Transcription

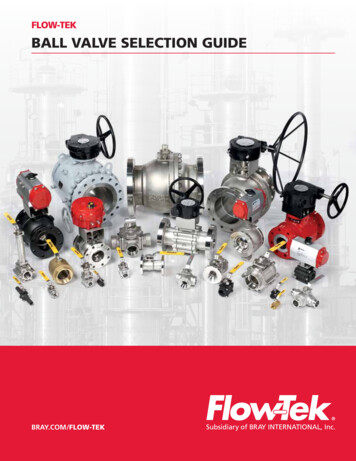

FLOW-TEKBALL VALVE SELECTION GUIDEBRAY.COM/FLOW-TEK

3 PIECE BALL VALVESTRIADFull Port¼" through 4" Firesafe – API 607StandardPort¾" through 2½" Designed in accordance withASME B16.34MaterialsStainless Steel & Carbon SteelPressureRatingsFull Port: 2200 psi WOGStandard Port: 2200 psi WOGFP & SP: up to 425 psi WSP ISO 5211 Secure Mount actuatortop flangeFeatures include live loaded Smart Stem seals through 2", a redundant body sealdesign, anti-static protection and locking safety handles. Hex head cap screws join endconnections to the tapped center section. Special body and trim materials available.SERIES 7000 & 8000Full Port¼" through 12"Materials7000 Stainless Steel8000 Carbon SteelPressureRatings¼"-4": 1000 psi WOG6"-12": 400 psi WOG ISO 5211 Secure Mountactuator top flangeFeatures include live loaded Smart Stem seals through 2½", anti-static protectionand locking safety handles. These valves are also available with cavity filler seats forspecial service requirements. Special body and trim materials available.SERIES 7500 & 7700 Comply with ASME BPETubeBore Port¼" through 2"Valve Sizes½" through 4"MaterialsStainless SteelPressureRatings¼"-4": 1000 psi WOG USP Class IV soft goods ISO 5211 (½"–2") Secure Mountactuator top flangeSpecifically designed for high purity applications. The ball and end connections havethe same I.D. as the tube piping system. Valves come standard with 20 RA maximum(SFV-1) surface finishes and all are solution cleaned and bagged. Features includelive loaded Smart Stem seals through 2½" and locking safety handlesSERIES 5000 & 6000Full Port¼" through 4"Materials5000 Stainless Steel6000 Carbon SteelPressureRatings¼"-2": 1000 psi WOG2½"-4": 800 psi WOG ISO 5211 Secure Mount actuatortop flangeAll the benefits of a 3 Piece body design at an economical price. Features include aswing out center section for ease of installation and maintenance, adjustable stempacking, heavy duty internal entry stems and stainless steel safety locking handles.3 PIECE – STANDARD END CONNECTIONS For custom end connections contact your Flow-Tek representative.TRIAD7000 & 80005000 & 6000S7500 & S77002 ThreadedButt Weld – ––BRAY.COM/FLOW-TEKExtendedWeld ––Socket WeldFlangedWeld Tube – ––––– QuickClamp––– OptionalCavity Fillers –

FLANGED BALL VALVESSERIES F15 & F30Body2 PieceFull Port½" through 12"MaterialsStainless Steel &Carbon SteelPressureRatingsF15: ASME Class 150F30: ASME Class 300 Firesafe – API 607 (Optional) Designed in accordance withASME B16.34 Face to face ASME B16.10long pattern ISO 5211 Secure Mountactuator top flangeFeatures include live loaded Smart Stem seals through 2", anti-staticprotection and locking safety handles. Larger sized valves featuretrunnion-type ball support. Special body and trim materials available.SERIES RF15 & RF301 Piece Firesafe – API 607 (Optional)StandardPortBody1" through 12" Designed in accordance withASME B16.34MaterialsStainless Steel &Carbon Steel Face to face ASME B16.10short patternRF15: ASME Class150RF30: ASME Class300 ISO 5211 Secure Mountactuator top flangePressureRatingsThese end entry flanged valves feature live loaded Smart Stem sealsthrough 2", anti-static protection and locking safety handles. Specialbody and trim materials available.SERIES F15/30 METAL SEATEDFull Port½"-12"Pressure RatingsCarbon SteelUp to 505 psi @ 750 FStainless SteelUp to 425 psi @ 750 FAvailable with a solid seat ring design. Using hardened metal seats andballs, the valves can be used in applications exceeding the limits of softseated ball valves. Each valve is tested to meet or exceed FCI 70-2 ClassV shutoff requirements as standard and class VI shutoff requirementsas an option. These metal seated valves are ideal for abrasive and hightemperature applications.VALVE SELECTION GUIDE 3

SEVERE SERVICESERIES M1DesignStandardsASME B16.34ASME Section VIII - Div 1, Appendix 2Sizes½ - 36 in. (DN 15 - 900), custom and larger sizes upon requestPressureRatingsASME 150 - 4500, custom higher pressures upon requestEndConnectionsRaised Face and Ring Type Joint (ASME B16.5 and DIN 2501)Butt welds (ASME B16.25), Socket weld (ASME B16.11)Hubs & Custom Ends AvailableTemperatureStandard design rated up to 1100 F (593 C), can be customized forhigher temperaturesEnd-To-EndASME B16.10 (Long Pattern)SERIES M4DesignStandardsASME B16.34, Bore sizes per ASME TDP-1Size RangeNPS ½ - 2½ SW or BW , DN 15 - 65, NPS 3 & 4 BW, DN 80 & 100Bore Sizes0.63”, 1.03”, 1.56”PressureRatingsASME 1700, 3100, 4500 ½” thru 2½”Limited Class 3” and 4” Standard ClassEndConnectionsSW per ASME B16.11, BW per ASME B16.25TemperatureUp to 1100 F (593 C)Body MaterialsA105, A182-F22 Cl.3, A182-F91Ball Materials410 SS/HVOF Chromium Carbide, Inconel 718/Fused Chromium CarbideSeat Materials410 SS/HVOF Chromium Carbide, Inconel 718/HVOF Chromium CarbideV-CONTROL CHARACTERIZED V-PORT BALLSValves SeriesSizes 4"½"-12"1"-12"When combined with Flow-Tek's line of pneumatic and electric actuatorsand controls, the V-Control delivers exceptional performance.With characterized V-ports, slotted ports or custom ports, V-Control ballvalves provide accurate flow control. Available in 3-Piece and flangedbodies, V-Control valves offer superior rangeability, repeatability and highflow capacity. These quarter turn valves are easily automated and makean ideal control element in process piping systems.Characterized ControlRound Bore90 V PortCv60 V Port30 V Port15 V Port1/8" Slotted Port0 4 10 20 BRAY.COM/FLOW-TEK30 40 50 PERCENT OPEN60 70 80 90 90º60º30º15ºSlotted

SPECIALTY PRODUCTSTRUNNIONBody2 Piece Cast or 3 Piece ForgedFull & Standard Port 2" through 24"MaterialsStainless Steel & Carbon SteelPressure RatingsASME Class 150, 300, 600,900, 1500 Firesafe – API 607 Designed in accordance withAPI 6DTrunnion Series valves are ideal for heavy duty applications such as oil and gasproduction, power and waste water industries. Standard design features include doubleblock & bleed, stem & seat grease fittings, body cavity drain, vent ports and self relievingspring energized seats. Special body and trim materials available.CRYOGENIC SERVICE All valves are permanently marked with aflow direction arrow.Full Port Flanged½" - 12"Full Port Triad¼" - 4"Standard Port Triad¾" - 2½" Available in a shorter stem/bonnet, lowtemperature version.TemperatureService to -260º F ISO 5211 (½"-2") actuator top flangeUsed in the production, transportation and storage of liquefied gases, these speciallydesigned valves have extended stems and bonnets that position the packing above thecryogenic fluid. Some key features include high-density TFM 1600 seat and seals andlive loaded stem packing. Valves are unidirectional with vent holes in the stem slot andupstream face of the ballSERIES 19 SEGMENTED1 Piece Body1"-12"MaterialsStainless Steel& Carbon SteelASME Class150, 300 & 600A versatile Segmented Ball Valve designed for throttling or on-off applicationsin various industries including pulp & paper, chemical, power, oil & gas, and mining.The valve features a characterized ball segment for high rangeability with splined stemconnection for precise control, maintenance friendly segment-stem assembly, lowfriction shaft and thrust bearings for longer life, integral actuator mounting pads, andinterchangeable seats. Special body and trim materials available.MEDIA CONTAINMENT UNITValve Sizes¼" - 10"Available ForTriad, 7/8000, S85, F15/F30, RF15/RF30, S7000Media Containment Units are designed to prevent costly downtime and provide doublestem sealing. Button-head check valve for injection of a sealing agent can be added.Designed for both automated and manual service, the MCU is easily installed in the fieldonto existing Flow-Tek ball valves.STEAM ISOLATIONValve Sizes½” - 12”Full port flanged ball valves are available for low temperature steam distribution andisolation service. Carbon steel, ASME Class 300 valve sizes 4” and larger are offered withoptional bypass, feature quarter turn operation, positive shutoff and live loaded packing.VALVE SELECTION GUIDE 5

MULTI-PORT BALL VALVESMulti-Port ball valves offer a wide range of flow patterns: 90 and180 T & L port 3-way balls, and 90 , 180 and 270 4-way balls.Features include a 4th seat to prevent leakage and maintain proper ballalignment, live loaded stem seal and locking handles.Ported 3 & 4-way ball valves offering excellent versatility for mixing anddiverting applications. ISO 5211 Secure Mount actuator top flangeLL-PortL-PortT-PortSERIES 130¼" through 2" Standard Port3 WayMaterialsStainless SteelPressure Ratings¼"-1¼": 1000 psi WOG1½"-2": 800 psi WOGSERIES 230 & 240¼" through 4" Full Port230 - 3 Way240 - 4 WayMaterialsStainless Steel & Carbon SteelPressure Ratings¼"-1": 1000 psi WOG1¼"-4": 800 psi WOGMUTLI-PORT FLANGEDMPF150 up to 10"MPF300 up to 6"Full PortMaterialsStainless Steel & Carbon SteelPressure RatingsMPF150: ASME Class 150MPF300: ASME Class 300 End connections designed to ASME 16.5MULTI-PORT – STANDARD END CONNECTIONS For custom end connections contact your Flow-Tek representative.130230 & 240FLANGED6 Threaded –BRAY.COM/FLOW-TEKButt Weld– –Socket Weld– –Flanged– Quick Clamp –Optional Cavity Fillers–

THREADED BALL VALVESSERIES 85 ISO 5211 Secure Mountactuator top flangeBody2 PieceFull Port½" through 3"MaterialsStainless SteelPressure Ratings½"-3": 1000 psi WOG/150psi WSGDesigned for ease of automation, features include live loaded Smart Stem seals through2", anti-static protection, replaceable seats and seals, and safety latch handles.SERIES 80 Optional seal welded bodyBody2 PieceFull Port¼" through 4"MaterialsStainless SteelPressure Ratings¼"-4": 1000 psi WOG/150psi WSGSeries S80 ball valves have been designed to meet the needs of the chemical, textile andprocess industries. An economical full port valve featuring adjustable stem packing, safetylatch handles, and optional oval handles.SERIES 70 & 90Body2 PieceStandard Port¼" through 3"MaterialsS70 Stainless SteelS90 Carbon SteelPressure Ratings¼"-1": 2000 psi WOG1¼"-2": 1500 psi WOG2½"-3": 1000 psi WOG150psi WSGAn economical solution for high pressure applications in the process industry. Features includeadjustable stem packing, integrally cast actuator mounting pad, safety latch handles, andoptional oval handles.SERIES 20Body1 PieceReduced Port¼" through 2"MaterialsStainless SteelPressure Ratings¼"-2": 2000 psi WOG/150psi WSG Firesafe – API 607 (Optional)One piece body design supplies maximum structural strength while reducing leak paths.Features include live loaded stem seals, safety latch handles, and optional oval handles.SERIES 40Body1 PieceReduced Port¼" through 2"MaterialsStainless SteelPressure Ratings¼"-2": 1000 psi WOG/150psi WSGAn economical, compact, one piece body design thatsupplies maximum structural strength while reducingleak paths. Features include low operating torque andsafety latch handles. Optional oval and wing handlesare available.VALVE SELECTION GUIDE 7

THREADED BALL VALVESSERIES HP, 3HP, & HX INSTRUMENTATION VALVES3 Piece Body¼" through 1"MaterialsStainless SteelPressure RatingsHP: 6000 psi WOGHX: 10,000 psi WOG3HP: 6000 psi WOGEnd ConnectionsNPT ThreadedPanelMountSERIES 51 COMMERCIAL UTILITY VALVES2 Piece Body¼” through 4”MaterialsBrassPressure Ratings¼”-2”: 600 psi WOG2½”-4”: 400 psi WOG¼”-4”: 150 psi WSPEnd ConnectionsNPT ThreadedELECTRIC AND PNEUMATIC ACTUATORSOutput Torque50 to 44,130 lb-in at 80 psiSERIES 92/93PNEUMATIC –DOUBLE ACTING &SPRING RETURNRack & pinion, opposed-pistonpneumatic actuators are selfcontained with integral internalporting. Units are suitable forboth on/off and throttlingapplications. Double Acting Rotation: 90 ,135 , 180 Spring Return Rotation: 90 Supply pressure up to 145 psi(10 bar) Temperature Range: -20 F(-29 C) to 200 F ( 95 C)Output Torque300 to 18,000 lb-inOutput Torque5,310 to 70,000 lb-inSERIES 70 ELECTRICACTUATORFTG SERIES WORMGEAR OPERATORSSRH SERIES SPRINGRETURN HANDLESThis design offers greatlyreduced space requirements,lighter weight and ease ofinstallation and maintenance.¼” through 12” Ball Valves(Deadman Handle) for ¼”through 2” Ball Valves Designed to meet NEMA 4,4x (IP 65) or NEMA 4,4x,7,9 120 or 220 VAC single phasepermanent split-capacitorreversible induction ULlisted motor, 24 VDC motoroptional 90 reversible rotation Temperature Range: -40 F(-40 C) to 150 F ( 65 C)A Subsidiary of BRAY INTERNATIONAL, Inc.8323 N. Eldridge Pkwy #100 Houston, Texas 77041832.912.2300 Fax: 832.912.2301www.flow-tek.comOptions: Locking Device,Chain Wheels, Horizontal FlagIndicator, 2” Square Input DriveNut, Grease Fitting & FlowPattern Indicators for MulitportValvesFeature a ductile iron housing,aluminum bronze gear segmentand one piece steel wormgear input shaft with taperedroller bearings on both ends.Adjustable travel stops provideprecise adjustment in both openand closed positions. Housingsare sealed and weather proof tofully isolate internal parts fromatmospheric conditions.Manufactured from heavy dutystainless steel components towithstand frequent daily use inrefueling, sampling, drains, andother OSHA applications thatrequire positive safety closureof a manual valve. Each SRHHandle has a standard lockingdevice.Available in three sizes thatmount directly to the ruggedinvestment cast ISO 5211mounting pads on compatibleFlow-Tek full or standard portball valves.All statements, technical information, and recommendations in this bulletin arefor general use only. Consult Flow-Tek representatives or factory for the specificrequirements and material selection for your intended application. The right tochange or modify product design or product without prior notice is reserved.Flow-Tek is a registered trademark of Bray International, Inc. 2019 Flow-Tek, Inc.F-2101 EN VSG 03 2019

ASME B16.34 ASME Section VIII - Div 1, Appendix 2 Sizes ½ - 36 in. (DN 15 - 900), custom and larger sizes upon request Pressure Ratings ASME 150 - 4500, custom higher pressures upon request End Connections Raised Face and Ring Type Joint (ASME B16.5 and DIN 2501) Butt welds (ASME B16.25), Socket weld (ASME B16.11) Hubs & Custom Ends Available