Transcription

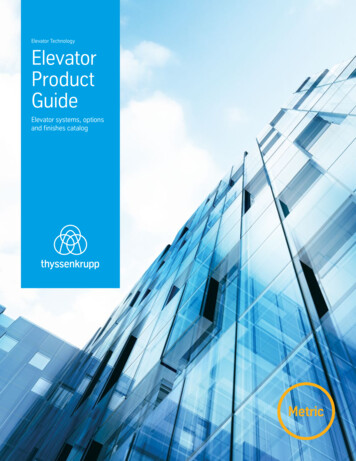

Elevator TechnologyElevatorProductGuideElevator systems, optionsand finishes catalogMetric

2 thyssenkrupp moves people –the future of urban mobility.In 40 short years, we’ve become one of the world’s leading elevator companies with uniqueengineering capabilities, offering next-generation solutions like MULTI, the ropeless elevator,ACCEL, an accelerated people mover and MAX, a cloud-based predictive maintenance service.Whether building a new state-of-the-art system or optimizing and modernizing existing ones,our solutions deliver crucial energy and time efficiencies, helping to address the challenges ofurbanization and transform cities into the best places to live.Customers in150countriesOver 900sales andservicelocations 8.550,000 employeesFigures for our Elevator Technology businessA trusted partnerWe support our customers throughout their project lifecycle, from thedesign to the end-of-life phase. Every step of the way, we strive to fullyunderstand their needs and consistently deliver the safest, highestquality passenger transportation solutions, maintenance andmodernization packages.Through our internal technical support function, International TechnicalServices Americas, thyssenkrupp trains its service technicians in amultibrand portfolio, enabling them to successfully service more than1.2 million units under maintenance.thyssenkrupp – the diversified industrial groupengineering.tomorrow.together – three words that describe who we are, what we do, and how we do it. Drivenby global megatrends such as urbanization and the need for efficient use of environmental resources, ourglobal community of more than 156,000 colleagues works together with our customers to harness ourengineering expertise and strive for technological and business solutions that satisfy the demand for “more”in a “better” way.Find out more: www.thyssenkrupp.com

3View from One World Trade CenterWe provide smart andinnovative products for a widevariety of applications: Passenger andfreight elevators Escalators and moving walks Passenger boarding bridges Stair and platform lifts Customized service andmodernization solutionsMercedes BenzMakkah Clock Tower/Source SL Raschthyssenkrupp Quartier

5ContentsLow-rise hydraulic elevators 06endura MRL – machine room-less 08endura – above-ground 10endura – below-ground 12endura – machine rooms and controllers 14Low-rise to mid-rise traction MRL elevators 16evolution 200 – overview 18evolution 200 – self supported 20synergy – self supported 22synergy – building supported – standard 23synergy – building supported – performance 24Support configurations 26Controller closets – self supported and building supported 28Mid-rise to high-rise traction elevators 30momentum – passenger standard and performance 32momentum – service standard 33Interior design 34Cab designs – laminate, steel and applied panel 36Finishes – color selections 39Cab accessory options – ceilings, handrails and sills 40Fixtures – standard and upgraded 41Upgraded and custom cabs 44Door and entrance configurations 48Innovations and enhancements 50AGILE – elevator technology 52TWIN – elevator system 54MAX – predictive maintenance 56Occupant evacuation operation 57Table of Contents

6 Reliable.Dependable.Powerful.Low-rise hydraulic elevatorsCost-effective, capable hydraulics get the job done, whether youare moving a few or even thousands of people each day.Small offices, shops, schools, worship facilitiesand hotels up to four stories need sensibleoptions in elevators. The uncomplicated designof the hydraulic elevator uses fewer movingparts to lift heavy loads and keepsmaintenance costs low. And you don't have tosacrifice building space or sustainability. Ourhydraulic elevators use environmentally-safefluids and we even make an innovative elevatorthat fits entirely in the hoistway.Speeds up to 1.0 m/sSave thousands.Low maintenance costs saves tens ofthousands spent over an elevator’s 25-yearlife span.Interior quality.UL–validated, low-emitting materials exceedstringent indoor air quality standards.Capacities up to 2268 kgYou can chooseenviromax, a productwith the PlatinumMaterial HealthCertificate.PLATINUM

endura MRLMachine ne roomand controllers08101214

8 Front opening (F)Hydraulic machine room-lessA Hoistway widthSendura MRLB Hoistway depthC Inside clear widthD Inside clear depthFGOE Door clear widthF Inside clear heightTwinpost above-groundG Door clear heightTravelSpeedCapacity1-Stage3861 mm 10.4, 0.56, 0.76 m/s953–1814 kg2-Stage7074 mm 10.4, 0.56, 0.76 m/s953–1814 kg3-Stage10.22 m 10.4, 0.5, 0.64, 0.76 m/s 953–1814 kg1, 2 & 3 – Stage JackJack typesO Minimum overheadTP Minimum pit depthS Safety beamT TravelGClick jack type for specific product specsPPassenger1- and 2-Stage3-StageCapacity(kg)HoistwayAxBHoistway 7AxBFront/rearInside clearCxDDoortypeDoor widthE953 32235 x 17532337 x 1753F1727 x 1295One-speed9142,732235 x 20512337 x 2051F/R1727 x 1308One-speed91411342540 x 17532642 x 1753F2032 x 1295One-speed106711342540 x 20512642 x 2051F/R2032 x 1308One-speed106713612540 x 19052642 x 1905F2032 x 1448One-speed106795313612540 x 22032642 x 2203F/R2032 x 1460One-speed106742540 x 21082642 x 2108F2032 x 1651One-speed10671588 42540 x 24072642 x 2407F/R2032 x 1664One-speed1067181442845 x 21082946 x 2108F2337 x 1651One-speed1067/12191814 42845 x 24072946 x 2407F/R2337 x 1664One-speed1067/12191588One-speedside opening doorsOne-speedcenter opening doorsDDBCCEEAAFront and rear opening (F/R)A Hoistway widthSB Hoistway depthC Inside clear widthD Inside clear depthDimensional data shown above is for both seismic and non-seismic zones and complies withcurrent ASME A17.1 and CSA B44 Safety Code for Elevators. Local codes may vary from thenational codes. Consult your thyssenkrupp Elevator representative for details.O Minimum overhead:Up to 0.5 m/s:1-Stage – 37082-Stage – 38613-Stage – 3937G Door clear height:2134 mm2235 mm 5Over 0.5 m/s:1-Stage – 37852-Stage – 38613-Stage – 3937S Safety beam requiredper OSHA 1926.502 6GOE Door clear widthF Inside clear heightG Door clear heightP Minimum pit depth:1219 mmT Max travel possible(mm): 11-Stage:Up to 0.5 m/s – 5766Over 0.5 m/s – 56902-Stage: 86873-Stage: 14,719O Minimum overhead1, 2 & 3 – Stage JackF Inside clear height:FTS Safety beamT TravelGPOne-speedside opening doors 1524 mm min. pit is required for additional travel. Travel above 4166 mm (1-Stage) or 7684 mm (2-Stage) or 11,138Amm (3-Stage) requires additional pit and/or overhead by adding 25 mm for every 25mm (1-Stage) or 51 mm (2-Stage)or 76 mm (3-Stage) of additional travel. Max increase 610 mm allowed in overhead.2 In areas where a 178 mm deep pit ladder is required, additional hoistway width or wall pocket will be required.3 T his capacity is not available with center-opening doors.4 To meet the requirements of IBC code for 2134 mm stretchers, a 1219 mm center-opening (for 1814 kg capacity only)or 1067 mm side opening (for 1588 kg or 1814 kg capacity) door is required. For a 1588 kg capacity car with front andrear doors, the doors must be in adjacent corners.5 Dimension shown is based on suspended ceiling design. An increase in cab height will result in an increase inoverhead requirements.6 Provided and installed by others, as directed by your thyssenkrupp Elevator representative. Clear overhead is shown tothe bottom of the safety beam.7 F or multiple elevators: Add 102 mm for a divider beam between hoistways.P Minimum pit depthOne-speedcenter opening doors1DDCBCEAEA

endura MRL 9Front opening (F)A Hoistway widthHydraulic machine room-lessSendura MRLB Hoistway depthC Inside clear widthD Inside clear depthFE Door clear widthG OF Inside clear heightTwinpost above-groundG Door clear height1, 2 & 3 – Stage JackO Minimum overheadP Minimum pit depthS Safety beamT TravelTGJack typesTravelSpeedCapacity1-Stage3861 mm 10.4, 0.56, 0.76 m/s2041–2268 kg2-Stage7074 mm0.4, 0.56, 0.76 m/s2041–2268 kg3-Stage10.22 m 110.4, 0.5, 0.64, 0.76 m/s 2041–2268 kgClick jack type for specific product specsPTwo-speedside opening doorsService1- and 2-Stage3-StageCapacity(kg)HoistwayAxBHoistway 6AxBFront/rearInside clearCxDDoortypeDoor width 3E20412235 x 29082337 x 2908F1727 x 2375Two-speed1219/137220412235 x 32832337 x 3283F/R1727 x 2388Two-speed1219/137222682235 x 30992337 x 3099F1727 x 2565Two-speed1219/137222682235 x 34372337 x 3473F/R1727 x 2578Two-speed1219/1372E2268H2235 x 32772337 x 3277F1727 x 2743Two-speed1219/1372A2268H2235 x 36512337 x 3651F/R1727 x 2756Two-speed1219/1372DBC2,6Front and rear opening (F/R)A Hoistway widthDimensional data shown above is for both seismic and non-seismic zones and complies withcurrent ASME A17.1 and CSA B44 Safety Code for Elevators. Local codes may vary from thenational codes. Consult your thyssenkrupp Elevator representative for details.SB Hoistway depthC Inside clear widthF Inside clear height:D Inside clear depthFE Door clear widthG2235 mm 4O2134 mmO Minimum overhead (mm):F Inside clear heightUp to 0.5 m/s:1-Stage – 37082-Stage – 38613-Stage – 3937G Door clear height1, 2 & 3 – Stage JackO Minimum overheadP Minimum pit depthS Safety beamT TravelTG Door clear height:Over 0.5 m/s:1-Stage – 37852-Stage – 38613-Stage – 3937S Safety beam requiredper OSHA 1926.502 5P Minimum pit depth 1:1219 mmT Max travel possible(mm):1-Stage:Up to 0.5 m/s – 5766Over 0.5 m/s – 56902-Stage: 86873-Stage: 14,719GP 1524 mm min. pit is required for additional travel. Travel above 4166 mm (1-Stage) or 7684 mm (2-Stage) or 11,138Amm (3-Stage) requires additional pit and/or overhead by adding 25 mm for every 25 mm (1-Stage) or 51 mm (2-Stage)or 76 mm (3-Stage) of additional travel. Max increase 610 mm allowed in overhead. (For 2041 and 2268 kg capacities,max additional travel and speed could be reduced based on cab weights. Consult your thyssenkrupp Elevatorrepresentative for details.)2 In areas where a 178 mm deep pit ladder is required, additional hoistway width or wall pocket will be required.3 W ith optional 1372 mm two-speed side opening door, hoistway width becomes 2489 mm.4 Dimension shown is based on suspended ceiling design. An increase in cab height will result in an increase inoverhead requirements.5 Provided and installed by others, as directed by your thyssenkrupp Elevator representative. Clear overhead is shown tothe bottom of the safety beam.6 F or multiple elevators: Add 102 mm for a divider beam between hoistways.1Two-speedside opening doorsBDCEA

10 Front opening (F)Hydraulic with machine roomA Hoistway widthSenduraB Hoistway depthC Inside clear widthD Inside clear depthFGOE Door clear widthF Inside clear heightTwinpost above-groundTravelSpeedCapacity1-Stage3861 mm10.4, 0.56, 0.76 m/s953–1814 kg2-Stage7074 mm 10.4, 0.56, 0.76 m/s953–1814 kg3-Stage10.22 m0.4, 0.5, 0.64, 0.76 m/s953–1814 kg11, 2 & 3 – Stage JackJack typesG Door clear heightO Minimum overheadP Minimum pit depthTS Safety beamT TravelGClick jack type for specific product specsPPassenger1- and 2-Stage3-StageCapacity(kg)HoistwayAxBHoistway 7AxBFront/rearInside clearCxDDoortypeDoor widthE953 32235 x 17532337 x 1753F1727 x 1295One-speed91495332235 x 20512337 x 2051F/R1727 x 1308One-speed91411342540 x 17532642 x 1753F2032 x 1295One-speed106711342540 x 20512642 x 2051F/R2032 x 1308One-speed106713612540 x 19052642 x 1905F2032 x 1448One-speed106713612,72540 x 22032642 x 2203F/R2032 x 1460One-speed106742540 x 21082642 x 2108F2032 x 1651One-speed10671588 42540 x 24072642 x 2407F/R2032 x 1664One-speed1067181442845 x 21082946 x 2108F2337 x 1651One-speed1067/12191814 42845 x 24072946 x 2407F/R2337 x 1664One-speed1067/12191588One-speedside opening doorsOne-speedcenter opening doorsDDBCCEEAAFront and rear opening (F/R)A Hoistway widthSB Hoistway depthC Inside clear widthD Inside clear depthDimensional data shown above is for both seismic and non-seismic zones and complies withcurrent ASME A17.1 and CSA B44 Safety Code for Elevators. Local codes may vary from thenational codes. Consult your thyssenkrupp Elevator representative for details.2134 mm2235 mm 5O Minimum overhead (mm):Up to 0.5 m/s:1-Stage – 37082-Stage – 38613-Stage – 3937G Door clear height:Over 0.5 m/s:1-Stage – 37852-Stage – 38613-Stage – 3937S Safety beam requiredper OSHA 1926.502 6O1219 mmT Max travel possible(mm): 11-Stage:Up to 0.5 m/s – 5766Over 0.5 m/s – 56902-Stage: 86873-Stage: 14,719E Door clear widthF Inside clear heightG Door clear heightP Minimum pit depth: ax travel possible in note T (above) is obtained by adding 25 mm for every 25mm (1-Stage) or 51 mm (2-Stage) or 76Mmm (3-Stage) of net travel over the standard. Max increase 610 mm allowed in overhead. (For 2021 and 2268 kgcapacities, max additional travel and speed could be reduced based on cab weights. Consult your thyssenkruppElevator representative for details.)2 In areas where a 178 mm deep pit ladder is required, additional hoistway width or wall pocket will be required.3 T his capacity is not available with center-opening doors.4 To meet the requirements of IBC code for 2134 mm stretchers, a 1219 mm center-opening (for 1814 kg capacity only)or 1067 mm side opening (for 1588 kg or 1814 kg capacity) door is required.5 Dimension shown is based on suspended ceiling design. An increase in cab height will result in an increase inoverhead requirements.6 Provided and installed by others, as directed by your thyssenkrupp Elevator representative. Clear overhead is shown tothe bottom of the safety beam.7 F or multiple elevators: Add 102 mm for a divider beam between hoistways.*R efer to page 14 for elevator machine room sizes.1GO Minimum overhead1, 2 & 3 – Stage JackF Inside clear height:FTP Minimum pit depthS Safety beamT TravelGPOne-speedside opening doorsDOne-speedcenter opening doorsDCBCEAEA

endura 11Front opening (F)A Hoistway widthHydraulic with machine roomSenduraB Hoistway depthC Inside clear widthD Inside clear depthFE Inside clear heightG OF Door clear widthTwinpost above-groundG

Consult your thyssenkrupp Elevator representative for details. F Inside clear height: 2235 mm 5 G Door clear height: 2134 mm O Minimum overhead: Over 0.5 m/s: 1-Stage – 3785 2-Stage – 3861 3-Stage – 3937 Up to 0.5 m/s: (mm): 1-Stage – 3708 2-Stage – 3861 3-Stage – 3937 P S Safety beam required per OSHA 1926.502 6 Minimum pit depth: 1219 mm T Max travel possible 1 1-Stage: Up to 0.5 .