Transcription

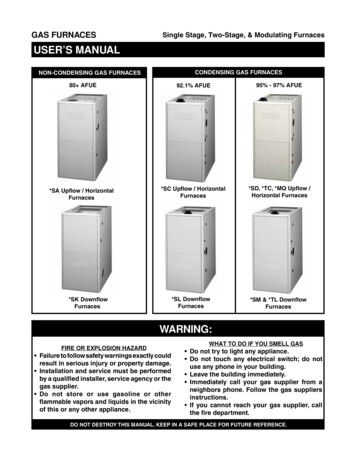

GAS FURNACESSingle Stage, Two-Stage, & Modulating FurnacesUSER’s MANUALNON-CONDENSING GAS FURNACESCONDENSING GAS FURNACES80 AFUE92.1% AFUE95% - 97% AFUE*SA Upflow / HorizontalFurnaces*SC Upflow / HorizontalFurnaces*SD, *TC, *MQ Upflow /Horizontal Furnaces*SL DownflowFurnaces*SK DownflowFurnaces*SM & *TL DownflowFurnacesWARNING:FIRE OR EXPLOSION HAZARD Failure to follow safety warnings exactly couldresult in serious injury or property damage. Installation and service must be performedby a qualified installer, service agency or thegas supplier. Do not store or use gasoline or otherflammable vapors and liquids in the vicinityof this or any other appliance.WHAT TO DO IF YOU SMELL GAS Do not try to light any appliance. Do not touch any electrical switch; do notuse any phone in your building. Leave the building immediately. Immediately call your gas supplier from aneighbors phone. Follow the gas suppliersinstructions. If you cannot reach your gas supplier, callthe fire department.DO NOT DESTROY THIS MANUAL. KEEP IN A SAFE PLACE FOR FUTURE REFERENCE.

2

TABLE OF CONTENTSIMPORTANT SAFETY INFORMATION.4Gas Supply & Piping.4Venting System.4Clearances to Combustibles.5Sources of Corrosion.5Filter.5Flood Damage.5About the furnace.6Introduction.6Category I Furnaces.6Category IV Furnaces.6Filter.6Thermostat.6Furnace Location.6COMPONENT Locations fornon-condensing type furnaces.7Single Stage & 2-Stage Models.7COMPONENT Locations forcondensing type furnaces.8Single Stage Models.8Two-Stage Models.9STARTUP & SHUTDOWN. 10Starting the Furnace. 10Shutting Down the Furnace. 10Troubleshooting. 10Maintenance & INSPECTION. 11Furnace & Air Ducts. 11Venting System. 11Blower & Filter . 11Burner Operation . 11New Construction . 11Maintenance Table . 113

Important SAFETY INFORMATIONSafety markings are used frequently throughout thismanual to designate a degree or level of seriousness andshould not be ignored. WARNING indicates a potentiallyhazardous situation that if not avoided, could result inpersonal injury or death. CAUTION indicates a potentiallyhazardous situation that if not avoided, may result in minoror moderate injury or property damage.WARNING:The safety information listed below must befollowed during the installation, service, andoperation of this furnace. Failure to follow safetyrecommendations could result in possibledamage to the equipment, serious personalinjury, or death.WARNING:PROPOSITION 65 WARNING: This productcontains chemicals known to the state ofCalifornia to cause cancer, birth defects or otherreproductive harm.WARNING:This furnace is not approved for installation inmobile homes. Installing this furnace in a mobilehome could cause fire, property damage, and/or personal injury.GAS SUPPLY & PIPING WHAT TO DO IF YOU SMELL GASDo not try to light any appliance.Do not touch any electrical switch; do not useany phone in your building.Leave the building immediately.Immediately call your gas supplier from aneighbors phone. Follow the gas suppliersinstructions.If you cannot reach your gas supplier, call thefire department.Installation and service must be performed bya qualified installer, service agency or the gassupplier.This furnace does not have a pilot. It is equipped withan ignition device which automatically lights the burner.DO NOT light the burner by hand.4IMPORTANT NOTE: If the gas supply fails to shut offor if overheating occurs, shut off the gas valve tothe furnace before shutting off the electrical supply!WARNING:The furnace was shipped from the factoryequipped to operate on natural gas. Conversionto LP/propane gas must be performed by alicensed HVAC technician using a factorysupplied conversion kit. Failure to use theproper conversion kit can cause fire, explosion,property damage, carbon monoxide poisoning,personal injury, or death.WARNING:All gas piping and shutoff valves must beinstalled in compliance with local codes andutility regulations by licensed installers. DONOT attempt to modify, or tap into existinggas lines yourself. Fire or explosion may resultcausing property damage, personal injury orloss of life. Failure to follow the safety warningsexactly could result in serious injury, death orproperty damage.VENTING SYSTEMWARNING:It is imperative to maintain proper operationof the venting system, including the masonrychimney (if applicable). Insufficient ventingcould create the production of excessiveamounts of Carbon Monoxide (CO) - a colorless,odorless gas that is produced during incompletecombustion of any fuel. It can cause deathwithout warning. Carbon monoxide poisoningcan cause flu- like symptoms and also dizziness,fatigue, headaches, nausea, and irregularbreathing.If you suspect that you are experiencing COpoisoning, get fresh air immediately. Leave thehome and call for assistance from a neighbor’shome. The U.S. Consumer Product Safety Commission (CPSC)recommends every home have a Carbon Monoxide

Important SAFETY INFORMATIONdetector in hallways near the bedrooms in each sleepingarea. CO detectors should be certified to the mostrecent requirements of the UL, IAS OR CSA Standardand should be installed, operated, and maintained inaccordance with the detector manufacturers instructions.CAUTION:This furnace requires unrestricted airflow forcombustion and ventilation. For proper andsafe operation, it is extremely important thatthe furnace receives an unobstructed flow ofclean, fresh air to properly burn the fuel gas. Ifthis flow of air is restricted, the partially burnedcombustion gases may create dangerousamounts of carbon monoxide that can causepersonal injury or death. Do not block or obstruct air openings on the furnace, airopenings or spacings around the furnace area or theroom or closet the furnace is in. Furniture and draperyshould be arranged so that the supply air registers andreturn grilles are not obstructed. If your furnace obtains its air through a pipe to theoutdoors, do not allow the inlet of the pipe to becomeblocked. If the furnace is operated without adequateair for combustion, the flame roll-out switch will open,turning off the gas supply to the burners. This indicatesthat a serious problem with the burners has occurredand must be corrected immediately. Only a licensedHVAC technician can reset this switch. Before remodeling near the furnace, consult with alocal code official or the National Fuel Gas Code tomake sure you will be in compliance with supplyingadequate air for combustion. By erecting new walls,it is sometimes possible to inadvertently restrict thefurnace’s air supply. You can find more informationabout supplying combustion air in the NFGC, which isavailable at many libraries.CLEARANCES TO COMBUSTIBLESWARNING:Do not place combustible materials on or againstthe furnace cabinet or within 6 inches of the ventpipe. Furnace area must be kept clear and freeof combustible materials, gasoline and otherflammable vapors and liquids. A fire or explosionmay result causing property damage, personalinjury or loss of life. Failure to follow the safetywarnings exactly could result in serious injury,death or property damage.The furnace is designed to have certain clearances tocombustible items such as wood, paper, etc. Some typesof insulation are combustible. If your furnace is installedin an attic, near unfinished walls, or in other insulatedspace, keep area surrounding the furnace free of insulatingmaterial.SOURCES OF CORROSIONIt is known that certain common household chemicals cancause heat exchanger corrosion if the vapors are pulled intothe furnace’s burners The following is a list of chemicalsthat should not be used or stored near the furnace.Do not store these chemicals near the furnace: Permanent wave solutions Chlorinated waxes and cleaners Chlorine based swimming pool chemicals Water softening chemicals De-icing salts or chemicals Carbon tetrachloride Halogen type refrigerants Cleaning solvents (perchloroethylene) Printing inks, paint removers, varnishes, etc. Hydrochloric acid Cements and glues Antistatic fabric softeners Masonry acid washing materialsFILTERWARNING:Never operate the furnace without a filter inplace. Accumulating dust in the return air canbuild up on internal components, resultingin loss of efficiency, equipment damage, andpossible fire.Keep air filters cleaned. Clean or replace filter to maintainproper airflow and achieve maximum efficiency. Refer topage 11 for Maintenance & Inspection information.FLOOD DAMAGEWARNING:Do not use this furnace if any part has beenunder water. A flood damaged furnace isextremely dangerous. Attempts to use thefurnace can result in fire or explosion. A qualifiedservice agency should be contacted to inspectthe furnace and to replace all gas controls,control system parts, electrical parts that havebeen wet or the furnace if deemed necessary.5

About the furnaceIntroductionCongratulations on the purchase on your new furnace!With our dedication to quality, superior reliability, andoutstanding warranty, we know you will be pleased withthis new appliance. This furnace has been designed andbuilt to provide many years of safe and dependable homecomfort, providing it is properly installed and regularmaintenance has been performed. Improper use orinsufficient maintenance can shorten the life of the furnaceand result in serious personal injury or property damage.Please read this manual thoroughly and familiarize yourselfwith the safety, operation and maintenance procedures forthis furnace. DO NOT DESTROY THIS MANUAL. KEEPIN A SAFE PLACE FOR FUTURE REFERENCE.Your furnace is designed to fulfill the requirements of beingclassified as either a Category I or Category IV furnace.These classifications are related to the furnace’s AnnualFuel Utilization Efficiency (AFUE) rating, the percentageof fuel that is converted into usable heating energy.The furnace components shown on pages 7 - 9 will helpto identify and locate various parts of the furnace. Thecomponent you need to familiarize yourself with is thegas valve. You will use this to turn the furnace on and off.There are no user serviceable parts. All repairs mustbe performed by a licensed HVAC technician.Category I (Non-Condensing) FurnacesThese furnaces typically have an AFUE rating of about80% and may be vented through a properly designed metalvent or masonry chimney. This venting system needs tobe primarily vertical, so that the hot combustion productswill develop a natural upwards draft action.Category IV (Condensing) FurnacesCategory IV furnaces typically have an AFUE rating over90% and are mainly vented through plastic PVC pipe.These furnaces also produce liquid condensate whichis slightly acidic. The vent pipe must be sloped upwardsaway from the furnace to properly drain the condensateback to the condensate disposal system. Condensing type furnaces require condensate drainlines to be properly installed by the installer. Dependingon your configuration, the drain lines may be routedout the left or right sides of the furnace. These drainlines must maintain a downward slope to ensure propercondensate drainage. Condensate must flow freely during furnace operation.The homeowner must make sure the condensate drainlines do not become blocked, pinched or crushed. If the furnace is installed in an area where temperaturesfall below freezing, special precautions must be madefor insulating condensate drain lines that drain to theoutdoors. If condensate freezes in the lines, this willcause the condensate drain switch to shut down6the furnace. Only a licensed HVAC technician canreset this switch.FILTERWARNING:Never operate the furnace without a filter inplace. Accumulating dust in the return air canbuild up on internal components, resultingin loss of efficiency, equipment damage, andpossible fire. Air filter(s) are not supplied with the furnace asshipped from the factory. The installer must providea high velocity filter and rack for a filter in the return airduct adjacent to the furnace, or in a return air grill tothe furnace. The furnace should always have a clean filter locatedeither at the air return on the furnace or in an air returnregister. If the filter becomes dirty, it should be cleanedor replaced. New or newly renovated homes may require morefrequent changing until the construction dust hasminimized. Filters designed to remove smaller particlessuch as pollen, may require additional maintenance. Always reinstall the doors on the furnace after servicingor cleaning/changing the filters. Do not operate thefurnace without all doors and covers in place.THERMOSTATThis family of furnaces includes single stage, two-stage andmodulating capabilities.These different capabilities requiredifferent thermostats to reach their best performance. Single stage furnaces (SA, SK, SC, SL, SD, & SMmodels) should be controlled by a conventional singlestage thermostat. Two-stage furnaces (TA, TK, TC & TL models) willperform best with a conventional two - stage thermostat.NOTE: It is possible to control two

Air filter(s) are not supplied with the furnace as shipped from the factory. The installer must provide a high velocity filter and rack for a filter in the return air duct adjacent to the furnace, or in a return air grill to the furnace. The furnace should always have a clean filter located