Transcription

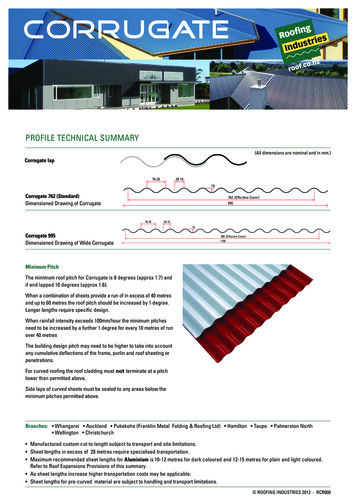

CORRUGATEPROFILE TECHNICAL SUMMARYCORRUGATE 762(AllCorrugate lap76.20Roofing and Standard Wall Cladding Configuration.dimensionsare nominal and in mm.)All measurements are in millimetres and are nominal.38.1019Corrugate 762 (Standard)Dimensioned Drawing of Corrugate762 (Effective Cover)84576.20CORRUGATE 995Roofing and Standard Wall Cladding Configuration.All measurements are in millimetres and are nominal.38.1019Corrugate 995Dimensioned Drawing of Wide Corrugate995 (Effective Cover)76.20110038.1019Minimum PitchThe minimum roof pitch for Corrugate is 8 degrees (approx 1:7) andif end lapped 10 degrees (approx 1:6).When a combination of sheets provide a run of in excess of 40 metresand up to 60 metres the roof pitch should be increased by 1 degree.Longer lengths require specific design.When rainfall intensity exceeds 100mm/hour the minimum pitchesneed to be increased by a further 1 degree for every 10 metres of runover 40 metresThe building design pitch may need to be higher to take into accountany cumulative deflections of the frame, purlin and roof sheeting orpenetrations.For curved roofing the roof cladding must not terminate at a pitchlower than permitted above.Side laps of curved sheets must be sealed to any areas below theminimum pitches permitted above.Branches: Whangarei Auckland Pukekohe (Franklin Metal Folding & Roofing Ltd) Hamilton Taupo Palmerston North Wellington Christchurch Manufactured custom cut to length subject to transport and site limitations. Sheet lengths in excess of 28 metres require specialised transportation. Maximum recommended sheet lengths for Aluminium is 10-12 metres for dark coloured and 12-15 metres for plain and light coloured.Refer to Roof Expansions Provisions of this summary. As sheet lengths increase higher transportation costs may be applicable. Sheet lengths for pre-curved material are subject to handling and transport limitations. ROOFING INDUSTRIES 2012 - RCR000

Information TableSubstrate MaterialThicknessSteelAluminium.40mm BMT.55mm BMT.70mm BMT.90mm BMT3.24.271.842.37Aprox weight per lineal metre forsubstrate material (kg/lm)Purlin Spacings -GeneralRefer to separate section.Refer to separate section.Unsupported Overhang (mm) 1150150100150Drape Curved Roof-Minimum Radius (m)12101210Purlin Spacings for Curved Roofs-Intermediate (mm)-End (mm)90060012008008005501200800Precurved Roof-Minimum Radius (mm)-Recommended Minimum Radius (mm)N/R 2N/R 23004003004003004001Not suitable for roof access without additional support2N/R - Not recommendedThis technical data sheet is for steel and aluminium based substrates. Corrugate can also be manufactured in other metals such as copperor titanium zinc. Refer to Roofing Industries.SpecificationRefer to our Full Specification on Masterspec, our website, and our Selection Guide.Building Design / Performance Criteria / Product SelectionDuring the design of buildings, it is necessary for the designerto take into account a number of issues to ensure that the mostappropriate roofing and cladding product is chosen.Whilst aesthetics and product availability do play a part, the chosenprofile must meet certain performance criteria. These are centredaround the profile’s ability to shed water from the roof and the abilityof the product to span purlin and girt spacings and meet designcriteria. The minimum pitch for this profile is outlined elsewherewithin this literature.In terms of purlin spans and girt spacing it is necessary to follow dueprocess.If a building is being designed and constructed in full accordancewith E2/AS1 and roofing and cladding products as covered by thatdocument are chosen, then it is necessary for the design spans andfixing methodology to comply with those of E2/AS1. However E2/AS1states that the use of the manufacturers information may providea more optimum spacing of fixings, and this is recommended byRoofing Industries.Further where a building is outside of the scope of E2/AS1 and thebuilding or parts thereof are of specific design then it is necessary forthe roofing and cladding to be suitable for the design and vice versa.Loadings referred to in Roofing Industries graphs are the result oftesting to a serviceability limit state which is more conservativethan an ultimate limit state as quoted by some manufacturers.Our Design Graphs are presented in a form to allow the designer toselect suitable products and purlin spacings.For most roof installations the purlin spacings will be limited by thetrafficable limitations of the profile or the structural design. It is thennecessary for the designer to calculate the design wind load forthe roofing and cladding in accordance with generally acceptablepractice, by reference to AS/NZS 1170.2:2011 and/or NZS 3604:2011.CORRUGATEFor a fuller explanation of this refer to the NZ Metal Roof and WallCladding Code of Practice. This result should be referenced to theWind Load Span Design Graphs.The purlin spacings should be limited to the lower of the trafficablelimitations and design wind load with the capacity of the structurebeing greater than the design load for the application. Howeverfor roofs that are not able to be walked on and for wall claddingapplications, the trafficable limitations may be exceeded providingthe design wind loading criteria is met. However this should bedone with caution as it may require considerable extra secondaryfasteners within the laps.The designer should always take into account in areas of heavy rooftraffic, snow loadings, or where the roofing supports such items asair conditioning units, purlin spacing should be reduced accordingly.Consideration also needs to be given to limitations of purlin spacingsfor any translucent sheeting.Reference should be made to the notes in the graphs.It is our recommendation that for commercial and industrial roofingapplications that .55mm BMT steel or .90mm BMT Aluminium is usedas it has more resilience to damage particularly by other trades.Underlay as per the project specifications should be used.With an aluminium substrate steel netting should not be used whereit may be in contact (either directly or through underlay degradation)with the aluminium roofing or cladding. Alternative material such aspolypropylene strapping should be used where support is required,or the cladding separated from the underlay by a high densitypolystyrene batten or Thermakraft Drainage Matt or similar, and theuse of an aluminium gutter flashing. This is also applicable to coatedmetal and zinc roofing in severe marine applications. As corrugatedhas a minimum pitch of 8º, self supporting paper (without the use ofnetting or other support) can generally be used, and in any case selfsupporting paper is recommended even when support is required, inthe above situations.

WIND LOAD SPAN DESIGN GRAPHRoofing - Steel Based MaterialkPa .40 Steel G550 High Strength6.0kPa .55 Steel G550 High 61.82.02.22.4Intermediate span in metres, end spans to be 2/3 of intermediate Intermediate span in metres, end spans to be 2/3 of intermediate spanC1L, C2L, C1, C3L,C2 and C3 represent alternative primary fixing methodsTesting confirms that .70mm Aluminium has similar results to .40mm Steel and that .90mm Aluminium has similar results to .55mm Steel and is adjusted forpractical application. Aluminium requires load spreading washers and EPDM washers at all times.For compliance with NZ Metal Roof and Wall Cladding Code of Practice.Primary Fixing Methods*Primary Fixing Methods**Roofing ApplicationWall Cladding ApplicationC1L Fix side laps and every 2nd crest with approved screws andload spreading profiled metal washers and EPDM washers.Fix in the pan adjacent to every side lap over rib and every 2nd pan,and at all external and internal corners.(No metal washer required)C2L Fix side laps and miss 1, hit 1, miss 2, hit 1, miss 1, hit 1, miss 2 etcwith approved screws and load spreading profiled metalwashers and EPDM washers. End purlins and peripheryof roof to be fixed every 2nd crest.C1 Fix side laps and every 2nd crest with approved fastenersalone.C3L Fix side laps and miss 2, hit 1, miss 3, hit 1,miss 2 etc withapproved screws and load spreading profile metal washersand EPDM washers. End purlins and periphery of roof to befixed every 2nd crest.C2 Fix side laps and miss 1, hit 1, miss 2, hit 1, miss 1, hit 1, miss 2 etcwith approved fasteners alone. End purlins and periphery of roofto be fixed every 2nd crest.C3 Fix side laps and miss 2, hit 1, miss 3, hit 1, miss 2 etc withapproved fasteners alone. End purlins and periphery of roof tobe fixed every 2nd crest.* Note - Compliance with E2/AS1 is dependent on purlin spacing andgauge of roofing. See section on Purlin/Girt Spacing Limitations andRecommendations.Drape Curved RoofingThe first two purlins at each end of the sheet in drape curvingsituations should, in all cases, be fixed using profile metal washersand EPDM washers with the balance of the roof fixed as above.To be read in conjunction with Roof Expansion ProvisionsCORRUGATEWall Cladding Wind Load SpanPan fixed wall cladding can be assumed to have a wind load designat least equivalent to C1L from the above graphs.** Note - Compliance with E2/AS1 is dependent on girt spacing andgauge of cladding. See section on Purlin/Girt Spacing Limitationsand Recommendations.

PURLIN/GIRT SPACING LIMITATIONS AND RECOMMENDATIONSDimensions in metresSection 1.For compliance with E2/AS1Fixing Patterns (Refer to section on Primary Fixing Methods)Steel Based Material.40mm BMT.55mm BMTWindzoneWindzoneEnd SpanIntermediateSpanLow & MedHigh & Very High Extra HighLow & Med High & Very HighExtra 3C3C3C3C3C3C2C2C1C1N/AC3C3C3C3Aluminium H36.70mm BMT .90mm BMTRefer to manufacturersrecommendation.N/A - Not applicableSection 2.Manufacturers recommendation in accordance with NZ Metal Roof and Wall Cladding Code of Practice (When compliance with E2/AS1 not required)Steel Based Material.40mm BMT.55mm BMTAluminium H36.70mm BMT .90mm BMTRestricted Access Roof (Type 2B)Intermediate(Where walking is permitted within End300mm of the purlin line or over2 estricted Access Roof (Type 2A) Intermediate(Where walking is permittedEndanywhere on the roof cladding)N/R*N/R*1.2000.800N/R*N/R*0.9000.600Non Accessible Roof andWall Cladding (Type 001.400Maximum Recommended PurlinSpacing for standard roof(See notes 01.2000.800Wind Design Load using fixingIntermediatemethod C2 (minimum) as an example Endat these purlin spacings from theWind Load Span Design 6kPa* Not recommendedClassification Types are from the NZ Metal Roof and Wall Cladding Code of Practice.For other than compliance with E2/AS1 purlin spacing limitations to be read in conjunction with Wind Load Span Design Graphs.In areas of heavy traffic purlin spacing should be reduced accordingly.For curved roofing refer to Information Table.When self supporting paper is preferred to be used (without any support) purlin spacings must be limited to a maximum of 1.200 mtr centres for vertically rununderlay and 1.150 mtr centres for horizontally run underlay. This is particularly relevant with aluminium and /or severe marine environments for the reasonsdesignated under Building Design/Performance/Product Selection part of this document.Snow LoadsWhen the possibility of snow exists it is necessary to allow forthe extra imposed snow loads by increasing the strength of thestructure, and/or minimising the build up of snow, and this isgenerally achieved by increasing the roof pitch by allowing easiershedding of the snow or otherwise as the designer determines.The objective is to simplify rather complex loading patterns whileremaining adequately cautious. The design loads should takeaccount of drifting snow due to wind,but wind loads are not requiredto be combined with snow loads.As snow loads are uniformly distributed loads they are similar towind loads.CORRUGATESnow loadings are not required to be taken into account for theNorth Island of New Zealand north of a line drawn from Opotiki toTurangi and New Plymouth.However for other areas snow loadings may need to be taken intoaccount dependent on the area and altitude of the proposed project.A fuller reference including a map and chart is available from the NZMetal Roofing Roof and Wall Cladding Code of Practice Section 3.5.

PRIMARY FIXING CHARTRoofing - Crest fixed (To be read in conjunction with Roof Expansion Provisions and Load Span Design Graphs)Wood PurlinsSteel Purlins or girtsup to 1.5mmSteel Purlins or girts1.5-4.5mmSteel Purlins or girts4.5-12mmWashers(When required)Steel BasedMaterial12-11x50 Class 4Type 17 Woodteksor Roofzips withneos or 60mmweatherseal nails12-14x45 Class 4Steelteks with neosor 12x50 Roofzipswith neos12-14x45 Class 4Steelteks with neos12-24x 50 Class 4Series 500 Steeltekswith neosCorrugated loadspreading profileMetal and 30mmEPDMAluminium BasedMaterial14-11x55 Alutitewith bonded washerwith Corrugate loadspreading profileAli washer & 30mmEPDMStainless steel grade304, 14-14x70Steelteks and bondedwashers through a10mm dia. clearancehole with Corrugateload spreadingprofile Ali washer &30mm EPDMStainless steel grade304, 14-14x70Steelteks and bondedwasher through a10mm dia. clearancehole with Corrugateload spreadingprofile Ali washer &30mm EPDMFabco stainless steelgrade 304, 14-14x70Type B screw andbonded washer througha 10mm dia clearancehole with Corrugateload spreading profileAli washer and 30mmEPDMCorrugate loadspreading profileAli and 30mmEPDMWood PurlinsSteel Purlins or girtsup to 1.5mmSteel Purlins or girts1.5-4.5mmSteel Purlins or girts4.5-12mmWashers(When required)Steel BasedMaterialDirect fixed12-11x40 Class 4Type 17 Woodtekswith neos12-14x20 Class 4Steelteks withneos12-14x20 Class 4Steelteks withneos12-24x32 Class 4Steelteks Series 500with neosSteel BasedMaterial20mm Cavity12-11x50 Class 4Type 17 Woodteksor Roofzips withneos12-14x45 Class 4Steelteks with neosor 12x50 Roofzipswith neos12-14x45 Class 4Steelteks with neos12-24x50 Class 4Steelteks Series 500with neosAluminium BasedMaterialDirect Fixed12-11x35 Alutitewith bonded washerStainless steel grade304, 14-14x25Steelteks and bondedwasher througha 10mm diameterclearance hole with19mm bonded AliwasherStainless steel grade304, 14-14x25Steelteks and bondedwasher througha 10mm diameterclearance hole with19mm bonded AliwasherFabco stainless steelgrade 304, 14-14x20Type B screw andbonded washerthrough a 10mmdiameter clearancehole with 19mmbonded Ali washer19mm bonded AliwasherAluminium BasedMaterial20mm Cavity12-14x55 Alutitewith bonded washerStainless steel grade304, 14-14x70Steelteks and bondedwasher througha 10mm diameterclearance hole with19mm bonded AliwasherStainless steel grade304, 14-14x70Steelteks and bondedwasher througha 10mm diameterclearance hole with19mm bonded AliwasherFabco stainless steelgrade 304, 14-14x70Type B screw andbonded washerthrough a 10mmdiameter clearancehole with 19mmbonded Ali washer19mm bondedAli washerWall Cladding - Pan fixedNote: All primary fasteners to have a minimum embedment into structural timber of 30mm. Adjust fastener length for both timber and steel fixings when necessaryfor battens etc. When using load spreading profile washers for roofing fix ridging, roof flashings etc. using a 25mm Aluminium embossed washer and appropriatescrew.Secondary Fasteners (To be used in accordance with the NZ Metal Roof and Wall Cladding Code of Practice.)These should be: Aluminium Blind Rivets AS5-3 x 4mm minimum (Residential) Aluminium Blind Rivets AS 6-3 x 4.8mm minimum (Commercial) Aluminium Bulb-tite RivetsCORRUGATE 12-11x35 Alutites 12-11x25 Class 4 Type 17 Woodteks (Steel based material only)

ROOF EXPANSION PROVISIONSFix with recommended fasteners and systems from the Primary Fixing Chart and additionally allow for the following where applicable.Steel Based MaterialE2/AS1 ComplianceSheet LengthsUp to 8 metres 8-12 metres 12-18 metres 18 metresNo special provisionLower 50 % of the roof should be fixedusing oversize holes at fastening points withapproved load spreading profile washer, and30mm EPDM washersNot ApplicableNZ Metal Roof and Wall Cladding Code of Practice ComplianceSheet LengthsUp to 15 metres 15-18 metres 18-24 metres 24-30 metresZincalume and light colours inFavourable Installations(Refer NZMRM C.O.P. Section 4.1.6)No special provisionNo special provisionexcept screws arerecommendedNo special provisionexcept screws arerecommendedSolid fix using screwsfrom the ridge down 24metres and oversize holesshould be used for the remainder of the sheet withapproved load spreadingprofile washers, and30mm EPDM washersDark Colours in FavourableInstallations(Refer NZMRM C.O.P. Section 4.1.6)No special provisionNo special provisionexcept screws arerecommendedSolid fix usingNot recommended*screws from theridge down 18 metresand oversize holesshould be used forthe remainder of thesheet with approvedload spreading profilewashers, and 30mmEPDM washersZincalume and light colours inUnfavourable Installations(Refer NZMRM C.O.P. Section 4.1.6)No special provisionNo special provisionexcept screws arerecommendedSolid fix using screws from the ridge down 18metres and oversize holes should be used forthe remainder of the sheet with approved loadspreading profile washers, and 30mm EPDMwashers. *Maximum recommended sheet lengthis 25 metresDark Colours in UnfavourableInstallations(Refer NZMRM C.O.P. Section 4.1.6)No special provisionSolid fix using screws from the ridge down15 metres and oversize holes should be usedfor the remainder of the sheet with approvedload spreading profile washers, and 30mmEPDM washers.* Not recommendedover 25 metresFor sheet lengths in excess of the above a step joint or other special provision for expansion is required. Refer to Roofing Industries.When using load spreading profile washers for roofing fix ridging, roof flashings etc. using a 25mm Aluminium embossed washer and appropriate screw.Oversize holes should be 3mm greater diameter than the screw or as per the Primary Fixing Chart for stainless steel screws.For further information on the fixing of Corrugated refer to E2/AS1 of the NZ Building Code and NZ Metal Roof and Wall Cladding Code of Practice, www.metalroofing.org.nzThese publications along with the foregoing technical data should form the basis of the design and installation of metal roofing and claddingAlso refer to our suite of detail drawings, and to NZ Steel Ltd and Pacific Coilcoaters literature.CORRUGATE

ROOF EXPANSION PROVISIONSFix with recommended fasteners and systems from the Primary Fixing Chart and additionally allow for the following where applicable.AluminiumSheet LengthsUp to 10 metres10-12 metres12-15 metresPlain Aluminium & lighter colours inFavourable Installations(Refer NZMRM C.O.P. Section 4.1.6)Fix using oversize holes with screws and approved load spreading profileAli washers, and 30mm EPDM washersDark Coloured Aluminium inFavourable Installations(Refer NZMRM C.O.P. Section 4.1.6)Fix using oversize holes with screws andapproved load spreading profile Ali washers,and 30mm EPDM washersNot recommendedPlain Aluminium & lighter colours inUnfavourable Installations(Refer NZMRM C.O.P. Section 4.1.6)Fix using oversize holes with screws and approved load spreading profile Ali washers, and30mm EPDM washersNot recommendedDark Coloured Aluminium inUnfavourable Installations(Refer NZMRM C.O.P. Section 4.1.6)Fix using oversizeholes with screwsand approved loadspreading profile Aliwashers, and 30mmEPDM washers. 15 metresNot recommendedNot recommendedFor sheet lengths in excess of the above a step joint or other special provision for expansion is required. Refer to Roofing Industries.When using load spreading profile washers for roofing fix ridging, roof flashings etc. using a 25mm Aluminium embossed washer and appropriate screw.Oversize holes should be 3mm greater diameter than the screw or as per the Primary Fixing Chart for stainless steel screws.For further information on the fixing of Corrugated refer to E2/AS1 of the NZ Building Code and NZ Metal Roof and Wall Cladding Code of Practice, www.metalroofing.org.nzThese publications along with the foregoing technical data should form the basis of the design and installation of metal roofing and claddingAlso refer to our suite of detail drawings, and to NZ Steel Ltd and Pacific Coilcoaters literature.CORRUGATE

load spreading profiled metal washers and EPDM washers. C2L Fix side laps and miss 1, hit 1, miss 2, hit 1, miss 1, hit 1, miss 2 etc with approved screws and load spreading profiled metal washers and EPDM washers. End purlins and periphery of roof to be fixed every 2nd crest. C1 Fix side laps and every 2nd crest with approved fasteners alone.