Transcription

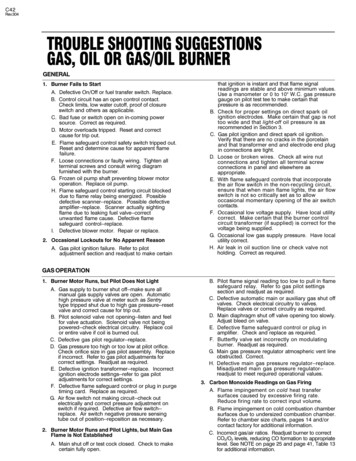

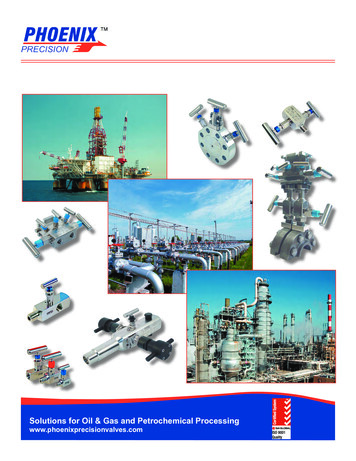

Solutions for Oil & Gas and Petrochemical Processingwww.phoenixprecisionvalves.com

Innovation in InstrumentationPhoenix Precision products are designed to meet and exceed the day-to-day expectations of end users. By implementingindustry feedback from engineers and instrumentation technicians, and incorporating results into the designs andspecifications of instrumentation valves and manifolds, Phoenix Precision develops ideas into innovation.DesignPhoenix incorporates all industrialstandards and codes into the designand testing of its products andutilizes current CAD systems todesign its products, ensuring thetechnical integrity of each productand the addressing of all pertinentspecifications. These disciplinesand engineering processes resultin superior quality and innovativeproduct.CNC MachiningLeading-edge CNC machiningtechnology allows Phoenix toaccurately convert detailedengineering specifications intoclose-tolerance, quality products,manufactured, assembled andtested in our North America facility.Quality AssurancePhoenix Precision is ISO 9001certified and employs rigid qualitycontrol, offers full materialtraceability on all pressurecontaining components as standard,and adheres to all applicable ASME,API, and MSS-SP design andtesting specifications. The criticaltest for instrumentation valves andmanifolds is successful performancein industrial applications. Phoenixproducts are utilized with confidencethroughout the oil, gas andpetrochemical processing industryand are backed by committedcustomer service.CERTIFICATEOF AUTHORIZATIONISSUEDBY ABSA2

DESIGN FEATURES AND SPECIFICATIONSDESIGN FEATURES AND SPECIFICATIONSHAND VALVESGAS MINI VALVESNEEDLE VALVES10,000 PSI NEEDLE VALVES45GAUGE VALVESGAUGE VALVES10,000 PSI GAUGE VALVESGAUGE BLOCK AND BLEED VALVES6BLOCK AND BLEED VALVESBLOCK AND BLEED VALVES10,000 PSI BLOCK AND BLEED VALVESDOUBLE BLOCK AND BLEED VALVES7MANIFOLD VALVES2, 3, 5-VALVE COPLANAR MANIFOLDS2, 3, 5-VALVE BOTTOM MOUNT MANIFOLDS2, 4-VALVE DOUBLE VENT MANIFOLDS2-VALVE PRESSURE AND LIQUID LEVEL MANIFOLDSDIFFERENTIAL PRESSURE STYLE MANIFOLDSGAS MANIFOLDS8-9SPECIALTY PRODUCTSPURGE MANIFOLDSMONOFLANGESGAS CHROMATOGRAPH MANIFOLDSHIGH TEMPERATURE MANIFOLDSTAP STYLE DOUBLE BLOCK AND BLEED VALVESBELLOWS SEAL VALVESVALVE ACCESSORIESBRACKETS, ADAPTERS AND ACCESSORY TOOLSSTEM AND SEAT CONFIGURATIONSSTEM AND SEAT CONFIGURATIONSPHOENIX MOUNT SYSTEMFUTBOLS, STABILIZED FUTBOLSSTABILIZED FUTBOLS WITH INTEGRATED BLOCK VALVESVALVELESS ADAPTERS2-VALVE BLOCK MANIFOLDS5-VALVE MANIFOLDSOTHER ADAPTERSAPPLICATIONSAPPLICATIONS10-11121213-15163

DESIGN FEATURES AND SPECIFICATIONSPHOENIX PRECISION MEETS AND/OR EXCEEDS THE FOLLOWING SPECIFICATIONSENGINEERING DESIGN SPECIFICATIONS-ASME B31.1 POWER PIPING-ASME B31.3 PROCESS PIPING-ASME B16.34 VALVES - FLANGED, THREADED, AND WELDINGEND-ASME B16.5 PIPE FLANGES AND FLANGED FITTINGS-ANSI/ISA-75.01 FLOW EQUATIONS FOR SIZING CONTROLVALVES-ANSI B1.20 PIPE THREADS, GENERAL PURPOSE (INCH)-ASME B16.11 FORGED FITTINGS, SOCKET-WELDING ANDTHREADED-NACE MR0175 STANDARD FOR METALS IN SOUR OIL FIELDENVIRONMENTSDESIGN FEATURESVALIDATION SPECIFICATIONS-API 598 VALVE INSPECTION AND TESTING-ASME SECTION VIII CONSTRUCTION OF PRESSUREVESSELS-MSS-SP99 INSTRUMENT VALVES-MSS-SP105 INSTRUMENT VALVES FOR CODE APPLICATIONS-MSS-SP25 STANDARD MARKING SYSTEMS FOR VALVES,FITTINGS, AND FLANGE UNIONS-NACE MR0175-2002 FOR ALL 316SS AND A105CS VALVEBODIES/316SS BONNETS (SC MATERIAL CODE)TESTING SPECIFICATIONS-SHELL TEST: 1.5 TIMES THE RATED PRESSURE AS PER ASMEB31.3 SECTION 345.4.2, ASME B16.34 SECTION 7.1-CLOSURE TEST: 1.1 TIMES THE RATED PRESSURE AS PERASME B16.34 SECTION 7.2OTHER TESTING INCLUDES:-BURST TEST: AS PER ASME SECTION VIII DIVISION IUG-101(M), BURSTING TEST PROCEDURE-GAS TEST: 0 BUBBLES FOR 15 SECONDS AS PER API 598,VALVE INSPECTION AND TESTING, SECTIONS 3 AND 4.PHOENIX TYPICALLY EXPANDS THIS RATE TO A MINIMUM OF60 SECONDS FOR MOST APPLICATIONS-BACKSEATING TEST: AS PER API 598, SECTION 4.2,BACKSEATING TESTCERTIFICATIONS-ISO 9001-CSA B51 BOILER, PRESSURE VESSEL AND PRESSUREPIPING CODE SAFETY CODES ACT-ABSA, ALBERTA BOILERS SAFETY ASSOCIATION-ABSA DESIGN REGISTERED CRN# 0C06740.24-“V” TYPE COMPOSITE TEFLON -GRAFOIL PACKING-DUAL O-RING SEALS WITH ADDITIONAL TEFLON BACK-UPRING IN O-RING BONNETS-BACK-SEATING TO PREVENT STEM BLOWOUT AND PROVIDEA METAL-TO-METAL SECONDARY STEM SEAL IN FULL OPENPOSITION-PACKING BELOW STEM THREADS TO PREVENTCORROSION AND CONTAMINATION OF STEM THREADS-METAL BODY TO BONNET SEALS ARE IN COMPRESSION NOTTENSION-STEM THREADS ARE ROLLED FOR SUPERIOR STRENGTHAND TO PREVENT GALLING-DUST CAPS PROTECT BONNET ASSEMBLIES FROMCONTAMINANTS

HAND VALVESGAS MINI VALVESThe N6G gas mini valve is designed specifically for the natural gasindustry. It features a double O-ring design with a TFE backup ringbelow the threads, backseating capability, blowout proof stem, anda unique seat design for pressure up to 6,000 psi. It is availablewith a variety of rupture discs with varying pressure ratings from1,800 psi to 5,000 psi.Orifice Sizes: 1/8”, 3/16”Connections: 1/4” MNPT and FNPTMaterials:Carbon Steel, 316 SS (stainless steel), exoticsavailablePressure:Up to 6,000 PSIGTemperature: Up to 200 FPacking:Dual Viton O-rings with Teflon backup ringSeats:Delrin standardStyle:Globe StyleHandles:Aluminum Knurled Round or TeeOptional:Large Round Handle, Rupture DiscNEEDLE VALVESPhoenix needle valves feature packing below the threads,backseating capability, blowout proof stems and large roundedhandles for easy operation.Orifice acking:Seats:Style:1/8”, 3/16”, 1/4”, 3/8”1/4” thru 1” FNPT, MNPT, SW, Integral TubeCarbon Steel, 316 SS, exotics availableUp to 6,000 PSIGUp to 1,000 FDual Viton O-rings with Teflon backup ring,Teflon , Grafoil Integral (Hard)-Needle or Ball Tip, or SoftGlobe Style, Roddable10,000 PSI NEEDLE VALVESPhoenix’s certified 10,000 psi needle valve is proof tested to 20,000 psi andburst tested to 53,000 psi without yield, as per ASME Section VIII, MSSSP-105 and MSS SP-99. The 10,000 psi valve features packing belowthe threads, back seating capability, blowout proof stems and large roundhandles for easy operation.Orifice acking:Seats:Style:3/16”1/4” thru 1” FNPT, MNPT, SW, Integral TubeCarbon Steel, 316 SS, exotics availableUp to 10,000 PSIGUp to 450 FDual Viton O-rings with Teflon backup ring,Teflon Integral (Hard)-Needle or Ball TipGlobe Style5

GAUGE VALVESGAUGE VALVESThe multiport gauge valve is designed to use with pressure gauges, pressure transmitters and pressure switches.It offers flexible mounting for both vertical and horizontal applications. The valve is constructed from bar stock andfeatures robust stems. The bonnets are pinned for security. This innovative design ensures a bubble tight seal and theglobe pattern of the valve provides maximum shut off employing a variety of stem tips, materials and configurations.Orifice acking:Seats:Style:1/8”, 3/16”, 1/4”, 3/8”1/4” thru 1” FNPT, MNPT, SW, Integral TubeCarbon Steel, 316 SS, exotics availableUp to 6,000 PSIGUp to 1,000 FDual Viton O-rings with Teflon backup ring,Teflon , Grafoil Integral (Hard)-Needle or Ball Tip, or SoftGlobe Style, Roddable10,000 PSI GAUGE VALVESPhoenix’s certified 10,000 psi gauge valves are proof tested to 20,000 psi and burst tested to 53,000 psi without yield,as per ASME Section VIII, MSS SP-105 and MSS SP-99. These valves feature packing below the threads, back seatingcapability, blowout proof stems and large rounded handles for easy operation.Orifice acking:Seats:Style:3/16”1/4” thru 1” FNPT, MNPT, SW, Integral TubeCarbon Steel, 316 SS, exotics availableUp to 10,000 PSIGUp to 450 FDual Viton O-rings with Teflon backup ring, Teflon Integral (Hard)-Needle or Ball TipGlobe StyleGAUGE BLOCK AND BLEED VALVESPhoenix’s block and bleed gauge valve is designed to use with pressure gauges, pressure transmitters, and pressureswitches. It features a two-valve block and bleed design with three 1/2” FNPT gauge ports. It is constructed from barstock and features robust stems. Bonnets are pinned for security. The design ensures a bubble tight seal and the globepattern provides maximum shut-off employing a variety of stem tips, materials, and configurations.Orifice Sizes: 3/16”, 1/4”Connections: 1/4” thru 1” FNPT, MNPT, SW, BW, Flanged, IntegralTubeMaterials:Carbon Steel, 316 SS, exotics availablePressure:Up to 6,000 PSIGTemperature: Up to 1,000 FPacking:Dual Viton O-rings with Teflon backup ring,Teflon , Grafoil Seats:Integral (Hard)-Needle or Ball TipStyle:Globe Style6

BLOCK AND BLEED VALVESBLOCK AND BLEED VALVESPhoenix Precision offers a wide range of valves for static pressureisolation including: Multiport, Integral Bleed, and Block and Bleed valves.Orifice acking:Seats:Style:1/8”, 3/16”, 1/4”, 3/8”1/4” thru 1” FNPT, MNPT, SW, Integral TubeCarbon Steel, 316 SS, exotics availableUp to 6,000 PSIGUp to 1,000 FDual Viton O-rings with Teflon backup ring,Teflon , Grafoil Integral (Hard)-Needle or Ball Tip, or SoftGlobe Style, Roddable10,000 PSI BLOCK AND BLEED VALVESPhoenix’s certified 10,000 psi block and bleed valves are proof testedto 20,000 psi and burst tested to 53,000 psi without yield, as per ASMESection VIII, MSS SP-105 and MSS SP-99. These valves feature packingbelow the threads, back seating capability, blowout proof stems and largeround handles for easy operation.Orifice acking:Seats:Style:3/16”1/4” thru 1” FNPT, MNPT, SW, Integral TubeCarbon Steel, 316 SS, exotics availableUp to 10,000 PSIGUp to 450 FDual Viton O-rings with Teflon backup ring, Teflon Integral (Hard)-Needle or Ball TipGlobe StyleDOUBLE BLOCK AND BLEED VALVESThe double block and bleed valve (DBB) is designed for hightemperature and severe service applications. This globe-style valveprovides maximum shut-off, using a ceramic ball-tip stem on theprocess valve and a needle tip stem on the bleed valve. Available in avariety of materials and configurations. The DBB provides an excellenttransition between process piping and instrumentation.Orifice Sizes: 3/16”, 1/4”, 3/8”Connections: 1/4” thru 1” FNPT, MNPT, SW, BW, Flanged, IntegralTubeMaterials:Carbon Steel, 316 SS, exotics availablePressure:Up to 6,000 PSIGTemperature: Up to 1,000 FPacking:Dual Viton O-rings with Teflon backup ring,Teflon , Grafoil Seats:Integral (Hard)-Needle or Ball TipStyle:Globe StyleDesign:Standard and Severe Service7

MANIFOLD VALVES2, 3, 5 - VALVE COPLANAR/POWER STYLE MANIFOLDSThe 1/8” bore coplanar manifold mounts directly to a coplanar-style transmitter (i.e.: Rosemount 3051 Seriestransmitters) eliminating the need for a coplanar flange. The globe-style manifold affords maximum shut-off and isavailable in 2-valve, 3-valve, 5-valve gas and 5-valve power configurations in a variety of materials and stem tips. Themanifold includes robust stems, pinned bonnets, and two mount holes for connecting to Phoenix Precision’s bracketmount and additional mounting holes for alternate bracket mounts.Orifice acking:Seats:Style:1/8”1/4” thru 1/2” NPT, FlangedCarbon Steel, 316 SS, exotics availableUp to 6,000 PSIGUp to 1,000 FDual Viton O-rings with Teflon backup ring,Teflon , Grafoil Integral (Hard)-Needle or Ball Tip, or SoftGlobe Style, Roddable2, 3, 5 - VALVE BOTTOM MOUNT MANIFOLDSThe 1/8” bore bottom mount manifold is designed for transmitters having flanged bottom inlets with 2-1/8” spacing. Theglobe-style manifold affords maximum shut-off and is available in 2-valve, 3-valve, 5-valve gas and 5-valve powerconfigurations in a variety of materials and a range of special tips. The manifold includes robust stems, pinned bonnets,and two mount holes for connecting to Phoenix Precision’s bracket mounts.Orifice acking:Seats:Style:1/8”1/4” thru 1/2” NPT, Flanged, Integral TubeCarbon Steel, 316 SS, exotics availableUp to 6,000 PSIGUp to 1,000 FDual Viton O-rings with Teflon backup ring,Teflon , Grafoil Integral (Hard)-Needle or Ball Tip, or SoftGlobe Style, Roddable2, 4 - VALVE DOUBLE VENT MANIFOLDSThe P2MDV provides a double block on the vent/calibrate connections on transmitters designed for superior control offugitive emissions and utilizes a double block for safety and as preventative measure against accidental releases. TheP2MDV can be incorporated into ISO 14001 Environmental Management Systems.Orifice acking:Seats:Style:81/8”, 3/16”, 1/4”, 3/8”1/4” thru 1/2” NPT, FlangedCarbon Steel, 316 SS, exotics availableUp to 6,000 PSIGUp to 200 FDual Viton O-rings with Teflon backup ring,Teflon Delrin , Tefzel Integral (Hard)-Needle or Ball Tip, or SoftRoddable

MANIFOLD VALVES (CONT.)2 - VALVE PRESSURE AND LIQUID LEVEL MANIFOLDSPhoenix offers a wide range of valve product for static pressure and liquidlevel applications from gauges to “smart” pressure applications.Orifice acking:Seats:Style:1/8”, 3/16”, 1/4”1/4” thru 1/2” NPT, FlangedCarbon Steel, 316 SS, exotics availableUp to 6,000 PSIGUp to 1,000 FDual Viton O-rings with Teflon backup ring,Teflon , Grafoil Integral (Hard)-Needle or Ball Tip, or SoftGlobe Style, RoddableDIFFERENTIAL PRESSURE STYLE MANIFOLDSPhoenix also offers a wide selection of 3-valve, 5-valve, and specialpurpose manifolds for every type of Differential Pressure (DP) instrument.Orifice acking:Seats:Style:1/8”, 3/16”, 1/4”, 3/8”1/4” thru 1/2” NPT, Flanged, Integral TubeCarbon Steel, 316 SS, exotics availableUp to 6,000 PSIGUp to 1,000 FDual Viton O-rings with Teflon backup ring,Teflon , Grafoil Integral (Hard)-Needle or Ball Tip, or SoftGlobe Style, RoddableG

Section VIII, MSS SP-105 and MSS SP-99. These valves feature packing below the threads, back seating capability, blowout proof stems and large round handles for easy operation. Orifice Sizes: Connections: Materials: Pressure: Temperature: Packing: Seats: Style: The double block and bleed valve (DBB) is designed for high temperature and severe service applications. This globe-style valve .