Transcription

OIL & GAS INDUSTRY – VALVE LUBRICATION

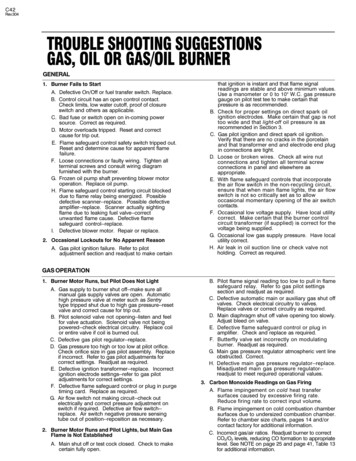

The RS Clare range of advanced Valve Lubricants forthe Oil & Gas Industry has been developed inconjunction with Original Equipment Manufacturersand Production, Drilling and Service Operators.RS Clare’s valve lubricants have been well proven inthe field providing the user with ‘failsafe’ and ‘costeffective’ valve lubrication.In the exploration and production of crude oil &natural gas, severe problems can be encountered dueto the presence of H2S, CO2, condensates,hydrocarbon solvents, acids and other chemicalspresent in the well production system.Such chemicals and compounds can breakdownconventional lubricants, resulting in the lubricantbeing ‘leached out’ of the valve cavity. This canrender the internal valve components dry, exposed towear and damage from increased friction andcorrosion and will permit the build up ofcontaminants in the valve cavity.This process can cause severe valve operationalproblems. Such problems include damage to thecomponent sealing surfaces and an increase in therequired actuation torque or ultimately in seizure ofthe valve.The function of the gate valve lubricant is to:Displace harmful chemicals and fluids fromthe valve cavity.Provide corrosion protection to the ‘exposed’internal valve components.Provide a ‘secondary seal’, thus reducing thebuild up of contaminants in the valve cavity,such as sand, that may be deposited from theflow line.Provide an integral lubricating film betweenthe gate & seat and to the gate stem thread,thus controlling friction and minimisingcomponent wear.The torque required to operate anun–lubricated valve at a specific pressure canbe as high as twice the torque figure for aneffectively lubricated valve.The lubricant must have high adhesion to theinternal surfaces of the valve cavity andcomponents to withstand the high cavitypressures and component contact stresses.GATE AND SEAT COMPONENTSRoutine valve re-lubrication using a premiumRS Clare valve lubricant is a highly importantaspect of preventative maintenance and will ensureoptimum operation.GATE VALVE LUBRICATIONGATE VALVE LUBRICANT PRODUCTSThe Standard Service lubricant, GP Valve Grease, isa mineral oil based grease with a concentration ofsolid lubricant. GP Valve Grease exhibits good metaladhesion and water resistance. However, fieldexperience has demonstrated that the performanceof Standard Service lubricants is limited by theaggressive production and process chemicals andalso the hydrocarbon fractions within the crude itself.In order to ensure optimum valve performance, anon-mineral oil based, premium RS Clare gate valvelubricant should be selected.

Valve Lubricant 601 is a fully synthetic productensuring long term lubricating and sealing qualitieswithin a temperature range of -20 F to 450 F.601 is specially formulated to provide optimumresistance to aggressive produced fluids and gasesand process chemicals.Valve Lubricant 601 is used to lubricate gateThe adhesive texture of 601 ensures maximumretention in the valve cavity during cycling. The useof 601 permits extended re-lubrication intervals whencompared with Standard Service valve lubricants.Valve Lubricant 601 has been field proven as aValve Lubricant 501, an ‘Extended TemperatureRange’ valve lubricant, has been developed to providecomparable performance to 601 within a temperaturerange of -75 F to 350 F.601 Cleaner is a non hazardous, syntheticcleaning fluid. It can be used to remove 601, 501and all other Clare valve lubricants during valverepair and refurbishment or to flush the valveduring in–situ maintenance.Where Oil & Gas is produced in cold climate regionslow temperature pumpability is important, similarlyvalve shutdown temperatures can be extremely low.501 permits lubricant mobility within the valve cavityat such temperatures, ensuring the valve can beopened or cycled within the rated torque range. Forproduction conditions, 501 remains stable atoperating temperatures up to 350 F.Resistance of valve lubricants tohydrocarbon fluid:A sample of lubricant is applied to a glass platewhich is then placed within a container ofhydrocarbon fluid. The hydrocarbon fluid breaksdown the GP Valve Grease Standard Servicelubricant, leaving only the solid lubricant in thebottom of the container. In the field, high frequencyre-lubrication is required to maintain a completecavity fill of the Standard Service lubricant.Valve Lubricant 601 is unaffected by thehydrocarbon fluid.valves that are installed in a large range of oilfieldproduction and drilling equipment. This unique ‘wideapplication’ capability of 601 allows the operator tostandardise on one gate valve lubricant whilstensuring maximum operational protection.high performance sealant. 601 may be injected into aleaking valve and will provide long term, highpressure sealing properties without hardening.Examples of equipment for productapplication:1. BOP STACK – GATE VALVES

2. SURFACE PRODUCTION TREE – GATE VALVES5. CHOKE MANIFOLD – GATE VALVES3. SUBSEA PRODUCTION TREE – GATE VALVES6. HEAT EXCHANGER – GATE VALVES4. SAND FILTER – GATE & PLUG VALVES7. SEPARATOR EQUIPMENT – GATE & PLUG VALVES

PLUG VALVE LUBRICATIONPLUG VALVE INSTALLED IN A SAND FILTER SYSTEMAs detailed in the application photographs, plugvalves are used as compact, shut-off valves in arange of production equipment downstream of theproduction tree. Plug valves are designed to operatewith a sealant type lubricant.When the lubricant is applied to the valve, it isdistributed between the seating faces of the valvebody and plug. The lubricant provides an integralsealing and corrosion preventative film. As the plug iscovered by the lubricant over all surfaces, a smooth,controlled actuation is achieved over extendedmaintenance periods.Valve Lubricant 601 is used for the lubrication andsealing of plug valves. 601 has been field proven toremain cohesive within the valve whilst providing thenecessary sealing. This is unlike other sealants whichmay harden, resulting in leakage and exceptionallyhigh actuation torques that can damage the valvestem.TAPER PLUG VALVE CROSS-SECTIONThe use of 601 in plug valves has allowed operators tostandardise on one lubricant product on all wellheadand downstream equipment for the lubrication of gateand plug valves.For operational temperatures to -75 F or at lowambient temperatures where pumpability is aproblem, Valve Lubricant 501 should be used.BALL VALVE LUBRICATIONBALL VALVE CROSS-SECTIONThe lubrication of a ball valve requires a differentpractice to the lubrication of either a gate valve orplug valve.Field experience has shown that greases and sealantscan cause severe problems with the seatarrangement. If a non-leaking ball valve is lubricatedwith an adhesive grease or sealant, the floatingspring loaded seats can become stuck within theirseat pockets. When the ball floats due to a pressuredifferential across the valve, the seats cannot trackthe ball and leakage can occur.A fluid type lubricant such as B70 or B70S shouldbe used to routinely flush and lubricate the valve.The fluid does not disrupt the operation of the seatand seal arrangement.B70 is a Standard Service ball valve lubricant.B70S is a synthetic ball valve lubricant designedto provide enhanced resistance to hydrocarbonfluids and gases, sour service, CO2, acids andcompletion fluids.For leaking ball valves, 601 should be injected, whichacts as a high pressure sealing compound withouthardening within the seal arrangement.SEAT AND SEAL ARRANGEMENT CROSS-SECTION

PRODUCT RANGE – APPLICATION & SERVICE CHARTLT Valve LubricantGate Valve-75 F to 250 F-59 C to 121 CHL LubricantGate Valve0 F to 500 F-18 C to 260 CGP Valve GreaseGate Valve0 F to 250 F-18 C to 121 CB70 Ball Valve OilBall Valve0 F to 250 F-18 C to 121 CB70S Ball Valve OilBall Valve-20 F to 350 F-29 C to 177 CLimited CompatibilityNo CompatibilityKeyHigh CompatibilityLUBRICANT APPLICATION EQUIPMENTRS Clare’s premium valve lubricants are adhesive, viscouslubricants designed for severe operational conditions. Theability of conventional air operated pumping equipment islimited when used with such lubricants, particularly in coldtemperatures or when the lubricant is to be pumped over along distance.Field experience has proven that high pressure pumpsystems incorporating a positive priming follower plate and ahigh ratio air pump are required to overcome such problems.RS Clare’s Technical Field Personnel can provide assistanceto operators in the selection of suitable pumping equipment.Acid-75 F to 350 F-59 C to 177 CDiesel Completion FluidGate / Plug ValveGas Well CondensateValve Lubricant 501High CO2-20 F to 450 F-29 C to 232 CH2S – Sour Crude & GasGate / Plug ValveSand IngressValve Lubricant 601ServiceSteam & Hot WaterTemperature RangeNatural GasApplicationStandard Crude OilProduct

non-mineral oil based, premium RS Clare gate valve lubricant should be selected. Valve Lubricant 601is a fully synthetic product ensuring long term lubricating and s ealing qualities within a temperature range of -20¡F to 450¡F. 601 is specially formulated to pr ovide optimum resistance to aggressive produced fluids and gases and process chemicals. The adhesive texture of 601 ensures maximum .