2 Simplified Arc Solution.613.2.3 Arc Heating in a cross flow .663.3 SIMPLIFIED BREAKUP MODEL .72CHAPTER 4PARTICLE TRANSPORT: IN-FLIGHT PARTICLES.754.1 BACKGROUND.754.2 SPATIAL CHARACTERISTICS OF THE SPRAY .774.3 BIMODAL PARTICLE SIZE DISTRIBUTION AND SEPARATION TECHNIQUE .824.3.1 Size Distribution of Anodic and Cathodic Particles.844.3.2 Separation Technique.864.3.3 Error Estimation.874.3.4 Effect of Varying Wire-Arc Parameters .924.4 AXIAL VARIATION OF PARTICLE PROPERTIES .964.4.1 Drag Force and Force Balance Relation .974.4.2 Heat Transfer and Exothermic Oxidation of Particles .97CHAPTER 5PARTICLE DEPOSITION: SPLAT AND COATING FORMATION.1025.1 EFFECT OF SUBSTRATE TEMPERATURE ON SPLAT FORMATION.1025.1.1 Experimental Procedure.1045.2 SPLAT MORPHOLOGY .108vii

5.3 MODEL FOR TRANSITION TEMPERATURE .1125.4 COATING PROPERTIES .118CHAPTER 6CLOSURE.1226.1 CONCLUSIONS .1226.2 RECOMMENDATIONS FOR FUTURE WORK .124REFERENCE .125APPENDIX A: METAL PROPERTIES .132APPENDIX B: TRANSPORT PROPERTIES OF AIR.133viii

List of FiguresFigure 1.1 Basic principles underlying the thermal spray processes: Production, Transport,and Deposition of molten particles. .3Figure 1.2 Schematics of wire-arc spraying system and its major components .5Figure 2.1 (a) Picture of DPV-2000 scanning unit alongside the wire-arc spraying gundetecting the in-flight particles (b) The computer system containing the DPV-2000operating system and CPS-2000 modules; the two are connected to the scanningunit via fiber-optic cables. .19Figure 2.2 Schematic diagram of the DPV’s optical sensing head and its field of view [9] .20Figure 2.3(a) A schematic diagram showing the signal sensed by the DPV-2000 sensing headwhen a particle passes through its field of view. (b) Picture of the two slits inP4590170 photo mask.20Figure 2.4 Wire-arc sprayed stainless-steel particles are approximately spherical. .20Figure 2.5 Size distribution of particles was measured using two additional methods (opticalpicture measurements, and PSA measurements) to calibrate DPV’s particle sizemeasurements. .

WIRE-ARC SPRAYING SYSTEM: Particle Production, Transport, and Deposition AmirHossein Pourmousa Abkenar Doctor of Philosophy Graduate Department of Mechanical and Industrial Engineering University of Toronto 2007 Protective coatings are important to metal working. Thermal spray is a rapidly growing market, and wire-arc spraying is gaining a significant share of this market because