Transcription

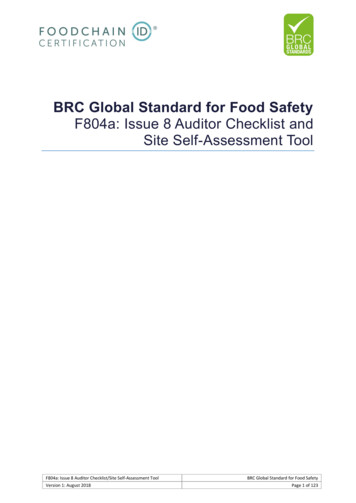

BRC Global Standard for Food SafetyF804a: Issue 8 Auditor Checklist andSite Self-Assessment ToolF804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 1 of 123

1Senior management commitment1.1Senior management commitment and continual improvementSOIThe site’s senior management shall demonstrate they are fully committed to theimplementation of the requirements of the Global Standard for Food Safety and toprocesses which facilitate continual improvement of food safety and quality management.ClauseRequirementsFundamental1.1.1 signed by the person withoverall responsibility for thesitecommunicated to all staff.The site’s senior management shalldefine and maintain a clear plan forthe development and continuingimprovement of a food safety andquality culture. This shall include: 1.1.3CommentsThe site shall have a documentedpolicy which states the site’s intentionto meet its obligation to produce safe,legal and authentic products to thespecified quality, and its responsibilityto its customers. This shall be: 1.1.2Conformsdefined activities involving allsections of the site that havean impact on product safetyan action plan indicating howthe activities will beundertaken and measured,and the intended timescalesa review of the effectivenessof completed activities.The site’s senior management shallensure that clear objectives aredefined to maintain and improve thesafety, legality and quality of productsF804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 2 of 123

manufactured, in accordance with thefood safety and quality policy and thisStandard. These objectives shall be: 1.1.4documented and includetargets or clear measures ofsuccessclearly communicated torelevant staffmonitored and resultsreported at least quarterly tosite senior management.Management review meetingsattended by the site’s seniormanagement shall be undertaken atappropriate planned intervals,annually at a minimum, to review thesite performance against the Standardand objectives set in clause 1.1.3. Thereview process shall include theevaluation of: previous management reviewaction plans and timeframesthe results of internal, secondparty and/or third-partyauditsany objectives that have notbeen met, to understand theunderlying reasons. Thisinformation shall be usedwhen setting future objectivesand to facilitate continualimprovementany customer complaints andthe results of any customerfeedbackany incidents (including bothrecalls and withdrawals),corrective actions, out-ofspecification results and nonconforming materialsF804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 3 of 123

the effectiveness of thesystems for HACCP, fooddefence and authenticityresource requirements.Records of the meeting shall bedocumented and used to revise theobjectives. The decisions and actionsagreed within the review process shallbe effectively communicated toappropriate staff, and actionsimplemented within agreedtimescales.1.1.5The site shall have a demonstrablemeeting programme which enablesfood safety, legality, integrity andquality issues to be brought to theattention of senior management.These meetings shall occur at leastmonthly.Employees shall be aware of the needto report any evidence of unsafe orout-of-specification product or rawmaterials, to a designated manager toenable the resolution of issuesrequiring immediate action.1.1.6The company shall have a confidentialreporting system to enable staff toreport concerns relating to productsafety, integrity, quality and legality.The mechanism (e.g. the relevanttelephone number) for reportingconcerns must be clearlycommunicated to staff.The company’s senior managementshall have a process for assessing anyconcerns raised. Records of theF804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 4 of 123

assessment and, where appropriate,actions taken, shall be documented.1.1.71.1.8The company’s senior managementshall provide the human and financialresources required to produce foodsafely and in compliance with therequirements of this Standard.The company’s senior managementshall have a system in place to ensurethat the site is kept informed of andreviews: 1.1.91.1.101.1.11scientific and technicaldevelopmentsindustry codes of practicenew risks to authenticity ofraw materialsall relevant legislation in thecountry where the productwill be sold (where known).The site shall have a genuine, originalhard copy or electronic version of thecurrent Standard available and beaware of any changes to the Standardor protocol that are published on theBRC Global Standards website.Where the site is certificated to theStandard, it shall ensure thatannounced recertification audits occuron or before the audit due dateindicated on the certificate.The most senior production oroperations manager on site shallparticipate in the opening and closingmeetings of the audit for certificationto the Standard. RelevantF804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 5 of 123

departmental managers or theirdeputies shall be available as requiredduring the audit.1.1.121.1.13The site’s senior management shallensure that the root causes of anynon-conformities against the Standardidentified at the previous audit havebeen effectively addressed to preventrecurrence.The BRC Global Standards logo andreferences to certification status shallonly be used in accordance with theconditions of use detailed in the auditprotocol section (Part III, section 5.6)of the Standard.1.2Organisational structure, responsibilities and management authoritySOIClause1.2.11.2.2The company shall have a clear organisational structure and lines of communication toenable effective management of product safety, legality and quality.RequirementsConformsThe company shall have anorganisation chart demonstrating themanagement structure of thecompany. The responsibilities for themanagement of activities whichensure food safety, integrity, legalityand quality shall be clearly allocatedand understood by the managersresponsible. It shall be clearlydocumented who deputises in theabsence of the responsible person.The site’s senior management shallensure that all employees are awareof their responsibilities. Wheredocumented work instructions existfor activities undertaken, the relevantF804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 6 of 123

employees shall have access to theseand be able to demonstrate that workis carried out in accordance with theinstructions.2The food safety plan – HACCPFundamentalThe company shall have a fully implemented and effective food safety plan incorporatingthe Codex Alimentarius HACCP principles.SOI2.1Senior management commitment and continual improvementClauseRequirements2.1.1ConformsThe HACCP or food safety plan shall bedeveloped and managed by a multidisciplinary food safety team thatincludes those responsible for qualityassurance, technical management,production operations, engineeringand other relevant functions.The team leader shall have an indepth knowledge of Codex HACCPprinciples (or equivalent) and be ableto demonstrate competence,experience and training. Where thereis a legal requirement for specifictraining, this shall be in place.The team members shall have specificknowledge of HACCP and relevantknowledge of products, processes andassociated hazards.In the event of the site not having theappropriate in-house knowledge,external expertise may be used, butday-to-day management of the foodsafety system shall remain theresponsibility of the company.F804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 7 of 123

2.1.2The scope of each HACCP or foodsafety plan, including the products andprocesses covered, shall be defined.2.2Prerequisite programmesClauseRequirements2.2.1ConformsThe site shall establish and maintainenvironmental and operationalprogrammes necessary to create anenvironment suitable to produce safeand legal food products (prerequisiteprogrammes). As a guide these mayinclude the following, although this isnot an exhaustive list: cleaning and sanitisingpest managementmaintenance programmes forequipment and buildingspersonal hygienerequirementsstaff trainingpurchasingtransportation arrangementsprocesses to prevent crosscontaminationallergen controls.The control measures and monitoringprocedures for the prerequisiteprogrammes must be clearlydocumented and shall be includedwithin the development and reviewsof the HACCP or food safety plan.2.3Describe the product (equivalent to Codex Alimentarius Step 2)ClauseRequirements2.3.1ConformsA full description for each product orgroup of products shall be developed,which includes all relevantinformation on food safety. As aF804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 8 of 123

guide, this may include the following,although this is not an exhaustive list: 2.3.2composition (e.g. rawmaterials, ingredients,allergens, recipe)origin of ingredientsphysical or chemicalproperties that impact foodsafety (e.g. pH, aw)treatment and processing (e.g.cooking, cooling)packaging system (e.g.modified atmosphere,vacuum)storage and distributionconditions (e.g. chilled,ambient)maximum safe shelf life underprescribed storage and usageconditions.All relevant information needed toconduct the hazard analysis shall becollected, maintained, documentedand updated. The company will ensurethat the HACCP or food safety plan isbased on comprehensive informationsources, which are referenced andavailable on request. As a guide, thismay include the following, althoughthis is not an exhaustive list: the latest scientific literaturehistorical and known hazardsassociated with specific foodproductsrelevant codes of practicerecognised guidelinesfood safety legislationrelevant for the productionand sale of productscustomer requirements.F804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 9 of 123

2.4Identify intended use (equivalent to Codex Alimentarius Step 3)ClauseRequirements2.4.1The intended use of the product bythe customer, and any knownalternative use, shall be described,defining the consumer target groups,including the suitability of the productfor vulnerable groups of thepopulation (e.g. infants, elderly,allergy sufferers).2.5Construct a process flow diagram (equivalent to Codex Alimentarius Step 4)ClauseRequirements2.5.1ConformsConformsA flow diagram shall be prepared tocover each product, product categoryor process. This shall set out allaspects of the food process operationwithin the HACCP or food safety planscope, from raw material receiptthrough to processing, storage anddistribution. As a guide, this shouldinclude the following, although this isnot an exhaustive list: plan of premises andequipment layoutraw materials, includingintroduction of utilities andother contact materials (e.g.water, packaging)sequence and interaction ofall process stepsoutsourced processes andsubcontracted workpotential for process delayrework and recyclinglow-risk/high-risk/high-carearea segregationfinished products, intermediate/semiprocessed products, by-products andwaste.F804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 10 of 123

2.6Verify flow diagram (equivalent to Codex Alimentarius Step 5)ClauseRequirements2.6.1The HACCP food safety team shallverify the accuracy of the flowdiagrams by on-site audit andchallenge at least annually. Daily andseasonal variations shall beconsidered and evaluated. Records ofverified flow diagrams shall bemaintained.2.7List all potential hazards associated with each process step, conduct a hazard analysis andconsider any measures to control identified hazards (equivalent to Codex AlimentariusStep 6, Principle 1)ClauseRequirements2.7.1ConformsConformsThe HACCP food safety team shallidentify and record all the potentialhazards that are reasonably expectedto occur at each step in relation toproduct, process and facilities. Thisshall include hazards present in rawmaterials, those introduced during theprocess or surviving the process steps,and consideration of the followingtypes of hazard: microbiologicalphysical contaminationchemical and radiologicalcontaminationfraud (e.g. substitution ordeliberate/intentionaladulteration)malicious contamination ofproductsallergen risks (see clause 5.3).It shall also take account of thepreceding and following steps in theprocess chain.F804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 11 of 123

2.7.2The HACCP food safety team shallconduct a hazard analysis to identifyhazards which need to be prevented,eliminated or reduced to acceptablelevels. Consideration shall be given tothe following: likely occurrence of hazardseverity of the effects onconsumer safetyvulnerability of those exposedsurvival and multiplication ofmicro-organisms of specificconcern to the productpresence or production of toxins,chemicals or foreign bodiescontamination of raw materials,intermediate/semi-processedproduct, or finished product.Where elimination of the hazard is notpractical, justification for acceptablelevels of the hazard in the finishedproduct shall be determined anddocumented.2.7.3The HACCP food safety team shallconsider the control measuresnecessary to prevent or eliminate afood safety hazard or reduce it to anacceptable level. Where the control isachieved through existing prerequisiteprogrammes, this shall be stated andthe adequacy of the programme tocontrol the specific hazard validated.Consideration may be given to usingmore than one control measure.2.8Determine the critical control points (CCPs) (equivalent to Codex Alimentarius Step 7,Principle 2)ClauseRequirements2.8.1For each hazard that requires control,control points shall be reviewed toidentify those that are critical. ThisF804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018ConformsBRC Global Standard for Food SafetyPage 12 of 123

requires a logical approach and maybe facilitated by use of a decision tree.Critical control points (CCPs) shall bethose control points which arerequired in order to prevent oreliminate a food safety hazard orreduce it to an acceptable level. If ahazard is identified at a step wherecontrol is necessary for safety but thecontrol does not exist, the product orprocess shall be modified at that step,or at an earlier step, to provide acontrol measure.2.9Establish critical limits for each CCP (equivalent to Codes Alimentarius Step 8, Principle 3)ClauseRequirements2.9.1For each CCP, the appropriate criticallimits shall be defined in order toidentify clearly whether the process isin or out of control. Critical limits shallbe: 2.9.2Conformsmeasurable wherever possible(e.g. time, temperature, pH)supported by clear guidance orexamples where measures aresubjective (e.g. photographs).The HACCP food safety team shallvalidate each CCP. Documentedevidence shall show that the controlmeasures selected and critical limitsidentified are capable of consistentlycontrolling the hazard to the specifiedacceptable level.2.10Establish a monitoring system for each CCP (equivalent to Codex Alimentarius Step 9,Principle 4)ClauseRequirements2.10.1ConformsA monitoring procedure shall beestablished for each CCP to ensurecompliance with critical limits. Themonitoring system shall be able toF804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 13 of 123

detect loss of control of CCPs and,wherever possible, provideinformation in time for correctiveaction to be taken. As a guide,consideration may be given to thefollowing, although this is not anexhaustive list: online measurementoffline measurementcontinuous measurement (e.g.thermographs, pH metersetc.).Where discontinuous measurement isused, the system shall ensure that thesample taken is representative of thebatch of product.2.10.2Records associated with themonitoring of each CCP shall includethe date, time and result ofmeasurement and shall be signed bythe person responsible for themonitoring and verified, whenappropriate, by an authorised person.Where records are in electronic form,there shall be evidence that recordshave been checked and verified.2.11Establish a corrective action plan (equivalent to Codex Alimentarius Step 10, Principle 5)ClauseRequirements2.11.1The HACCP food safety team shallspecify and document the correctiveaction to be taken when monitoredresults indicate a failure to meet acontrol limit, or when monitoredresults indicate a trend towards loss ofcontrol. This shall include the action tobe taken by nominated personnel withregard to any products that have beenmanufactured during the period whenthe process was out of control.F804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018ConformsBRC Global Standard for Food SafetyPage 14 of 123

2.12Establish verification procedures (equivalent to Codex Alimentarius Step 11, Principle 6)ClauseRequirements2.12.1ConformsProcedures of verification shall beestablished to confirm that the HACCPor food safety plan, including controlsmanaged by prerequisiteprogrammes, continues to beeffective. Examples of verificationactivities include: internal auditsreview of records whereacceptable limits have beenexceededreview of complaints byenforcement authorities orcustomersreview of incidents of productwithdrawal or recall.Results of verification shall berecorded and communicated to theHACCP food safety team.2.13HACCP documentation and record-keeping (equivalent to Codex Alimentarius Step 12,Principle 7)ClauseRequirements2.13.1Documentation and record-keepingshall be sufficient to enable the site toverify that the HACCP and food safetycontrols, including controls managedby prerequisite programmes, are inplace and maintained.2.14Review the HACCP planClauseRequirements2.14.1ConformsConformsThe HACCP food safety team shallreview the HACCP or food safety planand prerequisite programmes at leastannually and prior to any changeswhich may affect food safety. As aF804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 15 of 123

guide, these may include thefollowing, although this is not anexhaustive list: change in raw materials orsupplier of raw materialschange in ingredients/recipechange in processing conditions,process flow or equipmentchange in packaging, storage ordistribution conditionschange in consumer useemergence of a new risk (e.g.known adulteration of aningredient or other relevant,published information, such as therecall of a similar product)review following a recallnew developments in scientificinformation associated withingredients, process or product.Appropriate changes resulting fromthe review shall be incorporated intothe HACCP or food safety plan and/orprerequisite programmes, fullydocumented and the validationrecorded.Where appropriate, the changes shallalso be reflected in the company’sproduct safety policy and food safetyobjectives.3Food safety and quality management system3.1Food safety and quality manualSOIThe company’s processes and procedures to meet the requirements of this Standard shallbe documented to allow consistent application, facilitate training, and support duediligence in the production of a safe product.F804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 16 of 123

ClauseRequirements3.1.1The site’s procedures, workingmethods and practices shall becollated in the form of a printed orelectronic quality manual.3.1.2The food safety and quality manualshall be fully implemented and themanual or relevant components shallbe readily available to relevant staff.3.1.3All procedures and work instructionsshall be clearly legible, unambiguous,in appropriate languages andsufficiently detailed to enable theircorrect application by appropriatestaff. This shall include the use ofphotographs, diagrams or otherpictorial instructions where writtencommunication alone is notsufficient (e.g. there are issues ofliteracy or foreign language).3.2Document controlSOIThe company shall operate an effective document control system to ensure that only thecorrect versions of documents, including recording forms, are available and in use.ClauseRequirements3.2.1ConformsConformsThe company shall have a procedureto manage documents which formpart of the food safety and qualitysystem. This shall include: a list of all controlleddocuments indicating thelatest version numberthe method for theidentification andauthorisation of controlleddocumentsa record of the reason forany changes or amendmentsto documentsF804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 17 of 123

the system for thereplacement of existingdocuments when these areupdated.Where documents are stored inelectronic form these shall also be: stored securely (e.g. withauthorised access, control ofamendments, or passwordprotected)backed up to prevent loss.3.3Record completion and maintenanceSOIThe site shall maintain genuine records to demonstrate the effective control of productsafety, legality and quality.ClauseRequirements3.3.1Records shall be legible, maintainedin good condition and retrievable.Any alterations to records shall beauthorised and justification for thealteration shall be recorded. Whererecords are in electronic form theseshall also be: 3.3.2Conformsstored securely (e.g. withauthorised access, control ofamendments, or passwordprotected)suitably backed up to preventloss.Records shall be retained for adefined period with considerationgiven to: any legal or customerrequirementsthe shelf life of the product.This shall take into account, where itis specified on the label, thepossibility that shelf life may beF804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 18 of 123

extended by the consumer (e.g. byfreezing).At a minimum, records shall beretained for the shelf life of theproduct plus 12 months.3.4Internal auditsSOIThe company shall be able to demonstrate that it verifies the effective application of thefood safety plan and the implementation of the requirements of the Global Standard forFood Safety.ClauseRequirements3.4.1There shall be a scheduledprogramme of internal audits.FundamentalConformsAt a minimum, the programme shallinclude at least four different auditdates spread throughout the year.The frequency at which each activityis audited shall be established inrelation to the risks associated withthe activity and previous auditperformance. All activities shall becovered at least once each year.At a minimum, the scope of theinternal audit programme shallinclude the: HACCP or food safety plan,including the activities toimplement it (e.g. supplierapproval, corrective actions andverification)prerequisite programmes (e.g.hygiene, pest control)food defence and food fraudprevention plansprocedures implemented toachieve the Standard.Each internal audit within theprogramme shall have a definedF804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 19 of 123

scope and consider a specific activityor section of the HACCP or foodsafety plan.3.4.23.4.3Internal audits shall be carried out byappropriately trained, competentauditors. Auditors shall beindependent (e.g. not audit theirown work).The internal audit programme shallbe fully implemented. Internal auditreports shall identify conformity aswell as non-conformity and includeobjective evidence of the findings.The results shall be reported to thepersonnel responsible for the activityaudited.Corrective and preventive actions,and timescales for theirimplementation, shall be agreed andtheir completion verified.3.4.4In addition to the internal auditprogramme, there shall be aseparate programme of documentedinspections to ensure that thefactory environment and processingequipment are maintained in asuitable condition for foodproduction. At a minimum, theseinspections shall include: hygiene inspections to assesscleaning and housekeepingperformancefabrication inspections toidentify risks to the product fromthe building or equipment.The frequency of these inspectionsshall be based on risk but will be noF804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 20 of 123

less than once per month in openproduct areas.3.5Supplier and raw material approval and performance monitoring3.5.1Management of suppliers of raw materials and packagingSOIThe company shall have an effective supplier approval and monitoring system to ensurethat any potential risks from raw materials (including primary packaging) to the safety,authenticity, legality and quality of the final product are understood and managed.ClauseRequirements3.5.1.1The company shall undertake adocumented risk assessment of eachraw material or group of rawmaterials including primarypackaging to identify potential risksto product safety, legality andquality. This shall take into accountthe potential for:Fundamental Conformsallergen contaminationforeign-body risksmicrobiological contaminationchemical contaminationvariety or species crosscontaminationsubstitution or fraud (see clause5.4.2)any risks associated with rawmaterials which are subject tolegislative control.Consideration shall also be given tothe significance of a raw material tothe quality of the final product.The risk assessment shall form thebasis for the raw materialacceptance and testing procedureand for the processes adopted forsupplier approval and monitoring.F804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 21 of 123

The risk assessment for a rawmaterial shall be updated: 3.5.1.2when there is a change in a rawmaterial, the processing of a rawmaterial, or the supplier of a rawmaterialif a new risk emergesfollowing a product recall orwithdrawal, where a specific rawmaterial has been implicatedat least every 3 years.The company shall have adocumented supplier approvalprocedure to ensure that allsuppliers of raw materials, includingprimary packaging, effectivelymanage risks to raw material qualityand safety and are operatingeffective traceability processes. Theapproval procedure shall be basedon risk and include either one or acombination of: a valid certification to theapplicable BRC Global Standardor GFSI-benchmarked standard.The scope of the certificationshall include the raw materialspurchasedsupplier audits, with a scope toinclude product safety,traceability, HACCP review andgood manufacturing practices,undertaken by an experiencedand demonstrably competentproduct safety auditor. Wherethe supplier audit is completedby a second or third party, thecompany shall be able to: demonstrate thecompetency of theauditorF804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 22 of 123

confirm that thescope of the auditincludes productsafety, traceability,HACCP review andgood manufacturingpractices obtain and review acopy of the full auditreportor 3.5.1.3where a valid risk-basedjustification is provided and thesupplier is assessed as low riskonly, a completed supplierquestionnaire may be used forinitial approval. Thequestionnaire shall have a scopethat includes product safety,traceability, HACCP review andgood manufacturing practices,and it shall have been reviewedand verified by a demonstrablycompetent person.There shall be a documented processfor ongoing supplier performancereview, based on risk and definedperformance criteria. The processshall be fully implemented.Where approval is based onquestionnaires, these shall bereissued at least every 3 years andsuppliers shall be required to notifythe site of any significant changes inthe interim, including any change incertification status.Records of the review shall be kept.3.5.1.4The site shall have an up-to-date listor database of approved suppliers.This may be on paper (hard copy) orF804a: Issue 8 Auditor Checklist/Site Self-Assessment ToolVersion 1: August 2018BRC Global Standard for Food SafetyPage 23 of 123

it may be controlled on an electronicsystem.The list or relevant components ofthe database shall be readilyavailable to the relevant staff (e.g. atgoods receipt).3.5.1.5Where raw materials (includingprimary packaging) are purchasedfrom companies that are not themanufacturer, packer orconsolidator (e.g. purchased from anagent, broker or wholesaler), the siteshall know the identity of the lastmanufacturer or packer, or for bulkcommodity products theconsolidation place of the rawmaterial.Information to enable the approvalof the manufacturer, packer orconsolidator, as in clauses 3.5.1.1and 3.5.1.2, shall be obtained fromthe agent/broker or directly from thesupplier, unless the agent/broker isthemselves certificated to a BRCStandard (e.g. BRC Global Standardfor Agents and Brokers) or astandard benchmarked by GFSI.3.5.1.6The company shall ensure that itssuppliers of raw materials (includingprimary packaging) have an effectivetraceability system. Where a supplierhas been approved based on aquestionnaire instead of certificationor audit, verification of the supplier’straceability system sha

F804a: Issue 8 Auditor Checklist/Site Self-Assessment Tool BRC Global Standard for Food Safety Version 1: August 2018 Page 6 of 123 departmental managers or their deputies shall be available as required during the audit. 1.1.12 The site's senior management shall ensure that the root causes of any non-conformities against the Standard