Transcription

Cer t ainTeedE d uc a ti on & D e ve l o pm e n t Pr o gr a m

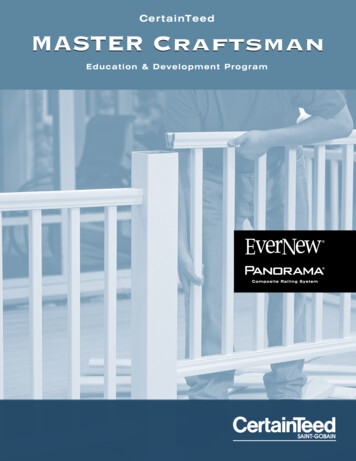

Become a CertainTeedThe Panorama Composite Railing Education and DevelopmentWorkbook is a key element in CertainTeed’s Master Craftsmaneducation and training program. We hope that you will use itto master the information critical to installing our railing products. The more you know about CertainTeed railing, the better ableyou’ll be to recommend solutions and estimate jobs for yourcustomers. Also, a mastery of the workbook is one of thecomponents needed to benefit from the opportunities offeredby CertainTeed’s Master Craftsman program.After you have reviewed this workbook, you will be preparedto take the Master Craftsman Test, which will earn youvaluable rewards. These rewards—and more importantly, theleg up you’ll have on the competition—are not available toeveryone, just to those who have successfully passed the test.When you pass, you will: Receive a personalized Certificate of Completion that youcan use to promote your professional services Be listed as a Master Craftsman on our website; the listingwill include your name, company name, phone number,email address, and a link to your website if you have oneIf you complete two or more Master Craftsman educationprograms, you’ll receive: A certificate designating you as a Building SolutionsSpecialist; your certificate will highlight the CertainTeededucation programs you have successfully completed Preferential listing on our contractor locator sitewhen a consumer searches for multiple products atwww.certainteed.com For more information about this and other Building Solutionsprograms, visit www.building-solutions.com.

CertainTeed Composite Railing Master Craftsman Education & Development ProgramTable of ContentsGlossary . . . . . . . . . . . . . . . . . . . . . . . . . 21. EverNew Composite Railing—Its History and Benefits . . . . . . . . . . . . . . 41.11.21.31.48. Jobsite Safety and Workmanship . . . . . . 228.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228.2 Ladders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228.3 Personal Protective Equipment . . . . . . . . . . . . . . 228.4 Housekeeping . . . . . . . . . . . . . . . . . . . . . . . . . . . 238.5 Professionalism . . . . . . . . . . . . . . . . . . . . . . . . . . 23What Is Composite Railing? . . . . . . . . . . . . . . . . . 4Homeowners Prefer Composites . . . . . . . . . . . . . 4Benefits of EverNew Composite Railing . . . . . . . . 4EverNew Is Easy to Use . . . . . . . . . . . . . . . . . . . . 49. Sales Support . . . . . . . . . . . . . . . . . . . . . 242. Company History . . . . . . . . . . . . . . . . . . . 59.1 Sales Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249.2 Follow-up Tools . . . . . . . . . . . . . . . . . . . . . . . . . 242.1 One Man’s Dream . . . . . . . . . . . . . . . . . . . . . . . . . 52.2 Building Products Today . . . . . . . . . . . . . . . . . . . 53. Manufacturing . . . . . . . . . . . . . . . . . . . . . 610. Taking the Master Craftsman Test . . . . . 25The Master Craftsman Test . . . . . . . . . . . . . . . . . . . . 263.1 Raw Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63.2 Manufacturing Process . . . . . . . . . . . . . . . . . . . . . 63.3 Quality Control . . . . . . . . . . . . . . . . . . . . . . . . . . 64. Panorama Composite Railing WillWork For You . . . . . . . . . . . . . . . . . . . . . . 74.1 Lower Installed Cost . . . . . . . . . . . . . . . . . . . . . . 74.2 Higher Profit Margins . . . . . . . . . . . . . . . . . . . . . . 74.3 More Referrals . . . . . . . . . . . . . . . . . . . . . . . . . . . 85. Panorama Composite Railing . . . . . . . . . 96. Installation Overview . . . . . . . . . . . . . . 106.16.26.36.46.56.6Storage & Handling . . . . . . . . . . . . . . . . . . . . . . 10Exposure to Weather . . . . . . . . . . . . . . . . . . . . . 10Cutting & Drilling . . . . . . . . . . . . . . . . . . . . . . . 10Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Building Code Requirement . . . . . . . . . . . . . . . . 10Installation Overview . . . . . . . . . . . . . . . . . . . . . 117. Installation Instructions for Panorama Composite Railing . . . . . . . . . . . . . . . . . 127.1 Install Post Support Kits . . . . . . . . . . . . . . . . . . 127.2 Install Post Sleeves . . . . . . . . . . . . . . . . . . . . . . . 147.3 Assemble Railing Sections . . . . . . . . . . . . . . . . . 147.4 Install Railing Sections . . . . . . . . . . . . . . . . . . . . 167.5 Install Top Rails . . . . . . . . . . . . . . . . . . . . . . . . 177.6 Install Post Caps . . . . . . . . . . . . . . . . . . . . . . . . 177.7 Installation Instructions for Stair Railing . . . . . . 187.8 Install Stair Railing Sections . . . . . . . . . . . . . . . . 207.9 Install Stair Top Rails . . . . . . . . . . . . . . . . . . . . . 217.10 Installation Instructions for Mitered/Angled Deck and Porch Railing . . . . . . . . . . . . . 211

CertainTeed Composite Railing Master Craftsman Education & Development ProgramGlossaryACQ Alkaline copper quaternary. Chemicalpreservative for wood that replaces CCA.Actual dimensions The exact measurements of a pieceof lumber.Baluster (spindle) The numerous vertical pieces thatprovide a fence-like structure by filling the spacesbetween rail posts; one of a series of vertical supportsused between posts of a railing.Board Any piece of lumber more than 1" wide and lessthan 2" wide in thickness.Building codes (1) Municipal rules regulatingsafe building practices and procedures; the codesencompass structural, electrical, plumbing andmechanical remodeling and new construction.(2) Regulations detailing accepted materials andmethods of building, such as the size of the deck,setback distances, railing and stair construction,footing depths, fastening methods, lumber grades forcertain deck components and fence or screen heightaround the deck. Usually adopted by city, county, orstate building departments; most counties have localbuilding codes.CCA Chromated copper arsenate. This chemicalpreservative is being phased out in favor of ACQ.Check Lengthwise separation of wood that usuallyextends across annual growth rings and commonlyresults from stresses arising in wood during drying.Composite An item manufactured out of wood andplastics to form a profile with better durability andperformance properties than wood.Culling The process of selecting the best pieces ofwood or lumber for a project; particularly used toremove warped and checked boards.Cup Type of warp; the distortion or deviation of aboard flat-wise from a straight line across the width ofthe board. Cupping occurs when shrinkage is unequalbetween two faces of a board, such as the top andbottom of a decking board. The tendency of a boardto cup varies with its density, moisture content whensurfaced, width, thickness, and grain orientation.2Decking Floor boards of a deck; the actual decksurface; 5/4 x 6, 2 x 6, and 2 x 4 planks are commonlyused for decking and are attached to the joists.Decking boards Planks nailed or otherwise attachedto joists, used for the deck surface. Decking lumberis available in a number of different species of woodand brands of wood composite and in a variety ofdimensions.Extractives Substances in wood that are not anintegral part of the cellular structure and can beremoved by solution in hot or cold water, ether,benzene, or other solvents that do not react chemicallywith the wood components.Fastener Generic term for nails, screws, bolts, andmetal hardware used to connect deck members.HDG (hot-dipped galvanized) Twist nail, casing nail,common nail, decking screw, etc., with thick zinccoating and rough surface.Hot-dipped Fasteners single- or double-dipped inmolten zinc (usually 0.85 oz./ft2), which providesthe best corrosion protection for wood used in dampconditions.Joists (1) Structural members, usually 2-by lumber,commonly placed perpendicularly across beams tosupport decking boards. (2) Lateral support boardsthat are attached to (or lay on top of) beams. (3)Horizontal framing members that support decking,usually set perpendicular to the house face.Live load The amount of weight a deck is designedto support; most deck designs call for a live load of100 lbs./ft2.Maintenance Regular cleaning and inspection of deck;may include light sanding to remove raised grain,washing to remove mildew, and reapplication of awater-repellent preservative or semi-transparent stainon a wood deck.Mildew Black fungus that grows on the surface of wood,causing a wood deck to darken.

CertainTeed Composite Railing Nominal dimensions (1) The identifying dimensionsof a piece of lumber; nominal dimensions are largerthan the actual dimensions. (2) The label given to astandard piece of lumber. For example, a 2 x 4 is thename for a roughcut piece of about 2" x 4".On center (o.c.) (1) A point of reference formeasuring; “16" on center” means 16 inches from thecenter of one framing member to the center of thenext. (2) A method of measuring distance between twostructural members, such as joists.Post (column) (1) Vertical member, usually 4" x 4" or6" x 6", that supports either the deck or railing. Postssupport the deck beams and transfer the weight of thedeck to the concrete footings. Posts extending abovethe level of the deck can also serve as railing supports.(2) The upright support lumber members that areattached to piers and footings. (3) The verticalstructural element that rests on the footing andsupports the beam.Post anchor (1) Metal fastener designed to keep thepost from wandering and to inhibit rot by holdingthe post a bit above the concrete. (2) A metal pieceattached to or imbedded in the footing that attachesthe post to the footing and keeps the post from beingexposed to moisture in the ground.Post cap Small piece of wood, plastic, or wood-plasticcomposite material attached to the top of the post toprotect the post from the weather. Available in a varietyof styles.Posthole digger Clamshell-type tool used to dig holesfor posts.Power auger Tool that is powered by a gasoline engineand used for drilling into the ground; often used inlarger projects to dig postholes.Preservative Chemical used to protect wood againstdecay. See ACQ and CCA.Pressure-treating Preservatives are forced intosoftwood under pressure to make the wood repelrot and decay and withstand fungal and insect attack;pressure-treated wood is known as green wood becauseof the residual color of the chemical; usually made fromSouthern Yellow Pine (SYP) or Lodgepole pine.Rail A horizontal member that is placed between postsand used for support and as a barrier.Master Craftsman Education & Development ProgramRailing Portion of deck constructed for enclosure;includes rail post, cap rail, head rail and balusters.Rail post A vertical structural support for the railing.Rail posts are thicker than balusters and are attachedwith bolts to the joists and beams.Recommended span The distance a piece oflumber can safely traverse without being supportedunderneath.Ring-shank nail A nail with grooves and ridgesaround the shank to prevent the nail from poppingout of the wood as the wood contracts and expandsbecause of changes in moisture and temperatures; alsocalled an annular grooved nail.Riser (kick plate) Vertical boards placed betweenstringers on stairs to support stair treads; the verticaldistance the step rises from one step to the next;also, the board that creates the rise; the vertical piecebetween two stair steps, located between each tread.Span The distance between supports, usually theledger board to the beam.Spiral-shank nail A nail with helical grooves andridges around the shank to prevent the nail frompopping out of the wood as the wood contractsand expands because of changes in moisture andtemperature; this nail looks as if it has been twistedalong its axis.Tread On stairs, the horizontal boards supported bythe stringers; a term used with stair construction thatrefers to the horizontal walking surface or step.Treated lumber Lumber that has been pressure-treatedwith an approved preservative under appropriatestandards of the American Wood Preservers’Association (AWPA) or American Society for Testingand Materials (ASTM).Weathering Photochemical degradation of the woodsurface caused by the combined effects of sunlight(UV radiation), water, and abrasion by wind-blownsand or other particulates. Color changes occur inwood as it weathers, leading to a driftwood-grayweathered finish. Although weathering is oftendesirable in some applications (shakes, shingles,and siding), some protection is necessary to avoidchecking, cracking and splintering.3

CertainTeed Composite Railing Master Craftsman Education & Development Program1. EverNew Composite Railing—Its History and BenefitsDo you really need to add another railing material toyour already wide product offering? Absolutely!EverNew composite railing offers the look of woodwith exceptional weatherability. It provides the solidfeel of wood railing with the strength of a durablecomposite that replicates the look of wood.1.1 What Is Composite Railing?In general, the term composite lumber refers to anyblend of plastic and wood or plastic and other naturalfibers extruded into railing products.1.2 Homeowners Prefer CompositesThough relatively new, composite lumber is quicklybecoming the preferred alternative to wood railingfor four main reasons:1. Composite lumber is low maintenance.Homeowners don’t want to sand and stain orpaint wood railing. Thus, they continue to choosemodern, low-maintenance building products overmore traditional materials.2. Homeowners are questioning the safety ofpressure-treated lumber. Their children play ontreated deck and railing systems, and parentsworry about the toxicity of CCA (chromatedcopper arsenate) used to treat wood. Also, there isconcern about the chemicals, sealants, and stainsused to maintain wood building products.3. Homeowners are making purchase decisions thatreflect their concerns about the environment andthe ecological cost of harvesting trees for woodrailing. The recycled content of our innovative,composite railing products is a feature that attractsthese environmentally aware consumers.4. D ecreasing supply and increased transportation costshave dramatically increased the prices for premiumnatural lumber like cedar and redwood. Prices forquality exotic hardwoods like mahogany and ipéhave also increased substantially in recent years.4As a result of this increased preference for lowmaintenance, durable railing, the market for compositeand plastic lumber is predicted to grow an averageof 15 percent every year through 2016. This is anopportunity you don’t want to miss!1.3 Benefits of EverNew CompositeRailingEverNew combines the look of wood with thedurability of a composite, while wood railing requiresongoing maintenance. Periodically, wood railingsmust be sanded and stained, and split or warped railsshould be replaced. But EverNew composite railingdoesn’t rot, twist, split, or crack. Cleaning with a milddetergent and water will keep EverNew compositerailing looking good for years. And you’ll never becalled back to replace split or warped rails.1.4 EverNew Is Easy to UseIf you can install wood railing, you can installEverNew. There are no special tools or installationtechniques required. You and your customers will bedelighted with your beautiful railing, and you’ll enjoyfewer callbacks and more positive referrals.Remodelers love EverNew because it’s easy to use andbecause it: is dimensionally stable installs like wood uses standard woodworking tools and fasteners cuts, fastens, and sands easily does not need to be painted or stainedBest of all, installing EverNew railing is profitable.Composite railing is a high-end home improvement,so profit margins can be higher. And, unlike wood,you won’t be competing with the do-it-yourselfer orneighborhood handyman. The more you use EverNewrailing, the more you’re going to like what it can dofor your business.

CertainTeed Composite Railing Master Craftsman Education & Development Program2. Company HistoryObjectivesThis chapter will give you some insight into thehistory of CertainTeed: Beginnings Commitment to building products Commitment to qualityQuality Made CERTAIN Satisfaction GuaranTEED.More than just a slogan, it’s our name. And since1904, when the General Roofing ManufacturingCompany began producing asphalt roofing materials,quality products and satisfied customers have been thehallmark of CertainTeed Corporation.2.1 One Man’s DreamFirst established in 1904 by George M. Brown, theGeneral Roofing and Manufacturing Company wascreated to produce a less flammable and less expensivealternative to wood shingles. In 1917, the companychanged its name to CertainTeed to reflect its expandingproduct line and Brown’s business philosophy. In 1923,it began manufacturing gypsum wallboard for new homeconstruction.During World War II, CertainTeed lent its extensivemanagement and production expertise to the wareffort, but in 1946 began investigating the potential ofa new product—fiber glass insulation. Within 10 years,CertainTeed was supplying roofing materials, gypsum,and fiber glass insulation to the booming constructionindustry and had established itself as a leader in thecountry’s effort to supply affordable housing to formerGIs and their families.In 1965, CertainTeed took its first step into PVC. Itslater acquisition of Plains Plastic made CertainTeeda major manufacturer of plastic pipe. In 1969, thecompany began offering solid vinyl (PVC) sidingto builders and contractors. The development ofdecking and railing began in 1996 with the acquisitionof Bufftech vinyl fence and the development ofEverNew vinyl decking and railing. In 2006,CertainTeed added Panorama composite railingto its EverNew product portfolio.Today, CertainTeed is a leading North Americanmanufacturer of ceilings; walls; vinyl and polymersiding and millwork; vinyl fence, railing and decking;residential, commercial and mechanical insulation andresidential and commercial roofing.2.2 Building Products TodayThe Outdoor Living division, which supplies EverNewcomposite railing, is just one of a number of operatinggroups that make up CertainTeed Corporation. Amongapproximately 20 manufacturers and over 30 brandnames, CertainTeed is number one in sales of vinylsiding and accessories. More importantly, CertainTeedroofing and vinyl building products are consistentlyrated at the top for quality and performance byconsumer and trade magazines alike.From its humble beginnings in East St. Louis,through two World Wars and the Great Depression,CertainTeed has become one of the nation’s largestand most respected manufacturers of buildingproducts. Today, CertainTeed celebrates more than100 years of leading the building industry withcreative advancements, insightful solutions, andunparalleled dedication to service.Summary CertainTeed was established in 1904 to produce afire-resistant roofing shingle and quickly grew intoa manufacturer of building products. CertainTeed building products are consistentlyrated highest for product quality and performanceby homeowners and builders.5

CertainTeed Composite Railing Master Craftsman Education & Development Program3. Manufacturing3.1 Raw Materials3.3 Quality ControlThe quality you’ve come to expect from CertainTeedis built in at the factory. From the time raw materialsare received at our plant until the finished product isshipped to our customers, we control, adjust, inspect,and test throughout the manufacturing process. Aspart of ongoing quality assurance, we work with oursuppliers to develop and test for tight specifications.The result is composite lumber you can counton for superb appearance, durability, and ease ofinstallation—every time.Panorama composite railing undergoes ongoingquality control checks as it is being extruded and afterit is manufactured. More importantly for you, thespecifications and quality control testing for Panoramacomposite railing products have been reviewed andapproved by Intertek.ObjectivesThis chapter describes the process used tomanufacture Panorama composite railing: Raw materials Manufacturing process Quality control3.2 Manufacturing ProcessTechnical excellence, processing expertise, and anunwavering commitment to quality characterizethe equipment, processes, and personnel at ourmanufacturing plant. Since the 1960s, CertainTeed hasbeen developing innovative products and processes toimprove the look and durability of our products.At the same time, tried and true manufacturingmethods are tested and re-tested to ensure that youconsistently receive the highest quality product.6Summary Panorama composite railing is manufactured withrecycled wood flour or recycled natural fibers. Composite railing is shaped in an extruder, thenformed into rails. The extrusion line is computercontrolled, so the size and shape of the railsare consistent. Panorama composite railing is tested for qualitycontrol at several points during the manufacturingprocess. The products are tested against the rigidspecifications suggested by Intertek.

CertainTeed Composite Railing Master Craftsman Education & Development Program4. Panorama Composite Railing Will Workfor YouWhy, in the highly competitive remodeling market,should you recommend Panorama composite railing?The answer is obvious: Performance! Performance thatturns the higher initial cost of EverNew railing intolong-term savings and distinct advantages for yourcustomers and your business.ObjectivesIn this chapter, you’ll learn why adding Panoramacomposite railing to your product offering makesgood business sense:4.1 Lower Installed CostHomeowners will choose Panorama composite railingover traditional wood products because compositelumber lasts longer and costs less to maintain. Onaverage, railings made of pressure-treated wood mustbe replaced every 10 years. In contrast, Panoramacomposite railing is warranted against defects for25 years! And homeowners will never have to sand,stain, or replace Panorama composite railing. In theend, Panorama lasts longer and costs less than typicalwood railings. Cost of composite lumber versus wood4.2 Higher Profit Margins Profit marginsFor you, recommending Panorama composite railingmakes good business sense. First, Panorama compositerailing is recognized as a premium building product.You won’t be competing on price with the low-endweekend remodelers, and you can position yourbusiness as the modern, professional alternative toremodelers offering only wood railing. High-quality referralsSecond, in markets where severe weather—extremeheat and cold, salt air, high humidity—significantlyreduce the life of wood products, homebuilders andowners are looking for a long-lasting, low-maintenancealternative to wood. Panorama composite railing lookslike wood, but offers outstanding performance.7

CertainTeed Composite Railing Finally, Panorama composite railing lets you spend lesstime on installation. Profits will improve because youwon’t: Spend time culling warped, split, or knotty rails Invest time or money in painting or staining Be called back to replace checked, cracked, orwarped rails. When you’re finished, you’re finished.You can confidently move on to the next job.4.3 More ReferralsPanorama composite railing is an attention getter, evenafter years of use. It resists mildew better than wood,so Panorama railing keeps its good looks for years. Youcan be assured of continued referrals, especially whenhomeowners experience the joys of a railing that: does not splinter stays cool to the touch requires only occasional cleaning with water ormild detergent will not rot or decay is impervious to termites and other wood-boringinsects never needs painting or stainingCan you sell a product that, on the surface, lookspricier than wood? Certainly—once you demonstratethe lower installed cost, significantly less maintenance,and longer life of Panorama composite railing.8Master Craftsman Education & Development ProgramSummary While the initial installed cost for composite railingis higher than wood, composite lumber lasts longerand costs less to maintain. Panorama composite railing is a premium product.When you recommend it, profit margins will behigher because you won’t have to compete on pricewith low-end remodelers. Once homeowners see the performance advantagesof composite railing, they will be more likely toconsider this premium alternative.

CertainTeed Composite Railing Master Craftsman Education & Development Program5. Panorama composite railing Classic painted wood style with truearchitectural details Top and bottom universal rails with a decorativetop rail cap Concealed external rail-to-post connection for flat,stair, column and 45º applications Powder-coated, hot-dipped galvanized steeldecorative balusters create a rustic yet customizablesystem approach for both flat and stair applications Suitable for one- and two-family dwellings/townhouses not more than three stories high Available in two heights and two lengths Independent tested as designated in reportCCRR-0115 Available in two colors: white and almond Class A flame spread rating Choice of two baluster styles: square compositeand decorative steel 25-year limited warranty with 2-yearSureStart protection9

Master Craftsman Education & Development ProgramCertainTeed Composite Railing 6. Installation Overview6.1 Storage & Handling6.4 CleaningPanorama composite railing components should bestored on a dry, flat surface. Do not store in an areawhere excessive heat build up can occur, such as on anasphalt surface covered by a tarp. Individual Panoramacomponents may weigh more than wood so takethis into account before lifting or moving Panoramacomposite railing.Panorama composite railing resists most commonhousehold stains but it will become dirty like anyproduct exposed to atmospheric conditions. Periodicwashing with a soft bristle brush and clean water froma garden hose may be necessary to remove surfacedirt which may accumulate on the surface. For bestappearance, clean your Panorama composite railingat least once a year, unless local conditions requireadditional cleaning.Panorama composite railing does not producerespirable dust when it is cut or fastened, but youshould always wear eye protection and safetyequipment when working with any wood product.For more information about the safety of Panoramacomposite railing, consult the Material Safety DataSheet (MSDS).6.2 Exposure to Weather6.5 Building Code RequirementPanorama composite railing is designed for 1- and2-family residential applications. Contact your localcode authority for requirements in your area.ToolsExposure to sunlight and water willnot adversely affect the appearance ofPanorama composite railing. Normalweathering should be expected.3/4" of dia.6.3 Cutting & DrillingWorking with Panorama compositerailing is as easy as working withwood. Use conventional woodworkingtools to cut, drill and rout Panorama1/2"– 3/4"composite railing. Carbide-tip bladesprovide improved tool wear and results. A fine-toothsaw will help reduce chipping and provide a cleanercut surface. Eye protection and protective clothingshould always be worn for your safety.CARBIDERequired ToolsOptional Tools- Miter Saw- Jigsaw/Coping Saw- Power Drill and Bits- Utility Knife- No. 2 Square Head Driver- File-1 /4" Drive Socket,extension, and 7/16" Socket- Box-End Wrenches- Level- Square- S ilicone Caulkand Caulk Gun- Tape Measure-A ngle Finder- Pencil-E xtension Bit forCrush Block- S afety Glasses (andequipment as identifiedby tool manufacturers)- Chalk Line16"Panorama boxed kits are available in 6' and 8' lengths. Measurements are from post center to post center. Panorama 6'and 8' products are designed not to exceed 6' or 8' from center of post to center of post, respectively. Actual rail lengthsare 67-1/2" (6') and 92-1/2" (8').1/8" gap102skids

Master Craftsman Education & Development ProgramCertainTeed Composite Railing 6.6 Installation OverviewStep 1: Install Post SleevesBe sure posts are plumb. Cut post sleeve to length.Slide the post sleeve over the post to rest on the decksurface. Slide post trim ring (1a) over the post sleeveto also rest on the deck surface.Step 2: Assemble Railing SectionMeasure the distance between post sleeves. Layuniversal rails side-by-side, aligning pre-drilled holes,not the rail ends. Calculate the center of the universalrails and assign the center either directly to a predrilled baluster hole or the space centered betweentwo baluster holes. Measure and cut rails from thecalculated center. Attach the balusters to the top andbottom universal rails (2a). Then attach the crushblock to bottom universal rail (2b). Place and securerail brackets.Step 3: Install Railing SectionDrive lag bolts into posts leaving approximately1/2" gap from lag bolt head to post sleeve surface.Place railing assembly over bottom lag bolts. Markthe position for the top lag bolts using the top railbracket’s position as a guide. Use a 1/4" drive socketwith an extension to tighten lag bolts to the posts.Step 4: Install Top RailMeasure the distance between post sleeves. Cut the toprail to length. Secure from underneath with suppliedwhite-head screws.Step 5: Install Post CapsSlide inverted post trim ring over top of the postsleeve. Place post cap over top of the post sleeve.Screw through side holes of the post cap to secure.Snap inverted post trim ring onto secured post cap.5432aRail BracketsClosed rail bracket;for use in top rails only1Open rail bracket;for use in bottom railsor flat sections2a1a2bPanorama boxed kits are available in 6' and 8' lengths. Measurements a

Workbook is a key element in CertainTeed's Master Craftsman education and training program. We hope that you will use it to master the information critical to installing our railing products. The more you know about CertainTeed railing, the better able you'll be to recommend solutions and estimate jobs for your customers.