Transcription

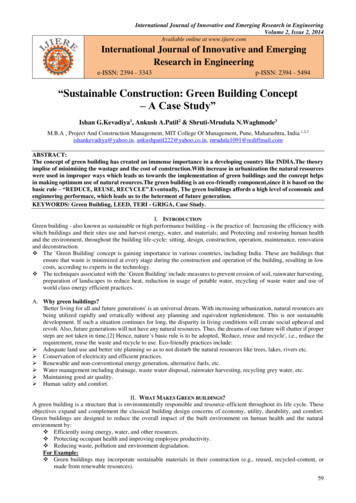

1010.0B U I L D I N G M AT E R I A L S“Instead of just achieving the material character or using sustainable materials,we were interested in trying to find the solution that maximizes both of thoseobjectives.”– Gerry McGeough, University Architect, UBCB U I L D I N G M AT E R I A L SLESSONS LEARNEDStart the research effort earlyFind sustainable alternative totraditional materialsTest materials options in realconditionsUse the right toolsExcercise precaution1.0E xe c ut i ve S umma r y2.0Pro je c t B ac kgro und& O ve r vi ew3 . 0.Vi s i o n & Le ader ship4 . 0.G o al s & Targ e ts5 . 0.Par t ne r s hi p s6 . 0.R e s e arc h7 . 0.B ui l di ng D e s i gn8 . 0.D e s i gn Pro ce ss9 . 0.St r uc t ural Sys tem & Wo od1 0 . 0. B ui l di ng M ate r ia lsImage 10.1 View from an Atrium Social Space to the Living RoofPhotograph by Martin Tessler10.1 OverviewBuildings materials are one of the elements in a sustainable building that canhave the greatest environmental impact as well as directly affecting the qualityof both the building’s interior and exterior appearance. They directly andindirectly impact the wider ecological context through the processes used toextract, manufacture, transport and ultimately reuse or dispose them. Buildingmaterials must also be chosen with a consideration of the context in whichthe building will be placed and the desired quality of building spaces. Duringthe design of CIRS, both the ecological and human health impacts of buildingmaterials, as well as the visual and tactile expression of the building materialswere considered along with cost, durability and maintenance requirements.CIRS is located in the Campus Core precinct of the UBC Vancouver campus, whichhas many examples of the international style of architecture. The UBC CampusPlan and Design Guidelines direct new projects to respect the campus contextand traditions, in terms of material palettes and applications, in order to builda cohesive urban design on campus. The primary exterior materials used in theCampus Core include white brick, clear glazing, wood and neutral colouredconcrete. The Design Guidelines also encourage project teams to highlight thesustainable material choices made in the project design.10.1O ve r vi ew10.2D e s c r i p tion10.3Cam p us Contex t10.4G o al s & Ta rg ets10.5B e ne fi t s10.6Chal l e ng es10.7Le s s o ns Lea r ned1 1 . 0. E ne rg y Sys te ms1 2 . 0. R ai nwate r Sys tem1 3 . 0. R e c l ai m e d Water System1 4 . 0. Lands c ap e & S ite1 5 . 0. Li vi ng R o o f & L iv ing Wa ll1 6 . 0. Li g ht i ng1 7 . 0. Ve nt i l at i o n1 8 . 0. B ui l di ng R at i n g SystemsF U T U RE S E C T IO N S TO B E A DDED:1 9 . 0. M o ni to r i ng & M ea surement2 0 . 0. Co ns t r uc t i o n2 1 . 0. Co m m i s s i o ni n g &Pe r fo r m ance Testing2 2 . 0. I nhab i t ant s vs. O cc up a nts2 3 . 0. Co m m uni t y2 4 . 0. O p e rat i o ns & M a intena nce2 5 . 0. Co nt i nual Evaluations1

C I R S T E C H N I C A L M A N UA LThe Living Building ChallengeRed ListThe LBC Red List is a list of materialsprohibited for use on a buildingproject seeking to achieve LivingBuilding Challenge certification,due to concerns about toxicity andhuman health impacts. The list isupdated as new scientific researchis published. Recognizing thecomplexity of the manufacturingprocess, there is an exception forsmall components on complexproducts made from ten or moreconstituent parts. The smallcomponent must be less than 10per cent of the total project by bothweight and volume and be discreteand contained in the form it isintroduced to the product. Anotherexception is made for materials onthe Red List that are required bylocal building codes.Perkins Will PrecautionaryListThe Perkins Will PrecautionaryList is a list of materials that havebeen classified by government andhealth regulatory entities as havingan adverse effect on the healthof humans and/or environments.This list is in keeping with theprecautionary principle, whichstates that when there is potentialfor harm to human health orenvironments, that precautionsshould be taken, even if fullunderstanding of the cause andeffect relationships has not beenachieved scientifically. It is meant tobe used as a guide to selecting andspecifying materials and products;it is not exhaustive or inclusive of allscientifically published informationand further research should beconducted into questionablesituations.10.2 DescriptionIn 2006, the Cascadia Chapter of the United States and Canada Green BuildingCouncils introduced the Living Building Challenge (LBC), a sustainable buildingrating system that went far beyond LEED and other green building ratingsystems used in North America. One of the unique components of the LBC isthat, unlike LEED in which project teams can decide which credits they willpursue, a certified Living Building must satisfy every imperative. The LivingBuilding Challenge has five rigorous requirements related to the life-cycle impactof building materials.Imperative 11Red List: A Living Building cannot contain any of the materials orchemicals on the Red List, which includes lead, mercury, cadmium,phthalates and polyvinyl chloride (PVC).Imperative 12Embodied Carbon Footprint: The project must account for the totalfootprint of the embodied carbon from its construction through a onetime carbon offset.Imperative 13Responsible Industry: The Forest Stewardship Council must certify100 per cent of the wood products in a Living Building as sustainablebuilding products.Imperative 14Appropriate Sourcing: The building must use materials from withinprescribed radii. The material radii correlate with product density andfunction. Heavier and dense materials have the tightest radius.Imperative 15Conservation Reuse: The building design must include durablematerials and systems that can be re-used or deconstructed andconstruction waste must be reduced or recycled.Image 10.2 LBC Materials Source Radaii2

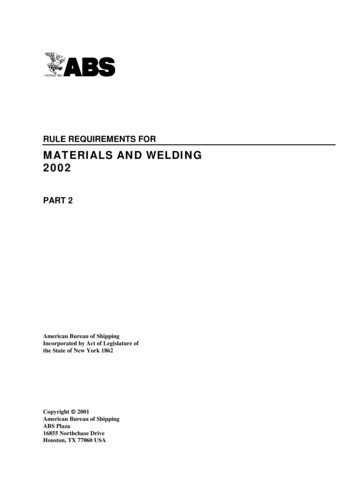

10B U I L D I N G M AT E R I A L SThe project team adopted the certification of CIRS through the Living BuildingChallenge as a project target when the building returned to the UBC Vancouvercampus in early 2008. Attempting to achieve the five LBC imperatives related tomaterials as well as satisfying the other considerations made choosing buildingmaterials especially challenging.Building Materials Significant IssuesStructural Elements:Timber Structure and Certified WoodAs described in 9.0 Structural System & Wood, the main structural material iswood, including glulam for heavy structural members and dimensional lumberfor the structural decking and framing. Dimensional lumber harvested fromforests infested by the mountain pine beetle is used for the structural decking,which helps to reduce the impact of the infestation and make use of a salvagedbuilding material. The project team looked into finding a local source of ForestStewardship Council (FSC) certified products for the lamstock for the glulamsand the substrate materials for the project millwork. The closest source of FSClamstock was forests in Oregon and much of the available FSC certified millworksubstrate was made from wood harvested in Chile. The project team decidedthat it was not feasible to use FSC certified wood for one hundred percent of thewood products in the project because they determined that using local woodproducts was more important that using FSC certified products. The projectteam found that sourcing local, FSC certified wood products for 50 per cent ofthe wood products in the project was feasible.Glued-laminated StructuralMembersA glue-laminated timber or glulamis a type of engineered structuralmember made by laminatinglayers of dimensional lumber witha high performance adhesive.The laminating stock or lamstockis typically sourced from smaller,younger trees than would beharvested to produce an equivalentsolid timber member. Lamstockhas to conform to specific gradingrequirements before it can be usedin a glulam.Image 10.3 Glulam Beams and Lumber Ceiling with Modular Interior Partitions.Photograph by Martin Tessler3

C I R S T E C H N I C A L M A N UA LAGENTSArchitects: Perkins WillUBC Campus ArchitectUBC Building OperationsCladding Materials:White BrickThe UBC Campus Plan and Design Guidelines direct projects in the CampusCore precinct of UBC to use white bricks to align a new building’s aesthetic withother important existing buildings on campus. Many of the existing buildingson campus (including the Lasserre and Buchanan Buildings) use a glazed, white,kiln fired clay brick, which has a higher carbon footprint for their production thanconcrete bricks. Concrete bricks are also produced in Surrey, British Columbia,while the local, kiln fired bricks are made at a location beyond500 kilometersfrom the CIRS site. The project team eventually chose a white concrete brickfor CIRS because it met both the aesthetic and cultural requirement of the UBCCampus Plan, in addition to the sustainability goals of the project.Stained Cedar PanelsThe project team determined that wood cladding was another material thatcould satisfy the project sustainability goals as well as the UBC Campus Planguidelines. The changing appearance due to aging and the durability of thewood cladding was a concern to some project stakeholders. Before choosingthe final stain, the project team investigated eleven different seals and stains forwood cladding by exposing small sample panels to local weather conditions forthree years.Image 10.4 Building Materials - Cedar Panels and Photovoltaic Sunshade Panels with Integrated RainwaterCollection. Photograph by Enrico Dagostini.4

10B U I L D I N G M AT E R I A L SPROCESSDesign process:Building materials were chosenduring the integrated designprocess, with input from the UBCCampus Architect.Construction:Building materials were installedas part of the base buildingconstruction and the tenant fitouts.Commissioning:Image 10.5 Screen and Planter Boxes for Living Wall. Photograph by Martin TesslerVegetated claddingOperations:The Building materials will bemaintained and replaced by UBCBuildings Operations.Two of the most prominent building elements on CIRS are the living wall thatshades the western façade and the living roof on top of the Modern GreenDevelopment Auditorium. The living wall on the west façade is composed of achocolate vine (Akebia quinata) supported by a metal framework. The plants ofthe living roof are a mix of shrubs and woody ground that shade the roof surfacebelow. The living wall and the living roof not only perform a significant functionby shading the building and thus reducing heat island effects, but also providehabitat for small animals and communicate the project’s sustainability agenda ina very prominent location on campus.Galvanized MetalsOne of the substances on the LBC Red List is cadmium, a toxic metallic element,found in small quantities in most zinc ores. The galvanization process adds aprotective layer of zinc to the surface of metals and there was some concern atthe Cascadia Region Green Building Council that galvanized metals exposed toweather outside the building envelope could leach cadmium. During the CIRSdesign process, the Cascadia Region Green Building added a note to the RedList restricting the use of galvanized metals outside of the building envelope.There are a number of steel elements outside of the CIRS building envelope, sothe project team decided to use epoxy and powder coat finishes in place of agalvanized finishes. During the construction phase of the project, the restrictionon the use of galvanized metals was removed from the Living Building Challengebecause of a lack of evidence that cadmium was present in or could leach fromgalvanized metals. This experience highlighted the need for further researchon the environmental impact of building materials and their componentingredients, as well as the need for solid life-cycle costing and assessmentsolutions to properly evaluate material choices5

C I R S T E C H N I C A L M A N UA LCO S T SCosts will be added in a futureupdateInterior Components:SeatingAll new furniture in the building is supplied by Haworth using finishes withminimal or no off-gassing of volatile organic compounds. The foam used inthe chair cushions was initially an issue with the LBC Red List requirements.Polyurethane, the standard foam, was initially on the Red List due to concernsabout the use of formaldehyde in the production. During the design process,polyurethane was removed from the LBC Red List because it would haveprecluded the use of polyurethane-based spray insulation. This experiencealso highlighted the need for further research on the environmental impactof building materials and wider communication of existing research. Haworthis currently testing alternative bio-based foams but has not found one that isdurable enough for office and classroom applications.Image 10.5 Interior Furnishing - Open Office Area. Photograph by Angelique Pilon6

1010.3 Campus ContextUBC Design GuidelinesThe UBC Design Guidelines contain direction on the character and expressionof university buildings through the exterior material palette. In order to createa cohesive urban design, all building on campus must include the requiredcommon materials of wood, aluminum and natural concrete. In addition,buildings in each distinct district (Campus Core, Forest Edge, Contemporaryand Athletic) have a dominant primary material and a range of secondary andaccent materials. In the Campus Core, where CIRS is located, the primary materialis a speckled white brick in keeping with the historic legacy of internationalstyle buildings. Acceptable secondary materials, used to add colour and vitality,include patterned clear glass, terra cotta, granite, dark metals and coloured metalor glass panels in soft blue, green, grey or brown.The UBC Design Guidelines emphasize sustainability in the design andconstruction of campus buildings. Materially, this focuses on using renewablematerials with low embodied energy that can be reused and recycled at theend of their life spans, are acquired from regional sources and manufactured inan environmentally responsible manner. Other concerns which heavily rely onmaterial choices include durability and waste reduction with an emphasis onlongevity and reuse, and passive design strategies that utilize daylight and solargains and regulate temperature swings through thermal mass.UBC Design Guidelines, 2.3.5 Architectural Expression (p14-16), 2.3.10 Sustainability BestPractice (p18-20), 3.1 Campus Core District (p.45-47)B U I L D I N G M AT E R I A L SR AT I N G S Y S T E M SLEEDMaterials & Resources Credits:4.1 & 4.2 – Recycled Content5.1 & 5.2 Regional Materials7 – Certified Wood8 – Durable BuildingIndoor Environmental QualityCredits:4.1, 4.2., 4.3, 4.4 – Low-EmittingMaterialsInnovation & Design Credits:1.4 – Exemplary PerformanceMRc4Living Building Challenge8 – Civilized Environment9 – Healthy Air10 – Biophilia11 – Red List12 – Embodied Carbon Footprint15 – Conservation Reuse16 – Human Scale HumanePlaces19 – Beauty Spirit20 – Inspiration Education7

C I R S T E C H N I C A L M A N UA LUBC Technical GuidelinesBuilding materials are covered by a range of Divisions in the UBC TechnicalGuidelines, and does contain conflicts with the requirements for the LivingBuilding Challenge and the ecological and human health aims of sustainability.With the exception of chlorine added to the water supply, the Guidelines donot require the use of any prohibited materials, however they do list them asan acceptable choice, or even as a preferred or recommended material. Thesematerials listed include Polyvinyl Chloride (PVC), Neoprene rubber (chloroprene),Phenolic Melamine (made from formaldehyde), and linoleum and vinyl flooring,all of which are included on the Red List. Conflicting material recommendations:Section 02720 -Storm Drainage Polyvinyl Chloride (PVC) pipe is the preferred material for pipes 300millimeters in diameter or lessSection 02730 - Sanitary Sewer Polyvinyl Chloride (PVC) is a preferred material for pipes.Section 02900 - Landscape Systems & Waste Management Polyvinyl Chloride (PVC) is a preferred material for pipes.Section 04090 - Masonry Accessories Neoprene rubber sheet is an acceptable material for waterproofing.Section 07200 - Materials Polyvinyl Chloride (PVC) is an acceptable material for fasteners in wallcavities.Section 07272 - Air Barrier Systems Neoprene rubber is an acceptable material for air barriers.Section 1.3 Windows - Materials Selected Polyvinyl Chloride (PVC) compounds are an acceptable material forwindow frames.Section 09001 - Finishes General Requirements Heat welded sheet vinyl flooring is an acceptable material for laboratoryflooring.Section 09650 - Resilient Flooring Linoleum, Sheet Vinyl and Vinyl Composite Tile are acceptable flooringmaterials.Section 10150 - Toilet Partitions Solid Phenolic Melamine is a recommended material for toilet partitionsystems.UBC Technical Guidelines, 2011 Edition8

10B U I L D I N G M AT E R I A L S10.4 Goals & TargetsTable 10.1 lists the project goals and targets specifically related to the buildingmaterials. For a complete list of all the goals and targets for CIRS, refer to Section4.0 Goals & Targets.CategoryGoals2- LIFE CYCLEASSESSMENTConduct a life cycleassessment of all buildingassemblies and productsto examine environmentalimpact, including embodiedenergy and greenhouse gasemissions - minimize CO2emissions associated withconstruction.3 - SITE DESIGN - NETIMPACTNeutralize ecological impacton site by having a netpositive biomass And oxygenprovided on-site.5 – SUPPLY SYSTEMSAchieve net positive energyperformance.6 – REDUCTIONDesign CIRS to be as passiveand simple as possible.TargetsExisting site plant coveragewas 44% grass and shrubs.The new site will have moreplant coverage (100% ofwhich must be native/Regenerate ecosystems toadaptive species) than theattract local fauna (birds, bees, existing site.herons, & butterflies).Reduce energy loads.Design a high-performancebuilding envelope.11 - RESOURCEEFFICIENT BUILDINGMinimize the resourceconsumption and GHG impactof building materials andconstruction.Make design and operationchoices based on the lowestlife-cycle costs.Produce a core buildingthat exemplifies replicable,economical solutions.Target a buildingconstruction footprint thatis 50% of typical buildingecological footprint & GHGprofile of construction.Maximize the life, flexibilityand recycling potential ofthe building.Maximize the intensity ofuse of resources for buildingmaterials12 - WASTEELIMINATIONZero Waste in constructionand operation.Zero construction waste(95% minimum diversion).15 - AIR QUALITYThe building will provide thepurest possible indoor airquality.Preclude the use of materialson the Living BuildingChallenge ‘Red List’.17 – COMFORT &CONTROLProvide local control overcomfort conditions to adaptto individual preferences.Install ergonomically soundsoffice furniture.21 – COMMUNITY &EXTERNAL IMPACTSMinimize external andcommunity environmentalimpacts of CIRS’s staff andvisitors.Table 10.1 Goals & Targets for CIRS Building Materials9

C I R S T E C H N I C A L M A N UA L10.5 BenefitsRELATED SECTIONS:3.0 Vision& Leadership4.0 Goals & Targets5.0 PartnershipsThe building materials in CIRS benefitted the project in the following ways:Reduces ‘Red List’ Materials 6.0 Research7.0 Building Design8.0 Design Process9.0 Structural System & WoodImproved Indoor Air Quality Avoiding materials that can release volatile organic compounds, phthalatesor other pollutants to the indoor environment can lead to higher qualityindoor air and improved inhabitant health. Buildings that use natural ventilation must consider the quality of theoutside air that surrounds the building. Using vegetation as a buildingmaterial can help improve the quality of the building’s surrounding exteriorair source by increasing the concentration of oxygen in the air.15.0 Living Roof & Living Wall18.0 Building Rating SystemsBy avoiding building materials that contain chemical or substances onthe Red List, the project team chose to avoid including toxic or potentiallytoxic material in CIRS. Sustainable building should not be constructed withmaterials that negatively affect human and environmental health.20.0 Construction24.0 Operation & MaintenanceReduced Material Waste Designing the building to make efficient use of materials, to minimizerequired finishes and to utilize standard manufacturing processes reducesthe waste of material, as well as its embodied energy and carbon emissions,thereby reducing the overall environmental impact of the building.Reduced Carbon Emissions10 Alternative materials with lower rates of carbon emissions throughmanufacturing methods reduce the overall carbon footprint of the buildingconstruction. Sourcing materials that are extracted, harvested and manufactured inrelatively close proximity to the project reduces the carbon emissionsassociated with the transportation of materials.

10B U I L D I N G M AT E R I A L S10.6 ChallengesSourcing Acceptable Sustainable Materials Sourcing materials that met the combined project criteria as well as therequirements of the LBC was very challenging. The design team had toresearch carefully every building material that was considered for use onthe project. Finding materials that met the LBC Red List was difficult for thefollowing reasons:Awareness of the LBC Many manufacturers understand the LEED rating system, have developedproducts to meet the LEED requirements and have systems in place toproduce the documentation for certification. The industry producingbuilding materials do not yet know or understand the LBC rating system andits imperatives.Knowledge Gaps To determine if a product meets the requirements of the Living BuildingChallenge, the project team had to do extensive research to find the properdocumentation that explains the constituents of a building product. Manymanufacturers and product representatives do not know what componentingredients go into the building materials they produce.Proprietary Information Some building material manufacturers are aware of the components of theirproducts, but are reluctant to reveal information they feel is proprietary.Some manufacturers may list their proprietary name rather than thegeneric name for the chemical that they have developed in the productdocumentation.Streamlining the Palette The project team found that some materials that met the requirements ofthe Red List and the other project criteria could not be sourced within theAppropriate Sourcing radii. Many of the building product manufacturersin North America are located in eastern Canada or the eastern UnitedStates. The manufacturers of many electrical or mechanical componentsand products are located in China. The project team had to streamline thepalette of materials because some acceptable building materials may not bemanufactured locally.11

C I R S T E C H N I C A L M A N UA LRESOURCES:Diagrams linksDrawings links10.7 Lessons LearnedStart the Research Effort Early Perkins Will: www.perkinswill.caPerkins Will Precautionary List:transparency.perkinswill.comUBC Campus Design GuidelinesUBC Climate Action Plan: www.sustain.ubc.ca/climate-actionLiving Building Challenge: ilbi.orgFind Sustainable Alternative to Traditional Materials In some cases, it may be possible to substitute sustainable buildingmaterials for common conventional materials containing potentially harmfulsubstances. If project teams cannot find sustainable material alternatives, they will haveto look to alternative design solutions. For example, a polished concrete flooris often an appropriate alternative to applying resilient flooring (containingtoxic chemicals) over a rough concrete slab.Canadian Green Building Council(LEED): www.cagbc.orgPharos Project: www.pharosproject.netThe combined difficulty of meeting the requirements of the AppropriateSourcing and Red List imperatives proved to be very challenging. Findingsustainable building materials is not an impossible task but to satisfy themany criteria of the project it was necessary to start the research effort earlyin the design process.Test Materials Options in Real Conditions The project team exposed eleven different seals and stains for the woodcladding to local weather conditions for three years before choosing the finalproduct. While many projects may not have the ability to test a material forthree years, some material testing can likely be done on every project.Use the Right Tools Many manufacturers use brand names for the chemicals in the materialsdeclaration documentation. Use the Chemical Abstracts Service (CAS)registry numbers for product chemicals and tools such as the Pharos Projectto learn more about the chemicals in building products.Exercise Precaution Extensive testing for human and environmental health impacts have beenperformed on only a few building materials. The impacts on human andenvironmental health from the chemicals and substances in many buildingmaterials are not know or properly understood. When there is evidence thata material has a negative impact on human health, design teams shouldexercise caution and search for alternatives.10.8 Future LearningAdditional lessons learned over the operational life of the building will beadded at periodic intervals12

that, unlike LEED in which project teams can decide which credits they will pursue, a certified Living Building must satisfy every imperative. The Living Building Challenge has five rigorous requirements related to the life-cycle impact of building materials. Imperative 11 Red List: A Living