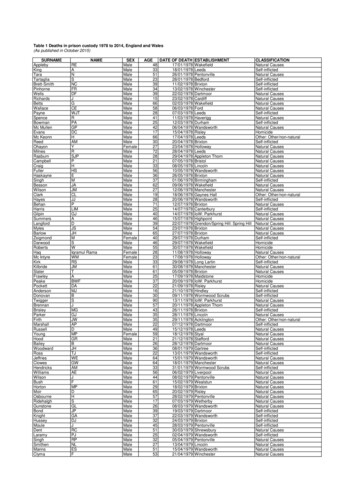

Transcription

NATURAL GAS 101Prepared for:U.S. Department of EnergyOil and Natural Gas Sector Coordinating CouncilDRAFT 7/1/2015

NATURAL GAS 101Presentation Outline1Overview2Production & Processing3Transmission & Storage4Distribution5Liquefied Natural Gas6Industrial Control System2DRAFT 7/1/2015

OVERVIEWWhat is Natural Gas?What is natural gas?o Odorless, colorless, naturally-occurringhydrocarbon consisted mostly of methane (7090%) and other gases.o Found in reservoirs deep within the earth andbrought to surface through production wells.Where does the U.S. get its natural gas from?o Domestic production: 90%o Import from Canada through pipeline: 8-9%o LNG import from other countries: 1-2%What makes natural gas a “clean fossil fuel”?– Natural gas is the cleanest burning fossil fuel,emits 50% less CO2 than coal and 30% less CO2than oil, and has no mercury emissions.3DRAFT 7/1/2015

OVERVIEWNatural Gas Production in the WorldWorld Dry Gas Production by Region (2010)Source: Energy Information Administration4DRAFT 7/1/2015

OVERVIEWNatural Gas Production in the U.S.Natural Gas Production by Source (1990-2040)The share of shalegas in total naturalgas production inthe U.S. is projectedto continue toincrease, from 40%in 2012 to 53% in2040.Source: Energy Information Administration5DRAFT 7/1/2015

OVERVIEWNatural Gas Consumption in the U.S.Natural Gas Consumption by End Use (2013)The U.S. consumed more than 23 trillion cubic feet (tcf)of natural gas in 2013.Source: Energy Information Administration6DRAFT 7/1/2015

OVERVIEWNatural Gas FlowNatural Gas Flow and Segments OverviewTHE PIPELINE SYSTEM Production & Processing:Natural gas is found inreservoirs deep within theearth and brought to surfacethrough production wells.Gathering lines transportnatural gas from wellhead totransmission line. Transmission & Storage:Transmission lines transportnatural gas from a gathering,processing or storage facility toa processing or storage facility,large volume customer, ordistribution system. Distribution:Delivers natural gas to theconsumer (residential/commercial/industrial).Production & Processing 1. Drilling & Well Completion 2. Producing Wells 3. Gathering Lines 4. Field Compression (includes,wellhead, gathering, plant inlet)& Treating/Dehydration 5. Gas Processing FacilityTransmission & Storage 6. Transmission CompressorStation 7. Transmission Pipeline 8. Underground Storage(geological formations)1011Distribution 9. Distribution Mains/Lines 10. City Gate (includes regulators& meters) Customers - includes regulators& meters) 11. Large Volume 12. Residential 13. Commercial91213Source: Adopted from American Gas Association and EPA Natural Gas STAR Program7DRAFT 7/1/2015

OVERVIEWKey Segments and FunctionsOperationProduction &ProcessingTransmission& StorageDistributionSegments & FunctionsU.S.Infrastructure*Production. Companies explore and drill for natural gas and sell theirproduct to marketers, local distribution companies (LDCs), or end users.(#1 & 2, previous slide)487,000 productionwellsGathering System. Small-diameter pipelines move natural gas from thewellhead to the natural gas processing plant or to an interconnection with alarger mainline pipeline. (#3 & 4, previous slide)20,000 miles ofgathering pipelinesProcessing. This operation extracts natural gas liquids and impurities fromthe natural gas stream. (#5 in previous slide)493 processingplantsTransmission Compression. The purpose of compressor stations is tomaintain the movement of natural gas along the pipeline. (#6, previous slide)1,400 compressorstationsTransmission Pipeline. Large-diameter, long-distance pipelines transportnatural gas from the producing area to market areas. (#7, previous slide)305,000 miles oftransmission linesUnderground Storage. Natural gas is stored in depleted oil and gasreservoirs, aquifers, and salt caverns for future use. (#8, previous slide)400 undergroundstorage facilitiesDistribution. Natural gas utilities typically transport natural gas fromdelivery points located on interstate and intrastate pipelines to householdsand businesses through small-diameter distribution pipelines. (#9 through13, previous slide)2.2 million miles ofdistributionpipelines; 1,200LDCs* Approximate/estimated data available as of May 2012.Sources: Energy Information Administration; Pipeline and Hazardous Materials Safety Administration8DRAFT 7/1/2015

NATURAL GAS 101Presentation Outline12OverviewProduction & Processing3Transmission & Storage4Distribution5Liquefied Natural Gas6Industrial Control System9DRAFT 7/1/2015

PRODUCTION & PROCESSINGNatural Gas Production & ProcessingSimplified Illustration of Natural Gas FlowProductionTransmissionSource: Natural Gas CouncilNatural Gas Production Segment Includes . . .ProductionGatheringProcessing10DRAFT 7/1/2015Distribution

PRODUCTION & PROCESSINGNatural Gas Production & ProcessingProduction & Processing 1. Drilling & Well Completion 2. Producing Wells 3. Gathering Lines 4. Field Compression (includes,wellhead, gathering, plant inlet)& Treating/Dehydration 5. Gas Processing Facility11DRAFT 7/1/2015

PRODUCTION & PROCESSINGTypes of Natural GasSchematic Geology of Natural Gas ResourcesThree categories of naturalgas produced in the U.S.– Non-associated gas thatoccurs in conventionalgas fields.– Associated-dissolved gasthat occurs inconventional oil fields.– Unconventional gas thatoccurs as coal-bedmethane, tight gas, shalegas, and associateddissolved gas in tight oil.Source: Energy Information Administration12DRAFT 7/1/2015

PRODUCTION & PROCESSINGNatural Gas ProductionProductionAfter discovery, completion of a well gas isbrought to the surface to begin its pipelinejourney to its final destination.Natural gas does not require refining in thesense crude oil does, but it does requirecleaning, due to the presence of other gasesand liquids. These gases are removed at agas processing plant.13DRAFT 7/1/2015

PRODUCTION & PROCESSINGHydraulic FracturingWELL CONSTRUCTION:PREPARATION & DRILLING231645 1All operations at the site must comply with federal law, state law, andcorporate policies incorporating good industry practices. 2Companies plan with communities to reduce noise and traffic disruptions. 3The land needed for well construction is cleared and the well is drilled. 4To protect water, state regulations based on local geology may specifyimportant construction details like the depth, strength, and cementing ofcasing. 5Any waste from the well site is disposed of according to federal and statesafety and environmental regulations. 6The well must pass operator testing and inspection before hydraulicfracturing.Source: American Petroleum Institute14DRAFT 7/1/2015

PRODUCTION & PROCESSINGHydraulic FracturingPROTECTING GROUNDWATER: STRONG WELL CONSTRUCTIONREGULATED BY JURISDICTION Well Construction: Material selection;* Performance; Evaluation* - e.g., cement quality,*casing and cementing depth,* etc. Well integrity*: Protect groundwater throughcombination of redundant steel casing andcement sheaths,* mechanical isolation devices* Well testing and logging*SPOTLIGHT Over 1 million wells have been constructed and hydraulicallyfractured since the 1940s.A typical natural gas well is constructed with 3 million pounds ofsteel and cement.Each layer of steel casing is cemented into place to create aseal that is air tight.A horizontal well is drilled like a conventional vertical well until itreaches a kickoff point where it extends horizontally.The kickoff point is normally over a mile below the surface.Source: American Petroleum Institute15DRAFT 7/1/2015*Also covered by API Standards, RecommendedPractices, or Guidance

PRODUCTION & PROCESSINGNatural Gas Shale Plays in the U.S.Shale Plays in the Lower 48 States (2013)In 2013, morethan 70% of allnatural gasproduction in theU.S. came fromthe following sixStates. Texas Pennsylvania Wyoming Oklahoma Louisiana ColoradoSource: Energy Information Administration16DRAFT 7/1/2015

PRODUCTION & PROCESSINGNatural Gas Gathering and ProcessingGathering PipelinesThe following isan overview of thepath natural gastravels afterproduction.Details provide innext few slides. Small diameter pipelines directly connect to the productionarea, transporting raw natural gas to a common location forprocessing and treating.Field Compression Typically used to allow a gathering system to operate at alower pressure or provide sufficient discharge pressure todeliver natural gas into a higher pressure system.Treating and Dehydration To meet downstream pipeline and end-user natural gasquality standards, the natural gas is dehydrated to removethe saturated water and is chemically treated to remove thecarbon dioxide and hydrogen sulfide from the gas stream.Processing Once the contaminants are removed, the next step involvesthe separation of pipeline quality residue gas from mixedNGLs, a method known as processing.17DRAFT 7/1/2015

PRODUCTION & PROCESSINGGathering LinesNatural Gas Gathering PipelinesA natural gas pipeline system begins at anatural gas producing well or field.The first component of the pipeline system isa gathering line, usually of 12 inches or lessin diameter.Gathering lines link production areas tocentral collection points and can includeprocessing facilities.A gathering system needs field compressorsto push gas through the lines (see next slide).Source: http://www.ensyte.com/gastar-gathering/18DRAFT 7/1/2015

PRODUCTION & PROCESSINGField CompressionNatural Gas Field CompressorCompression prior to the transmission lineis considered “field compression.” (not to beconfused with transmission compression,which occurs on the transmission line, notgathering line)Three segments of field compression arerequired.–––Wellhead: To boost the pressure ofnatural gas from the wellhead forsubsequent reinjection for pressuremaintenance or gas lift operations.Gathering: To combine gas flowing fromseveral wells into a gathering line headedfor a transmission line.Plant Inlet: To combine the output ofseveral gathering lines for final gasprocessing/treating and to boost pressureto enter the transmission tos.com/photos of pipeline equipment for.htm19DRAFT 7/1/2015

PRODUCTION & PROCESSINGNatural Gas ProcessingU.S. Lower 48 States Natural Gas Processing Capacity (2012)Source: Energy Information Administration20DRAFT 7/1/2015Natural gas must beprocessed to remove liquidsand non-hydrocarbon gasesto become pipeline quality.Over 517 processing plantsoperate in the U.S. with acombined operating capacityof 65 billion cubic feet (Bcf)per day.Although Texas andLouisiana continue toaccount for the largestportion of U.S. processingcapacity, other States haveincreased their capacity.

PRODUCTION & PROCESSINGNatural HazardsA significant percentage of domesticoil and gas production and processingis prone to disruption by hurricanes,because they are located in the Gulf ofMexico and onshore Gulf Coast.Since 1970, about two dozen majorhurricanes (categories 3-5) have madelandfall on the shores of Texas,Louisiana, Mississippi, and Alabama,the four states where both off-shoreand onshore infrastructure isconcentrated.Other natural hazards, increasing infrequency, include tornadoes,earthquakes, ice storms, and flooding.Oil and Gas Infrastructure and Hurricane Pathssince 1970Source: National Wildfire Federation21DRAFT 7/1/2015

PRODUCTION & PROCESSINGNatural Gas System ResilienceGulf Coast Gas PipelinesHurricanes Katrina & Rita in 2005.––––Considered the most damaginghurricanes in U.S. history.A total of 113 platforms weredestroyed and 52 were significantlydamaged, while 457 pipelines weredamaged.Six months after HurricanesKatrina and Rita, 46 percent of theaffected facilities were still shutdown.However, due to the resiliency ofthe pipeline network through builtin redundancy and alternatepipeline/supply options, thenatural gas market (i.e., end-users)did not experience disruptions.Source: ICF International22DRAFT 7/1/2015

NATURAL GAS 101Presentation Outline1Overview2Production & Processing3Transmission & Storage4Distribution5Liquefied Natural Gas6Industrial Control System23DRAFT 7/1/2015

TRANSMISSION & STORAGENatural Gas Transmission & StorageSimplified Illustration of Natural Gas FlowProductionDistributionTransmissionSource: Natural Gas CouncilNatural Gas Transmission Segment Includes . . .TransmissionPipelineCompression24DRAFT 7/1/2015Storage

TRANSMISSION & STORAGENatural Gas Transmission & StorageTransmission & Storage 6. Transmission CompressorStation 7. Transmission Pipeline 8. Underground Storage(geological formations)25DRAFT 7/1/2015

TRANSMISSION & STORAGENatural Gas Pipeline SystemNatural gas pipelinetransportation systemconsists of more than300,000 miles of highstrength steel pipes of14 to 48 inches indiameter.It moves natural gasthrough thousands ofmiles from producingregions to localnatural gas utilitiesand directly to largeend users.Most pipelines are buriedbelow ground.U.S. Natural Gas Pipeline Network (2012)Source: Energy Information Administration26DRAFT 7/1/2015

TRANSMISSION & STORAGELine PipesA line pipe is manufactured from carbonsteel and is made to strict engineering andmetallurgical specifications developed bythe American Petroleum Institute.Natural Gas Line PipesThe size of interstate pipelines varies,ranging up to 48 inches in diameter.Pipeline coating: Prevents externalcorrosion by prohibiting moisture fromcoming into direct contact with the metal,providing electrical insulation between thepipe and soil.Source: Interstate Natural Gas Association of America27DRAFT 7/1/2015

TRANSMISSION & STORAGEPipeline (Transmission) CompressionCompressor stations boost the pressure in anatural gas pipeline and move the naturalgas downstream.The size of the station and the number ofcompressors vary, based on the diameter ofthe pipe and the volume of gas to bemoved.Compressors run continuously or atvariable loads to match changing naturalgas demand patterns.Most compressor units are driven byengines or turbines fueled by natural gas(extracted from the pipeline flow). Forenvironmental reasons, the use of electricmotors to drive compressor units has beengrowing.Natural Gas Pipeline Compressor StationNote: Station Mainline natural gas pipeline entering the GallionCompressor station near DeMopolis, Alabama, with a view of thescrubber towers and filter units used to eliminate contaminatesprior to compression operations.Courtesy Southern Natural Gas Company, El Paso Corporation.Source: Energy Information Administration28DRAFT 7/1/2015

TRANSMISSION & STORAGECompressor StationsNatural Gas Compressor Stations in the U.S. (2010)Compressor stations are installedtypically every 50 to 100 miles ona pipeline.More than 1,400 compressorstations exist in the U.S.Basic components of a compressorstation are:–––––Source: Energy Information Administration29DRAFT 7/1/2015Prime mover (engine,turbine, motor).Compressor units.Scrubber/filters.Cooling facilities, emergencyshutdown systems.An on-site computerizedflow control and dispatchsystem or SupervisoryControl and Data Acquisition(SCADA) system.

TRANSMISSION & STORAGESupervisory Control and Data AcquisitionSupervisory Control and Data Acquisition,or SCADA, is used to monitor and controlcertain equipment on the natural gaspipeline system.SCADA transmits operating status, flowvolumes, pressure and temperatureinformation from compressor stations,metering & regulation stations and valvesto a centralized gas control facility. Most compressor stations areunmanned and monitored by an offsite SCADA system that manages andcoordinates the operation of the severalcompressor stations that tie together anatural gas pipeline system. For more information, see “IndustrialControl Systems” section of thepresentation.Supervisory Control and Data AcquisitionSources: Interstate Natural Gas Association of America30DRAFT 7/1/2015

TRANSMISSION & STORAGEMetering StationMetering stations measure all natural gasentering or exiting the pipeline system.Meter and regulator stations also includeequipment to regulate natural gas pressureand delivery volumes.Pressure regulation equipment ensuresnatural gas delivered into or out of apipeline system is maintained within aspecified pressure range. This is importantfor safety reasons, because pipeline systemsare designed to operate within specificpressure ranges.Valves along a gas pipeline system providea means of controlling flow.Metering StationsSources: http://www.energas.co.za/applic.html31DRAFT 7/1/2015

TRANSMISSION & STORAGEUnderground Gas Storage FacilitiesNatural gas is stored in geologicformations generally thousands offeet subsurfaceStorage plays a key role inbalancing supply and demand,particularly during peak-demandperiods.Storage is used to meet seasonaldemands, serve fluctuating dailyand hourly loads, and to maintainoperational flexibility andreliability. In general, large volume storagefacilities are connected to theinterstate pipeline network. On average, storage accountsfor about 20 percent of thenatural gas consumed eachwinter.Underground Storage Facilities in the U.S. (2010)Source: Energy Information Administration32DRAFT 7/1/2015

TRANSMISSION & STORAGETypes of Underground Gas StorageTypes of Underground Natural Gas Storage FacilitiesThree key types of undergroundnatural gas storage exist.–––Source: Interstate Natural Gas Association of America33DRAFT 7/1/2015Depleted reservoirs: Mostexisting gas storage in theUnited States is in depletednatural gas or oil fields.Aquifers: In some areas, mostnotably the Midwest, naturalaquifers are used for gasstorage reservoirs.Salt caverns: Majority of saltcavern storage facilities havebeen developed in salt domeformations in the Gulf Coaststates.

NATURAL GAS 101Presentation Outline1Overview2Production & Processing3Transmission & Storage4 Distribution5Liquefied Natural Gas6Industrial Control System34DRAFT 7/1/2015

DISTRIBUTIONNatural Gas DistributionSimplified Illustration of Natural Gas FlowProductionDistributionTransmissionSource: Natural Gas CouncilNatural Gas Distribution Segment Includes . . .DistributionStorage35DRAFT 7/1/2015Regulator

DISTRIBUTIONNatural Gas DistributionDistribution10 9. Distribution Mains/Lines 10. City Gate (includes regulators &meters) Customers (includes regulators &meters) 11. Large Volume 12. Residential 13. Commercial119121336DRAFT 7/1/2015

DISTRIBUTIONNatural Gas DistributionDistribution is the last step in delivering naturalgas to customers.– Some large industrial, commercial, and electric generation customersreceive natural gas directly from high capacity interstate and intrastatepipelines.– Most customers receive natural gas from their local gas utility, alsocalled a local distribution company (LDC).– Typically, distribution occurs through smaller pipelines at lowerpressures and across shorter distances than transmission pipelines.– The distribution system consists of more than 1.9 million miles of gaspipes.– Natural gas can be stored in underground storage (in geologicformations) for use during peak demand.37DRAFT 7/1/2015

DISTRIBUTIONDistribution System Component OverviewDistribution Pipes and MetersA city-gate is a custody transferpoint from a pipeline transmissioncompany to an LDC.Main lines run up and down thestreet; service lines run from themain to the houses or businesses. Pressure regulators controlpressure within a distributionsystem. Metering stations measurenatural gas that is consumed bycustomers. Meters measure the gas used at ahome or business.Source: Naturalgas.org andmainenaturalgas.com.38DRAFT 7/1/2015

DISTRIBUTIONCity Gate and RegulatorCity Gate and RegulatorCity gate stations serve three purposes:–––Reduce the pressure in the line fromtransmission levels to distribution levels.Mercaptans and other odorants with adistinctive sour scent associated withnatural gas are added so that consumerscan smell even small quantities of gas.Measure the flow rate of the gas todetermine the amount being received bythe utility.Regulators are:––Source: Pipeline and Hazardous Materials Safety Administration39DRAFT 7/1/2015Equipment installed for the purpose ofautomatically reducing and regulating thepressure in the downstream pipeline ormain to which it is connected.Include piping and auxiliary devices suchas valves, control instruments, controllines, the enclosure, and ventilationequipment.

DISTRIBUTIONReliabilityGas utilities have a record of extremely high levels of reliability.Most distribution equipment is unmanned and may be monitored/controlledremotely through a SCADA system.Distribution systems are reliant on the transmission supply.Most distribution pipelines (like transmission pipelines) have 'line pack' as aresult of the physical characteristic of natural gas compressibility, whichprovide a small amount of “real time” storage.As such, utilities generally have some time to react to system upsets before thepipeline supply is completely exhausted and pilot lights go out. The ultimateobjective of every gas utility is to keep customers' pilot lights burning.40DRAFT 7/1/2015

NATURAL GAS 101Presentation Outline1Overview2Production & Processing3Transmission & Storage4Distribution56Liquefied Natural GasIndustrial Control System41DRAFT 7/1/2015

LNGWhat is Liquefied Natural Gas (LNG)?LNG TankerLNG is natural gas that has been cooled to aboutminus 260 degrees Fahrenheit where itcondenses to a liquid for shipment and/orstorage.The volume of the natural gas in its liquid stateis about 600 times less than in its gaseous form.In this compact form, natural gas can be shippedin special tankers to receiving terminals in theUnited States and other importing countries.At these terminals, the LNG is returned to agaseous form and transported by pipeline todistribution companies, industrial consumers,and power plants.Source: http://lng.blogr.lt/files/2008/09/lng.jpg42DRAFT 7/1/2015

LNGOverview of LNG InfrastructureThe physical infrastructure of LNG consists of interconnected transportationand storage facilities:– Tanker ships: LNG is transported to the United States in very large, speciallydesigned tanker ships, each sealed and insulated to maintain safe LNGtemperature and prevent leakage during transit.– Marine terminals: LNG tankers unload their cargo at dedicated marine terminalswhich store and regasify the LNG for distribution to domestic markets. Theseterminals consist of docks, LNG handling equipment, storage tanks, andinterconnections to regional gas transmission pipelines.– Storage “peak shaving” plants: More than 100 peak shaving plants supplementpipeline gas supplies during periods of peak demand during winter cold snaps inthe United States. During periods of high demand, the LNG is vaporized andinjected into either the gas transmission system or a distribution system.43DRAFT 7/1/2015

LNGLNG TerminalSchematic of LNG TerminalLNG TerminalSource: Energy Information AdministrationSource: Energy Information Administration44DRAFT 7/1/2015

LNGLNG FacilitiesU.S. LNG Peaking Shaving and Import Facilities (2008)In the U.S., there are:– 8 LNG importfacilities; and– 100 LNG peakingfacilities.“Satellite” storage tanksthat depend on otherfacilities to receive LNG.Source: Energy Information Administration45DRAFT 7/1/2015

LNGLNG SecurityThe following regulatory bodies oversee/regulate the security and safety ofLNG facilities and tanks.––––The International Ship and Port Security code.FERC oversees siting of LNG terminals.PHMSA oversees LNG facilities and pipelines.U.S. Coast Guard regulates LNG safety and security.The Maritime Transportation Security Act of 2002 (MTSA), for foreign-flaggedvessels entering U.S. waterways.– DOE Office of Fossil Energy regulates natural gas imports and exports.– The Department of Transportation Office of Pipeline Safety regulates thesiting and safety of LNG pipeline facilities, including LNG peak-shavingplants– The DHS Transportation Security Administration (TSA) and InfrastructureSecurity Compliance Division (ISCD) regulate different portions of LNGoperations.– The regulation of LNG facilities by states varies from comprehensive tofragmented.46DRAFT 7/1/2015

LNGLNG as Transportation Fuel SchematicLNG as Transportation FuelLNG can be used by trucks, railroads, and ships as engine fuel for transportation.Source: s/article380864.ece47DRAFT 7/1/2015

NATURAL GAS 101Presentation Outline1Overview2Production & Processing3Transmission & Storage4Distribution5Liquefied Natural Gas6Industrial Control System48DRAFT 7/1/2015

ICSOverviewA wide variety of Industrial Control Systems (ICS) are used throughout the natural gasindustry.ICS is a general term encompassing a broad group of control systems used in industrial sectorsand critical infrastructures.–––Supervisory control and data acquisition (SCADA) systems, generally used to control dispersedassets using centralized data acquisition and supervisory control. Used to control transmission anddistribution systems.Distributed control systems (DCS), generally used to control production systems within a local areasuch as a factory using supervisory and regulatory control. Used in gas processing plants and LNGfacility control.Other control system configurations such as skid-mounted Programmable Logic Controllers (PLC),generally used for discrete control for specific applications and generally provide regulatorycontrol. PLCs are often used within DCS and SCADA systems. Used in compressor station, LNGplants, processing plants, etc.The primary difference between a DCS and a SCADA system is that a DCS is usually confinedwithin a facility or plant whereas a SCADA system is geographically distributed.––SCADA systems are highly distributed systems used to control geographically dispersed assets,often scattered over hundreds of miles, where centralized data acquisition and control are critical tosystem operation, such as managing gas flow or interstate gas transmission system.ICSs are used in critical infrastructure sectors including electric, water, oil and natural gas,chemical, transportation, etc. and are often highly interconnected and mutually dependent systems.49DRAFT 7/1/2015

ICSSCADAIn the past, ICS in general (including SCADA) operated in isolated environments, and rarelyshared information with systems outside their environment.Today, however, more components of control systems have become interconnected with theoutside world using Internet-based standards, and as control networks have becomeintegrated into larger corporate networks in order to share valuable data,.Thus the probability and risk of a cyber attack has increased.A SCADA system usually consists of the following subsystems.–––––A Human-Machine Interface or HMI is the apparatus (software and hardware) which presentsprocess data to a human operator, and through this, the human operator monitors and controlsthe process.A supervisory (computer) system, gathering (acquiring) data on the process and sendingcommands (control) to the process.Remote Terminal Units (RTUs) connecting to sensors in the process, converting sensor signals todigital data and sending digital data to the supervisory system.Programmable Logic Controller (PLCs) used in compressor stations and as field devices becausethey are more economical, versatile, flexible, and configurable than special-purpose RTUs.Communication infrastructure connecting the supervisory system to the Remote Terminal Unitsand remote field site instrumentation.50DRAFT 7/1/2015

ICSSCADA System SchematicSCADA System General LayoutSource: National Institute of Standards and Technology, 2011SCADAs are used in distribution systems such as water distribution, oil and natural gaspipelines, electrical power grids, and railway transportation systems.51DRAFT 7/1/2015

ICSChallenges to ICS SecurityThe increasing convergence of once-isolated industrial control systems has helpedorganizations simplify and manage their complex environments.However, connecting these networks and introducing IT components into ICS bringsunintended security challenges due to potential vulnerabilities, such as:––––––Increasing dependency on automation and industrial control systems.Insecure connectivity to external networks.Usage of technologies with known vulnerabilities, creating previously unseen cyber risk inthe control domain.Some control system technologies have limited security and are often only enabled if theadministrator is aware of the capability (or the security does not impede the process).Some control system communications protocols do not have basic security functionality (i.e.,authentication, authorization).Considerable amount of open source information that is available regarding industrialcontrol systems, their operations, and security vulnerabilities.Good cyber security programs encompass both IT and ICS.Operators are encouraged to participate in ICS CERT or other threat sharing resource.52DRAFT 7/1/2015

NATURAL GAS 101Trends Affecting Natural Gas InfrastructureChanging Production Profiles.– Production from large onshore shale basins is shifting the focus of U.S. productionfrom the Gulf of Mexico (GOM), where it has been for the last two decades, toonshore regions.– Between 2005 and 2011: GOM production declined by approximately 42% (from 9Bcf/day to 5 Bcf/day) while onshore production (lower 48 States) increased byapproximately 43% (from 40 Bcf/day to 60 Bcf/day).– The growth of Appalachian Basin shale gas, which is reducing the need to movegas from the Southwest and Rockies to the Northeast.Natural Gas and Electricity Interdependency.– Growing relationship between the gas and power infrastructures is highlighted bythe increased need for new pipeline capacity and high-deliverability storage tomatch the growth in gas-fired power generation associated with

oil and gas production and processing is prone to disruption by hurricanes, because they are located in the Gulf of Mexico and onshore Gulf Coast. Since 1970, about two dozen major hurricanes (categories 3 -5) have made landfall on the shores of Texas, Louisiana, Missis