Transcription

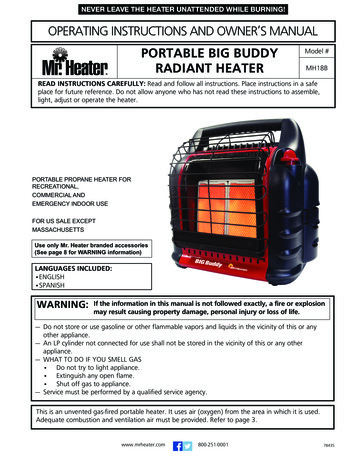

HYDRAULIC HOSEFITTINGS & ADAPTERS

YEARSSINC E 1956A 60-year long-lasting success made up of innovation,high-quality products and services, worldwidecoverage and daily commitment to customer value.This is what Alfagomma is celebrating in 2016, thanksto all the stakeholders who greatly contributed tobuilding up strategic partnerships, closing successfuldeals and fostering trust in our future.www.alfagomma.com

ALFAGOMMA // GLOBAL PRESENCE// PROVIDING EXCELLENCE AND RELIABILITY2ALFAGOMMAALFAGOMMADeveloping cutting-edge technology and innovativesolutions. Supplying top quality products worldwide.These are the pillars on which ALFAGOMMA’ssuccess has been built since 1956.Today, ALFAGOMMA plays a leading role in theindustrial and hydraulic rubber hoses segment, with16 plants, 79 subsidiaries and assembly plants anda worldwide presence spread across 21 countries.The Group has been providing top quality productsfor 60 years and it has always been known forits excellent technical department: a strongcommitment to quality and control design that isreflected in the Group’s state-of-the-art productportfolio, which also include adapters and swivelconnectors.MANUFACTURINGPLANTSSUBSIDIARIES ANDASSEMBLY PLANTSQUALITYCERTIFICATIONEMPLOYEES1679ISO3.000IN 8 COUNTRIESIN 21 COUNTRIESISO 9001ITALY – FINLANDGERMANY – UKUSA – BRAZILCHINA – MALAYSIAANDSINCE 1993AROUNDTHE WORLD5 CONTINENTSISO 14001www.alfagomma.comSINCE 1999

ALFAGOMMA // MAIN PLANTS OVERVIEV// MAIN PLANTS OVERVIEWALFAGOMMA3

ALFAGOMMA // APPLICATIONS OVERVIEW// APPLICATIONS OVERVIEWALFAGOMMA4www.alfagomma.com

COMPLETEAND INTEGRATEDHYDRAULIC SYSTEMALFAGOMMA COMPLETE SYSTEMSAFE AND RELIABLE INTEGRATED SYSTEMFULL RANGE OF HOSES, FITTINGS, ADAPTORS AND QUICK RELEASE COUPLINGSCARBON STEEL AND STAINLESS STEEL RIGID PIPESCUSTOMISED SYSTEMS AND KITSWIDE RANGE OF ARTICLES IN STOCKTOP COAT SURFACE TREATMENT ON ALL OUR METAL PARTS100% TRACEABILITY FOR EVERY SINGLE COMPONENTwww.alfagomma.com

MINETUFFHIGH ABRASIONRESISTANCEMINETUFF COVEREXCELLENT ABRASION RESISTANCE (10 TIMES HIGHER THAN EN-ISO 6945REQUIREMENT)HIGH OZONE RESISTANCE (10 TIMES MORE THAN THE STANDARD)MSHA APPROVED COVERALTERNATIVE TO PROTECTIVE SLEEVE IN APPLICATIONS REQUIRINGABRASION RESISTANCEwww.alfagomma.com

ALFAGOMMA // APPENDIXALFAGOMMA cares for the environment and for yourequipment among ALFAGOMMA’s newest products areALFATECH 4000, 5000, 6000 spiral hose, low temperature,Temp Tech, MineTuff, SuperTuff hose and a completecoupling line (two pieces and precrimped ALFACRIMPsystems).They join the extensive range of ALFAGOMMA hose, thehigh pressure hydraulic components that have set thestandard for reliability and durability.DESIGNThroughout the world ALFAGOMMA has build up a namesynonymous with quality, a reputation based on first classproduct, a commitment to research and development andongoing capital investment.The development and product engineering staff inALFAGOMMA, continue to provide fluid conveying productinnovations that assure better performance and cost savingto our customers.ALFAGOMMA hose and couplings are designed to worktogether as a system for problem free performance, nomatter what machine you operate. The performance ofall our product exceeds SAE, DIN, JIS requirements andsome hoses meet the MSHA and LOBA flame resistancerequirements, as well.LEADERSHIP IN HYDRAULIC HOSEAND COUPLING COMPONENTSALFAGOMMA has developed into a world leadingmanufacturer, of fluid power and fluid system components.A positive attitude towards the demands from newequipment which is using the latest technology has seenALFAGOMMA introduce many outstanding new hydraulichose types. These hoses have found acceptance in a widerange of industry, some examples eManufacturingPulp and Plywood MillsGLOBAL COMPANYDue to our world-wide organisation of subsidiariesand distributors you will always be near a source forALFAGOMMA products. Your ALFAGOMMA dealer hastrained personnel to consult with you on your hose andcoupling requirements guaranteeing consistent quality andperformance.OUR COMMITMENTBy remaining alert to customer’s needs, ALFAGOMMA isconstantly engineering new products for tomorrow’s marketsas well as modifying them for even higher performances.ALFAGOMMA commitment to innovation and servicemakes our products known throughout the world for quality,reliability and leadership, when you need quality hose andcouplings, use the best available.Now you can count on ALFAGOMMA for all your needs.TESTINGALFAGOMMA laboratories are fully equipped to carry outtests according to standards like SAE, ISO, DIN and JIS.New products are also subjected to laboratory simulation ofactual service prior to being released on the market.WORLD CLASS QUALITYALFAGOMMA is working to internationally recognisedquality programs requiring stringent standards. Many of ourcustomers are demanding ISO qualification or equivalent asa prerequisite for purchasing. This standard is an assuranceof consistent quality.For ALFAGOMMA this is just the start “do it right from thebeginning”.IMPORTANT NOTE FOR USERSHose assemblies require caution in use not only to providelong service life but also to guard against potentiallydangerous failure.Serious injury, death and destruction of property can resultfrom the rupture or blowing-apart of a hydraulic hoseassembly that is damaged, worn out, badly assembled orinstalled incorrectly.Users should follow good maintenance practices. Avoidexpensive downtime by establishing a program ofinspection, testing and replacement of hose assembliesbefore failure occurs; taking into account factors including:severity of application, frequency of equipment use,past performance of hose assemblies. Document yourmaintenance, inspections and testing.Only properly trained persons should inspect, test or servicehose assemblies and this training should be updatedregularly.Users should carefully observe the precautions listed belowunder “be aware that” as well as following closely ourrecommendations for the selection of hose and couplings.In addition, care should be taken not to exceed the minimumbend radius listed for each hose size and type. Maximumoperating pressure should not exceed the pressures listed.Instruction for assembling fittings to different hoses shouldbe followed carefully to ensure the safe performance of thecomplete assembly.By following the recommendations on hose assemblyrouting and installation, improved safety and longer servicelife of any hose installation will result.Hydraulic fluid under pressure can be potentiallydangerous!!An explosive burst or stream of escaping fluid can causedamage to equipment as well as serious injury to personsnearby.BE AWARE THAT.1. Highly pressurised fluid escaping from a small pinhole canbe almost invisible and, yet, exert extreme force capableof penetrating the skin and other body tissues, causingpossible severe injury.2. Hot fluids or chemicals can cause severe burns.3. Pressurised fluids, if released uncontrolled, can exert atremendous explosive force.4. All hydraulic hoses listed in this catalogue are electricallyconductive.5. Some hydraulic fluids are highly flammable.7ALFAGOMMASETTING NEW STANDARD

ALFAGOMMA // APPENDIXAND.ALFAGOMMA81. Always position a shield between you and any pressurisedhydraulic lines when working next to them. or shut thepressure off.2. Wear safety glasses.3. Do not use your hands to check for leaks. Do not touch apressurised hydraulic hose assembly with any part ofyour body, if fluid punctures the skin, even if no pain isfelt, a serious emergency exists.Obtain medical assistance immediately. Failure to do socan result in loss of the injured body part or death.4. Stay out of hazardous areas while testing hose assembliesunder pressure. Use proper safety protection.5. If an injury or reaction occurs, get medical attention rightaway.6. Use only non conductive thermoplastic hoses whereelectrical conductivity is not desired: for instance,equipment working on electric power lines.ALFAGOMMA hose and fitting are designed, engineeredand tested to be used together in an assembly.The use of ALFAGOMMA fittings on other manufactures hoseor the use of ALFAGOMMA hose with other manufacturesfittings may result in the production of unreliable or unsafeassemblies. It is neither recommended nor authorised byALFAGOMMA.www.alfagomma.comALFAGOMMA recommends only those hose and couplingcombinations specified in the ALFAGOMMA HydraulicProducts Catalogues.ALFAGOMMA disclaims any liability for any hose assemblieswhich have not been produced in conformance withALFAGOMMA assembly recommendations and currentcrimp data charts.Extensive impulse testing has been performed byALFAGOMMA to verify the recommendations containedin this catalogue. A simple burst or pressure test cannotdetermine a hose and coupling combination.Any claim for defects must be made in writing on theappropriate ISO9000 complaint form within 8 days fromreceipt of the product. ALFAGOMMA will have a reasonableopportunity thereafter to examine and investigate thealleged defect.The customer’s exclusive remedy with respect to any claimof any kind whatsoever shall be refund of the purchaseprice or replacement of the product at the option ofALFAGOMMA and in no event shall ALFAGOMMA be liablefor any incidental or consequential damages whatsoever.

ALFAGOMMA // TYPE APPROVALSREFERENCE SPECIFICATIONSSociety of Automotive EngineersDet Norske VeritasEuropean NormDeutsche Institute NormenCentre d’Etudes et RecherchesDes Charbonnages de FranceMSHA LOBA AS BV GL ISO -U.S. Mine Safety and Health AdministrationLandesobergamt Nordrhein - WestfallenAustralian StandardBureau VeritasGermanischer LloydInternational organization for Standardization9The listing below are intended only as guides in identifying which ALFAGOMMA hoses comply with requirements of variousagencies.HoseFlexor 1TE/R6 HFFlexor 2TE HFFlexor 3TE/R3 HFFlexor R4Flexor 5Flexor 7Flexor 8Flexor 1SN-R1AT HFFlexor 1SN-R1AT MTFlexor 1ST-R1ATFlexor 2SN-R2AT HFFlexor 2SN-R2AT MTFlexor 2ST-R2ATFlexopak PLTFlexopak 1SCFlexopak 2Flexopak 2SC HFFlexor 4SPFlexor 4SHFlexor R12Flexor R13Flexor R15Alfabiotech 3000Alfabiotech 4000Alfabiotech 5000Alfabiotech 5000PAlfabiotech 6000SAE J517100 T3TEST854 R6854 2TE854 3TE100 R3100 R4100 R5100 R7100 R8855 R7855 R83949100 R1AT100 R1AT100 R1A100 R2AT100 R2AT100 R2A853 1SN853 1SN853 1ST853 2SN853 2SN853 2ST1436XXXXXXXX143614361436XXXXXXXXXXXXXXXXXXXX100 R16100 R16100 R12100 R13100 R15857 1SC857 2SC857 2SC112371123711237856 4SP856 4SH856 R12856 R13EX SAE R12EX SAE R151875218752187521875218752XXXXXXXXAlfatech 3000Alfatech 7000Alfatech 8000100 R17857 Ø 3/8”11237Flexopak 2 HTTemp Tech 1SNTemp Tech 2SN100 R16100 R1AT100 R2AT857 2SC853 1SN853 2SN1123714361436Flexopak 2 LTAlfaforestFlexor 4SP LTFlexor 4SH LT100 R16857 2SCAlfajet 210Alfajet 400AlfagommaProprietaryHose856 4SP856 X1- DNV approvals are with permanent (crimp) type fittings only2- Hoses with MSHA approved cover are always branded “MSHA”3- DOT Type All TYPE AII FMVSS 106 approval up to size –12Listing may vary by style and size, for current and complete information, contact ALFAGOMMA for details.XXXXXXXXXXXXXXXALFAGOMMASAE DNV EN DIN CERCHAR -

ALFAGOMMA // HOSE GUIDELINESSAFETY GUIDE AND BASIC FACTORS FOR THE SELECTION, INSTALLATION AND MAINTENANCEOF HOSE AND HOSE ASSEMBLIESALFAGOMMA10Hydraulic hose (and hose assemblies) has a limited lifedependent on service conditions to which is applied.Subjecting hose (and hose assemblies) to conditions moresevere than the recommended limits significantly reduceservice life. Exposure to combinations of recommendedlimits (i.e., continuous use at maximum rated workingpressure, maximum recommended operating temperatureand minimum bend radius) will also reduce service life.Laminar flow - In laminar flow, the individual fluid particlesmove up to certain speeds in uniform layers alongside eachother. They scarcely disturb or influence each other.Turbulent flow - If the value for Re exceeds 2300, flowbecomes whirling and turbulent. The individual particlesno longer move in one direction in an orderly fashion, butinfluence and hinder each other.WARNING: FAILURE TO FOLLOW PROPERSELECTION, INSTALLATION AND MAINTENANCEPROCEDURES MAY RESULT IN PREMATUREFAILURES, BODILY INJURY, AND DAMAGE TOPROPERTY.LAMINAR1. SELECTION - The following is a list of factors which mustbe considered before the selection of a hose can be made:TURBULENT1.1 Line sizeIn order to achieve maximum efficiency in a hydraulic system,it is necessary to keep pressure losses (resistance to thevolumetric flow) to a minimum when a fluid is conveyed bythe different types of flow lines.When a fluid flows through a flow line, heat is generated byfriction. Thus part of the energy is lost as heat energy, whichresults in a pressure loss.These pressure losses depend upon: flow velocity (for a given volumetric flow, the fluid flowvelocity increases with a decrease in the cross sectionalarea of a flow line and vice versa) length of the flow line the viscosity of the fluid flowing the density of the fluid flowing the type of flow (laminar or turbulent)Types of flow - The type of flow changes from laminar toturbulent at a certain flow velocity. This velocity is givenby the Reynold’s Number Re.For cylindrical flow lines the following formula applies:Re vxdυwhere: v velocity (m/s)d flow line internal dia (m)υ kinematic viscosity (m2/s)As soon as the value for Re exceeds 2300, the laminar flowchanges to turbulent flow.www.alfagomma.comCertain fluid flow velocities have proved to be most suitablefor hydraulic flow lines.Recommended flow velocities:Suction lines:0.5 1.2 m/sReturn lines:2 3 m/sPressure lines:4 7.5 m/s1.6 4 feet/s6.5 10 feet/s13 25 feet/sFLOW CAPACITY NORMOGRAMFlow Capacities of Hose at Recommended Flow VelocitiesThe chart below is provided as an aid in the determinationof the correct hose size.Example: at 45 l/min, what is the proper hose size withinthe recommended velocity range for pressure lines?Locate 45 l/min in the left-hand column and 7,5 m/s in theright-hand column (the maximum recommended velocityrange for pressure lines).Lay a straight line across these two points. The insidediameters shown in the centre column is above 9,5 mm sowe have to use 12,7 mm (1/2”). For suction hose, follow thesame procedure except use recommended velocity rangefor intake lines in the righthand column.where Q flow in liters per seconds (l/sec)V velocity in meters per seconds (m/s)d hose inside diameter (mm & dash size)

ALFAGOMMA // HOSE GUIDELINESTECHNICAL INFORMATION – NORMOGRAM OF THE FLOWFlow Ql/min11ALFAGOMMAThe normogram herewith is pivotal to help you find the hose diameter by knowing the liquid flow and speed.In order to find the correct diameter you should trace a line between the flow value (l/min) and the suggested speed (m/sec)according to the kind of delivery (pressure or return). The value touched by the line in the central column will indicate the hoseID (mm/inches) that must be used.Gal/min *Inside diameter ocity forsuction linesRecommendedmaximumvelocity forreturn linesRecommendedmaximumvelocity forpressure lines* gallons are UK gallonsConversion factor: gal/min x 4,546 l/minfeet/s x 0,3048 m/s

ALFAGOMMA // HOSE GUIDELINESALFAGOMMA12It is therefore important to calculate correctly the requiredflow line sizes. Undersized pressure lines results in highfluid velocity causing an excessive pressure drop, and heatbuilt up, which impair overall system performance.Undersized suction lines can cause cavitation at thehydraulic pump inlet, affecting performance, shorteningpump life, and creating excessive noise levels.The flow capacity normogram on page (12) is an aid todetermine the correct hose internal diameter size, desiredflow rate and recommended velocity. By the use of any twoknown factors, the third can be determined.1.2 Pressure:After determining the system pressure for a hydraulicsystem, hose selection must be made so that therecommended maximum operating pressure specified bya given hose, is equal or greater than the system pressure.Dynamic pressure is common for all hydraulic systems.Pressure surges which exceed the maximum workingpressure (pressure relief valve setting) affect the servicelife of system components, including a hose assembly andtherefore need to be taken into consideration. Hoses usedfor suction lines must be selected to ensure the hose willwithstand the negative pressure of the system.1.3 Temperature:Care must be taken to ensure that the operating temperatureof the fluid being conveyed and ambient temperatures, donot exceed the limitations of the hose.Special care must be taken when routing near hot manifoldsor molten metal.1.4 Fluid Compatibility:Hose selection must assure compatibility of the hose tube,cover, reinforcement, and fittings with the fluid used.Additional caution must be observed in hose selection forgaseous applications. Some fire resistant fluids require thesame hose as petroleum oil. Some use a special hose, whilea few fluids will not work with any hose at all.For gas application, where compatible with AlfagommaHoses, and at pressure above 10bar, the hose cover shallbe pin-pricked.1.5 Permeation:Permeation (that is, seepage through the hose) will occurfrom inside the hose to outside when hose is used withgases, liquid and gas fuels, and refrigerants (includingbut not limited to such materials such as helium, fuel oil,natural gas or freon). This permeation may result in highconcentrations of vapours which are potentially flammable,explosive, or toxic and in loss of fluid.Even though the fluid compatibilty is acceptable, you musttake into account the fact that permeation will occur and couldbe hazardous. Permeation of moisture from outside the hoseto inside the hose will also occur. If this moisture permeationwould have detrimental effects (particularly but not limited torefrigeration and air conditioning systems), incorporation ofsufficient drying capacity in the system or other appropriatesystem safeguards should be selected and used.1.6 Routing:Attention must be given to optimum routing to minimiseinherent problems. Restrain, protect or guide hose withthe use of clamps if necessary to minimise risk or damagedue to excessive flexing, whipping or contact with othermoving parts or corrosives. Determine hose lengthsand configurations that will result in proper routing andprotection from abrasion, snagging or kinking and provideleak resistant connections.www.alfagomma.com1.7 Environment:Care must be taken to ensure that the hose and fittings areeither compatible with or protected from the environment towhich they are exposed. Environmental conditions includingbut not limited to ultraviolet light, heat, ozone, moisture,water, salt water, chemicals, and air pollutants can causedegradation and premature failure and, therefore, must beconsidered.1.8 Mechanical Loads:External forces can significantly reduce hose life.Mechanical loads which must be considered includeexcessive flexing, twist, kinking, tensile or side loads, bendradius, and vibration. Use of swivel type fittings or adaptorsmay be required to ensure no twist is put into the hose.Unusual applications may require special testing prior tohose selection.1.9 Abrasion:While a hose is designed with a reasonable level of abrasionresistance, care must be taken to protect the hose fromexcessive abrasion which can result in erosion, snagging,and cutting of the hose cover. Exposure of the reinforcementwill significantly accelerate hose failure.1.10 Proper End Fitting:Care must be taken to ensure proper compatibility existsbetween the hose and coupling selected based on themanufacturer’s recommendations substantiated by testingto industry standards such as SAE J517DIN 20024, JIS B 8360.1.11 Length:When establishing proper hose length, motion absorption,hose length changes due to pressure, as well as hose andmachine tolerances must be considered.1.12 Specifications and Standards:When selecting hose and fittings, government, industry,and manufacturer’s specifications and recommendationsmust be reviewed as applicable.1.13 Hose Cleanliness:Hose components may vary in cleanliness levels. Caremust be taken to ensure that the assemblies selected havean adequate level of cleanliness for the application.1.14 Welding and Brazing:Heating of plated parts, including hose fittings and adaptors,above 232 C (450 F) such as during welding, brazing, orsoldering may emit deadly gases.1.15 Electrical Conductivity:Certain applications require that a hose be non-conductiveto prevent electrical current flow. Other applications requirethe hose to be sufficiently conductive to drain off staticelectricity.Extreme care must be exercised when selecting hose andfittings for these or any other applications in which electricalconductivity or non-conductivity is a factor.For applications that require hose to be electrically nonconductive, including but not limited to applications nearhigh voltage electric lines, only special non-conductivehose can be used.The manufacturer of the equipment in which the nonconductive hose is to be used must be consulted to becertain that the hose and fittings that are selected areproper for the application.

ALFAGOMMA // HOSE GUIDELINES2. INSTALLATION - After the selection of the correct hose,the following factors must be considered prior to hoseand fitting assembly and installation.2.1 Pre-Installation Inspection:Prior to installation, a careful examination of the hose mustbe performed. All components must be checked for correctstyle, size, and length. The hose must be examined forcleanliness, obstructions, blisters, cover looseness, or anyother visible defects.2.2 Hose and Fitting Assembly:Do not assemble an ALFAGOMMA fitting on anALFAGOMMA hose that is not specified by ALFAGOMMAfor that hose. Do not assemble ALFAGOMMA fittings onanother manufacturer’s hose or an ALFAGOMMA hoseon another manufacturer’s fitting unless ALFAGOMMAapproves the assembly in writing, and the user verifies theassembly and the application through analysis and testing.The ALFAGOMMA published hose assembly instructionsmust be followed for assembling the fittings on the hose.2.3 Related Accessories:Crimp or swage ALFAGOMMA hose or fittings only withALFAGOMMA approved swage or crimp machines andin accordance with the ALFAGOMMA published hoseassembly instructions.2.4 Parts:Do not use any ALFAGOMMA hose fitting part (includingbut not limited to sockets, or inserts) except with the correctALFAGOMMA mating parts, in accordance with ALFAGOMMApublished hose assemby2.5 Reusable/Permanent:Do not reuse any reusable hose coupling that has blown orpulled off a hose. Do not reuse an ALFAGOMMA permanent(that is, crimped or swaged) hose fitting or any part thereof.2.6 Minimum Bend Radius:Installation of a hose at less than the minimum listed bendradius may significantly reduce the hose life. Particularattention must be given to avoid sharp bending at the hose/fitting juncture.2.7 Twist Angle and Orientation:Hose installations must be such that relative motion ofmachine components does not produce twisting.2.8 Securement:In many applications, it may be necessary to restrain,protect, or guide the hose to protect it from damage byunnecessary flexing, pressure surges, and contact withother mechanical components. Care must be taken toensure such restraints do not introduce additional stress orwear points.2.9 Proper Connection of Ports:Proper physical installation of the hose requires a correctlyinstalled port connection while ensuring that no twist ortorque is transferred to the hose.2.10 External Damage:Proper installation is not complete without ensuring thattensile loads, side loads, kinking, flattening, potentialabrasion, thread damage, or damage to sealing surfacesare corrected or eliminated.2.11 System Checkout:After completing the installation all air entrapment must beeliminated and the system pressurised to the maximumsystem pressure and checked for proper function withoutany leaks. Personnel must stay out of potential hazardousareas while testing.3. HOSE AND FITTING MAINTENANCE INSTRUCTIONSEven with proper selection and installation, hose life maybe significantly reduced without a continuing maintenanceprogram. Frequency should be determined by the severityof the application and risk potential. A maintenance programmust be established and followed to include the followingas a minimum:3.1 Visual Inspection Hose/Fitting:Any of the following conditions require immediate shutdown and replacement of the hose assembly: Fitting slippage on hose. Damaged, cut or abraded cover (any reinforcementexposed). Hard, stiff, heat cracked, or charred hose. Cracked, damaged, or badly corroded fittings. Leaks at fitting or in hose. Kinked, crushed, flattened or twisted hose. Blistered, soft, degraded, or loose cover.3.2 Visual Inspection All Other:The following items must be tightened, repaired or replacedas required: Leaking port conditions Remove excess dirt build-up Clamp, guards, shields System fluid level, fluid type and any air entrapment3.3. Functional Test:Operate the system at maximum operating pressure andcheck for possible malfunctions and freedom from leaks.Personnel must stay out of potential hazardous areas whiletesting.3.4 Replacement Intervals:Specific replacement intervals must be consideredbased on previous service life, government or industryrecommendations, or when failures could result inunacceptable downtime, damage, or injury risk.13ALFAGOMMADo not use any ALFAGOMMA hose or fitting for anyapplication requiring non-conductive hose, including but notlimited to applications near high voltage electric lines, unlessthe application is expressly approved in the ALFAGOMMAtechnical publication for the product, the SAFETY GUIDE hoseis both orange in colour and marked “non-conductive”, andthe manufacturer of the equipment on which the hose is to beused specifically approves the particular ALFAGOMMA hoseand fitting for such use.ALFAGOMMA does not supply any hose or fittings forconveying paint in airless paint spraying or similar applicationsand therefore should not be used. A special hose and fittingassembly is required for this application, to avoid staticelectricity buildup which could cause a spark that may resultsin an explosion and/or fire.The electrical conductivity or non-conductivity of hoseand fittings is dependant upon many factors and may besusceptible to change. These factors include but are not limitedto the various materials used to make the hose and the fittings,manufacturing methods (including moisture control), how thefittings contact the hose, age and amount of deterioration ordamage or other changes, moisture content of the hose at andparticular time, and others factors.

ALFAGOMMA // HOSE GUIDELINESCORRECT ASSEMBLY INSTALLATIONALFAGOMMA14Satisfactory performance and appearance depend uponproper hose installation. Excessive length destroys the trimappearance of an installation and adds unnecessarily tothe cost of the equipment. Hose assemblies of insufficientlength to permit adequate flexing, expansion or contractionwill cause poor power transmission and shorten the life ofthe hose.The diagrams below offer suggestions for proper hoseinstallations to obtain the maximum in performance andeconomy.RIGHTWRONGAdequate hose length is most important to distributemovement on flexing applications and to avoid abrasion.WRONGWRONGRIGHTRIGHTSince hose may change in length from 2% to -4% underthe surge of high pressure, provide sufficient slack forexpansion and contraction.To avoid twisting in hose lines bent in two planes, clamphose at change of plane, as shown.RIGHTWRONGAvoid sharp twist or bend in hose by using proper angleadapters.RIGHTNever use abending radiusless than theminimumamount shownin the table.WRONGWRONGRIGHTRIGHTWhere the radius falls below the required minimum, anangle adapter should be used as shown above to avoidsharp bends in hose.To prevent twisting and distortion, hose should be bent inthe same plane as the motion of the boss to which the hoseis connected.WRONGWRONGRIGHTObtain direct routing of hose through use of 45 and 90 adapters and fittings. Improve appearance by avoidingexcessive hose length.High PressureNo PressureDue to changes in length when hose is pressurised, donot clamp at bends so curves absorb changes and protectthe hose with a spring guard. Do not clamp high and lowpressure lines together and protect the hose with a springguard.www.alfagomma.comHose should not be twisted. Hose is weakened wheninstalled in twisted position. Also pressure in twisted hosetends to loosen fitting connections. Design so that machinemotion produces bending rather than twisting.RIGHTWRONGHigh PressureRIGHTWRONGRIGHTNever use a bending radius less than the minimum shownin the hose specification tables. Avoid sharp bend in hoseto reduce collapsing of line and restriction of flow by usingproper spring guard. Exceeding minimum bend radius willgreatly reduce hose assembly life.

ALFAGOMMA // HOSE GUIDELINESHOW TO DETERMINE CORRECT ASSEMBLY LENGTHFor most assemblies, the correct assembly length maybe determined by direct measurement of the equipmentor a drawing. Minimum bend radii as shown in the hosespecification tables should be observed.Assemblies are measured to the end of the seal.To determine the length of hose needed in makingassemblies with permanent or reusable couplings, subtractDimension “C” (Cut off factor) for each coupling from therequired overall assembly length. Dimension “C” may befound in the coupling specification tables.HOW TO MEASURE ASSEMBLIESLength over nipplesLength between S.P. and nipple endsSwivel

reflected in the Group's state-of-the-art product portfolio, which also include adapters and swivel connectors. MANUFACTURING PLANTS 16 IN 8 COUNTRIES ITALY - FINLAND GERMANY - UK USA - BRAZIL CHINA - MALAYSIA 79 IN 21 COUNTRIES AND 5 CONTINENTS SUBSIDIARIES AND ASSEMBLY PLANTS QUALITY CERTIFICATION ISO ISO 9001 SINCE 1993 ISO 14001 .