Transcription

CaleffiNorthAmerica,America,Inc.Caleffi NorthInc.th3883W. Milwaukee9850 South54 StreetRdMilwaukee,Wisconsin 53208Franklin, WI 53132T: 414.238.2360414.421.1000 F:T:F:414.421.2878414.238.2366Dear Plumbing and Hydronics Professional,Dear Hydronic Professional,How often do yound turn on faucets, bathtubs or showers, and thenof idronicsCaleffi’ssemi-annualjournalWelcometo the2 editionwaitfor warmwaterto arrive?This–iscommonin manydesignhomesandforhydronic professionals.commercial buildings. It results in wasted water, wasted energy andannoyedoccupants.of idronics was released in January 2007 and distributed to overThe 1st edition80,000 people in North America. It focused on the topic hydraulic separation. Fromthe feedback received, it’s evident we attained our goal of explaining the benefitsA Technical JournalfromCaleffi Hydronic SolutionsCALEFFI NORTH AMERICA, INC3883 W. Milwaukee RdMilwaukee, Wisconsin 53208 USATel: 414-238-2360FAX: 414-238-2366E-mail: idronics@caleffi.comWebsite: www.caleffi.usTo receive future idronics issuesFREE, register online www.caleffi.us Copyright 2017Caleffi North America, Inc.Printed: Milwaukee, Wisconsin USAMostpeople would be surprised to learn that several thousandand proper application of this modern design technique for hydronic systems.gallons of heated water is wasted in a typical household, over a year,If you haven’tyet receiveda copy oftemperatureidronics #1, youdo sosending in thewaitingfor waterat the desiredto canarriveat byfixtures.attached reader response card, or by registering online at www.caleffi.us. Thepublication will be mailed to you free of charge. You can also download theThisissue journalof idronicsshowshowourtoWebavoidcompleteas a PDFfile fromsite.this waste and annoyanceusing recirculating domestic hot water systems. They range fromThis seconddirt buildings,in hydronic systems.Thoughnot a rinandsmallto complexmultitopic to our industry, the use of modern high-efficiency equipment demands abranchsystemsin largerthoroughunderstandingof buildings.the harmful effects of air and dirt, as well as knowledgeon how to eliminate them. Doing so helps ensure the systems you design willoperatemethodsat peak efficiencyand providetrouble-freeservice.Modernand hardwarecanlongprovidethe xrecirculatingDHWWe trust you will find this issue of idronics a useful educational tool and a handysystems.pagesaheaddescribeto size,detailand adjustreferenceThefor yourfuturehydronicsystemhowdesigns.We alsoencourageyou to sendus feedbackon this issueof idronics using the attached reader response card or bythesestate-of-the-artsystems.e-mailing us at idronics@caleffi.com.We hope you enjoy this issue and encourage you to send us anyfeedbackSincerely,about idronics by e-mailing us at idronics@caleffi.com.For prior issues please visit us at www.caleffi.us, and click on theicon. There you can download the PDF files. You can alsoMark OlsonGeneraltoManager,registerreceive hard copies of future issues.Caleffi North America, Inc.Mark OlsonGeneral Manager & CEOINDEX1. INTRODUCTIONSUMMARY2. SINGLE-LOOP RECIRCULATION SYSTEMSAPPENDIX A: PIPING SYMBOL LEGEND3. MULTIPLE-BRANCH RECIRCULATIONAPPENDIX B: HEAD LOSS ESTIMATING METHODSSYSTEMS4. DESIGN OF MULTI-BRANCH RECIRCULATIONSYSTEMS5. ELECTRONICALLY-MANAGED RECIRCULATIONSYSTEMSDisclaimer: Caleffi makes no warranty that the information presented in idronics meets the mechanical, electrical or other code requirements applicable within agiven jurisdiction. The diagrams presented in idronics are conceptual, and do not represent complete schematics for any specific installation. Local codes mayrequire differences in design, or safety devices relative to those shown in idronics. It is the responsibility of those adapting any information presented in idronics toverify that such adaptations meet or exceed local code requirements.10%Cert no. XXX-XXX-XXXX

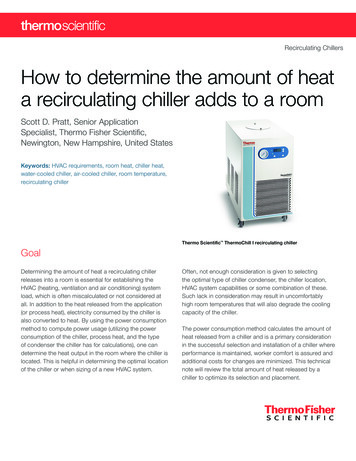

Recirculating Domestic Hot Water SystemsFigure 1-11. INTRODUCTIONAll people instinctively desire warm water for washing.Throughout human history that desire has been met inmany ways—from iron pots suspended over fires, tomodern electronically-controlled tankless water heaters.idronics 11 provides an overview of thehistory of domestic water heating.A reliable source of clean and safe domestic hot water(DHW) is now a requirement in most buildings intended forhuman occupancy. The importance of domestic hot waterin providing comfort, convenience and hygiene cannot beoverstated. Delivering it remains one of the most importantresponsibilities of plumbing system designers.There are currently many options for heating domesticwater, using almost any available fuel. Once the wateris heated, the building’s plumbing system must deliverit to fixtures such as showers, tubs, sinks, dishwashers,clothes washers or other processes requiring hot water.The ability of different plumbing systems to deliver hotwater efficiently and safely varies considerably. Forexample, a bathroom sink located 5 feet from a consistentsource of domestic hot water would likely have heatedwater at an acceptable delivery temperature flowing fromits tap within 2 seconds of opening the faucet. The samefixture located 75 feet from the hot water source may notreceive hot water at the same acceptable temperaturefor 30 seconds or more after the faucet is opened. Thisdelay between opening a faucet and having domestic hotwater at an acceptable temperature flow from the fixtureis undesirable from several standpoints:First, it’s annoying to building occupants. People in mostdeveloped countries have become intolerant of waitingfor expected results. They are accustomed to instantlight at the flip of a switch, instant heat from the burnerof a gas stove, and instant operation of an automobilewhen the key is turned or a button is pushed. It’s notsurprising they expect instant hot water to flow from ahot water faucet.Second, the cool water that flows down the drainwhile hot water is making its way from the heat sourceto the faucet is wasted, as is the heat that this wateronce contained. Wasted fresh water (hot and cold) hasbecome a major concern in many areas of North Americawhere long-term drought conditions have worsened atthe same time as population growth, and thus demandfor fresh water, has accelerated.Studies have shown that the average home wastes morethan 3,650 gallons of heated water per year waiting forhot water at the desired temperature to arrive at fixtures.1Assuming this wasted water was originally heated from 50to 120ºF using electricity priced at 0.15/kWhr, the wastedenergy cost is about 94 per year. This is in addition tothe cost of the water itself. Furthermore, some of the heatdissipated from the hot water distribution piping into thebuilding adds to that building’s cooling load, resulting infurther energy costs.1 Klein, Gary. “Hot-Water Distribution Systems Part 1.” Plumbing Systems & Design.Mar/Apr 2004.3

Beyond the costs of wasted water and energy, it’simportant to understand that some domestic hot waterdelivery systems can create conditions that allowpathogens, such as Legionella bacteria, to thrive. Thesepathogens represent a serious health threat. They aremore likely to exist in domestic hot water delivery systemsthat contain piping where heated water could remainstagnant, in some cases for days. They can also developin domestic hot water systems that are continuallyoperated at reduced water temperatures—typically lessthan 140ºF at the heat source. These conditions creategrowth environments favorable to the bacteria. If watercontaining these pathogens is discharged through fixturessuch as showers, the mist created by the shower can beinhaled. This can lead to a serious and even potentiallyfatal disease. Thus, all domestic hot water deliverysystems should be designed to minimize the potential forsuch pathogens to exist.One of the best ways to minimize wasted water andenergy in domestic hot water delivery systems is bycirculating hot water through the system at times whenit would otherwise not be moving because of no demandat the fixtures. Such systems are called “recirculating”domestic hot water systems. They are the principal focusof this issue of idronics.CONCEPT OF A RECIRCULATING DHW SYSTEMFigure 1-2 shows a simple trunk and branch plumbingdistribution system that supplies hot and cold water tothree lavatories and two showers.Domestic hot water is supplied from a tank-type waterheater to the hot water trunk. It flows along the trunk pipingand eventually into a “riser” that leads to the fixture withthe demand. Once that demand stops, hot water flow alsostops in all portions of the system. The water in the trunkand risers cools as heat is dissipated from the piping.If another demand for DHW occurs within a few minutes,and through the same portion of the distribution system,the water temperature in that piping may have onlydecreased a few degrees, especially if the piping was wellFigure 1-2isolation valvesDHW risercold water riserDHW trunkcold water trunkstandard trunk & riser plumbing systemcoldwatersupplystorage water heater4

insulated. The temperature at which it emerges from thefixture may be suitable within 3 or 4 seconds of openingthe faucet. This scenario is probably acceptable to theperson using the fixture.However, if there is no demand for DHW through thepiping for longer periods of time, perhaps an hour, orovernight, the water will have cooled substantially. Whena DHW demand occurs, it will take substantially longer—perhaps 30 seconds or more depending on pipe sizes,length of flow path, and air temperature surrounding thepiping—before DHW at the desired temperature flowsfrom the fixture. This can annoy the person waiting forthe anticipated comfort of the hot water at a desirabletemperature. It also wastes most of the water betweenthe heat source and fixture.Figure 1-3 shows how the standard system of Figure 1-2can be modified to include recirculation.The system now includes a small recirculation circulatorand a pipe that brings hot water not drawn off at a fixtureback to the heat source. The hot water piping now formsa complete circuit with the heat source, as compared tothe “one-way” path for hot water in the traditional trunkand branch system of Figure 1-2. Each fixture is suppliedby a short “riser” pipe from the hot water trunk. This risershould be as short as possible to minimize the watervolume not contained within the recirculating circuit.The end of the hot water supply piping connects to areduced-size return pipe, which leads back through thecirculator to the heat source. A check valve is installedin this return pipe to ensure that cold water cannot flowbackward towards the hot water risers.The size of the return pipe is smaller than the hot watersupply pipe. This is possible because the return pipe isnot responsible for carrying hot water to any fixture. Itonly has to carry sufficient flow to compensate for theFigure 1-3check valveDHW trunkcold water trunkrecirculationcirculatorcoldwatersupplyDHW return piperecirculating trunk & riser plumbing systemstorage water heater5

Figure 1-42. SINGLE-LOOP RECIRCULATION SYSTEMSThe fundamental objectives of adding a recirculatingfunction to a domestic hot water delivery system are:1. To ensure delivery of heated domestic water at allfixtures within 1-3 seconds of opening a faucet, orotherwise creating a demand.2. To significantly reduce water waste associated withclearing hot water piping of cooler water after a period ofno demand.The basic recirculation system shown in Figure 1-3could achieve these objectives. However, the plumbingdesigner also needs to ensure that:heat loss of the hot water supply piping—a quantity thatcan be calculated based on information given in a latersections.The recirculation circulator must be compatible with freshwater. Any wetted components within that circulator mustbe made of bronze, stainless steel or a suitable engineeredpolymer. These components must also conform to theno-lead requirement that applies to all domestic waterplumbing components within the United States.In some systems, the recirculation circulator operatescontinuously (24/7). In other systems, it runs based on a timerwith specific user-set on-times and off-times; the off-timestypically are overnight hours, or times when the building haslittle, if any, need for DHW throughout its plumbing system.The circulator might even operate automatically based on“learned” DHW usage patterns that have been sampledover several days. In any case, the objective is to ensurethat hot water is immediately available at the fixturesbased on some criteria that are acceptable to the buildingoccupants, and if possible, reduce electrical use by turningthe circulator off at other times.The system shown in Figure 1-3 is very simplified. Itdoes not include the components necessary to ensurethat domestic hot water at potentially high temperaturesdoesn’t reach the fixtures, nor does it ensure that stabletemperatures are maintained within the recirculationcircuit. The components and details necessary for thesefunctions are discussed in section 2, as well as in latersections of this issue of idronics.63. The water temperature delivered from any fixture issafe under all conditions.4. The domestic hot water delivery system does notcreate conditions favorable to growth of pathogens suchas Legionella bacteria.This section combines all four requirements into systemsthat are suitable for homes or small commercial buildingswhere a single-loop recirculating system is feasible. Latersections expand these concepts into more elaboratesystems suitable for larger commercial or institutionalbuildings.BURN PROTECTIONOne of the greatest hazards associated with heatedwater is the risk of moderate to severe burns when skin isexposed to excessively heated water at sinks, showers,bathtubs or other fixtures.The ability of hot water to burn human

Caleffi North America, Inc. 9850 South 54th Street Franklin, WI 53132 T: 414.421.1000 F: 414.421.2878 Dear Hydronic Professional, Welcome to the 2nd edition of idronics – Caleffi’s semi-annual design journal for hydronic professionals.