Transcription

Pre-Insulated Tubing Bundles1www.swagelok.comPre -Insulated Tubing Bundle sEle ctr ic-Trace d a nd Ste a m-Trace dTUBINGBUNDLESFe ature s Simplified field installation 1/8 to 3/4 in. and 6 to 12 mm seamless or welded tubing sizes 316 / 316L stainless steel, copper, and PFA tube materials

2Tubing, Tubing Tools, and Welding SystemContentsSwagelok Bundled Tubing . . . . . . . . . . . . . . . . . . . . . . 2Insulation Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2Jacket Material Specifications . . . . . . . . . . . . . . . . . . . . 2Tubing Bundle Technical Data . . . . . . . . . . . . . . . . . . . . 3TUBINGBUNDLESElectric-Traced Bundled Tubing . . . . . . . . . . . . . . . . . . 4Steam-Traced Bundled Tubing . . . . . . . . . . . . . . . . . . . 7Light Steam-Traced . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7Heavy Steam-Traced . . . . . . . . . . . . . . . . . . . . . . . . . . . 7Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . 9Tubing Material and Size . . . . . . . . . . . . . . . . . . . . . . .11Additional Products . . . . . . . . . . . . . . . . . . . . . . . . . . .11Swagelok Bundled TubingJacket Material SpecificationsSwagelok pre-insulated traced tubing bundles provide reliableprocess temperature maintenance in a variety of analyticaland process instrumentation applications, including impulselines, sample lines, and process lines. It is used to connectprocess lines to pressure transmitters and analyzers. Therugged elastomeric jacket offers excellent resistance toabrasion and many chemicals.PVC JacketSwagelok pre-insulated tubing bundles provide an economicalchoice compared to field tracing and insulating. The parallelconfiguration—process and tracer lines are parallel inside thebundle—allows all tubes to bend together in as little as an 8 in.(20.3 cm) radius in tubing sizes up to 3/4 in. or 12 mm, so thebundle is easier to route and connect in the field than cabledbundles.Choose from light steam-traced, heavy steam-traced, andelectric-traced bundles for freeze protection, viscositycontrol, and process temperature maintenance.Insulation Features Water soluble chlorides less than 100 ppm Absorption-resistant fibrous glass insulation Resists wickingThis jacket material is an economical choice when ambientinstallation temperature is above –10 F (–23 C). It offers UV,corrosion, and abrasion resistance.Urethane JacketThis jacket material is a nonhalogenated thermoplasticurethane that can be installed in ambient temperatures aslow as –40 F (–40 C). It also offers improved resistance toabrasion, aromatic hydrocarbons, and UV light.Jacket Colors (Urethane Only)The standard jacket color is black. Contact your authorizedSwagelok sales and service representative for other availablecolors.Jacket PropertiesPVCUrethaneTensile strength, psi (bar)2200 (151)3800 (261)700 %Elongation350 %Hardness, Shore A8080UL 94 flammability ratingV2V2UV resistance750 h UL-15812000 h in accordancewith QUV aging test

Pre-Insulated Tubing Bundles3Tubing Bundle Technical DataFractionalPVC Jacket Temperature ting➀ F ( C)Min Ambient Min AmbientServiceInstallationRating➁Rating➂ F ( C) F ( C)Pressure Rating at–20 to 100 F(–28 to 37 C)➃psig (bar)SeamlessWeldedMinBendRadiusin. (cm)SupportCentersft (m)HorizVertMax ContinuousLength➄ft (m)SeamlessWeldedStainless Steel (ASTM A269, A213➅) TP 316/316L1/810 900 (751)—900 (274)—0.0355 100 (351)4080 (281)2200 (671)2500 (762)0.0497 500 (516)—3 300 (227)2640 (181)4 800 (330)—0.035➆2 600 (179)2080 (143)0.0493 700 (254)2960 (203)825 (251)1000 (305)—250 (76.2)—0.0353/80.0491/2220 (104)–30 (–34)–10 (–23)0.0655 100 (351)3/40.049➆2 400 (165)1/40.0303/80.032➆1300 (396)8.006.0015.0(20.3)(1.80)(4.60)1000 (305)—2500 (762)—2000 (610)Copper (ASTM B68, B68M, B75, UNS 12200)0.035➆1/21 400 (96.4)900 (62.0)220 (104)–30 (–34)–10 (–23)0.0493/42600 (792)800 (55.1)—1 100 (75.7)0.049➆8.006.0015.0(20.3)(1.80)(4.60)700 (48.2)2000 (610)1000 (305)—500 (152)PFA1/40.030➇3/81/2155 (10.6)220 (104)–30 (–34)–10 (–23)95 (6.5)0.062—97 (6.6)8.006.0015.0(20.3)(1.80)(4.60)1000 (305)—MetricPVC Jacket Temperature ng➀ C ( F)Min Ambient Min AmbientServiceInstallationRating➁Rating➂ C ( F) C ( F)Pressure Rating at–28 to 37 C(–20 to 100 F)➃bar (psig)SeamlessWeldedMinBendRadiuscm (in.)SupportCentersm (ft)HorizVertMax ContinuousLength➄m (ft)SeamlessWeldedStainless Steel (ASTM A269, A213➅) TP 316/316L681012420 (6095)1.01.01.5310 (4499)104 (220)–34 (–30)–23 (–10)1.01.5240 (3483)300 (984)—400 (5805)200 (2902)160 (2322)330 (4789)—210 (688)20.31.804.60(8.00)(6.00)(15.0)165 (541)150 (492)120 (393)—300 (984)—Copper (ASTM B68, B68M, B75, UNS 12200)681294.0 (1364)1.0104 (220)–34 (–30)–23 (–10)60.0 (870)54.0 (783)➀ The bundle is designed so that the jacket surface temperature will not exceed140 F (60 C) with a process temperature of 400 F (204 C), an ambienttemperature of 80 F (26 C), and a 10 mph (16 km/h) wind. The maximumjacket rating for urethane is 250 F (121 C).➁ – 60 F (–51 C) urethane jacket.➂ – 40 F (–40 C) urethane jacket.➃ For elevated pressure-temperature ratings, see Swagelok Tubing Datacatalog, MS-01-107.—20.31.804.60(8.00)(6.00)(15.0)600 (1968)455 (1492)—300 (984)➄ Standard tolerance for continuous length tubing is 5 %.➅ Nominal wall thickness, not minimum wall thickness. Seamless metricsizes also meet DIN 17458 test 1 class material 1.4401/1.4404.➆ Not recommended for use with tube fittings in gas service.➇ Not recommended for use with Swagelok groove cutter tool or PFA fittingsdue to minimum wall thickness.TUBINGBUNDLES1/40.035

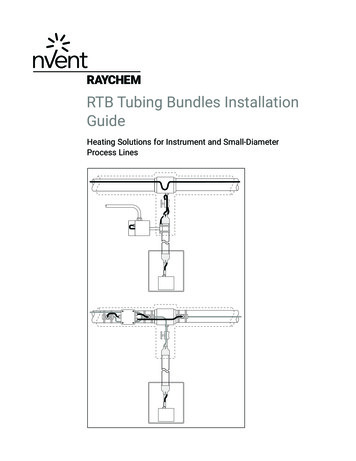

4Tubing, Tubing Tools, and Welding SystemElectric-Traced Bundled TubingA simple and economical choice for applications whereelectric tracing is preferred, Swagelok electric-traced bundledtubing maintains consistent temperatures in long, continuouslengths of impulse and sample lines for freeze protection,temperature maintenance, or viscosity control. The standardRaychem self-regulating tracer lowers heat output as thebundle gets warmer. For more precise temperature control, anoptional line-sensing thermostat is available.TUBINGBUNDLESFeatures Raychem self-regulating electric tracers Tinned copper braided shield Fluoropolymer tracer jacket ATEX, FM , and CSA approved tracer for use in hazardousareas Maintains process temperatures up to 250 F (121 C) One or two process tubes available as standardTechnical Data—Tracer SpecificationsHigh-Temperature TracersLow-Temperature TracersHigh-temperature tracers are used to maintain processtemperatures or for viscosity control up to 250 F (121 C).They are also used for freeze protection or if the tracers willbe exposed to intermittent temperatures up to 482 F (250 C),such as during steam cleaning.Low-temperature tracers are used for freeze protection ormain taining temperatures up to 100 F (37 C) and can beexposed to continuous process temperatures of 150 F (65 sureTracer Voltage Temperature Temperature➀CodeV (ac) F ( C) F ( C)PowerW/ft(W/m)TRating5 (16)H110 (32)120Hightemperature250 (121)H2420 (215)15 (49)T2D20 (65)T2CT3T2CATEXGroup II, Category 2G, EEx e II15 (49)20 (65)FMClass I, Div. 2, Groups A, B, C, DClass II➁, Div. 2, Groups F, GClass III➁CSAClass I, Div. 1 and 2, Groups A, B, C, DClass II, Div. 1 and 2, Groups E, F, GClass III5 (16)10 (32)240T3Approvals5 (16)L1120FMClass I, Div. 2, Groups A, B, C, DClass II, Div. 2, Groups F, GClass III8 (26)10 (32)Lowtemperature150 (65)185 (85)T65 (16)L22408 (26)10 (32)➀ The temperature that the electric tracer can be exposed to for 1000 h during its lifetime.➁ The entire system requires approval for FM compliance.CSAClass I, Div. 1 and 2, Groups A, B, C, DClass II, Div. 1 and 2, Groups E, F, GClass IIIATEXGroup II, Category 2G, EEx e II

Pre-Insulated Tubing Bundles5Electric-Traced Bundled TubingDimensions and WeightAABABOne 1/4 in. process tube1.20 (30.5)1.20 (30.5)B0.3 (0.45)One 3/8 in. process tube1.40 (35.6)One 1/2 in. process tube1.50 (38.1)Two Process TubesTwo 1/4 in. process tubes1.30 (33.0)Two 3/8 in. process tubes1.60 (40.6)1.40 (35.6)0.6 (0.89)Two 1/2 in. process tubes1.80 (45.7)1.60 (40.6)0.8 (1.19)Maximum Tracer LengthVersus Circuit Breaker RatingExample: Given a nominal tracerpower output of 10 W/ft (32 W/m),a startup temperature of 0 F (–17 C),and a voltage of 120 V (ac) with abreaker size of 20 A, the maximumtracer length will be 130 ft (39.6 m).To determine maximum tracer lengthin meters: m ft 0.3048.0.4 (0.60)1.30 (33.0)0.5 (0.74)0.4 (0.60)Circuit Breaker VoltageNominalTracerPowerOutputW/ft (W/m)120 V (ac)StartupTemperature 15 A F ( C)240 V (ac)➀Circuit Breaker Size20 A30 A40 A50 A15 A20 A30 A40 A50 AMaximum Tracer Length, ftHigh-Temperature50 (10)5(16)1802403600 (–17)160210320–20 (–28)150200305–40 (–40)14519529050 (10)110145220270130195260125190250100 (–17)(32)–20 40–40 (–40)9012018024017523535547050 44085130170215125165250335420150 (–17)(49)–20 (–28)65220–40 (–40)608012516520512016024032040550 85380540540420420360360200 (–17)(65)–20 (–28)50–40 (–40)65100100Low-Temperature5(16)8(26)10(32)50 (10)2302700 (–17)140190–20 (–28)12516525025033050050 602153251451902852700 (–17)100130200–20 (–28)8511517550 (10)1201601800 (–17)80110160–20 (–28)7095140➀ 208 and 277 V (ac) will change the run lengths.270210180270210180540TUBINGBUNDLESOne Process TubeBundle DescriptionNominalWeightlb/ft (kg/m)Dimensions, in. (mm)

6Tubing, Tubing Tools, and Welding SystemElectric-Traced Bundled TubingOrdering Number ReferenceThis ordering information is for reference only. To order, contact your authorized Swagelok representative.SSE1 – 4W1 – L1SAF – FP4TUBINGBUNDLESMaterialSpooling Length OptionSS Stainless steelCU CopperP PFA1 Continuous length, 5 % tolerance2 Exact length, 0.5 % tolerance➄3 Continuous length with exactlength 0.5 % tolerance4 Standard length tolerance 5 %➄Bundle TypeElectric-traced➄ May contain more than one length of no lessthan 100 ft (30.5 m) each.Number of Process Tubes➀1 or 2Bundle Jacket MaterialP PVCU Urethane➀ Up to four metal or up to six PFA process tubesmay be available on request. Contact yourauthorized Swagelok representative.Units of Measure (Length)Process Tube OD➂Fractional2 1/8 in.4 1/4 in.6 3/8 in.8 1/2 in.12 3/4 in.➁Metric6m 6 mm8m 8 mm10m 10 mm12m 12 mmTracer Jacket MaterialFluoropolymerNominal Tracer Power Output➁ 3/4 in. process tubes require urethanejacket material.Process Tubing ConstructionS Seamless (SS, CU)W Welded (SS)E Extruded (PFA)Process Tubing Wall Thickness➂A 0.047 in.1 0.035 in.2 0.049 in.3 0.065 in.4 0.030 in.F FeetM Meters5 1.0 mm6 1.5 mm7 0.032 in.8 0.062 in.➂ To ensure that the part number is configurable, please reference theTechnical Data on page 3.➃ For available Electric Tracers see page 4.A 5 W/ft (16 W/m)B 8 W/ft (26 W/m)C 10 W/ft (32 W/m)D 15 W/ft (49 W/m)E 20 W/ft (65 W/m)Tracer Type➃Self-regulatingVoltage➃1 100 to 130 V2 200 to 277 VTemperature➃L Low-temperatureH High-temperature

Pre-Insulated Tubing Bundles7Steam-Traced Bundled TubingLight Steam-TracedSwagelok light steam-traced bundled tubing is typically usedfor freeze protection of instrument impulse lines and analyzertransport lines. It can also maintain temperatures in smallerdiameter process lines. The process and tracer tubes areindividually insulated to reduce the heat transfer rate, providinga more consistent tube temperature over long tubing lengths.FeaturesTUBINGBUNDLES Maintains process temperatures from 50 to 200 F (10 to 93 C) Individually wrapped process and tracer tubes reduceheat transfer One or two process tubes available as standardDimensions and WeightAProcessTube Sizein.ATracerTube Sizein.BNominalWeightlb/ft (kg/m)2.00 (50.8)1.60 (40.6)0.5 (0.74)2.20 (55.9)1.70 (43.2)Dimensions, in. (mm)AOne Process TubeBB3/83/81/23/81/21/20.6 (0.89)0.7 (1.04)Two Process TubesTwo Process TubesOne Process Tube3/83/81/23/81/21/2ProcessTube Sizein.TracerTube Sizein.2.30 (58.4)1.60 (40.6)2.70 (68.6)1.70 (43.2)0.6 (0.89)0.8 (1.19)0.9 (1.34)Heavy Steam-TracedSwagelok heavy steam-traced bundled tubing is typicallyused to maintain higher process temperature or for viscositycontrol. Applications can include impulse, sampling, andprocess lines. The process tubing is in direct contact withthe tracer, providing maximum heat transfer to help maintainhigher process temperatures.Features Maintains process temperatures from 200 to 400 F(93 to 204 C) Maximum tracer temperature of 400 F (204 C) Process and tracer tubes are in direct contact to maximizehigher heat transfer One or two process tubes available as standardDimensions and WeightAABNominalWeightlb/ft (kg/m)1.10 (27.9)0.5 (0.74)Dimensions, in. (mm)AOne Process TubeBOne Process TubeB3/83/81.50 (38.1)1/23/81.60 (40.6)1/21/21.70 (43.2)1.20 (30.5)0.6 (0.89)0.7 (1.04)Two Process TubesTwo Process Tubes3/83/81.90 (48.3)1/23/82.10 (53.3)1/21/22.20 (55.9)1.10 (27.9)1.20 (30.5)0.6 (0.89)0.7 (1.04)0.8 (1.19)

8Tubing, Tubing Tools, and Welding SystemSteam-Traced Bundled TubingOrdering Number ReferenceThis ordering information is for reference only. To order, contact your authorized Swagelok representative.SSL2 – 4S1 – CU4S4 – FP4TUBINGBUNDLESMaterialSpooling OptionSS Stainless steelCU CopperP PFA1 Continuous l

Electric-Traced Bundled Tubing A simple and economical choice for applications where electric tracing is preferred, Swagelok electric-traced bundled tubing maintains consistent temperatures in long, continuous lengths of impulse and sample lines for freeze protection, temperature maintenance, or viscosity control . The standard