Transcription

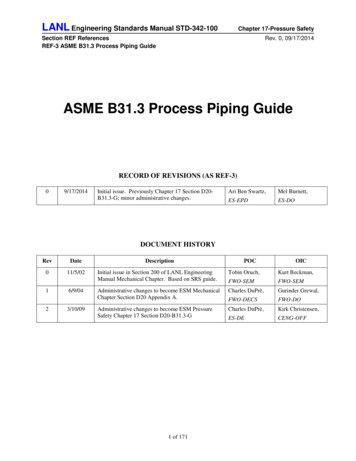

LANL Engineering Standards Manual STD-342-100Chapter 17-Pressure SafetySection REF ReferencesREF-3 ASME B31.3 Process Piping GuideRev. 0, 09/17/2014ASME B31.3 Process Piping GuideRECORD OF REVISIONS (AS REF-3)09/17/2014Initial issue. Previously Chapter 17 Section D20B31.3-G; minor administrative changes.Ari Ben Swartz,Mel Burnett,ES-EPDES-DODOCUMENT COICInitial issue in Section 200 of LANL EngineeringManual Mechanical Chapter. Based on SRS guide.Tobin Oruch,Kurt Beckman,FWO-SEMFWO-SEMAdministrative changes to become ESM MechanicalChapter Section D20 Appendix A.Charles DuPrè,Gurinder Grewal,FWO-DECSFWO-DOCharles DuPrè,Kirk Christensen,ES-DECENG-OFFAdministrative changes to become ESM PressureSafety Chapter 17 Section D20-B31.3-G1 of 171

LANL Engineering Standards Manual STD-342-100Section REF ReferencesREF-3 ASME B31.3 Process Piping GuideChapter 17-Pressure SafetyRev. 0, 9/17/2014TABLE OF CONTENTSPURPOSE .4B31.3 INTRODUCTION .4I - SCOPE AND DEFINITIONS .5II - DESIGN .6III - MATERIALS . 16IV -STANDARDS FOR PIPING COMPONENTS . 16V - FABRICATION, ASSEMBLY AND ERECTION . 16VI - INSPECTION, EXAMINATION AND TESTING . 21APPENDIX A – PIPING SPECIFICATIONS . 26APPENDIX B – FLUID SERVICE SHEETS . 80APPENDIX C – MATERIALS SELECTION . 101APPENDIX D – VALVE SELECTION GUIDE . 106APPENDIX E – FLANGED CONNECTIONS . 119APPENDIX F – ALIGNMENT FIT-UP TOLERANCES . 127APPENDIX G – COMPONENT IDENTIFICATION . 132APPENDIX H – LEAK/PRESSURE TESTING . 140APPENDIX I – STRESS ANALYSIS . 145APPENDIX J – FILLET WELD SIZES. 151APPENDIX K – CLEANING CARBON AND STAINLESS STEEL PIPE. 156APPENDIX L – BURIED PROCESS PIPE . 162APPENDIX M – MITERED JOINTS . 163APPENDIX N – BRANCH CONNECTIONS . 165APPENDIX O - SAFETY CLASS PIPING SYSTEMS . 167APPENDIX P – REPAIRS, MODIFICATIONS AND MAINTENANCE . 168APPENDIX Q - APPLICATION OF ASME B31.3 TO RADIOACTIVE FLUIDS . 170Page 3 of 171

LANL Engineering Standards Manual STD-342-100Chapter 17-Pressure SafetySection REF ReferencesREF-3 ASME B31.3 Process Piping GuideRev. 0, 9/17/2014APPENDIX R – DEFINITION OF ACRONYMS . 171PURPOSEThis Guide provides information for the proper application of the ASME B31.3 Code "Process Piping,” Itwas last updated for the 2002 edition. ASME B31.3 applies to process piping and tubing systems at LosAlamos National Laboratory (LANL). This Guide also contains ASME B31.1 and AWWA compliant PipingSpecifications. Guide users are responsible for compliance with all aspects of the applicable Code. ThisGuide addresses only B31.3, however this guidance is typical of the requirements of other piping Codes.The information contained in this Guide provides clarification to the Code text, additional information notcontained in ASME B31.3, and design input specific to LANL. This Guide is not to be used as a standalone document. This Guide is formatted to be used in conjunction with ASME B31.3, by following thesame section numbering as B31.3 Code. Appendix references herein are to this Guide, not B31.3 or theESM, unless otherwise noted.A user who desires clarifications on the application of piping related Codes and Standards should contactthe LANL Engineering Standards Pressure Safety Point-of-Contact.In the event of a contradiction between this and other ESM material, the other material shall have priority.B31.3 INTRODUCTIONThe Introduction to ASME B31.3 states "It is the owner's [Design Authority] responsibility to determinewhich Code Section is most applicable to the piping installation.”The other ASME B31 Code Sections and other common National Consensus Codes are listed in Table 1.Building and plumbing Codes as required by state and local jurisdictional requirements apply to potablewater, and for sewer and drain systems that do not have a process function.Table 1- National Consensus Codes and Standards for .4B31.5B31.8B31.9B31.11Z223.1C 100C 200C 300C 400C 500C 600C 900M9M11MultipleTitlePower PipingLiquid Petroleum Transportation Piping SystemsRefrigeration PipingGas Transmission and Distribution Piping SystemsBuilding Services PipingSlurry Transportation Piping SystemsNational Fuel Gas Code (same as NFPA 54)Cast-Iron Pipe, FittingsSteel PipeConcrete PipeAsbestos Cement PipeValves and HydrantsPipe LayingPVC Pressure PipeConcrete Pressure PipeSteel Pipe-Guide for Design and InstallationFire Protection SystemsGuidance supplementing the Code is necessary because the Code provides no explicit rules forfunctional design, material compatibility with fluid and environment (erosion/corrosion protection, radiationPage 4 of 171

LANL Engineering Standards Manual STD-342-100Section REF ReferencesREF-3 ASME B31.3 Process Piping GuideChapter 17-Pressure SafetyRev. 0, 9/17/2014effects, etc.), layout, serviceability, steam tracing, grounding, valve and component selections, design ofpipe supports, material traceability, gasket selection, as-built tolerances, insulation, cleaning for specialprocess, etc. Also, for certain services some options available through B31.3 must be excluded, mademore stringent or supplemented by the designer.Warning: The original and continued safe operation of a piping system depends on the competentapplication of codes and standards.The Owner and Designer are responsible for compliance with the personnel and process qualificationrequirements of the codes and standards.In particular, the application of ASME B31.3 requires compliance with the Inspector qualificationrequirements of ASME B31.3 Section VI for all fluid services (safety or non-safety related).I - SCOPE AND DEFINITIONS300(b) -ResponsibilitiesThe following responsibilities are applicable at LANL:1)Owner - The Owner is the Design Authority. See Acronyms and Definitionssections in ESM Chapter 1 Section Z10 and Chapter 17, Pressure Safety.2)Designer - The Designer is the Design Agency.3)One of the signoffs on a piping work package must reflect an "Owner'sInspector" review. This means:The person signing must have the minimum experience of 340.4(b), andThe person signing must have verified, to the extent necessary, that code andengineering design requirements for examination and testing are met (341.4.1).300(c) -300.1.1 -300.1.3 -Intent of the Code1)The code addresses the structural integrity of the piping system. The designer isresponsible for all other aspects of the design including the functional design of thesystem.2)Recommendations for applying ASME B31.3 Code to repairs, modifications, andmaintenance are provided in Appendix P.3)Appendix B provides Fluid Service Sheets to assist in selection of materials forcompatibility with common fluid services. Historical TA-55 Specification 4401-J-1contains material recommendations for PF-4.Content and Coverage1)ASME B31.3 may be applied to Radioactive Fluid Services. See Appendix Q.2)Transfer lines between facilities (such as waste or steam transfer lines) thatsupport processing functions may be designed and constructed to ASME B31.3.Exclusions1)Note that paragraph 300.1.3 (a) does not exclude vacuum systems.Page 5 of 171

LANL Engineering Standards Manual STD-342-100Chapter 17-Pressure SafetySection REF ReferencesREF-3 ASME B31.3 Process Piping Guide300.2 -Rev. 0, 9/17/20142)Radioactive fluids should not be excluded from ASME B31.3 Scope.Appendix Q.3)For fire protection, refer to the NFPA Codes and ESM Chapter 2.SeeDefinitions1)Category M Fluid Service is recommended for safety class piping systems. SeeAppendix O.2)Radioactive fluids should not be classified as Category D Fluid Service.Appendix Q.3)The Owner’s Inspector is responsible for verifying the piping installation to theextent necessary to be satisfied that it conforms to all applicable examinationrequirements of the Code and of the Engineering Design. LANL Owner’sInspector(s) are designated by the Construction Engineering4)Normal fluid service Piping Specifications (Appendix A) may be used in CategoryD fluid service.5)Examiner - The person(s) certified by the employer as qualified to perform thequality control functions specified in ASME B31.3. The LANL ESM Chapter 13specifies how NDE is processed at LANL.SeeII – DESIGN301.1 -GeneralOf all the design considerations listed in 301, only pressure rating is covered in the PipingSpecifications in Appendix A. The Piping Specifications provide materials, fittings, andfasteners, which meet the pressure design requirements of B31.3. The designer mustaddress all design conditions.301.2.2 -Required Pressure Containment or ReliefPiping systems are designed to either safely contain or relieve the maximum pressurethat can be imposed. Plant fires can present a safety concern for certain piping systems.The installation of pressure relief devices should be considered for liquid systems greaterthan 6” ID that can have isolated fluid.Helpful information is available in ESM Chapter 17.301.5.1 -ImpactPiping systems must be designed to withstand anticipated fluid transients(waterhammers, pressure surges, etc.). These are the transients expected to occurduring normal operation of the system. Piping systems cannot be designed forunanticipated transients. These are the transients that can occur if the system is notproperly operated. Unanticipated transients must be eliminated by design (layout) andappropriate startup and operating procedures.Page 6 of 171

LANL Engineering Standards Manual STD-342-100Chapter 17-Pressure SafetySection REF ReferencesREF-3 ASME B31.3 Process Piping Guide301.5.2/3-Rev. 0, 9/17/2014Wind and EarthquakeThe applicable wind and earthquake requirements are defined LANL EngineeringStandards Manual Structural Chapter 5.301.5.4 -VibrationNew designs, modifications, repairs, replacements, should be visually inspected atstartup to verify that vibration is not excessive. The rules of ASME "Standards andGuides for Operation and Maintenance of Nuclear Power Plants" OM-S/G, Part 3, can beused for guidance. The ASME OM document provides a methodology to evaluatevibration using high cycle fatigue analysis and can be applied to any piping system.301.8 -Effects of Support, Anchor, and Terminal MovementsSoil settlement can adversely affect the integrity of a piping system and the flow in asloped line. When proper slope is required to maintain flow in an underground pipingsystem, soil settlements need to be evaluated in the design of the piping system.302.2.1 -Listed Components Having Established RatingsTables 326.1, A326.1, and K326.1 provide a listing of standards and specifications thathave been accepted by the Code. Some of these standards provide establishedpressure/temperature ratings for components (e.g., ASME B16.5). The components maybe used in piping systems within the specified ratings without additional analysis. If thesecomponents are used outside established ratings additional analysis is required.302.2.2-Listed Components Not Having Specific RatingsSome standards and specifications provided in Tables 326.1, A326.1, and K326.1 basepressure/temperature ratings on equivalent schedule (wall thickness) of straightseamless piping less mill tolerance (e.g., ASME B16.11). The ratings of thesecomponents are addressed in the piping specifications provided in Appendix A. If thesecomponents are used outside the limits established in the piping specification additionalanalysis and documentation must be provided.302.2.3 -Unlisted ComponentsThe ASME B31.3 Code defines unlisted components as components not in Tables 326.1,A326.1, or K326.1. Unlisted components can have pressure ratings but the owner and/orthe designer has the responsibility to verify that the design, materials, fabrication,examination, and testing of the component meet the requirements of ASME B31.3.Unlisted components are generally categorized as one of the following: Components built to Unlisted Published Standards,Components built to Manufacturers Standards, orComponents built to Site Standards or Engineering Design.Each of these categories is addressed below.COMPONENTS BUILT TO UNLISTED PUBLISHED NATIONAL STANDARDSComponents built to other published National Standards may be used provided that thedesign, material, fabrication, examination, and testing have been verified to meet thePage 7 of 171

LANL Engineering Standards Manual STD-342-100Chapter 17-Pressure SafetySection REF ReferencesREF-3 ASME B31.3 Process Piping GuideRev. 0, 9/17/2014requirements of ASME B31.3. The Code states that the pressure design must meet therequirements of paragraph 304 of B31.3. The rules described below for componentsfabricated at LANL should be followed when published National Standards are notacceptable.COMPONENTS BUILT TO M ANUFACTURERS STANDARDSComponents built to Manufacturers Standards have not been established by a consensusbody and require a more detailed review than components built to Published NationalStandards. Many manufacturers build components for application in ASME B31.3 pipingsystems therefore, evaluations of the design, materials, fabrication, examination, andtesting to B31.3 requirements is less difficult.The pressure/temperature design of the component should provide the same safetymargins as the Code. When evaluating these components the manufacturers should becontacted to determine what documentation is available for the components. Suppliersor distributors of the component may not understand the Code and may not be helpful inresolution of the issues associated with qualifications of the unlisted component.Manufacturers are the best source of information. If the manufacturer’s documentation isnot acceptable, the owner and designer must perform the component qualification. Therules described below for components fabricated at LANL should be followed whenManufacturers Standards are not acceptable. Another alternative is to select a differentmanufacturer to supply components that meet B31.3 requirements.COMPONENTS BUILT TO SITE STANDARDSPiping components that form part of the pressure boundary of a piping system, that arefabricated at LANL require qualification to the requirements of the B31.3 Code. Thepressure design of these components is specified in paragraph 304.7.2 of the Code. TheCode requires that calculations be performed to support the design of these components.These calculations must be consistent with the design criteria of the Code and mustconsider all applicable ambient and dynamic loads (ref. paragraph. 301.4 through301.11). The Code also requires that the calculations be substantiated by one of thefollowing methods: Extensive successful service of the component under comparable conditionsincluding loading, environment and fabrication of like materials,Experimental stress analysis to code requirements,Proof testing to code requirements, orDetailed stress analysis to ASME B&PV Code Section VIII, Div. 2.EVALUATION OF COMPONENTS FOR PRESSURE/TEMPERATURE RATINGSThe preceding describes actions to meet necessary Code requirements for unlistedcomponents. All piping components in a B31.3 system must meet the minimum Coderequirements for design, materials, fabrication, examination, and testing. The followingguidance is provided for review of these areas when evaluating an unlisted component.DESIGNThe rules in B31.3 address the pressure design of components in paragraph 304. Therules and equation in paragraph 304 can be applied to simple shapes, such as cylindersand other common piping geometry. Equations and rules for additional shapes can befound in the ASME B&PV Code Section VIII. The design methodology in Section VIII isacceptable for unlisted component analysis in B31.3. Additional methods used toevaluate unlisted components include the use of equations in “Roark’s Formulas forStress and Strain”. The use of all these equations requires that the components bePage 8 of 171

LANL Engineering Standards Manual STD-342-100Section REF ReferencesREF-3 ASME B31.3 Process Piping GuideChapter 17-Pressure SafetyRev. 0, 9/17/2014idealized into bounding shapes for which the equation is valid. Manufacturers generallyuse simple shapes in the design of components, to minimize fabrication costs.Design qualification of unlisted components can also be accomplished by comparison tolisted components with established pressure/temperature ratings. The comparisoninvolves a review of the wall thicknesses and geometry to demonstrate that the unlistedcomponent is bounded by a component with an established pressure rating.M ATERIALTypically, unlisted components are fabricated from B31.3 listed materials. However,when the materials are not listed by the Code, the material must be qualified inaccordance with the requirements of the Code. Reviewing the material of an unlistedcomponent is done to ensure a specified minimum allowable stress at the designtemperature. The sources for allowable stress values include the ASME B31 Codes ofPressure Piping and the ASME B&PV Code Section II. B&PV Code Cases should also bereviewed for allowable stresses for specific materials. The material should also bereviewed for susceptibility to degradation mechanisms associated with the serviceconditions, including a review of brittle fracture.FABRICATIONThe processes used to fabricate unlisted components must also be reviewed for Codecompliance. Some fabrication processes can cause gross or local wall thinning. If wallthinning is possible, thinning should be accounted for when the nominal thickness isspecified. Additional fabrication allowances should be added to the required thickness toaccount for manufacturing processes. Examples of wall thinning include the 12½% milltolerance that is applied to all piping and the allowances for wall thinning due to pipebending and threading. If welding is used, the welders and welding procedure must bequalified to ASME Section IX. If bolting is used, torquing procedures should beconsistent with Appendix E.EXAMINATIONSUnlisted components fabricated at LANL must be examined in accordance with the Code.Components that are mass-produced to manufacturer’s standards may have statisticalquality control methods applied. When components are built to manufacturer’s standardsthat require examinations, the standard should be reviewed to ensure that the extent ofrequired examination and acceptance criteria meet the Code requirements for thespecified fluid service category. When manufacturers do not specify examinationrequirements, the design should be reviewed to ensure that adequate margin (i.e., wallthickness) exists above the minimum design requirements to address the lack ofexamination. To review this aspect, the Basic Casting Quality Factors, Table A-1A ofB31.3, the Basic Quality Factors for Longitudinal Weld Joints, Table A-1B, and the JointEfficiencies, UW-12 B&PV Section VIII, can be used as guidance in determining anadequate wall thickness for castings or components joined by welding.TESTINGThe B31.3 Code requires leak testing for all components. This test does not assess thestructural integrity of the components. The Code leak test is performed at pressure levelsthat do not challenge the ultimate strength required by the Code. In most cases thecomponent is subjected to the leak test after being installed in the field. All componentsshould be reviewed to insure that their pressure/temperature rating is acceptable for thetest conditions.Some components will be qualified using a structural integrity test. The B31.3 Codeaccepts proof tests in accordance with the ASME B16.9, MSS SP-97, and ASME B&PVPage 9 of 171

LANL Engineering Standards Manual STD-342-100Section REF ReferencesREF-3 ASME B31.3 Process Piping GuideChapter 17-Pressure SafetyRev. 0, 9/17/2014Section VIII Division 1, UG-101.When components are qualified by proof test, thefactor of safety between failure and the pressure rating should be as specified in theCode to which the component was tested. When a factor of safety is not specified,margins against failure that ensure safety equal to or superior to the intent of the ASMEB31.3 Code must be applied.INSTRUMENTSInstruments are not in the scope of ASME B31.3. The Code defines the boundary toinclude all piping (tubing) and components used to connect instruments to other piping orequipment, but specifically excludes instruments. Instruments are usually purchased aspressure rated components. When evaluating instruments for use in pressure pipingsystems, the requirements of DOE Order 440.1A must be considered. This order states“When National Consensus Codes are not applicable (because of pressure range, vesselgeometry, uses of special materials, etc.), implement measures to provide equivalentprotection and ensure safety equal to or superior to the intent of the ASME Code.”When evaluating instruments the designer should ensure that the instruments areselected to meet the requirements of the fluid service. Specifically, the instrument’spressure/temperature rating must be equal to or exceed the design pressure and designtemperature of the system. The attachment of the instrument to the piping system mustmeet the requirements of B31.3. When instruments are fabricated from pipingcomponents (e.g., flanges and spool pieces), the piping components must meet therequirements of B31.3.OTHER LOADSThe design equations and rules in the B31.3 Code only address the pressure loading ofcomponents. Components must be designed for all applicable loads expected during thedesign life of the component. See paragraph 301 “Design Condition” of B31.3 for a listingof loads to be considered. At LANL, ESM Structural Chapter should be used to specifyNPH loading.302.3.5Limits of Calculated Stresses due to Sustained Loads and Displacement StrainsStress Analysis, for loading other than pressure, per ASME B31.1 is acceptable andrecommended. When the B31.1 Code is used for the stress analysis, Paragraph 104.8shall be used in its entirety. Appendix I provides guidance for stress analysis of pipingsystems.302.3.5(c)Longitudinal Stresses SLThe longitudinal stress SL due to deadweight only can be kept within approximately2300 psi if vertical hangers are spaced as shown in Table 2 (from ASME B31.1).Page 10 of 171

LANL Engineering Standards Manual STD-342-100Chapter 17-Pressure SafetySection REF ReferencesREF-3 ASME B31.3 Process Piping GuideRev. 0, 9/17/2014Table 2 - Spacing of Vertical SupportsNominalPipe SizeNPSWaterServiceft.Steam, Gas,or Air 203039243242Notes:1)Maximum spacing between vertical pipe supports for horizontal straight runs ofstandard and heavier pipe at maximum operating temperature of 750 F.301Does not apply where span calculations are made or where there are concentrated loadsbetween supports, such as flanges, valves, specialties, etc.302The spacing is based on a fixed beam support with a bending stress not exceeding 2300psi and insulated pipe filled with water or the equivalent weight of steel pipe for steam,gas, or air service. The pitch of the line is such that a sag of 0.1 in between supports ispermissible.303Applied only for deadweight design. Other loading conditions must be evaluated.302.3.6 -Limits of Calculated Stresses due to Occasional LoadsFor accident (faulted) conditions and one-time non-repeated anchor motions, theallowable stress may be increased to:S min (3Sh, 2Sy)Allowables (Sh) are from B31.1 which are lower than B31.3.304.1.2 -Straight Pipe under Internal PressureFor the pipe size, schedule, material and design pressure/temperature combinationsprovided in the Piping Specifications, this section is met. If the piping specifications inAppendix A are not applied for the pressure design, additional engineeringcalculations are required.304.2-Mitered Segments of PipeAdditional calculations are required for mitered joints. See Appendix M for mitered jointevaluation methodology.Page 11 of 171

LANL Engineering Standards Manual STD-342-100Section REF ReferencesREF-3 ASME B31.3 Process Piping Guide304.3 -Chapter 17-Pressure SafetyRev. 0, 9/17/2014Branch ConnectionsAdditional calculations are required to determine necessary reinforcement.Appendix N for branch connection evaluation methodology.307 -SeeValvesA selection guide for valves is provided in Appendix D. This guide provides informationto aid in selection of the proper valve for the intended fluid service.308.4 -GasketsAppendix C provides information on gasket ratings to be used in the selection of gaskets.Appendix B provides some information on compatibility of gasket materials with commonfluids.309 -BoltingTorque values for flanged joints are provided in Appendix E.319.4 -Flexibility AnalysisFormal flexibility analysis is not necessary if:1)The design temperature is at or below 150 F and the piping is laid out withinherent flexibility304The design temperature is at or below 250 F and the piping is analyzed for flexibilityusing simplified methods of calculation.321 -Piping SupportDesign of pipe supports are addressed in Standards such as ManufacturersStandardization Society of the Valve and Fittings Industry MSS-SP-58. Allowable stresslevels for supports are provided in the AISC Manual of Steel Construction and the AISCStandard N690. N690 is normally reserved for safety class and safety significantsystems. The ESM Structural Chapter provides more details for applications at LANL.Guidance for the design and modeling of piping supports is provided in Appendix I.322 -Specific Piping SystemsIn addition to the Code requirements, engineering practice has lead to rules of gooddesign practice to provide for safe and cost-effective piping systems. The following areexamples of such rules. These rules must be applied by competent engineers inaccordance with approved procedures.1)Arrangement304.1Piping should be grouped in banks, where feasible, and allow the most efficient supportarrangement. Piping oriented in one direction should be located at the same generalelevation, where feasible.304.2Piping arrangement should provide space for maintenance, inspection and repair ofcomponents (including disassembly).Page 12 of 171

LANL Engineering Standards Manual STD-342-100Chapter 17-Pressure SafetySection REF ReferencesREF-3 ASME B31.3 Process Piping GuideRev. 0, 9/17/2014304.3Piping arrangement should provide access to operating areas, corridors, observationwindows, manholes and handholes.304.4Piping should conform to plant clearances above floor and grade. A minimum clearanceof 7'-6" is desirable.305Vents and Drains305.1Vents and drains should be ¾ " or larger and as short as practical.305.2Drains from process lines should be piped to an appropriate collection or disposalreceptacle. Drains from steam systems should be piped to boiler feedwater system wheneconomically justified. Otherwise, they should be properly flashed and piped to waste.305.3Valves should not be installed where safety/process function of a piping system can beimpeded (e.g. tank overflow lines, relief valves, vacuum breakers, etc.).305.4Caps are needed if the vent and drain lines require pressure testing.305.5Caps are needed if the fluid service presents a contamination concern.305.6Vents located outside without caps should be configured so that rainwater won’t collect inthe end of the piping.305.7Leakage through vent and drain valves on capped lines is a safety is

contained in ASME B31.3, and design input specific to LANL. This Guide is not to be used as a stand-alone document. This Guide is formatted to be used in conjunction with ASME B31.3, by following the same section numbering as B31.3 Code. Appendix references herein are to this Guide, not B31.3 or the ESM, unless otherwise noted.