Transcription

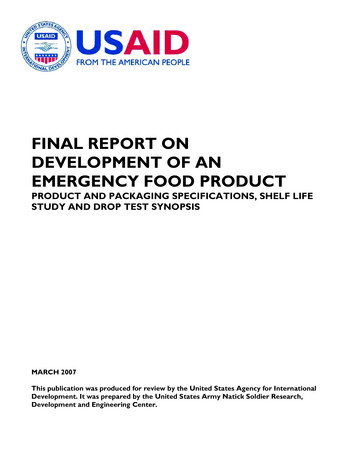

FINAL REPORT ONDEVELOPMENT OF ANEMERGENCY FOOD PRODUCTPRODUCT AND PACKAGING SPECIFICATIONS, SHELF LIFESTUDY AND DROP TEST SYNOPSISMARCH 2007This publication was produced for review by the United States Agency for InternationalDevelopment. It was prepared by the United States Army Natick Soldier Research,Development and Engineering Center.

FINAL REPORT ONDEVELOPMENT OF ANEMERGENCY FOOD PRODUCTPRODUCT AND PACKAGING SPECIFICATIONS, SHELF LIFESTUDY AND DROP TEST SYNOPSISDISCLAIMERThe authors’ views expressed in this publication do not necessarily reflectthe view of the United States Agency for International Development or theUnited States Government.2

This report is made possible by the generous support of the American peoplethrough the support of the Bureau for Democracy, Conflict and HumanitarianAssistance (DCHA) of the United States Agency for International Development(USAID), under terms of interagency Memorandum of Understanding PASAAgreement Number DCH-P-00-02-00004-00.Natick Soldier Research, Development and Engineering Center(NSRDEC)Department of Defense, Combat Feeding Directorate (CFD)Performance Enhancement and Food Safety TeamATTN: AMSRD-NSC-CF-PIndividual Combat Ration TeamATTN: AMSRD-NSC-CF-INatick, MA 01760-50182Warfighter Protection and Aerial Delivery Directorate (WarPAD )Aerial Delivery Engineering TeamNatick, MA 01760-5018Authors/Contributors:Jack Briggs1Paul Maguire1Peter Sherman2Betty Davis1Dr. Ann Barrett1John Mahon3John Doucette31Natick Soldier Research Development and Engineering CenterDepartment of Defense Combat Feeding DirectoratePerformance Enhancement and Food Safety Team; Natick, MA 01760-50182Individual Combat Ration Team; Natick, MA 01760-50183Warfighter Protection and Aerial Delivery Directorate (WarPAD2)Aerial Delivery Engineering Team; Natick, MA 01760-50183

AcknowledgmentsThe Natick Soldier Research Development and Engineering Command’s DoD Combat FeedingDirectorate would like to formally thank all the individuals, government agencies and industrial partnersthat contributed information, time, funds and equipment to this project. Special thanks are given to Dr.Samuel Kahn, Mr. Thomas Marchione and other personnel of the U.S. Agency for InternationalDevelopment (USAID) including Ms. Caroline Tanner, a consultant with the Food and NutritionTechnical Assistance (FANTA) project, for their nutritional guidance and their inherent knowledge of thetarget population’s organoleptic and performance requirements for the proposed Emergency FoodProducts (EFP). Especially helpful with the processing and production of the EFP productionprototypes were Mr. Scott Mills and all his colleagues at Datrex, Inc. and Mr. John Bell of KerryIngredients Inc., who worked with CFD personnel to produce high-quality, novel EFP prototypes thatmet and in some cases exceeded the Institute of Medicine’s (IOM) standards.4

TABLE OF CONTENTSI. BACKGROUND . 8-11A. History . 8B. Chronicle of Product Development . 9II. PRODUCT FORMULAS . 11-13A. HTST Extrusion Formulas . 11B. Bar Formulas (A-28, A-29) . 11C. Paste Formula (A-20) . 12D. Vitamin and Mineral Premix Requirements . 13III. PROCESSING PROTOCOLS 14-16A. Bar Variables (A-28 and A-29) . 141. Precooking and Grinding of Cereal Portion . 142. Mixing Procedure for Bar Production . 143. Bar Compression and Production . 154. Qualitative Assessment of Bar Functionality . 15B. Paste Variable (A-20) . 151. Mixing Procedure . 152. Fill Procedure . 15C. Nutrient Requirements. 16D. Final Product Description . 16IV. PACKAGING SPECIFICATIONS . 17-25A. Paste (A-20). 17B. Bars (A-28 and A29) . 18C. Quality Assurance Provisions Applicable to Paste Tubes/Pouches . 19D. Quality Assurance Provisions Applicable to Bars’ Brick Pack Pouches . 21E. Packaging Requirements and Quality Assurance Provisionsfor Dehydrated Product in a Brick Pack Pouch . 24ATTACHMENT I: RESULTS OF SIX MONTHS @ 100ºF AND 24 MONTHS@ 80ºF SHELF-LIFESTUDIES WITH VITAMIN AND MINERAL PREMIX RECOMMENDATIONSI. METHODS . 25II. RESULTS . 25-27A. Summary of the Six-Month, 100ºF Nutrient Stability Tests . 251. Oxidation Results . 252. Vitamin A Stability Results . 253. Vitamin C Stability Results . 254. Vitamin B1 Stability Results . 26B. Summary of the 24-Month, 80ºF Nutrient Stability Test . 261. Vitamin A Stability Results . 262. Vitamin C Stability Results . 263. Vitamin B1 Stability Results . 26C. Basis for Vitamin-Mineral Premix Recommendations . 26D. Summary of Vitamin-Mineral Premix Changes . 26E. Summary of Product Macronutrient Analysis . 27F. Summary of Textural Analysis of Bars. 27G. Summary of Organoleptic Changes during Storage . 27III. CONCLUSION . 28IV. TABLES. 29-345

V. FIGURES . 35-42ATTACHMENT II: FINAL DROP TEST SYNOPSIS. 43-47I . TYPES OF DROP TESTS PERFORMED . 43-46A. Simulated Low-Velocity Drop Tests (NSRDEC) .431. Results . 432. Recommendations . 44B. Airdrop Test (U.S. Army Yuma Proving Grounds). 451. Results . 452. Recommendations . 46ATTACHMENT III: SCOPE OF WORK . 47-536

IDCombat Feeding DirectorateDepartment of DefenseEmergency Food ProductFood and Nutrition Technical AssistanceInstitute of MedicineLinoleic Acid:Alpha Linolenic Acid RatioNatick Soldier Development and Engineering CenterProtein Digestability Corrected Amino Acid ScorePolyUnsaturated Fatty AcidUnited States Agency for International Development7

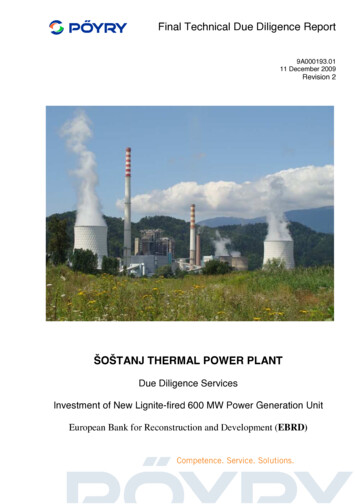

I.Background:A. HistoryThe United States Agency for International Development (USAID), in partnership with the U.S.Army Natick Soldier Development and Engineering Center (NSRDEC) Combat Feeding Directorate(CFD), developed three prototypes of a high-energy, nutrient-dense food, referred to as theEmergency Food Product (EFP). The EFP was developed specifically for large populations ofdisplaced people or refugees who are on the move due to civil disturbances, natural disasters orindustrial disasters. The EFP is expected to be the sole source of food during this period oftransition (up to 15 days) until a more permanent food supply can be established.In accordance with a Reimbursement Agreement between USAID and NSRDEC, several EFPswere co-developed by the two entities. The products were designed to provide humanitarian reliefto satisfy the projected nutritional needs of mobile refugee populations. These EFPs were designedto have a shelf life—without refrigeration—of at least 24 months at 70ºF.The CFD was tasked with developing three prototype rations with nutritional and performancerequirements approved by USAID project representatives. The aforementioned requirements weremodeled after the Institute of Medicine’s publication for a High-Energy, Nutrient-Dense Emergency1Relief Food Product. Each of the prototypes conformed as closely as possible to the requirementsoutlined in the publication; they were not, however, identical, since USAID approved slightdeviations, discussed in section III, subsections D and E, to better accommodate the nutritionalneeds of refugee populations.Two of the prototype food products are in the form of bars, similar to the Norwegian product BP-5(Compact), and one is a paste or semisolid emulsion/dispersion that resembles the French productPlumpy’Nut (Nutriset). The bars are grain-based rations that have been compressed into easy-toconsume rectangular bars that can also be crumbled up, dispersed in water and served as aporridge or gruel. The paste was developed to be consumed as is, right out of the pouch.Production-scale test quantities of a dairy-based, nutrient-rich paste (A-20) and two varieties offortified, grain-based, compressed bars (A-28 and A-29) were produced by Datrex, Inc. of Kinder,Louisiana. USAID requested two shelf stability tests to be conducted by Natick on the threeproduction variables. The final report on the shelf stability test is included in this report as is thereport on the drop tests that were carried out. FANTA conducted consumer tests of the threevariables (non-stressed) in Bangladesh, Ethiopia and Nicaragua. A final report was issued June 5,22005 .The following report includes formulas, processing/packaging specifications, product identificationand results of nutrient stability, macro/micro analysis, textural analysis and organoleptic evaluationsperformed at the U.S. Army NSRDEC’s Combat Feeding Directorate. Recommended changeswere made to the vitamin/mineral premix based on these results. In addition, as part of theevaluation of the products, USAID requested a determination of the airdrop survivability of the threeproducts, in the event that air delivery were the only safe means to expeditiously provide relief to1Subcommittee on Technical Specifications for a High-Energy Emergency Relief Ration, Committee on MilitaryNutrition Research. High-Energy, Nutrient-Dense Emergency Relief Food Product (2002) may be downloadedfree from: National Academy Press, 2101 Constitution Avenue, NW, Lockbox 285, Washington, DC 20055,telephone (800) 624-8373 or (202) 334-3313, Fax (202) 334-2451. Internet address:http://www.nap.edu/catalog.php?record id 103472Chris Moessner, Sarah Fulton, Brian O’Meara and Amie Kim. Assessment of an Emergency Food Product.Washington, DC: Food and Nutrition Technical Assistance Project, 20058

the refugee populations ‘on the move’. The synopsis of those results are included in this report aswell.B. Chronicle of Product Development2001:1. The Committee on Military Nutrition Research and the Food and Nutritional Board of theInstitute of Medicine (IOM) convened to develop technical specification for a ”High-Energy,Nutrient-Dense Emergency Relief Food Product.” The results from the committee have beenpublished 3 .2002:1. Based on the Institute of Medicine’s (IOM) outline of the desirable EFP characteristics, theDoD’s Combat Feeding Directorate entered into a contractual agreement with USAID todevelop three EFP prototypes for commercial production (two metric tons of each variable),field evaluation (testing of prototypes to target ethnic populations), nutrient and shelf lifestudies, low-velocity airdrop testing and development of technical specifications for USDAprocurement (see Attachment 3).2. September 30: Interagency agreement was signed and timelines for project wereestablished.3. December 5: CFD representative presented to USAID program officers a detailed descriptionof prototypes, processing schematics and packaging configurations for the EFP, which wereunder development at Natick.2003:1. January 23: USAID representatives visited CFD to evaluate prototype rations, evaluateproposed packaging configurations, select the most functional design and address vitaminand mineral fortification.2. January 30: USAID developed initial vitamin and mineral premix requirements. CFDcollaborated with a commercial vendor to produce a proprietary premix formulation for use inEFP prototypes.3. April 11-12: CFD representatives traveled to Washington D.C. to present six prototypes—baked, kettle-cooked, and high temperature short time (HTST) cooking extrusion—for USAIDto evaluate and select three variations. USAID and CFD also engaged in a roundtablediscussion regarding the feasibility of producing a non-genetically modified organism (GMO)EFP prototype.4. April 23: USAID chose three variables (rice-based bar, wheat-based bar, and a squeezablepaste) for testing. The HTST pre-cooking of the grains procedure was chosen as it bestpreserves the vitamins. USAID requested development of a non-GMO EFP variable alongwith cost analysis on said variable.5. April 28-May 1: USAID nutritional advisor visited CFD to assist in the fine-tuning of selectedvariables and cost analysis of developing a non-GMO EFP.6. May 13: A GMO-free product was developed at a cost 40 percent higher than the currentprototypes.7. May 22: It was determined that a GMO-free ration could not be procured due to priceconstraints. USAID stated that only the protein need be GMO-free.8. June 4: Final product selections were determined (two compressed bars—rice-based andwheat-based—and one paste variable were chosen) and final adjustments in the vitamin andmineral fortification premix were made by USAID’s nutritional advisor. Packagingconfigurations for bars and paste were also finalized.3Subcommittee on Technical Specifications for a High-Energy Emergency Relief Ration, Committee on MilitaryNutrition Research. High-Energy, Nutrient-Dense Emergency Relief Food Product (2002) may be downloadedfree from: National Academy Press, 2101 Constitution Avenue, NW, Lockbox 285, Washington, DC 20055,telephone (800) 624-8373 or (202) 334-3313, Fax (202) 334-2451. Internet address:http://www.nap.edu/catalog.php?record id 103479

9. July 31: The completion date was extended through no-cost agreement from September 30,2003 to September 30, 2004.10. September 24: Pilot-scale extrusion run was conducted at Kerry Foods Inc., and theextruded/ground precooked grain base was shipped to Datrex Inc. for pilot-scalecompression and bar production. Test variables were shipped back to Natick for evaluation.11. November 26: EFP box design was completed and approved by USAID.2004:1. February 18: CFD personnel attended extrusion of cereal production run at Kerry Foods Inc.in Omaha, Nebraska. Over 7,000 lbs. of grain-based extruded/ground products wereproduced to serve as a base for the EFP bars, which were produced later in the year.2. June 21-25: CFD personnel attended EFP production run at Datrex Inc. in Kinder, Louisianato produce six metric tons of EFP (three variables: two metric tons each). This productiontest was performed to optimize parameters to ensure contract specifications could be met forthe large-scale production run.3. July 1: EFP paste prototypes were well received by USAID representatives. EFP barprototypes were not as firm as anticipated; the lot was rejected by USAID. The textureproblem was determined to be caused by extrusion and grinding variances which resulted ina powdery product that did not compress firmly.4. July 2: USAID authorized an additional EFP production of the bars.5. July 28-29: CFD personnel were present at Kerry Foods for the second production of theextruded EFP grain-based pellets. Extrusion parameters were adjusted to obtain a suitableproduct.6. August 11-13: Extruded EFP pellets were received at CFD. The pellets were ground inhouse according to the specifications used for prototype development and shipped to Datrexfor bar production.7. August 25-26: CFD representatives attended supplemental bar production performed atDatrex, Inc. Both the rice-based and wheat-based EFP bars were highly acceptable and barintegrity was vastly improved over previous run.8. September 1: EFP paste shelf-life studies (6 months at 100ºF and 2 years at 80ºF) wereinitiated to include: micronutrient viability and sensory evaluations.9. September 27: EFP bar shelf-life studies (6 months at 100ºF and 2 years at 80ºF) wereinitiated to include: micronutrient viability and sensory evaluations.2005:1. March: USAID through FANTA conducted field assessments that were designed to evaluatethe usability and favorability of the three EFP prototypes for consumption. The assessmentswere carried out among residents of refugee camps in Bangladesh, Ethiopia and Nicaragua.2. July 26: CFD received FANTA report on field assessment of EFP prototypes. The resultsfrom this field test were very positive. All variables were well received with regard to tasteand utility. Approximately nine in 10 adults said they liked the bar products “a lot” (ricebased bar 91% and wheat-based bar 88%). Slightly fewer adults like the paste variable(84%) “a lot.” When compared with other types of emergency food products, 82-100% of allrespondents from all three countries reported that they were “Better than other foods I havebeen given.”3. September 12: Interim formulas and processing specifications on all three prototypes weresubmitted to USAID and USDA.4. December 6: EFP Accelerated Storage Study interim report on micronutrient stability wassubmitted to USAID for review. Some losses of target vitamins were reported: minor lossesof vitamin C in bars; B1 in paste and a significant loss of vitamin A in the paste. USAID mayneed to increase fortification amounts to compensate for labile vitamin losses.2006:1. March 23: USDA posted Request for Information (RFI) and Sources Sought Notice forEmergency Energy Bars/Paste.2. June 13: Simulated low-velocity airdrop was conducted by the Aerial Delivery EngineeringSupport Team on all three EFP products from drop tower asset at the Natick Soldier Center.All variables held up well to both drop heights of 36 and 63 feet (98-100% survivability rates).10

3. July 14: Free-fall (terminal velocity) airdrop conducted in Yuma, New Mexico; results weremixed. All EFP rations were tested through the free-drop method; the paste ration sufferedapproximately 60% failure while the bar rations suffered significantly less when dropped intheir commercial fiberboard packaging. When the EFPs were removed from their fiberboardcase and dropped individually, their survivability rate was substantially greater. Both the barsand the paste rations survived with minimal damage and 100% of each was consideredconsumable.4. September 27: The EFP two-year storage study was completed and final samples were sentto Eurofins for nutrient analysis.5. November 3: Drop-test synopsis and recommendations report was generated andsubsequently submitted to USAID for evaluation and feedback.6. November 15: In-house sensory panels were performed on control samples(stored at 0ºF) and stored samples. All samples surpassed quality metrics established inreimbursement agreement with USAID.2007:1. January: No-cost extension was approved for final report generation.2. January-March: Preparation of final EFP reports to include: Nutrient Shelf Life StudyReport and Product and Packaging Specifications Report.3. April 2: Submission of Final Reports to USAID.II. PRODUCT FORMULASA. HTST Extrusion 05.005.002.000.751.66Total100INGREDIENTRice Flour (White)Wheat Flour (White 9-11% Protein)Oat Flour (dehulled & kilned 9% Protein)Potato FlourNFDMWhey Protein Concentrate ( 80% Protein)*SugarPea Protein Isolate (82% Protein)**Soybean OilLecithin (Soybean 5.008.505.005.002.000.751.66100* Recommended source: Davisco Foods International: Phone 952-941-0400** Recommended source: Norben (Food Ingredients Group) Phone 440-951-2715*** Use American Lecithin Co. (Alcolec BF) or equivalent.B. Final Bar FormulasRICE(A-28)INGREDIENTPre-cooked Cereal Mix Rice-Based Type 8B*Pre-cooked Cereal Mix Wheat-Based Type 9B*Sucrose (Confectioners Sugar 6x’s)Part Hydro Soybean oil 10.4088.016

Cream Powder (76% Butter Fat) ***Maltodextrin DE 10 (GPC M-100 or equivalent)Rice Syrup 26 DE (California Natural Products)****Vit/Min Premix*****Canola OilLecithin #Mixed Tocopherols #BHA (Tenox 4B) 8.0006.7503.0001.4201.0000.5000.0030.003100* Type 8B and 9B pre-cooked cereals: See specifications for production of pre-cooked cereals.**“Cream Flex 30009” from Ventura Foods, 633 South Mission Rd., Los Angeles, CA 90023 orequivalent*** Cream Powder from Quality Ingredients Corp., 14300 Rosemount Dr., Burnsville, MN 55306 (QualiCream 7211) or equivalent.**** Clarified White Rice Syrup from California Natural Products (Product code: WRSRDCL) orequivalent***** Vit/Min Premix Fortitech or Equivalent Phone 518-372-5155# American Lecithin Co: (Alcolec BS) or equivalent.## ChemPoint Phone 800-485-9569C. Paste Formula (A-20)INGREDIENTMaltodextrin DE 10 (GPC M-100 or equivalent)Soybean OilConfectionary sugar (6x’s)Nonfat Dry Milk PowderWhey Protein Conc.( 80% Protein)*Cream Powder 76% Fat**Lecithin (liquid)Pea Protein Isolate (82%Protein)***Vit/Min Premix Fortitech****SaltSensient Colors (Brown Lake Blend R)#Ascorbyl PalmitateBHA##Mixed 112.4802.2041.5711.1020.0370.0280.0050.005Total 100*Possible Source: Norben (Food Ingredients group) Phone 440-951-2715**Cream Powder from Quality Ingredients Corp., Phone 952-250-0289*** Possible Source: Davisco Foods International: Phone: 952-914-0400****Vit/Min Premix, Fortitech or Equivalent Phone 518-372-5155# Sensient (Brown Lake Blend R) Contains: FD&C Yellow #5 Lake,FD&C Red #40 Lake, and FD&C Blue #1 Lake##ChemPoint Phone 800-485-956912

D. Vitamin and Mineral Premix Formula (Required vitamins and mineral for 500-gram barsand 450 grams of paste)500 gram bars 450 grams pasteEncapsulated Vitamin A (as Palmitate, USP-FCC)Vitamin D3 (as Cholecalciferol, USP-FCC)Vitamin E (as acetate, USP)Vitamin K1 (as Phytonadione, FCC)Encapsulated Vitamin C (as Ascorbic Acid, USP-FCC)Encapsulated B1 (as Thiamin Mononitrate, USP-FCC)Vitamin B2 (as Riboflavin, USP-FCC)Niacin (as Niacinamide, USP-FCC)Vitamin B6 (as Pyridoxine HCl, USP-FCC)Folic Acid (USP-FCC)Vitamin B12 (as Cyanocobalamin, USP)Biotin (FCC)Pantothenic Acid (D-Calcium Pantothenate, USP)Calcium (as Tricalcium Phosphate, FCC)Phosphorus (as Dipotassium&Tricalcium Phosphate, FCC)Magnesium (as Magnesium Oxide, USP)Zinc (as Zinc Oxide, USP)Copper (as Cupric Oxide)Manganese (as Manganese Sulfate, USP-FCC)Selenium (as Sodium Selenate)Chromium (as Chromium Chloride (6 H2O), USP)Iodine (as Potassium Iodide, USP-FCC)Iron (as Iron EDTA for bars and ferrous fumarate for paste)13A-28 and gmcgmgmgmgmgmgmgmgmcgmcgmgmg

III. Processing ProtocolsA. Bar Variables (A-28 and A-29)1. Precooking and Grinding of Cereal Portiona. Mix all dry ingredients thoroughly using a ribbon blender or equivalent for dry blending.Premix the oil and lecithin together and add slowly to dry ingredients while mixing.The oil and lecithin mix may be metered into the extruder during processing. Meteredlevels must be monitored at regular intervals to insure the delivery of the required levels.b. Cook mixture using High Temperature Short Time Cooking (HTST) extruder. A WengerTX52 twin screw extruder was used to produce prototypes.- Use 4-6mm circular die holes- Extruder screw configuration, jacket temperatures, yield, production rates, etc., shouldbe established to insure a complete cook of the starch (Maltese Cross Test may beemployed to validate starch cook) without any product scorching or burning of exteriorof the extrudate.- Maintain die extrusion temperature between 295ºF -315ºF.- The extruded pellets should be a medium to dark tan without any burnt odors orflavors.c. Extrudate Drying Procedure: Use a fluid bed, forced hot air or other types of forced airdryers, to dry product to a moisture range of 4-7%. Avoid scorching: there should be noburnt odors or flavors.d. Grind: Grind dried pellets to a nominal particle size:- Rough Screen Analysis on prototype product ground at Natick Soldier Center (NSC)using a standard gravity-fed Fitzpatrick Comminuting Mill with a #2 (1.65mm) screen:US StandardSieve #20% Through98-1004060-656040-452000-3Note: Avoid a fine grind; do not exceed the 60 and 200 sieve recommendation. Product that hastoo small of a particle size will not compress properly during manufacturing phase of the barproduction.e. Other types of precooking methods may be explored as long as the final product meetsall the functional requirements as demonstrated by the prototype. (Swept surface heatexchange, etc.)2. Mixing Procedure for Bar Productiona. Mixing procedure successfully used by Combat Feeding Directorate in developingbenchtop EFP prototype bar products.- Weigh out all dry and liquid ingredients (keep dry separate from liquid).- Add all dry ingredients (ground cereal mix, cream powder, sucrose, maltodextrin,vitamin/mineral premix) into a surface-sweeping High Shear (HS) Mixer (RoboCoupeBlixer BX6V with serrated S-type blade was used for prototype development) and blendon low speed (1,000-1,200 rpm) for 1 minute or until product is completely uniform.- In a separate container (steam-jacketed kettle or equivalent) heat: oils, rice syrup,lecithin, BHA, tocopherols to 140 F and mix until uniform.- Slowly add oil dispersion to HS Mixer while mixing at a low speed.14

- Mix for 3-5 minutes on medium speed ( 1,500 rpm) until mix appears to behomogeneous (no clumping, uniform color).b. Alternative mixing procedures may be employed; however high-shear mixing isrecommended and was the methodology used in the development of the aforementionedprototypes. Othe

Department of Defense, Combat Feeding Directorate (CFD) Performance Enhancement and Food Safety Team ATTN: AMSRD-NSC-CF-P Individual Combat Ration Team ATTN: AMSRD-NSC-CF-I Natick, MA 01760-5018 Warfighter Protection and Aerial Delivery Directorate (WarPAD2) Aerial Delivery Engin