Transcription

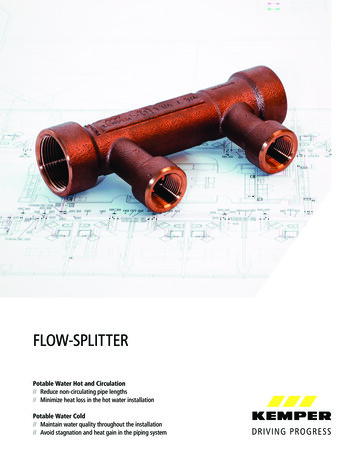

FLOW-SPLITTERPotable Water Hot and Circulation// Reduce non-circulating pipe lengths// Minimize heat loss in the hot water installationPotable Water Cold// Maintain water quality throughout the installation// Avoid stagnation and heat gain in the piping system

Potable water quality maintained?Potable water installation – potential health and safety riskPotable water quality, economy and ecology in focusWater quality experts consistently find inadequate water quality in potable water installations.The problems occur in both cold and hot watersystems. Professionals claim stagnation to be oneof the leading factors contributing to poor waterquality. Stagnation in building water systemsoccurs when water stops flowing during periodsof non use.Stagnation in building water systems can resultfrom dead legs, dead ends or from the infrequentuse of fixtures in a room. Stagnant water can leadto water quality issues including the growth ofbiofilm and bacteria. It has therefore becomecommon practice for building owners to removedead ends as well as fixtures that are not being“used as intended”.“Use as intended” means that a calculated frequency of water usage needs to be maintainedafter the commissioning of the water system. Thiscalculated usage is often not achieved requiringthe use of controlled water changes in order tomaintain water quality. If water use does notoccur as designed the growth of biofilm andbacteria can lead to poor water quality.The Flow-Splitter was developed in order to assistengineers and building owners with code andcompliance requirements associated with potablewater systems. It is an innovative valve designed tominimize stagnation and the consequential negativeimpact of stagnant water. The Flow-Splitter supports the maintenance of high quality water whileincreasing user comfort levels.2

Why does the Flow-Splitter make sense?Maintaining potable water qualityQUALITYClean potable water// helps to maintain potable waterquality (microbiological, chemical and physical)// reduces the risk of stagnation// helps to maintain cold and hotwater temperaturesECONOMYReduces costs and conserves resources// reduces installation, labor, materialand operating costs// provides for more efficient piping design layouts// supports compliance with plumbingand energy codesThe Flow-Splitter can contribute significantly tothe maintenance of hot and cold potable waterquality in both new and existing buildings. Everybuilding is a “prototype” because of its individualusage characteristics. Even two buildings of thesame kind cannot be compared equally – they arealways specific objects that have to be regardedindividually. The “intended usage” which is a basicassumption in the design of potable water installations, should be maintained after commissioningof the water system. The Flow-Splitter technologyintroduces new, innovative solutions that positivelyimpact potable water quality, economy and ecology.The installation and operation of a plumbing systemwith Flow-Splitters contributes to the safeguardingof public health and safety while conserving ourplanet’s valuable resources.ECOLOGYProtects the environment and saves energy// helps to conserve water// supports the distribution of disinfectantsand helps to increase residuals// reduces heat loss in hot watercirculation systems3

Preventing stagnation manuallyWith costly labor intensive measuresThe challenge of minimizing the growth of bacteria in hot and cold water is of prime importancefor operators of large potable water installations.Historically, trunk and branch piping configurations have been a common design practice forpotable water installations in public and privatebuildings (hotels, hospitals, schools, etc.). Thishas resulted in the potential for stagnant waterto remain in pipes leading to seldom used fixtures.For a frequent water change and to reduce waterage, extensive and costly manual flushing procedures are performed on a daily basis.These flushing measures are commonly carriedout by nursing staff and maintenance personneland have, in the long run, proven to be ineffective, disruptive and costly.Labor-intensive and costly manual flushing protocols are becoming commonplace as building operatorsattempt to eliminate stagnation.Standard T-installation. Stagnation occurs increasing the risk of bacteria growth with infrequent waterdraw at the fixture.4

Preventing stagnation automaticallyWith the innovative Flow-Splitter from KEMPERFrequent “water change”in loop installationTo avoid ineffective and cost intensive measuresto minimize stagnation, the piping layout shownabove should be considered in the design of hotand cold potable water installations.This innovative pipe layout in combination withthe Flow-Splitter creates a water change in theloop pipework when water is demanded downstream of the Flow-Splitter – even if there is nouse of water in the loop itself.Flow-Splitter Unit, Figure 651 065

Flow-SplitterThe Flow-Splitter can be installed in cold andhot water distribution pipework of a plumbinginstallation.The function is based on the principle of theVenturi nozzle. In case of water flow through theFlow-Splitter, a small pressure difference is createdby the Venturi to direct a portion of the water flowthrough the connected loop piping. The result is aparallel flow through both the loop and throughthe main pipe of the Flow-Splitter.The Venturi cartridge insert generates a maximumflow through the loop when the occuring flow inthe main pipe is much lower than the designedpeak flow rate.The use of the Flow-Splitter leads to an innovativeplumbing design, which can benefit both cold andhot water installations.Benefits of the Flow-Splitter in a hot waterinstallation://////////less hot water return pipeworkreduces energy consumptionreduces installation and operating costsincreases user comfortmaintains targeted hot watertemperatures throughout the installationLead- and dezincification-free brass alloy material incompliance with the Uniform Plumbing Code(UPC) and National Plumbing Code of Canada.Certifications:NSF/ANSI 61NSF/ANSI 372IAPMO IGC 302-2017Benefits of the Flow-Splitter in a cold waterinstallation:// reduces stagnation// reduces cold water temperature gain dueto high environmental temperatures// increases water quality// supports the distribution of disinfectants// increases user comfort6Flow-Splitter (cut sample), female thread,Figure 651 20

Low flow rate in thedistribution pipe:The Venturi cartridge remains ina minimum open position. Thepressure to open the cartridgefurther is not reached. Thereforewater bypasses the cartridge viathe loop.High flow rate (peak flow)in the distribution pipe:The Venturi cartridge is fullyopen to let the majority of thewater pass. The pressure dropof the Venturi causes a parallelflow through the loop.Water consumption at anoutlet in the loop:The outlet is supplied with water from both sides of the loop.Therefore the loop can be installed with smaller diameterpiping. The loop pipe createsless pressure drop which benefitsthe pipe sizing and the boosterpump requirements.7

Hot water installation with Flow-SplitterMinimize installation and operating costsOptimized circulation with energyand cost saving benefitsIt is beneficial to use the Flow-Splitter in the hotwater system of many buildings. However, thisdepends on the shape of the building and therouting of the pipework. As shown in the illustration to the right, outlets in a bathroom areconnected via a Flow-Splitter and a loop installation. A hot water return pipe is not required in thecorridor, as hot water circulation in the room isrealized by the Flow-Splitter and the loop installation. At the end of the corridor, the hot waterpipework is connected to a hot water return riserand a MULTI-THERM automatic balancing valve.During periods without hot water consumption,the pump driven circulation volume is led throughthe entire pipework via the venturi effect of theFlow-Splitter. This maintains the hot water temperature in all loops up to the connection pointof every outlet.Withdrawalat the sinkIn the event of water consumption at an outlet,e.g. at the washbasin on the 3rd floor, the outletwill be supplied from both sides of the loop installation improving the supply at each outlet. Reducing hot water circulation pipework with the use ofthe Flow-Splitter and the MULTI-THERM automatic balancing valve can lead to a 15 % reduction ofheat loss throughout the system.To design a hot water installation with FlowSplitters, traditional layouts with hot watersupply and return piping, in parallel, should beavoided in favor of the layout shown to theright. As a rule of thumb for the design of a hotwater installation with Flow-Splitters, the totallength of each loop shall not be more than approximately 100 ft (30 meter) and there shouldnot be more than approximately 15 Flow-Splittersin series. Design information and support will beprovided by Kemper Water Control Systems Inc.8Prevent stagnation and effectively maintain temperature// no stagnation due to Flow-Splitters and loop installation// temperature maintenance in the hot water pipework duringconsumption and circulation periods through loop installation// increased user comfort due to the immediate availabilityof hot water

Cold water installation with Flow-SplitterAvoid stagnation and maintain water qualityStagnant water in pipes of seldom used outletscan be found in many potable water installations.The installation of a Flow-Splitter prevents stagnation when flow occurs as a result of downstreamwater consumption.Downstream consumption causes waterexchange in the upstream Flow-Splitter loops.It is recommended to connect frequently usedoutlets, with high water demand, at the endof a loop or distribution pipe and to connectseldom used outlets via the Flow-Splitter loopfurther upstream.The frequently and seldom used outlets shouldbe identified during the design phase by theplumbing designer in order to determine theproper locations for the Flow-Splitter.A unique installation of the Flow-Splitters on ariser and an innovative piping layout in the bathrooms is shown to the right. Water flow in theriser due to downstream consumption causes awater change in the loops of the bathrooms effectively avoiding stagnation.Principle: Water movement – minimize stagnation// frequent water change// reduce temperature gain// water movement in the majority of the pipework9

Horizontal layout of hot and cold-water masterloop distribution utilizing KEMPER Flow-SplittersPipe savings, energy savings, water conservation and reduced stagnationInnovative hot and cold-water distribution designusing KEMPER Flow-Splitters in primary, horizontal loops located in a ceiling. The risers are located at the bottom right hand corner of the drawingand provide water for distribution throughoutthe floor via two master distribution loops. TheFlow-Splitters are installed on each master distribution loop which, in turn, serve to create smaller connected circulating loops into each room.Non-circulating pipe lengths have been minimizedand the hot water return piping has been greatlyreduced. This pioneering design utilizes provenKEMPER technology to reduce piping costs, saveenergy, conserve water and reduce stagnation.Flow-Splitter Unit, Figure 651 06MULTI-THERM AutomaticBalancing Valve, Figure 154 0210

11

Craig BoyceKemper Water Control Systems, Inc.518 Route 513, Suite BPO Box 195Califon, NJ 07830 USAPhone: 1 239 298 9273Email: Craig.Boyce@KemperWaterControl.comFlow-Splitter 05/20For more information, please contact:

Kemper Water Control Systems, Inc. 518 Route 513, Suite B PO Box 195 Califon, NJ 07830 USA Phone: 1 239 298 9273 Email: Craig.Boyce@KemperWaterControl.com Flow-Splitter 05/20. Created Date: