Transcription

Issued Jan. 2014 Index No. ED/4.78Trailblazer 302 Air Pak anceRepairStructural Steel WorkSheet Metal Gas Engine-Driven Welder/AC Generator/Air Compressor/12/24 V Battery Charge/Jump StartProcesses (X-Ray Quality)Output RangeStick (SMAW)MIG (GMAW)Flux-Cored (FCAW)AC/DC TIG (GTAW)Battery Charge/Jump StartAir Carbon Arc (CAC-A) Cutting and GougingRated: 3/16-inch carbons,Capable: 1/4-inch carbonsAir Plasma Cutting and Gouging withoptional Spectrum modelsRated: 5/8-inch mild steelDC Stick25– 300 AAC TIG/Stick 10 – 225 ADC TIG10 – 300 AMIG/FCAW 13 – 35 V, 350 AGenerator Power Output Rated at 104 F (40 C)Peak: 13,000 W — Continuous: 11,000 WAir Compressor31 CFM, 100% Duty Cycle, 80 – 160 PSIBattery Charge/Jump StartBattery Charge: 12/24 V, 10–75 ABattery Jump Start: 12/24 V, 450 A /350 AEasy to service.Toolless top access to: Engine air cleaner Engine oil check/fill dipstick Battery Compressor oil check/fill dipstick Compressor oil separator Air compressor air filterThe all-in-one tool thatdelivers multiprocessoutput for welding,plasma cutting, gouging,air tools, and 12/24-voltbattery charge/jump start.Toolless side access to: Engine oil filter Engine oil drain Engine fuel filterEasy operation. Reduce fuelconsumption and noise byusing the front panel air flowcontrol which matchesengine speeds to air flowrequirements for tools,plasma cutting and gouging.Rear access to: Compressor oil filter Compressor oil drainFront panel air pressure adjustment. Simple to adjust the correctair pressure for specific applications(80 –160 PSI) Lower pressure will increase enginepower for more gouging and plasmacutting output capabilitiesWelder/generator/air compressor/battery charger iswarranted for 3 years, parts and labor. Engine iswarranted separately by the engine manufacturer.Miller Electric Mfg. Co.Equipment Sales US and CanadaAn ITW Company1635 West Spencer StreetP.O. Box 1079Appleton, WI 54912-1079 USAPhone: 866-931-9730FAX: 800-637-2315International Phone: 920-735-4554International FAX: 920-735-4125MillerWelds.com

Trailblazer 302 Air Pak Features Size and WeightBattery Charge/Jump StartTakes only half the bed space of a separateengine-driven air compressor and welder,freeing up to 50 percent more room on yourtruck for equipment and supplies. Plusdecreases axle weight up to 25 percent. Provides selectable 12- or 24-voltbattery charging capability Provides up to 450 amps ofbattery jump-starting capability Convenient front panel batterycharge/jump start access 25-foot battery jumper cablesavailable (#300 422)Independent Weld and Generator AdvantagesIndustrial Rotary-Screw Air Compressor 13,000 watts of voltage-regulated power No interaction between grinders, power tools, etc. and thewelding arc Generator power is independent of weld Four-pole weld generator produces the best arc quality Runs most air impact wrenches at idle Produces 31 CFM of air at 100 percent duty cycle Delivers 80 –160 PSI of air with no storage tank Gives 100 percent deliverable air Compressor is warranted by Miller for three yearsWeld PowerGenerator Power2

Answers to Frequently Asked Trailblazer 302 Air Pak Questions Air FactsWhat Does Average vs Continuous CFM Mean? Moisture going into a compressor also comes out. Air compressors heat air, turning moisture droplets into vapor. Air tools are often rated as “Average CFM.” Average CFM istypically based on 15-second usage intervals.Impact wrenches, button punch/deck tools, and decking crimptools are typically used intermittently (short time durations). Continuous CFM: This rating is based on continuous usage.Air grinders and sand blasters are examples of air tools that areused continuously.How Can I Reduce Moisture in the Air?Air Cooler with Separator #300 420 Most popular. The cooler cools air which turns vapormoisture into droplets and the separatorremoves the droplets. Removes 70 percent of the moisture fromthe air. Use for most applications including tools,blasters, plasma cutters and gouging. Effective when temperatures are above freezing (this is alsowhen the most moisture is in the air). Below 32 degreesFahrenheit (0 C) the separator can freeze. If this happens,bypass the cooler/separator system and continue air operationswithout drying it. Fully integrated inside of the Air Pak.RTI Filter #300 491 Recommended for plasma cutting. Separatorsremove droplets of water, not vapor, but this isgood enough for most plasma cutting applications. Because compressors heat air, this filter option isless effective at removing moisture (heat turnsdroplets into vapor and vapor is not filtered).The Air Pak Will Easily Run the Following:Air ToolsAverageCFM*ContinuousCFM*3/4-inch Impact Wrench (IR 2141)10403/4-inch Impact Wrench (Speedaire)7261/2-inch Impact Wrench (IR 231C)422Needle Scaler (IR 182LNA1)3134-1/2-inch Grinder (Dayton)7261/4-inch Die Grinder (IR G1H350RG4)6251/2-inch Drill (IR 7AQSTB)417Air Shears (IR 7802SA)421Sand Blaster—6Soda Blaster—18Button Punch/Deck Tool—4Decking Crimp Tool415*1/2-inch air hose is recommended for better tool efficiency.Note: Impact wrenches use Continuous CFM when “free” spinning.In actual use, CFM requirements are less. Thus, the Trailblazer Air Pakis rated to run a 40 CFM impact wrench.Desiccant Air Dryer #300 690 Cools air and removes 99 percent of themoisture from the air. Primary use is when temperature rangesbelow freezing and moisture still must beremoved from the air. Has a built in heater. Mounted externally from the machine with some wiring thatneeds to take place inside of the machine.How Do I Access the Air?The Trailblazer Air Pak provides four convenient air compressoraccess points. The air outlet connection requires a 1/2-inchNPT swivel fitting.Note: Reduces air flow up to four CFM at all speeds.WATER IN AIR (g/ft.3)MAX FLOW ABSOLUTE HUMIDITY1050050100150DRYER AIR PRESSURE (PSI)Air Cooler with Separator (#300 420)Desiccant Air Dryer (#300 690)No Air Cooler or Dryer3

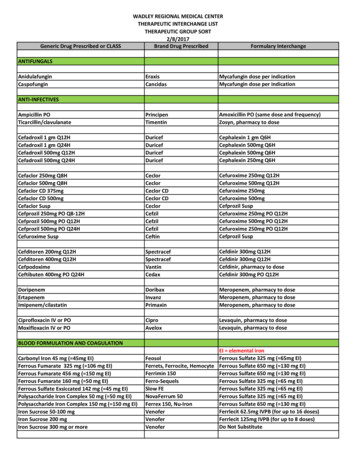

Specifications (Subject to change without notice.)WeldingModeProcessAmp/VoltRangesRated Weld Outputat 104 F (40 C)*Single-PhaseGenerator PowerSound Levels atRated Output 7 m (23 ft.)CV/DCMIG/FCAW13– 35 V300 A at 32 V, 100% Duty Cycle350 A at 32 V, 60% Duty Cycle2400 RPM (Idle)73.4 dB (98.4 Lwa)CC/DCStick/TIG10– 300 A280 A at 32 V, 100% Duty CycleCC/ACStick/TIG10– 225 A200 A at 25 V, 60% Duty Cycle12/24 VCharge: 10 – 75 AJump Start: 450 A, 12 VJump Start: 350 A, 24 VPeak:13,000 wattsContinuous:11,000 watts120/240 VAC,100/50 A, 60 HzBattery Charge/Jump Start*Rated at sea level. **Net weight without fuel.NetWeight**DimensionsH: 28 in. (838 mm)H: 34.5 in. (876 mm)(to top of exhaust)W: 20 in. (508 mm)D: 59.625 in. (1514 mm)3000 RPM76.5 dB (101.5 Lwa)3600 RPM81.2 dB (106.6 Lwa)771 lb.(350 kg)Certified by Canadian Standards Association to both the Canadian and U.S. Standards.Air Compressor SpecificationsCompressorBrand andWarrantyFeaturesMiller,3-yearwarrantyRotary screw with electricclutch for on/off. Oil changeintervals 500 hours.Free AirDelivery at3600 RPMFree AirDelivery at3000 RPMFree AirDelivery at2400 RPM utomaticCompressorShutdowns31 CFM(0.88 m3/min.)28 CFM(0.79 m3/min.)22 CFM(0.62 m3/min.)80–160 PSIG100%1.75 qt.(1.7 L)High Pressure(160 PSI)Engine Specifications (Engines warranted separately by the engine manufacturer.)Engine Brandand WarrantyHorsepower tandardShutdownsKohler CH750,3-year warranty27 HP at3600 RPMTwin-cylinder, four-cycle overheadvalve, industrial air-cooled, gasoline*3600/3000RPM2400RPM12 gal.(45 L)1.75 qt.(1.7 L)Low OilPressure*Fuel stabilizer is recommended for gas engines that are used infrequently.Performance DataAIR COMPRESSOR FUEL CONSUMPTION(at 100% Duty Cycle)WELD/GENERATOR FUEL CONSUMPTION2.251.22.001.11.75US GAL./HR.1.00.9US 0.000.2IDLE050100 150 200250 300 350 400DC WELD AMPS AT 100% DUTY CYCLE0.10.0240030003600024681012GENERATOR POWER IN KILOWATTS AT100% DUTY CYCLEENGINE SPEED RPMFUEL CONSUMPTION DATA 12-gallon fuel capacity. On a typical job using 1/8-inch 7018electrodes (125 A, 20% duty cycle) expectover 16 hours of operation. Welding at 150 A, 40% duty cycle usesapproximately: 3/4-gallon per hour —over 13 hours of operation. Many air tools can be used when running atidle. Running at idle with a compressor loadwill provide 14 hours of run time. Running the air compressor at 31 CFM willprovide 11 hours of run time. Reduce fuel consumption by turning the aircompressor off when the Air Pak is not in use.For weld/generator fuel consumption chart seechart at left.Mounting SpecificationsA4 HolesEngine EndGBCDEF4A. 20 in. (508 mm)B. 16.5 in. (419 mm)C. 1.75 in. (44 mm)D. 6.062 in. (154 mm)E. 32.75 in. (832 mm)F. 59.625 in. (1514 mm)G. .406 in. (10 mm) diameterHeight: 28 in. (838 mm)34.5 in. (876 mm)(to top of exhaust)Width: 20 in. (508 mm)Depth: 59.625 in. (1514 mm)Lifting eye rating:1000 lb. (453 kg)

Function and Benefit Guide1829341056111271314*Category Exclusive1. Self-calibrating digital weld meters withmeter maintenance displays capable ofdisplaying engine and air compressor oilchange intervals.5. Lift-Arc TIG with Auto-Crater * andAuto-Stop *2. Four preset DIG settings* offer the bestarc characteristics for different electrodesand joint designs. The amount of DIGdetermines how much amperage (heat)varies with Stick arc length. The combinedProcess switch along with preset DIGsettings make the Trailblazer easy to setwithout the complication of multiple switches.7. Air pressure gauge/regulator gives theapproximate air pressure settings neededfor common air tools/plasma/carbon arcgouging. The pressure gauge also reads theactual air pressure being used. The regulatorallows user control of the pressure settingsup to 160 PSI.3. Adaptive Hot Start * (Stick) automaticallysets starting amperage for great arc starts.4. Great MIG/FCAW performance and arcstarts make the Trailblazer’s arc best in itsclass. Easy to run all wires from .023-inchsolid wires to large diameter 5/64-inchflux-cored wires.6. Air compressor, battery charge/jump start,and maintenance selector8. Front panel fuel gauge* LEDs indicate fuellevel. The “E” LED lights when fuel is low.9. AC/DC and battery charge/jump startswitch allows selection between AC orDC weld output and battery charge/jump function.10. Battery charge/jump start receptaclefor connection to battery charge/jump cable(12 or 24 volt).11. Standard 14-pin receptacle for simpleconnection of remote controls and wirefeeders. It features Auto Remote Sense *which automatically switches from Panel toRemote Amperage/Voltage (A/V) controlwith remote connected. Eliminatesconfusion of the Panel/Remote A/V switch.12. Speed control switch allows for control ofengine speed based on the switch position.In the auto speed mode, the speed will beauto selected depending on total powerneeded. The speed will auto select between3000 and 3600 RPM depending on welddemand or weld plus air demand. Anytimeauxiliary load is needed the engine will go to3600 RPM.13. Engine choke control14. 120 VAC and 240 VAC receptacles withcircuit breakersNote: For matching plug, order #119 172.5

Genuine Miller Options *Available as factory option. See ordering information on back page. Air Cooler withSeparator* #300 420Cools and removesmoisture from the airsupply. Designed foruse above 32 degreesFahrenheit (0 C). Bypassin colder temperatures.See air dryer choices onpage 4 for details.GFCI Receptacles* #195 496 FieldKit contains two GFCI 120 VAC duplex receptacles.(240 VAC GFCI receptacle not required).Electric Fuel Pump* #195 214 FieldImproves engine starting and high-outputperformance at high altitude.Remote Oil Drain and Filter Kit#300 236 FieldFront/chassis truck mounted for Kohler.FemaleReceptacleMicron Filter Element #203 877Replacement micron filter for the Air Coolerwith Separator.RTI Filter and Bracket#300 491Dryer will remove water, dirt andoil as small as one micron with99.9 percent efficiency. Can bemounted on plasma cutter or onwall. Install as close as possibleto point of air consumption.Designed for use above 32degrees Fahrenheit (0 C). Bypassin colder temperatures. See airdryer choices on page 4 for details.Adapter Cord, Full KVA #300 517 FieldNEMA 14-50P to NEMA 6-50R. Adapts enginedrive 120/240 V plug to common Millermatic and Spectrum 240 V plug.Full KVA Plug Kit#119 172 Field120/240 VAC, 50 A plug(NEMA 14-50P) to fit full KVAreceptacle.Desiccant Air DryerSystem #300 690A regenerating inline airdryer system thateliminates moisture inthe air stream to preventair tool freeze-ups incold climates. See airdryer choices on page 4 for details.Order the following from Miller Service Parts.Engine Tune-Up Kit #238 743 FieldFor Kohler CH750. Includes spark plugs andengine filters.Air Compressor Tune-Up Kit #235 202 FieldIncludes oil filter, air filter and oil separator.Genuine Miller Accessories Protective Cagewith Cable Holders#300 473Rugged cage withcable holdersprotects yourinvestment. Can beused with trailer.25-foot BatteryCharge/Jump Cable#300 422Protective Cover#300 379Heavy-duty, waterresistant andmildew-resistantcovers protect andmaintain the finishof the welder. Formodels withoutProtective Cage.Stick (SMAW) WeldingWeld Leads#173 851 2/0, 350-amp, 100 percent dutycycle. 50-foot stinger and 50-footwork cable.#043 952 2/0, 300-amp, 100 percent dutycycle. 100-foot stinger and 50-footwork cable.Plasma CuttingDynasty 200 SeriesFor premium portableAC/DC TIG arc quality. SeeLit. Index No. AD/4.8.HF-251 Series #042 388HF-251D-1, 115 VACHigh-frequency arc starterand stabilizer. See Lit. IndexNo. AY/5.0.Multiprocess WeldingSpectrum 375 X-TREME and 625 X-TREME shown.Spectrum 375 X-TREME #907 529See Lit. Index No. PC/9.2.Spectrum 625 X-TREME #907 579See Lit. Index No. PC/9.6.Spectrum 875 #907 583See Lit. Index No. PC/9.8.The Spectrum 375 X-TREME and 625 X-TREMEcome complete with protective X-CASE (not shown).6TIG (GTAW) WeldingMultimatic 200 #907 518Portable, all-in-one multiprocess package weighsonly 29 pounds (13.2 kg), and features excellentarc characteristics. Exclusive Multi-Voltage Plug(MVP ) provides flexibility to plug into 115- or230-volt power. Take it anywhere you need to MIG,TIG or Stick weld. See Lit. Index No. DC/12.57.

Genuine Miller Accessories (Continued) RHC-14 Hand Control#242 211 020Miniature hand control forremote current and contactorcontrol. Dimensions: 4 x 4 x3.25 inches (102 x 102 x 82 mm).Includes 20-foot (6 m) cord and 14-pin plug.MIG/Flux-Cored WeldingMillermatic 211 Auto-Set with MVP shown.Millermatic 140 Auto-Set #907 335See Lit. Index No. DC/12.42Millermatic 180 Auto-Set #907 312See Lit. Index No. DC/12.44Millermatic 211 Auto-Set with MVP #907 422See Lit. Index No. DC/12.54Millermatic 212 Auto-Set #907 405See Lit. Index No. DC/12.46The Millermatic line of MIG welders are completearc welding power source, wire feeder and gunpackages designed for portability and ease of use.Note: The Millermatic machines can be operatedutilizing generator power.SuitCase 12RC Wire Feeder #951 189Lightweight, modular design and flexibleenough to run a variety of wires up to 5/64-inchdiameter. Includes remote voltage control, MIGgun and drive roll kit. See Lit. Index No. M/6.5.Spoolmatic 30ASpool Gun#130 831Air-cooled, 200-amp,1-pound spool gunfor aluminum MIG.See Lit. Index No. M/1.73. Requires WC-24Control (#137 549).XR Wire Feeders and GunsPush-pull system designed to handle difficultto-feed soft alloy wires such as aluminum.See Lit. Index Nos. M/1.7 – M/1.75.Remote ControlsSuitCase X-TREME 8VS Wire Feeder#951 583SuitCase X-TREME 12VS Wire Feeder#951 543Lightweight, voltage-sensing wire feeders includesecondary contactor, MIG gun, gas valve anddrive roll kit. See Lit. Index No. M/6.42.Wireless Remote HandControl #300 430For remote current,voltage and contactorcontrol. Receiver plugsdirectly into the 14-pinreceptacle of Miller machine. 300-foot (91.4 m)operating range.RFCS-14 HD FootControl #194 744Heavy-duty foot currentand contactor control.Includes 20-foot (6 m)cord and 14-pin plug.RMLS-14 #129 337 14-pin plugMomentary- and maintained-contact rockerswitch for contactor control. Push forward formaintained contact and back for momentarycontact. Includes 20-foot (6 m) cord.RCC-14 Remote Contactor and Current Control#151 086 14-pin plugRotary-motion fingertip control fastens to TIGtorch using two Velcro straps. Includes 28-foot(8.5 m) control cord.Extension Cords for 14-Pin Remote Controls#242 208 025 25 ft. (7.6 m)#242 208 050 50 ft. (15.2 m)#242 208 080 80 ft. (24.4 m)Trailers and Hitches (Note: Trailers are shipped unassembled.)HWY-224 Trailer #043 805For highway use. A 2650-pound (1202 kg)capacity trailer. Welded steel tubing frame,heavy-duty axle with roller bearing hubs andleaf-spring suspension. Includes jack stand,2-inch (50 mm) ball hitch, fenders and lights.Cable Tree #043 826Provides an area to conveniently wrap weldcables and extension cords.Dual Hitch #300 8312-inch (50 mm) ball hitchand 3-inch (76 mm)lunette eye in onereversible assembly.Trailer Specifications (Subject to change without notice.)ModelHWY-224Gross AxleWeight RatingGross VehicleWeight RatingNetPayloadHeightof BedRoadClearanceTrack (Centerto center oftires)Standard Tires(Standard ratingor P-size rating)3500 lb.(1588 kg)2960 lb.(1343 kg)2650 lb.(1202 kg)18.5 in.(470 mm)7.5 in.(191 mm)52 in.(1321 mm)B78-13DimensionsNetWeightLength: 105 in. (2667 mm)Width: 59.5 in. (1511 mm)*320 lb.(145 kg)*Width at outside of fenders.7

Ordering InformationEquipment and OptionsTrailblazer 302 Air Pakwith Battery Charge/Jump Start Stock No.DescriptionQty.#907 549-001#907 549#907 549-003Base model with Kohler engineKohler engine, with GFCI Receptacles and Electric Fuel PumpKohler engine, with Cooler/Separator, GFCI Receptacles and Electric Fuel PumpField Options Options listed below can be added to the above packages. Installation is required.GFCI Receptacles#195 496Electric Fuel Pump#195 214Remote Oil Drain and Filter Kit#300 236Adapter Cord, Full KVA#300 517Full KVA Plug#119 172Air Cooler with Separator#300 420See page 4 for more informationMicron Filter Element#203 877For use with Air Cooler with SeparatorRTI Filter and Bracket#300 491See page 4 for more informationDesiccant Air Dryer System#300 690Reduces air flow up to four CFM at all speeds. See page 4 for more informationEngine Tune-Up Kit#238 743For Kohler CH750 (Gas). Order from Miller Service PartsAir Compressor Tune-Up Kit#235 202For screw compressor. Order from Miller Service PartsImproves starting and performance at high altitudeAccessoriesProtective Cage with Cable Holders#300 47325-foot Battery Charge/Jump Cable#300 422Protective Cover#300 379Stick Weld LeadsBlue with logoSee page 6Spectrum Plasma CuttersSee page 7Dynasty 200 SeriesSee Lit. Index No. AD/4.8HF-251D-1#042 388115 VAC. See Lit. Index No. AY/5.0Multimatic 200 Welder#907 518All-in-one MIG, TIG and Stick welding. See Lit. Index No. DC/12.57Millermatic Series MIG WeldersSee page 7SuitCase Portable Wire FeedersSee page 7Spoolmatic 30A Spool Gun#130 831Requires WC-24 Control. See Lit. Index No. M/1.73WC-24 Control#137 549See Lit. Index No. M/1.73XR Wire Feeder Control and GunsSee Lit. Index No. M/1.7, M/1.71, M/1.73, M/1.74 and M/1.75Remote Controls and CordsSee page 7HWY-224 Trailer#043 805Cable Tree#043 826Dual Hitch#300 831Date:Distributed by: 2013 Miller Electric Mfg. Co.Total Quoted Price:Price

AC TIG/Stick10-225 A MIG/FCAW 13-35 V, 350 A Generator Power Output Rated at 104 F (40 C) Peak: 13,000 W — Continuous: 11,000 W Air Compressor 31 CFM, 100% Duty Cycle, 80-160 PSI Battery Charge/Jump Start Battery Charge: 12/24 V, 10-75 A Battery Jump Start: 12/24 V, 450 A/350 A Industrial Applications Fabrication Maintenance Repair